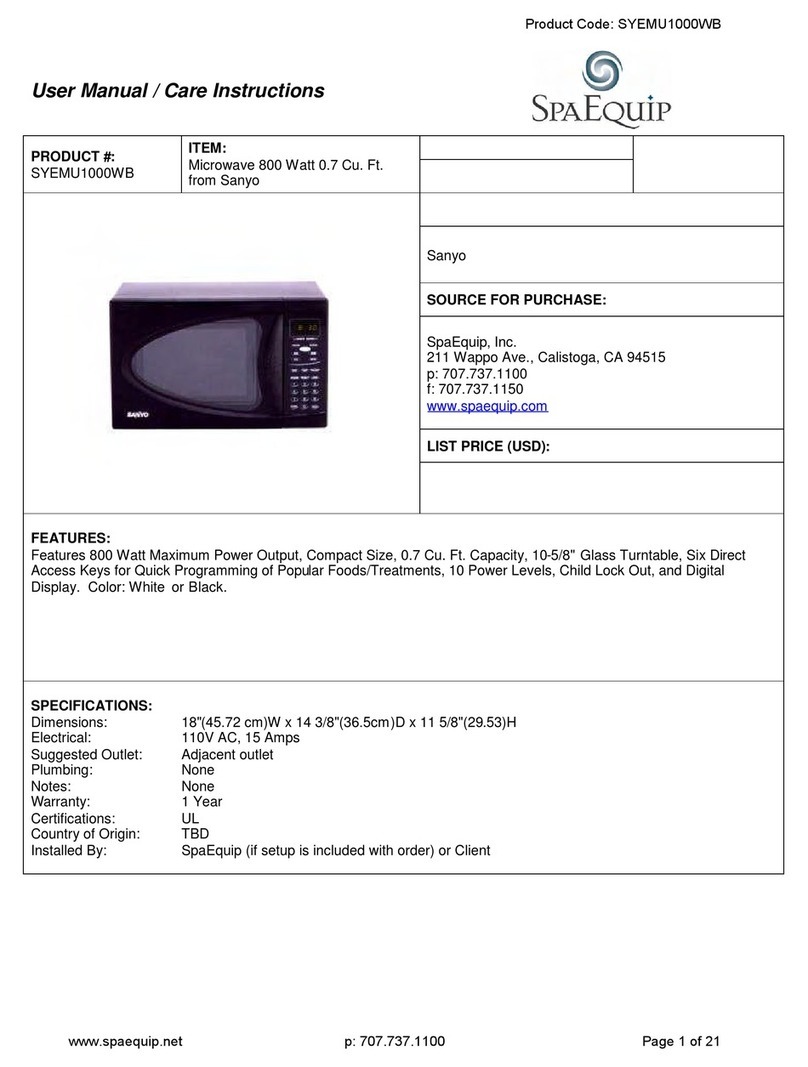

2. SPECIFICATIONS

Rated Power Consumption . . .

Microwave Output . . . . . . .

Frequency ..............

Power Supply ...........

Rated Current ...........

Safety Devices ...........

Timer .................

Overall Dimensions ........

Oven Cavity Size . . . . . . . . .

Turn Table Diameter . . . . . . .

Effective Capacity of

Oven Cavity ...........

Net Weight . . . . . . . . . . . . .

1400W

700W

(Adjustable 155W through

700W)

2,450 MHz f50 MHz

230- 240V50HZ

6.0 Amp.

Thermal Protector, Open

at 135°C for Magnetron

Fuse (Cartridge Type 8A)

Primary Interlock Switch

Door Sensing Switch and

Relay 2

Interlock Monitor Switch

Electronic Digital, up to

99 min. 99 sec.

550(W) x453(D) x309(H) mm

375(W)X 404(D) x237(D) mm

360 mm

31 liter

Approx. 20 kg

3. POWER OUTPUT MEASUREMENT

(1) Fill two beakers (glass or plastic) with each one liter

of taP water (about 20° C) and measure the water

temperature. (Use athermometer with a1/10

degree gauge. )

(2) Place the beakers side by side in the center of the

glass tray.

(3) Close the door, set the “TIME” for two minutes.

(.,2 O(y? in the display window. )Touch the

“START” key and heat the water exactlv for two

minutes.

(4) Take the beakers out, immediately stir the water

and measure the water temperature respectively.

(5) Calculate the temperature rise of water in each

beaker. Then calculate the average value of two

temperature rises.

Output power can be calculated by the equation;

Power output (W) =70 x At

Where At is an average temperature rise in degrees

Centigrade.

(6) Output shall be in the following range:

Average temperature rise Power output

Minimum 9.O”C 630W

Maximum 11.5°c 805W

(7) Power output is affected by the line voltage under

load. For correct power output measurement, the

line voltage under load must be 240t 1volts.

