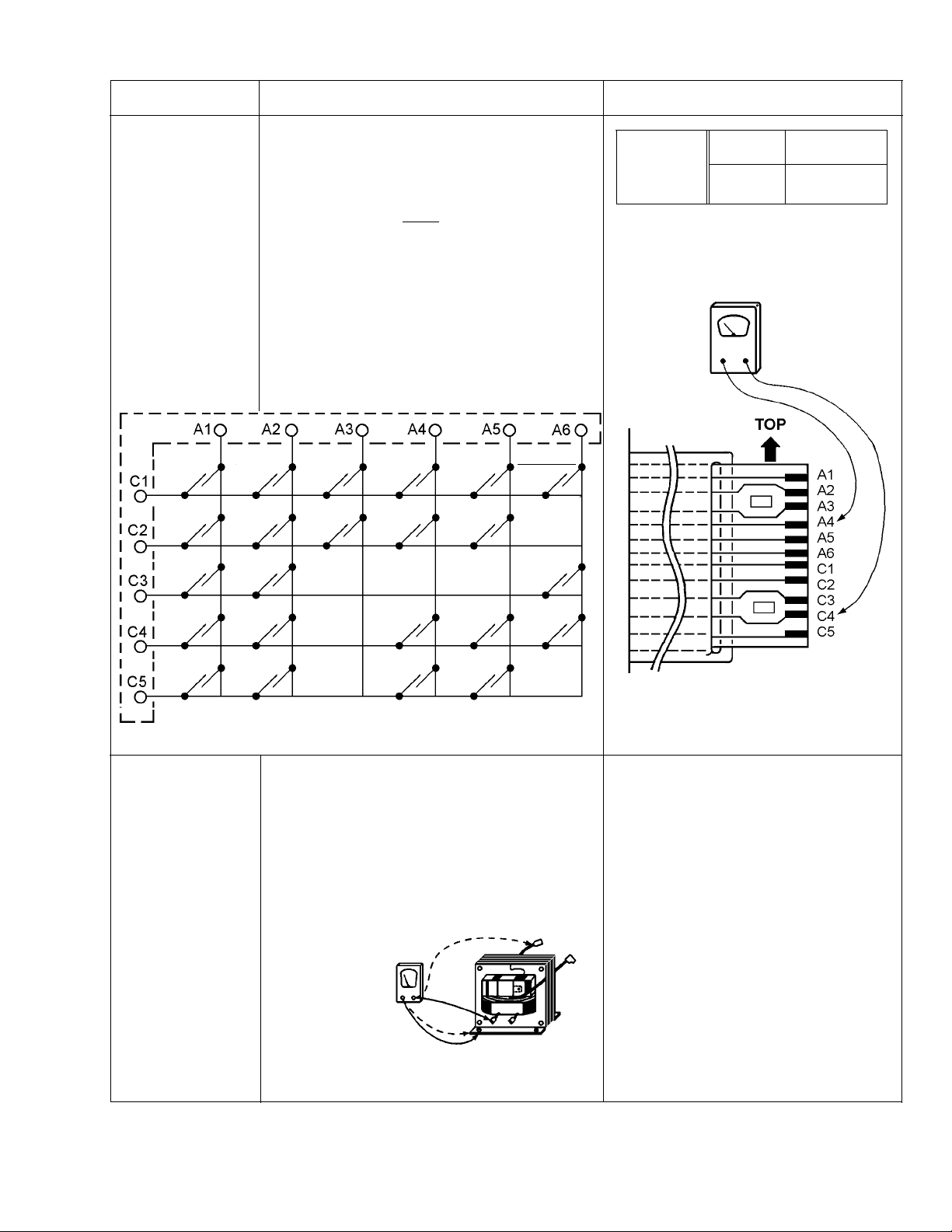

In the area emitting the highest reading, switch the meter

to SLOW RESPONSE, and take a reading for minimum of

three (3) seconds. We recommended the pattern outline

shown below when the door surface is surveyed.

