Contents

Simple parameter setting................................................................................................................................................................. 2

1. Preface..........................................................................................................................................................................................4

1.1 Precautions for purchase:....................................................................................................................................................4

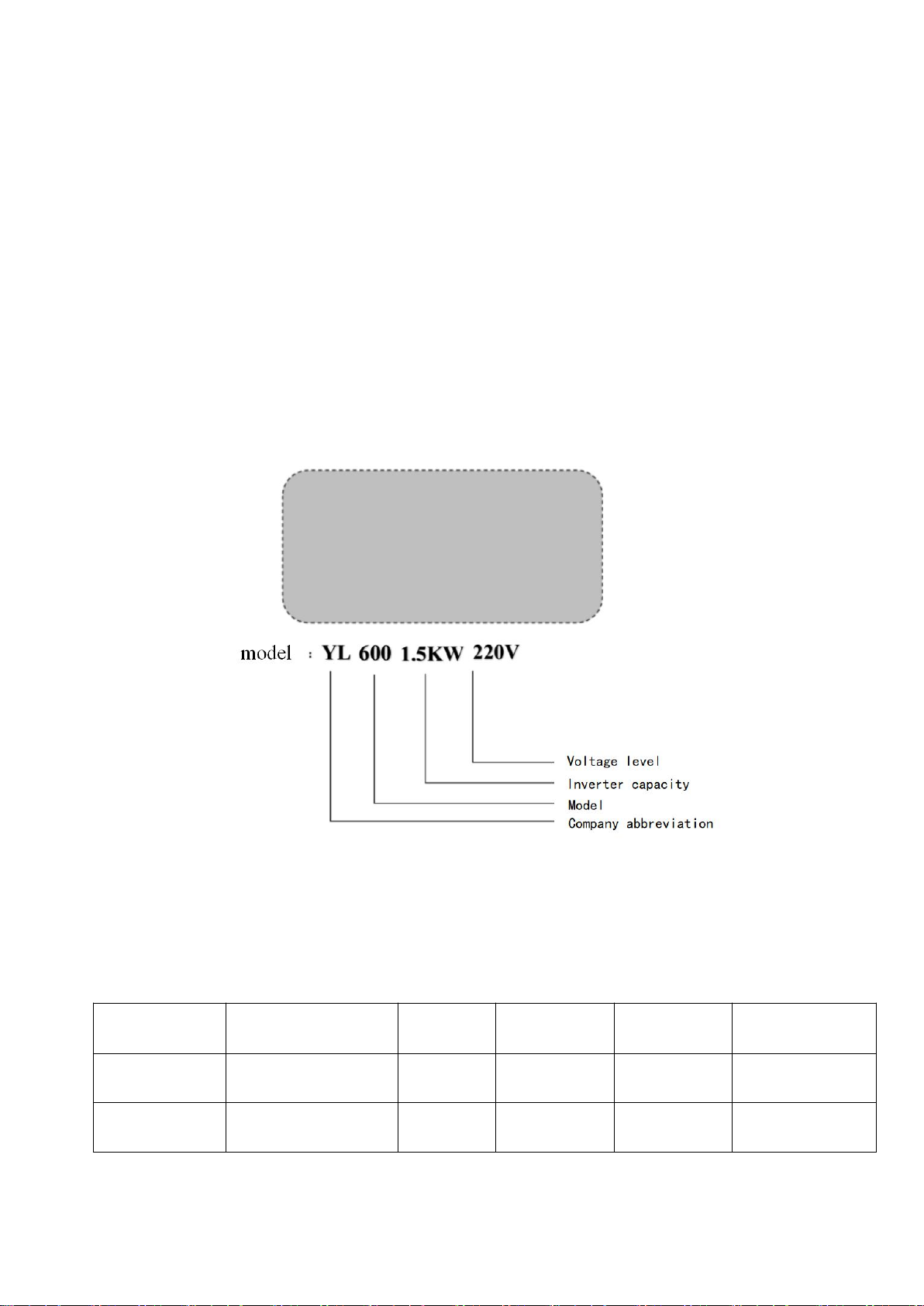

1.2 Inverter nameplate description:.......................................................................................................................................... 4

2. Product model and specification..................................................................................................................................................4

2.1 Product model and specification:....................................................................................................................................... 4

