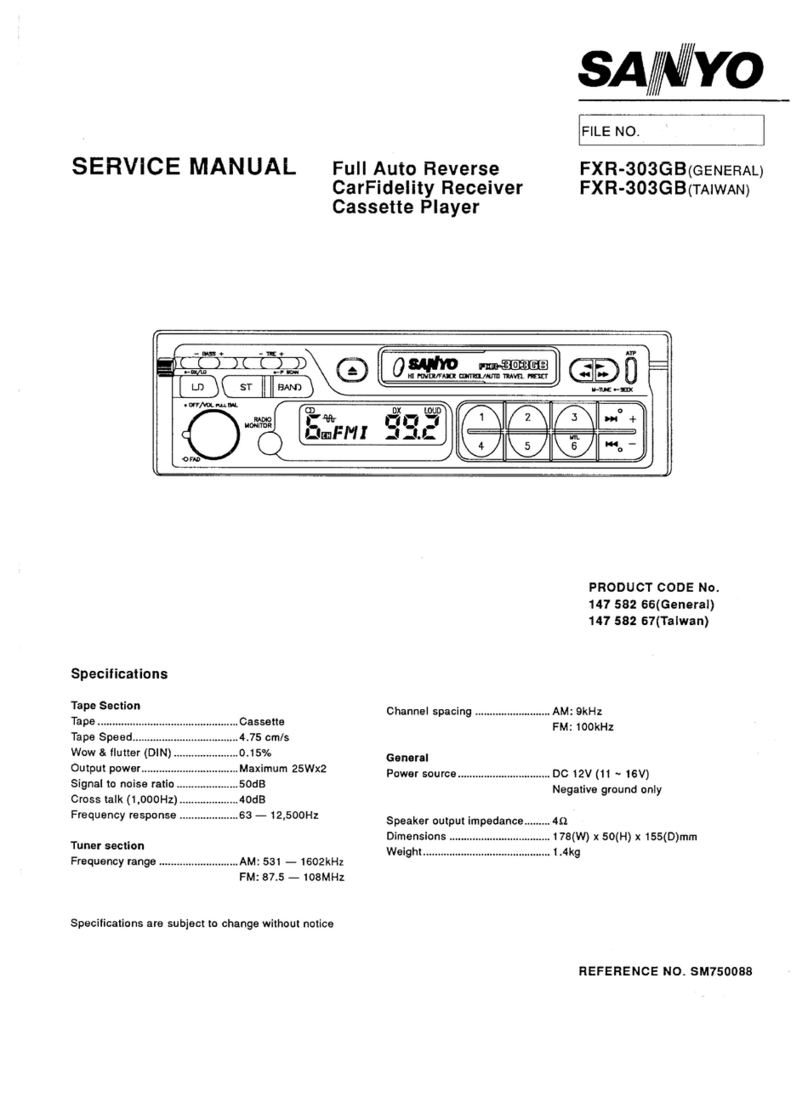

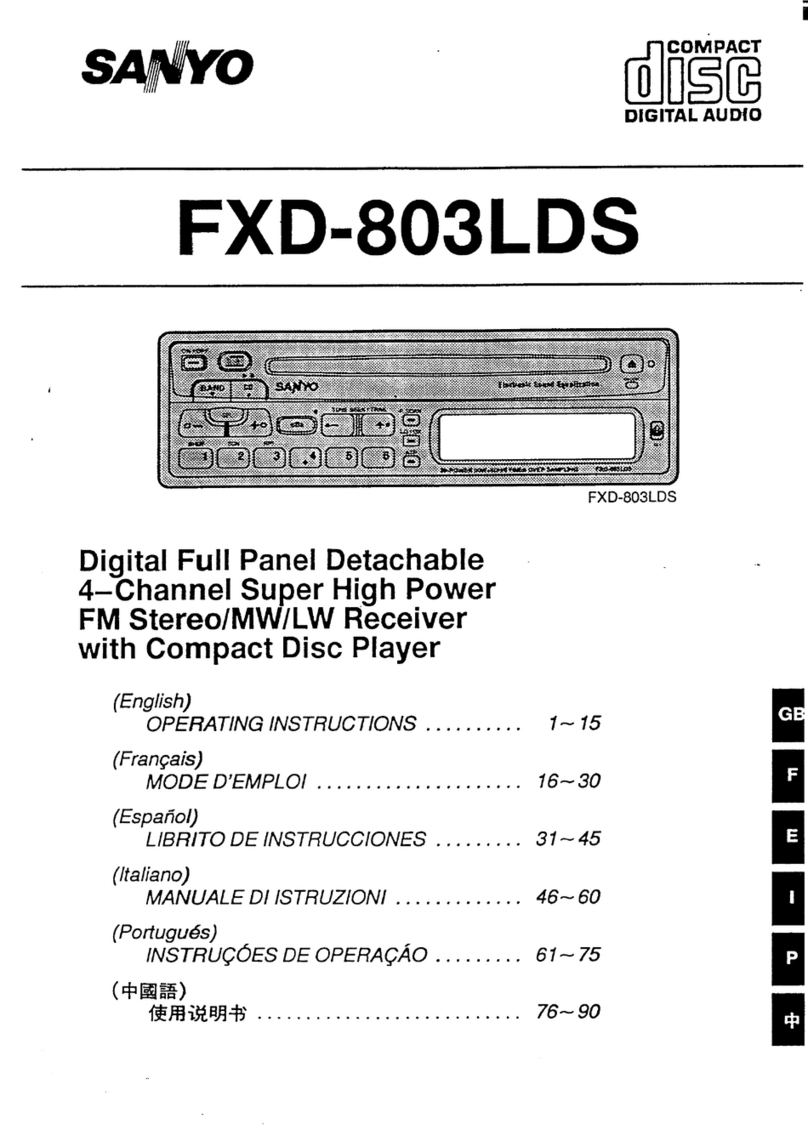

SERVICE MANUAL DIGITAL FULL PANEL

DETACHABLE 4-CHANNEL

SUPER HIGH POWER

FM STEREO/MW/LW RECEIVER

COMPACT DISC PLAYER

FILE NO.

FXD-803LD

(General)

PRODUCT CODE No.