NOTE : Periodically check to be sure that the probe tip is

not worn or dirty.

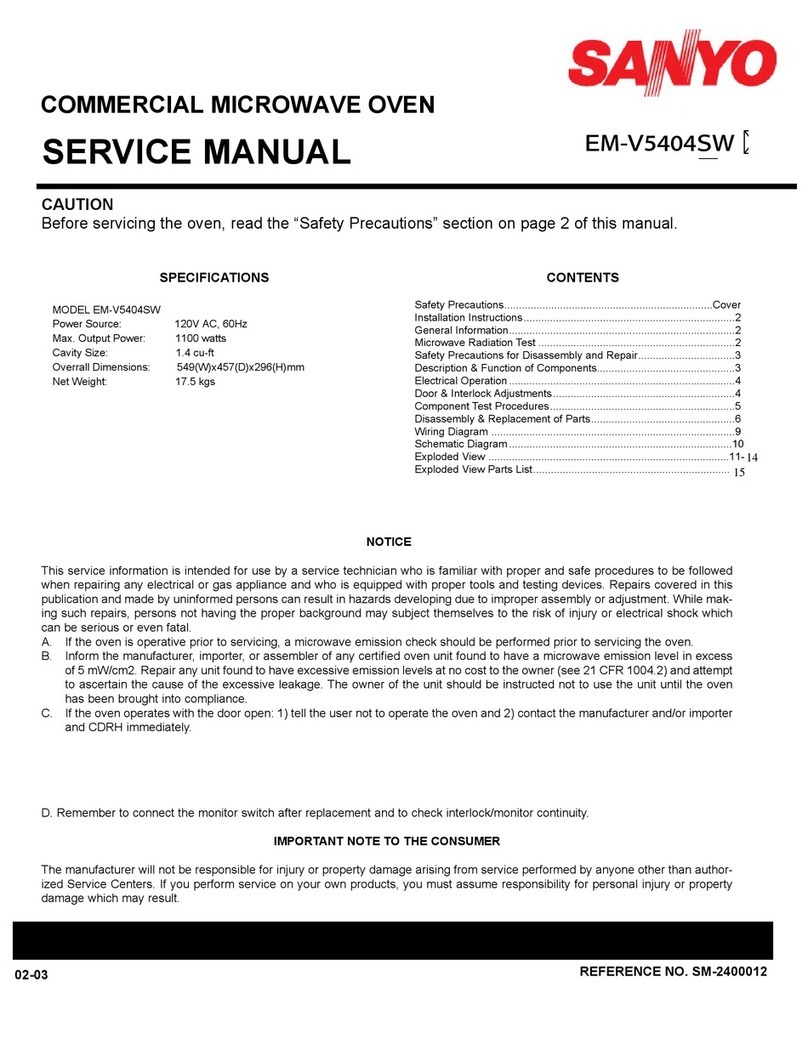

The following U.S. standard applies to microwave ovens :

21 CFR 1030.10, Performance Standard for Microwave

Ovens.

It requires that the power density of the microwave

radiation emitted by a microwave oven shall not exceed

five (5) milliwatts per square centimeter at any point 5

centimeter (about 2 inches) or more from the external

surface of the oven.

All microwave ovens exceeding the emission level of

4mW/cm2must be reported to Dept. of Service for

microwave ovens and the manufacturer immediately and

the owner should be told not to use the microwave oven

until it has been repaired completely.

If a microwave oven is found to operate with the door open,

report to Dept. of Service, the manufacturer and CDRH*

immediately. Also tell the owner not to use the oven.

*CDRH : Center for Device and Radiological Health.