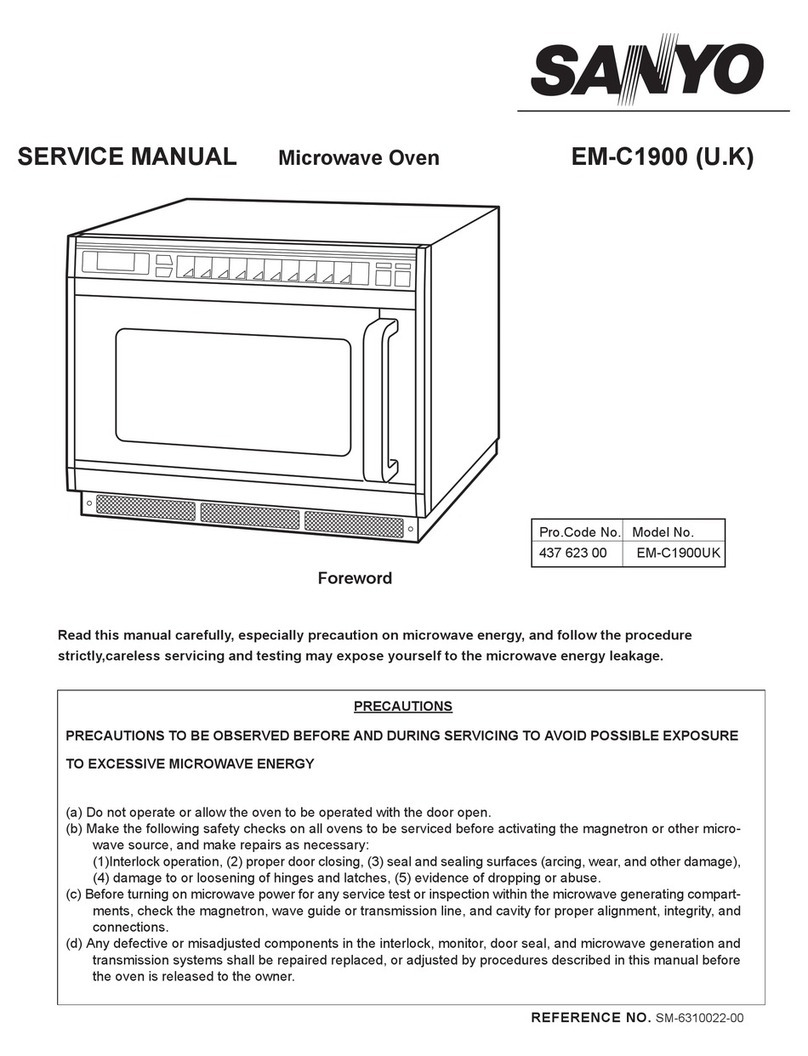

4. PRECAUTIONS

PRELIMINARY

A. SINCE NEARLY

AND REPAIR SERVICE TIPS

4,OOO VOLTS EXISTS IN SOME

CIRCUITS OF THIS MICROWAVE OVEN, REPAIRs

SHOULD BE CARRIED OUT WITH GREAT CARE.

B. TO AVOID POSSIBLE EXPOSURE TO MlCROWAVE

ENERGY LEAKAGE, THE FOLLOWING PRE-

CAUTIONS MUST BE TAKEN BEFORE SERVICING.

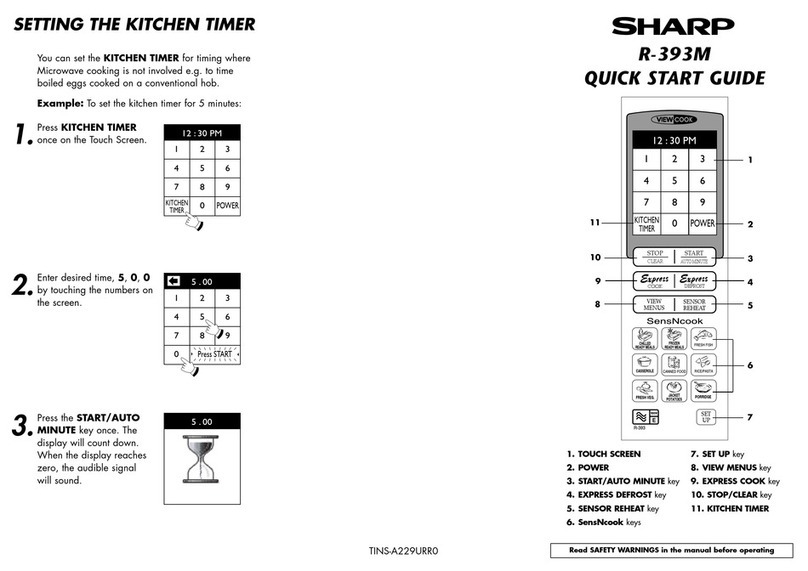

(1) Before the power is applied:

(a) Open and close door serveral times to make sure the

primary interlock switch, the interlock monitor

switch and the door sensing switch operate proper-

ly. (Listen for the clicking sound from the switches. )

Make sure the interlock monitor switch closes after

the primary interlock switch is opens when the door

is opened.

(Seepages 1and 6)

(b) Make sure the perforated screen and the choke di-

electric of the door are correctly mounted.

(2)

(a)

(b)

(3)

(a)

(b)

(c)

(d)

(e)

(f)

(4)

(a)

(b)

(c)

(d)

(e)

The

After the power IS applied:

Open and close the door to see if the interlock

mechanism operates properly.

Check microwave energy leakage with aleakage

detector and confirm the energy leakage is below 5

mW/cm2.

Do not operate the unit until it is completely re-

paired, if any of the following conditions exists.

Door does not close firmly against the cavity front.

The hinge is broken.

The choke dielectric or the door seal is damaged.

The door is bent or warped, or there is any other

visible damage to the oven that may cause micro-

wave energy leakage.

NOTE: Always keep the seal clean.

Make sure that there are no defective parts in the

interlock mechanism.

Make sure that there are no defective parts in we

microwave generating and transmission assembly.

(especially waveguide)

The following items should be checked after the

unit is repaired:

The interlock monitor switch is connected correctly

and firmly.

The magnetron gasket on the magnetron is properly

positioned.

Waveguide and oven cavity are intact (no leakage of

microwave energy).

The door can be properly closed and the safety

switches work properly.

The oven must be stopped when the door is opened

or the time is up.

oven must not be operated with any of the above

components removed or bypassed.

–2–