-8-

● Cleaning with air spray

1. Remove the cabinet top following to “Mechanical

Disassemblies”.

2. Clean up the LCD panel and polarizing plate by

using the air spray from the cabinet top opening.

Caution:

Use a commercial (inert gas) air spray designed for

cleaning camera and computer equipment. Use a

resin-based nozzle only. Be vary careful not to damage

optical parts with the nozzle tip. Never use any kind of

cleanser on the unit. Also, never use abrasive materials

on the unit as this may cause irreparable damage.

After long periods of use, dust and other particles will accumulate on the LCD panel, prism, mirror, polarized

glass, lens, etc., causing the picture to darken or color to blur. If this occurs, clean the inside of optical unit.

Remove dust and other particles using air spray. If dirt cannot be removed by air spray, disassemble and clean

the optical unit.

● Disassembly Cleaning

Disassembly cleaning method should only be per-

formed when the unit is considerable dirty and cannot

be sufficiently cleaned by air spraying alone.

Be sure to readjust the optical system after per-

forming disassembly cleaning.

1. Remove the cabinet top and main units following to

“Mechanical Disassemblies”.

2. Remove the optical base top following to “Optical

Unit Disassemblies”. If the LCD panel needs clean-

ing, remove the LCD panel unit following to “LCD

panel/Prism ass'y replacement”.

3. Clean the optical parts with a soft cloth. Clean

extremely dirty areas using a cloth moistened with

alcohol.

Caution:

The surface of the optical components consists of mul-

tiple dielectric layers with varying degrees of refraction.

Never use organic solvents (thinner, etc.) or any kind of

cleanser on these components.

Since the LCD panel is equipped with an electronic cir-

cuit, never use any liquids (water, etc.) to clean the

unit. Use of liquid may cause the unit to malfunction.

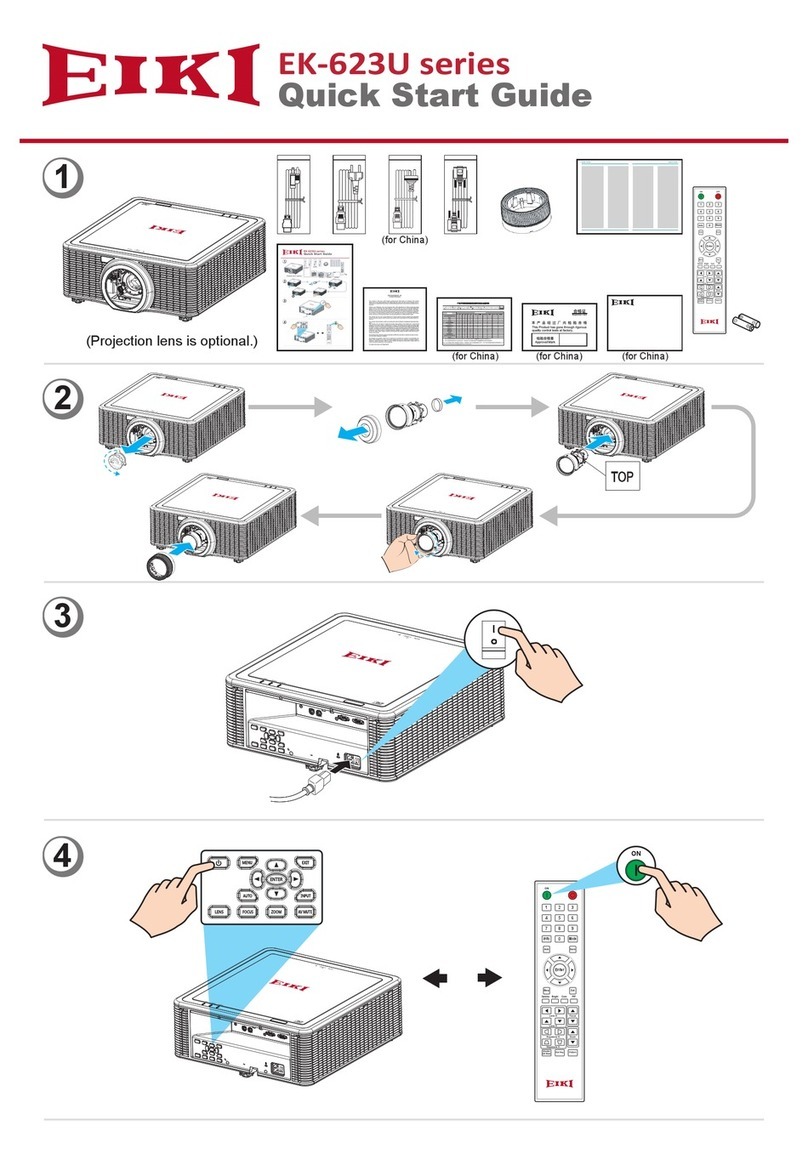

● Cleaning with the cleaning function

1. Press MENU button to display the On-Screen Menu

and select the Setting menu by pressing the Point

Up/Down button. Then press Point Right button to

enter the sub-menu.