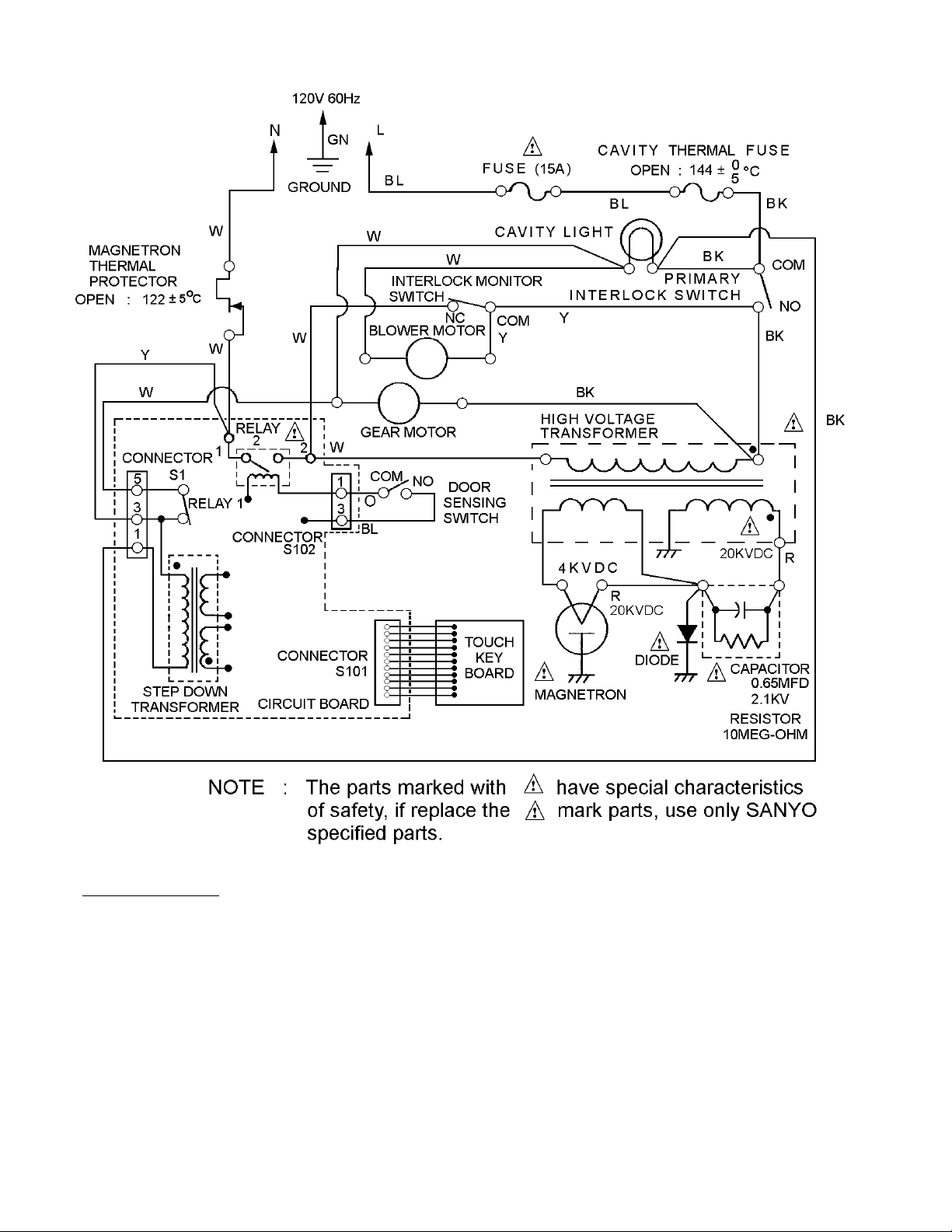

The interlock monitor switch acts as the final safety switch

protecting the customer from microwave radiation. If the

interlock monitor switch operates to blow the fuse with

interlocks failed, you must replace all interlock switches

primary and secondary interlock switches and the monitor

switch with new ones because the contacts of those

interlock switches may be melted and welded together.

