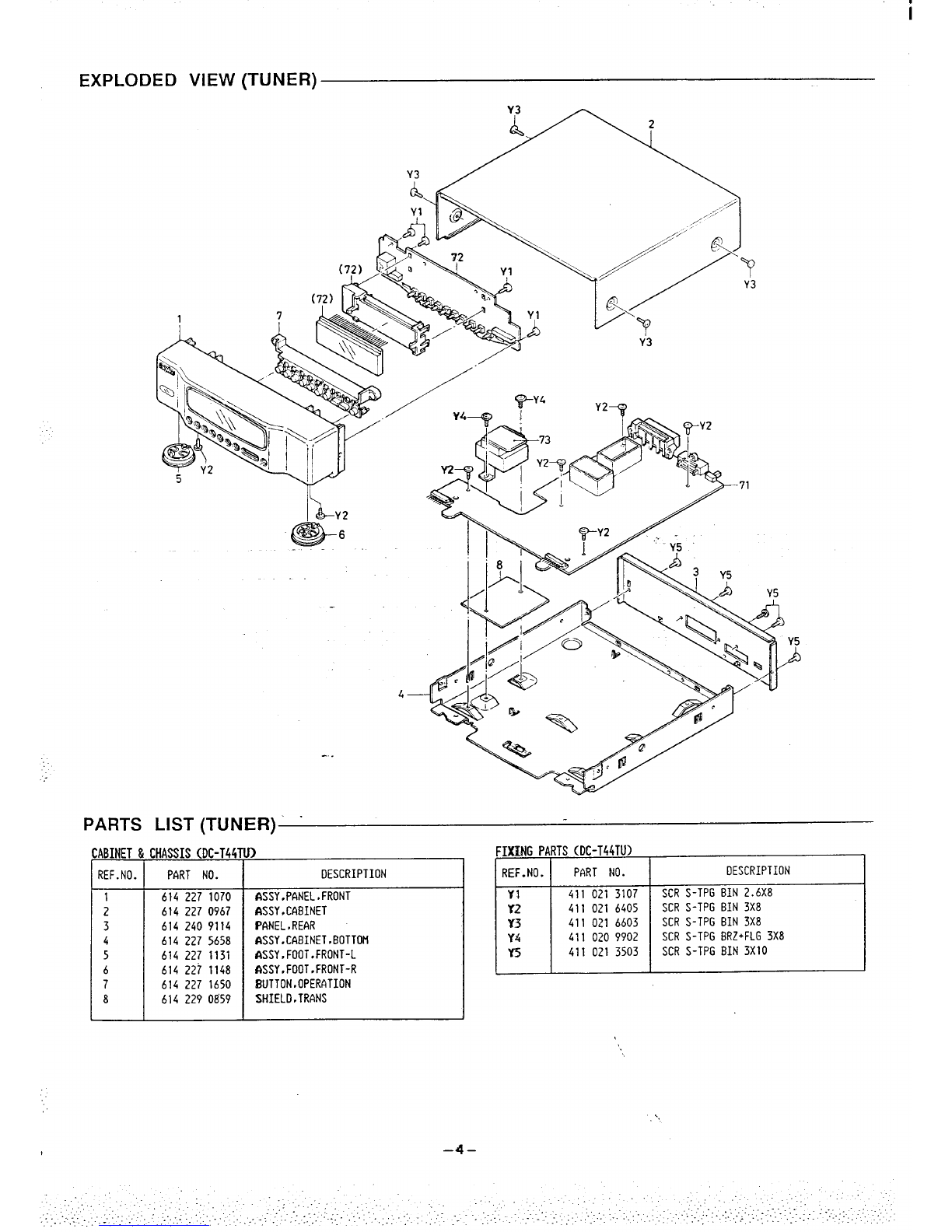

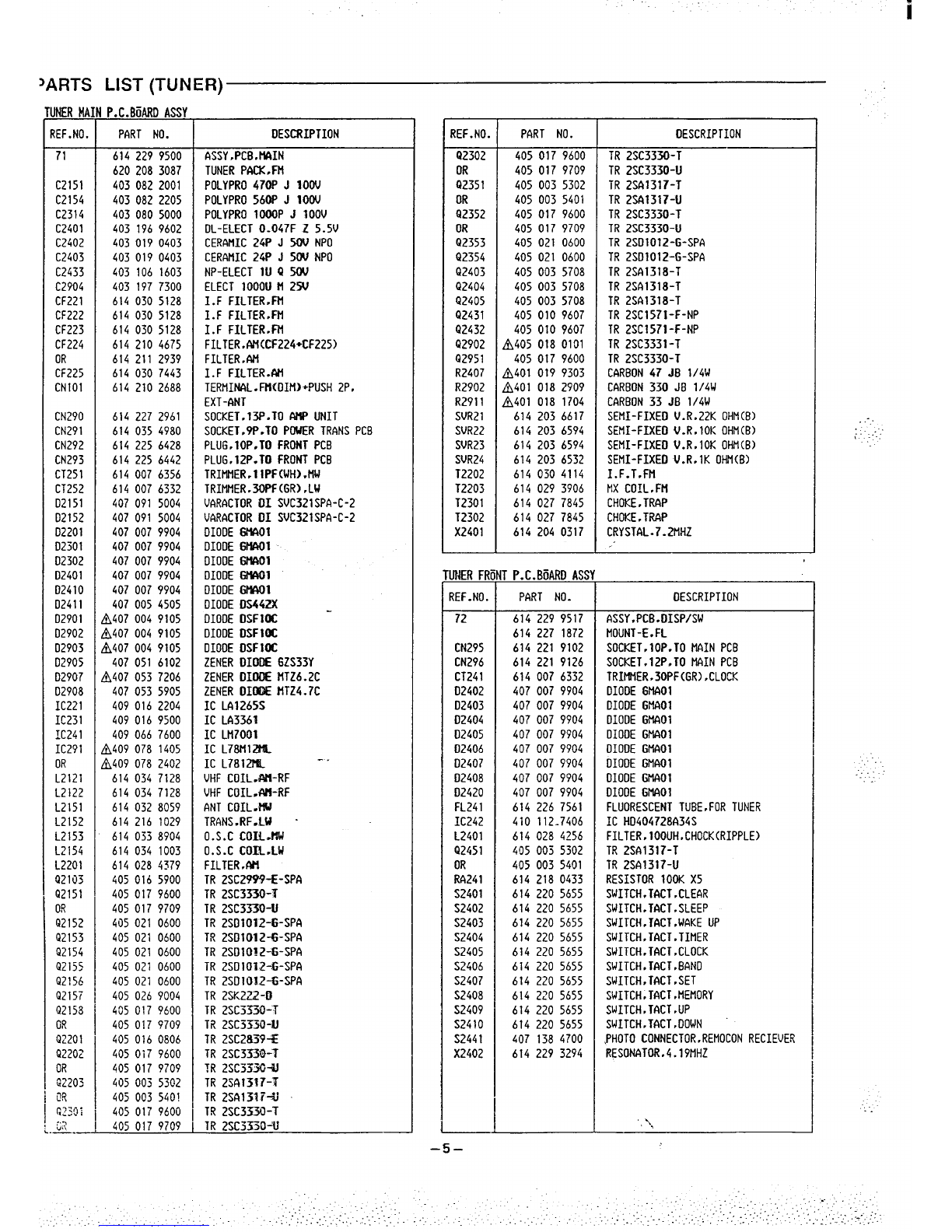

JARTS LIST (TUNER)

JNERMA

tEF. NO.

71

C2151

C2154

C2314

C2401

C2402

C2403

C2433

C2904

CF221

CF222

CF223

CF224

OR

CF225

CN101

CN290

CN291

CN292

CN293

CT251

CT252

02151

02152

02201

02301

02302

02401

02410

02411

02901

02902

02903

02905

02907

D2908

IC221

IC231

IC241

IC291

OR

L2121

L2122

L2151

L2152

L2153

L2i54

L2201

Q21iJ3

Q2151

0!?

Q2152

Q2153

Q2154

Q2155

Q2156

Q2157

Q2153

OR

QZ201

Q2202

OR

02205

~~

(p::l:

~~

—.—

P. C. BiMRD ASSY

PART NO.