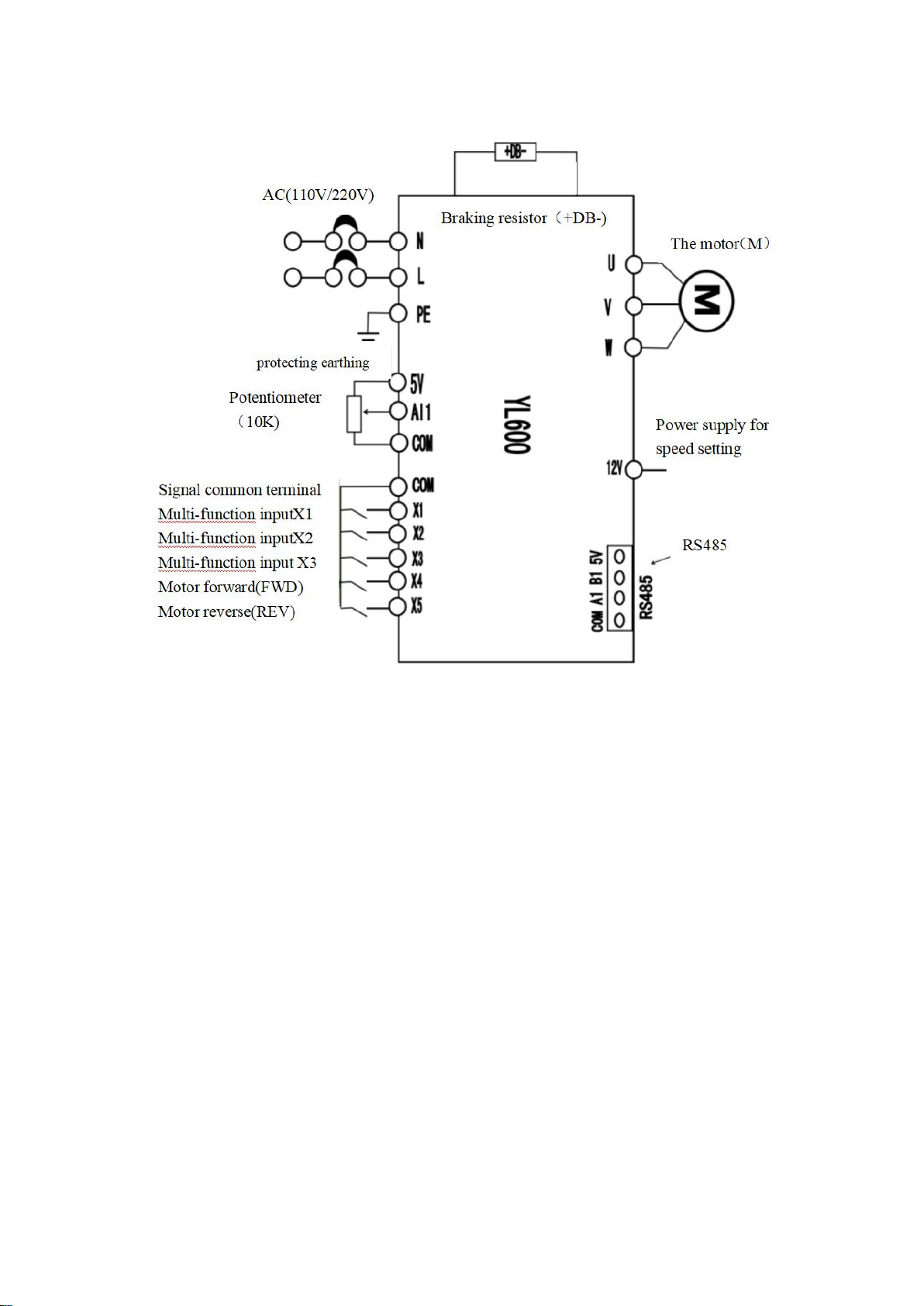

2.2 Schematic diagram:............................................................................................................................................................... 5

3. Wiring diagram and precautions for safe use..............................................................................................................................5

3.1 Installation location and environment:............................................................................................................................... 5

3.2 Main circuit terminal description:...................................................................................................................................... 6

3.3 Control terminal description:..............................................................................................................................................6

4. Digital operator description......................................................................................................................................................... 7

4.1 Description of digital operator panel:.................................................................................................................................7

4.2 Operation example:.............................................................................................................................................................7

5. Trial run....................................................................................................................................................................................... 8

5.1 Inspection and trial operation method before operation:................................................................................................... 8

6. Control function and parameter setting....................................................................................................................................... 9

6.1 Panel control wiring and parameter setting:..........................................................................................................................9

6.2 Three-wire control wiring and parameter setting:.................................................................................................................9

6.3 High, medium and low multi-speed control wiring and parameter setting.........................................................................10

6.4 Analog quantity control wiring and parameter setting:.......................................................................................................10

6.5 External potentiometer with switch control wiring and parameter setting:........................................................................11

7. Function description and list......................................................................................................................................................12

7.1 Function table:.................................................................................................................................................................. 12

8. Fault information and troubleshooting methods....................................................................................................................... 25

8.1 Fault information and troubleshooting methods:................................................................................................................ 25

9. Modbus485 communication protocol holding register address-inverter parameter correspondence table..............................26

10. External terminal two or three wire control motor wiring...................................................................................................... 30

11. Multi-speed command-frequency section-parameter item correspondence table.................................................................. 31

12. Toggle switch configuration table........................................................................................................................................... 31

13. Facilities selection configuration.............................................................................................................................................32

13.1 Braking resistor configuration:..............................................................................................................................................32

14. Customer feedback suggestions...............................................................................................................................................32

Due to the company's product updates, the content is subject to

change without notice