14782801

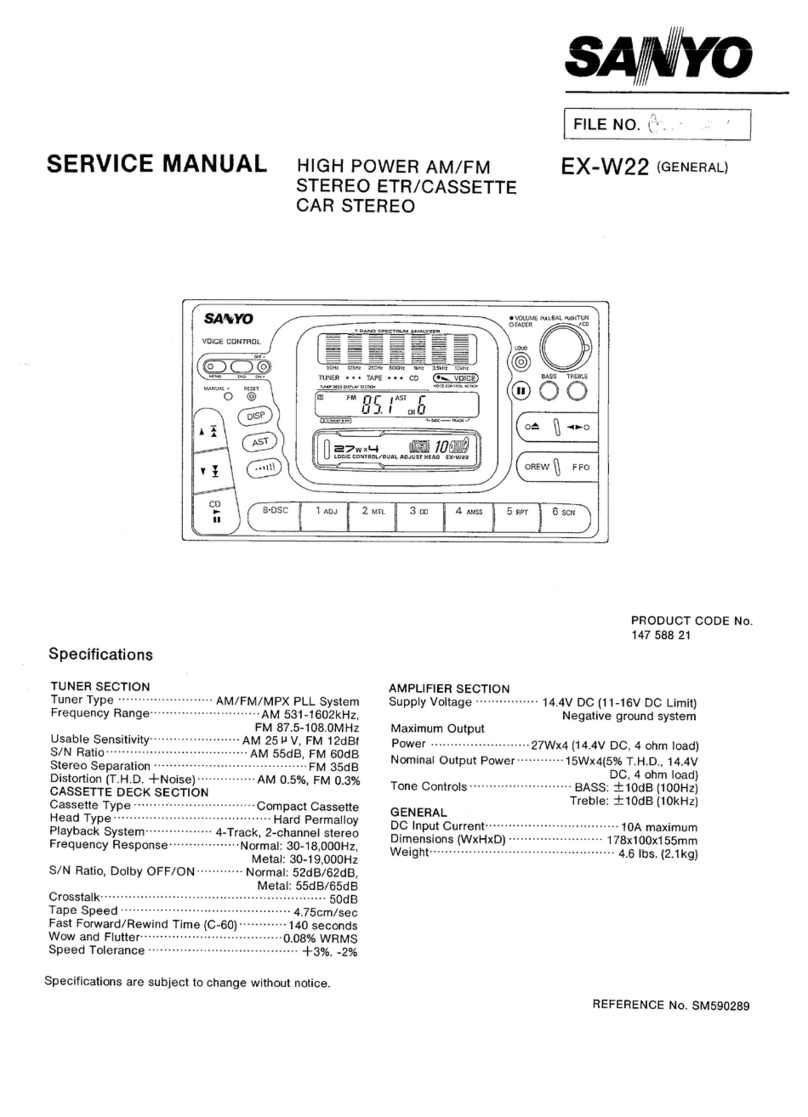

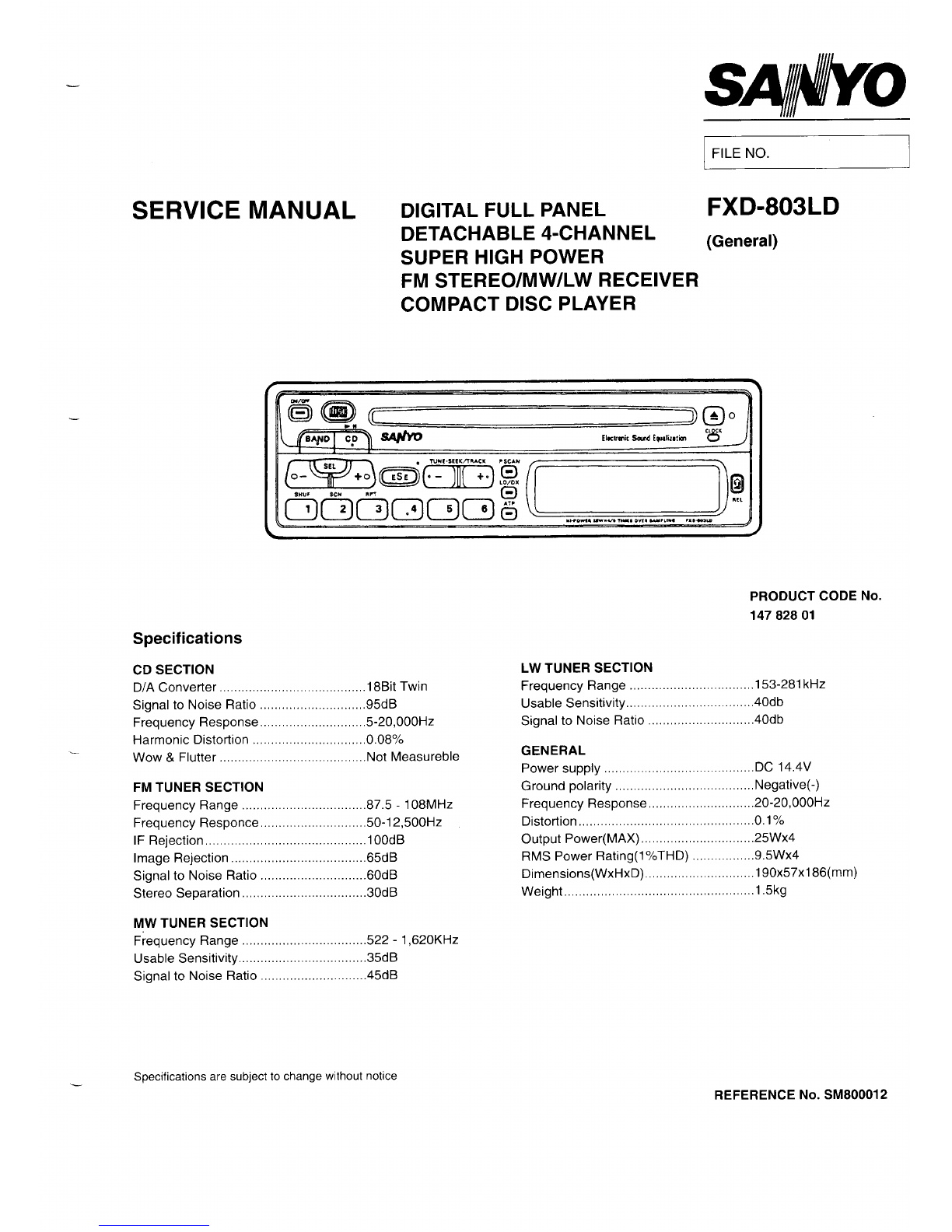

Specifications

CD SECTION

D/A Convetier ........................................18Bit Twin

Signal to Noise Ratio .............................95dB

Frequency Response, ............................5-20 .000Hz

Harmonic Distortion ..........................0....0.080/0

Wow& Flutter ........................................Not Measurable

FM TUNER SECTION

Frequency Range .....87...........................87.5 108 MHz

Frequency Response,.,.,., ......................5O-l2.5OOHz

IF Rejection ............................................l OOdB

Image Rejection .....................................65dB

Signalto Noise Ratio .............................6OdB

Stereo Separation ..................................3OdB

MW TUNER SECTION

Frequency Range ..................................522- 1,620 KHz

Usable Sensitivity ...................................35dB

Signal to Noise Ratio .............................45dB

LW TUNER SECTION

Frequency Range ..................................l53.28lkHz

Usable Sensitivity ...................................4Odb

Signalto Noise Ratio .............................4Odb

GENERAL

Power supply .........................................DCl4.4V

Ground polarity ......................................Negative(.)

Frequency Response, ............................2O-20.000Hz

Distotiion ................................................O.l Y0

Output Power(MAX),., ............................25Wx4

RMS Power Rating(l%THD) .,...............9.5WX4

Dimensions(WxHxD) ..............................l9Ox57xl86(mm)

Weight ....................................................l.5kg

—Specifications are subject to change without notice

REFERENCE No. SM800012