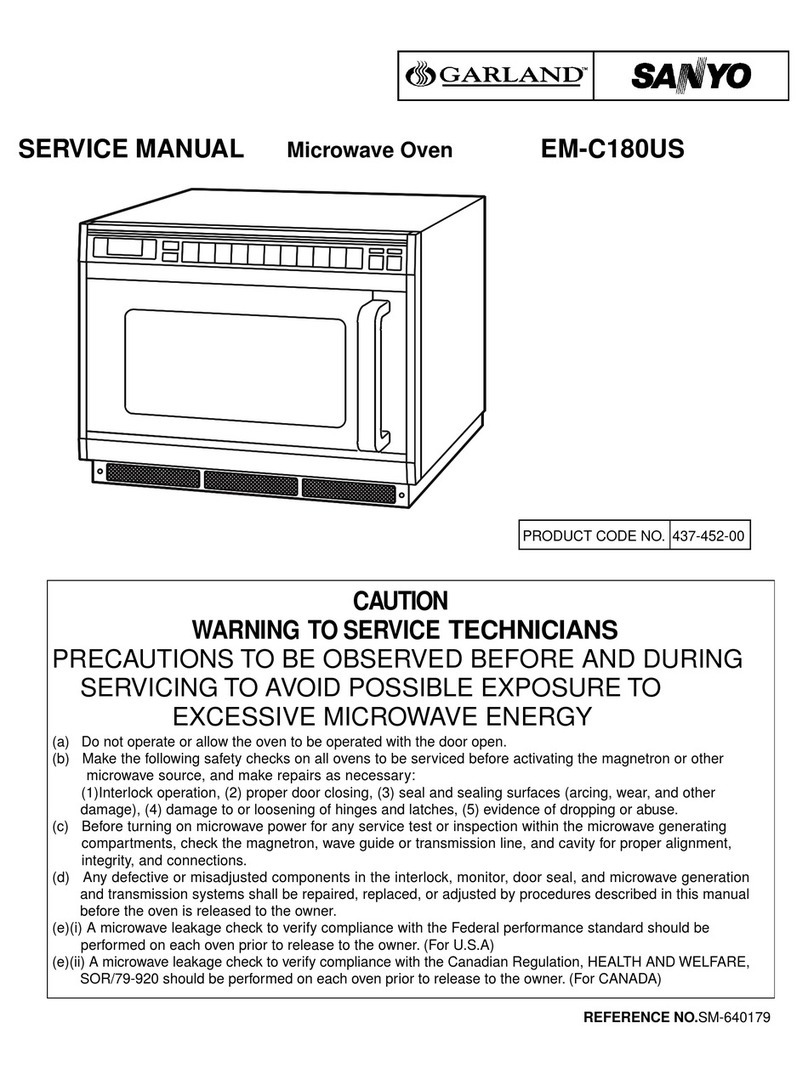

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

For micrFor micr

For micrFor micr

For microwave enerowave ener

owave enerowave ener

owave energy emissiongy emission

gy emissiongy emission

gy emission

On every service calls, check for microwave energy

emission, must be made according to the following manner.

MeasurMeasur

MeasurMeasur

Measurement of enerement of ener

ement of enerement of ener

ement of energy emissiongy emission

gy emissiongy emission

gy emission

Measurement must be made with the microwave oven

operating at its maximum output and containing a load of

275±15 milliliters of tap water initially at 20o±5ocelsius (68

±9oF) placed within the cavity at the center.

NOTE : The water container must be a 600 milliliter beaker

and made of an electrically none conductive

material such as glass or plastic.

The cook tray must be in place when measuring

emission.

