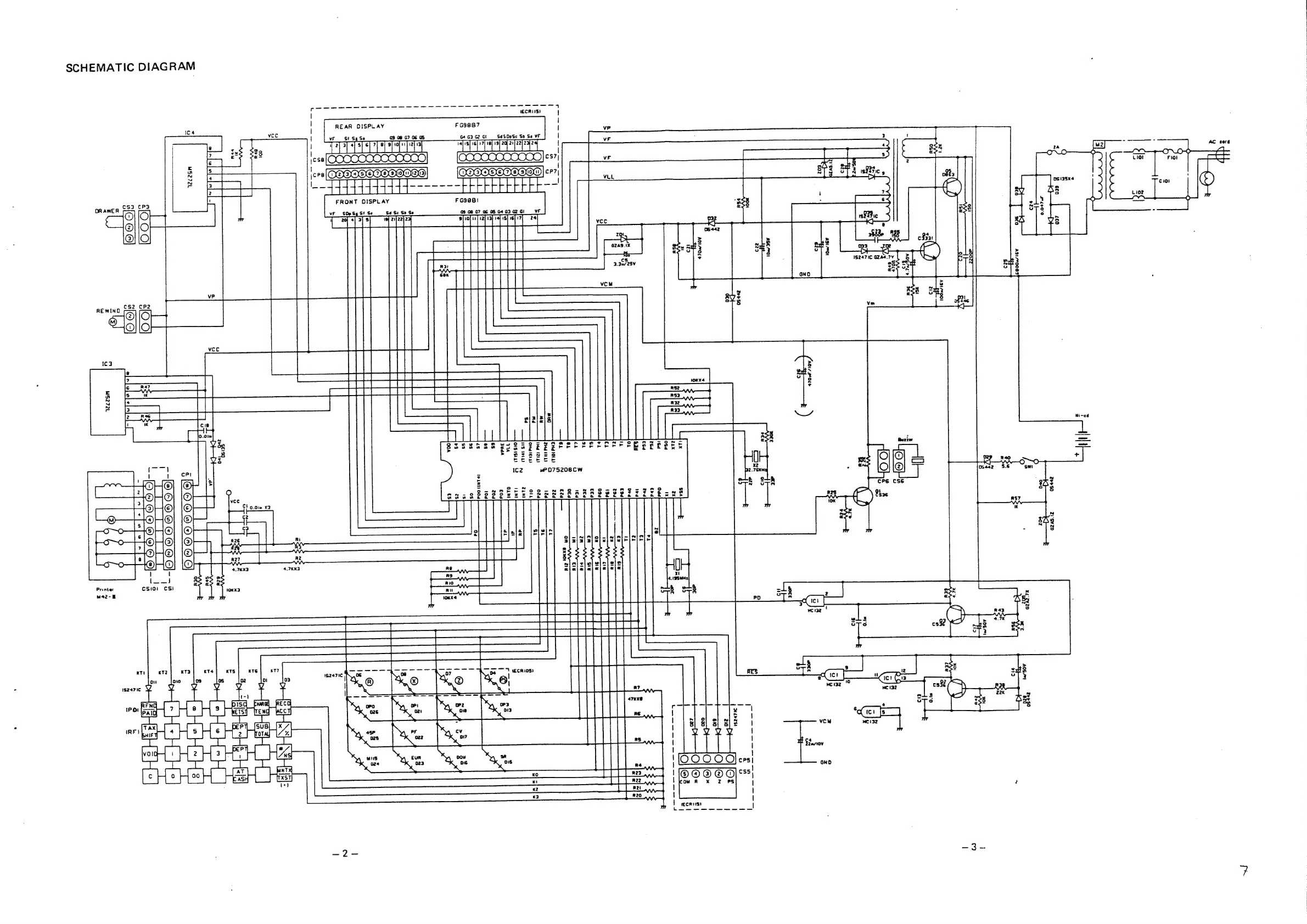

Sanyo ECR105 User manual

Other Sanyo Cash Register manuals

Popular Cash Register manuals by other brands

Sharp

Sharp XE-A137-WH Operation Basic user manual

Sharp

Sharp XE-A203 - Cash Register Thermal Printing Graphic Logo... instruction manual

TEC

TEC TEC MA-1060 owner's manual

Casio

Casio PCR-408 Operator's instruction manual

ELCOM

ELCOM Euro-2100TE user manual

American Changer

American Changer CLASSIC Series Operation manual