2. Press Point Up/Down button to select the Cleaning

function then press SELECT button to select the

item, and then the image is blacked out temporary.

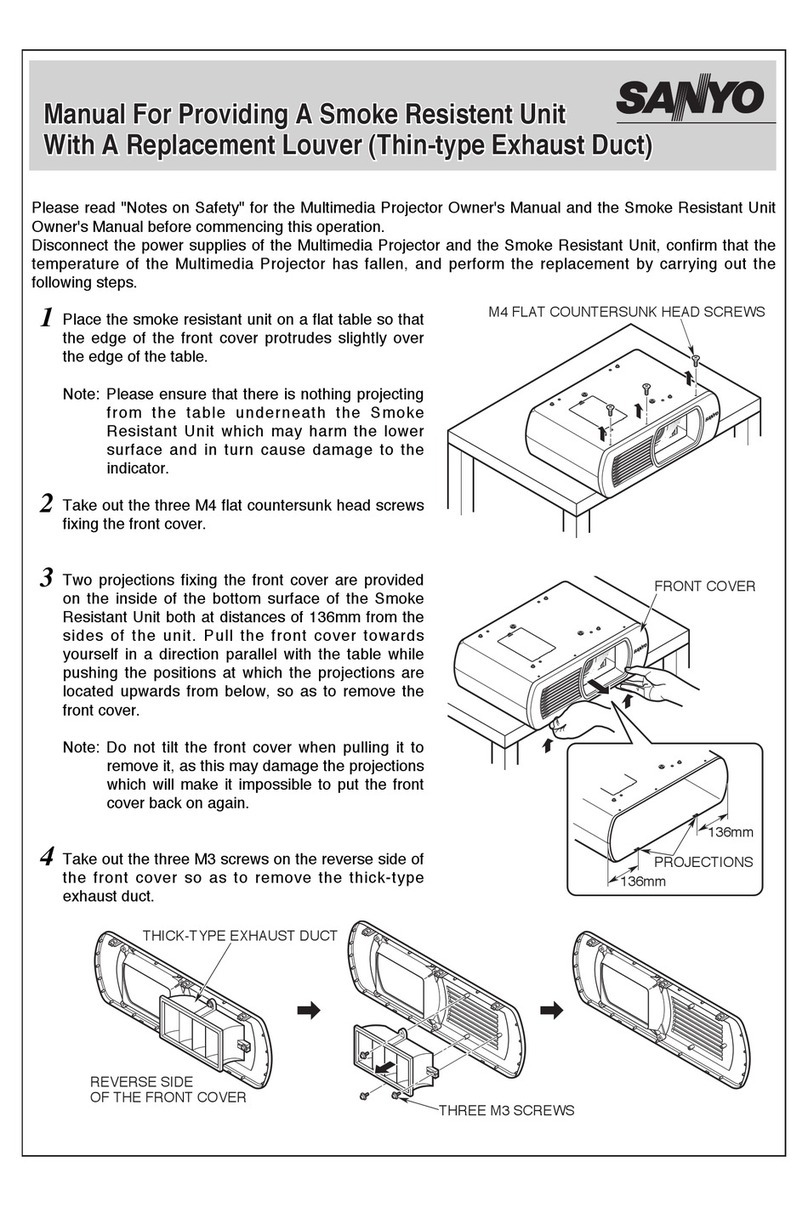

3. Turn over the projector then pull one of the hole cov-

ers upward gently, and put the blower nozzle in the

hole.

Note:

When you look at the screen

- When red spots (dust) are the most remarkable, put

the nozzle in the R panel cleaning holes.

- When Green spots (dust) are the most remarkable,

put the nozzle in the G panel cleaning holes.

- When Blue spots (dust) are the most remarkable,

put the nozzle in the B panel cleaning holes.

4. While watching the position of the dust on the

screen, blow air into the projector by the blower.

5. When finishing, pull the blower out and put the hole

cover back tightly.

Note:

When putting back the hole cover, starts from the

outside hole to make the operation easier and prevent

the hole cover from damaging.

6. Turn over the projector again, then press any button

on the top control or on the remote control to cancel

the Cleaning function.

The nozzle will be stopped

by the stoppers when

being put in the hole. Do

not try to force the nozzle

into further. The nozzle

could be break and fall into

inside of the projector.

When cleaning, wave the nozzle inside of the projector

back and forth. (Do not try to force the nozzle to bend.)

Caution: Use only supplied blower nd nozzle.

■Cleaning