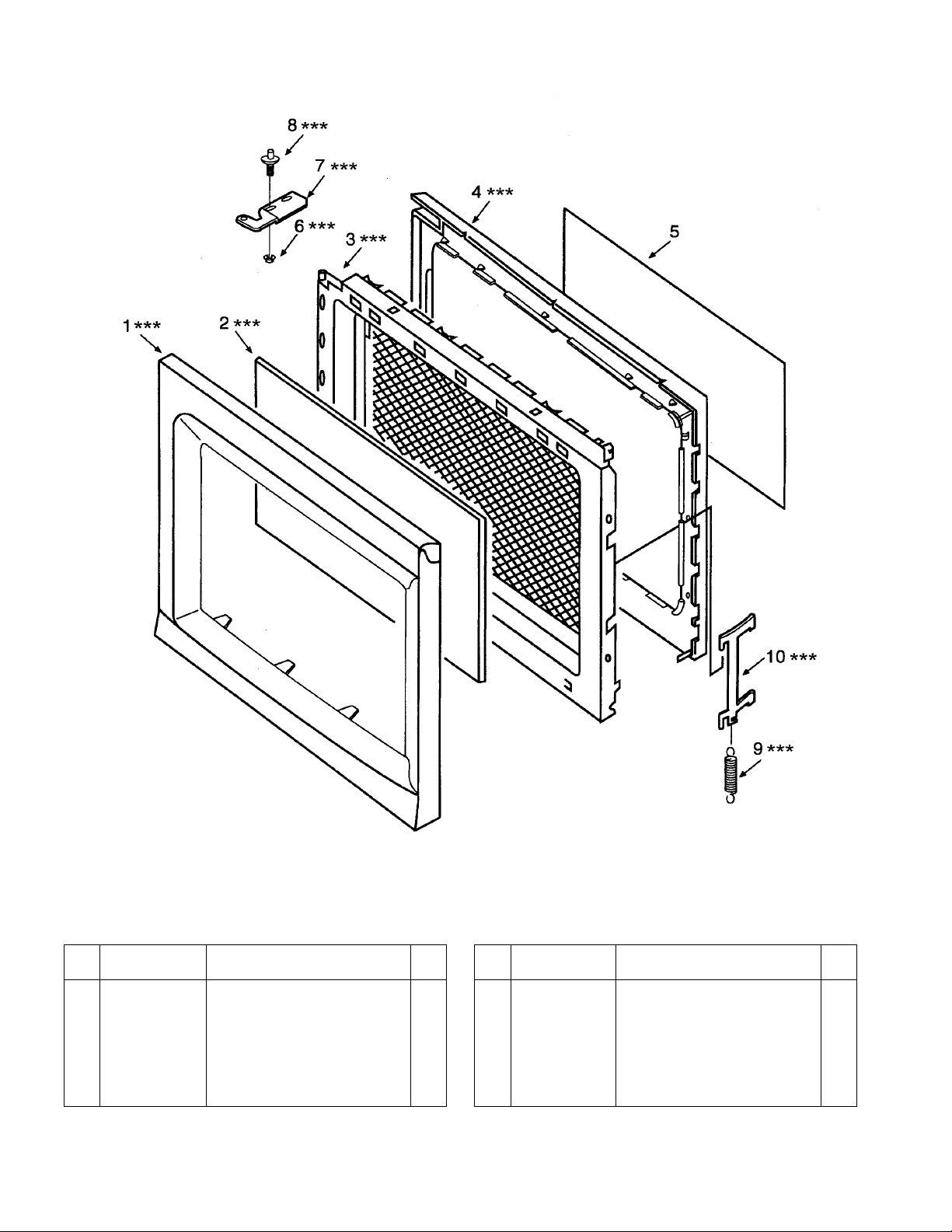

A properly operating door and seal assembly will normally

register emission on greater than 4mW/cm2 to allow for

measurement uncertainty with the cooking shelf or tray in

place.

All repairs must be performed in such a mannerAll repairs must be performed in such a manner

All repairs must be performed in such a mannerAll repairs must be performed in such a manner

All repairs must be performed in such a manner thatthat

thatthat

that

micrmicr

micrmicr

microwave enerowave ener

owave enerowave ener

owave energy emission argy emission ar

gy emission argy emission ar

gy emission are minimal.e minimal.

e minimal.e minimal.

e minimal.

Follow the instructions supplied with a detector being used

and performed an R.F. emission test around the door front

and edges and all edges and vent of the outer case. The

cabinet (wrapper) must be in place and the oven fully

assembled.

When performing emission survey, with the meter on FAST

RESPONSE the movement of a detector probe shall not

exceed one (1) inch per second.

- i -