6142299500

6202083037

4030822001

4030822205

4030805000

403 1969602

4030190403

4030190403

403 106 1603

403 1977300

614 030 5128

6140305128

6140305128

6142104675

614211 2939

614030 7443

6142102688

6142272961

6140354980

6142256428

6142256442

6140076356

6140076332

407091 5004

407091 5004

4070079904

4070079904

4070079904

4070079904

4070079904

4070054505

!h407 0049105

54070049105

f1407 0049105

407051 6102

ti407 0537206

4070535905

4090162204

4090169500

4090667600

N409 0781405

fi409 0782402

6140347128

6140347123

6140328059

614216 1029

6140338904

614034 1003

614 028 4379

405 016 5900

4050179600

405017 9709

405021 0600

405021 0600

405021 0600

405021 0600

405 021 0600

4050269004

405 017 9600

405017 9709

405 0160806

4050179600

4050179709

405 005 5302

405 003 540!

405017 9600

405 017 9709

DESCRIPTION

ASSY.PCB.NAIN

TUNER PoCK.FM

POLYPRO 470P J 100V

POLYPRO 560P J100V

POLYPRO 1000P JIOOV

OL-ELECT 0.047F Z5.5V

CERMIIC 24P J5W NPO

CERAHIC 24P JSW NPO

NP-ELECT lU Q50V

ELECT 1000U tl 25U

I.F FILTER.FN

I.F FILTER.FM

I.F FILTER.FN

FILTER .Atl(CF224+CF225)

FILTER,AN

I. FFILTER.AH

TERtlINAL.Ftl[OItlHliSH 2P,

EXT-ONT

SOCKET .13P.TOIMP UNIT

SOCKET.9P.TO POWER TR9NS PCB

PLUG. 10P.TO FRONT PCB

PLUG ,12P.TO FRONT PCB

TRItltlER .1 lPF(WH) .tiW

TRIMtlER.30PF(GR) ,LW

VARACTOR DI SVC321SPA-C-2

VARACTOR 01 SVC321SPA-C-2

DIODE Gf%iOl

DIODE GMOl

OIOOE Gt#uIl

DIODE GM301

DIODE GMAOl

DIOOE DS442X -

DIODE DSF1OC

DIODE DSF1OC

DIOOE DSFUIC

ZENER DIDOE 6ZS33Y

2ENER DIDOE tlTZ6.2C

ZENER DIDE$E flTZ4.7C

IC LA1265S

IC LA3361

IC Lt17001

XC L73t412$fL

IC L781214L

VHF COIL.IAH-RF

VHF COIL.AH-RF

ANT COIL .Md

TRANS.RF.LU -

O.s.c con-w

O.S.C COIL.LW

FILTER,AII

TR 2SC2%%E-SPA

TR 2SC3330-T

TR 2SC3330-LI

TR 2SDI012-G-SPA

TR 2SII1012-G-SPA

TR 2SDIO12-G-SPA

TR 2SD1012-G-SP~

TR 2SD1OI2-G-SPA

TR 2SK222-B

TR 2SC3330-”T

TR 2SC3X30-11

TR 2SC2839*

TR 2SC333tt-T

TR 2SC3Z3T*

TR 2SA1 517-?

TR 2SA133 T=Li

TR 2SC33XJ-T

TR 2SC3330’U

-..

REF. NO. PART NO. DESCRIPTION

Q2302 405017 9600 TR 2SC3330-T

OR 4050179709 TR 2SC3330-U

Q2351 4050035302 TR 2SA1317-T

OR 4050035401 TR 2S413t7-U

Q2352 405017 9600 TR 2SC3330-T

OR 405 017 9709 TR 2SC3330-U

Q2353 405 021 0600 TR 2SD1012-G-SPG

Q2354 405021 0600 TR 2SD1012-G-SPA

Q2403 4050035708 TR 2SA1318-T

Q2404 405003 5708 TR 2SA1318-T

Q2405 405 003 5708 TR 2SA1318-T

Q2431 405 0109607 TR 2SC1571-F-NP

Q2432 4050109607 TR 2SC1571-F-NP

Q2902 A405 0130101 TR 2SC3331-T

Q2951 405017 9600 TR 2SC3330-T

R2407 A401 0199303 CARBON 47 JB l/4W

R2902 A401 0182909 CARBON 330 JB 1/4W

R2911 A401 0181704 CARBON 33 JB l/4W

SVR21 614 2036617 SEtlI-FIXED V.R .22K OHtl(B)

SVR22 614 203 6591i SEflI-FIXED V.Rs 10K OHM(B)

SVR23 6142036594 SEMI-FIXED V. R,1OK OHN(B)

SVRZ4 614 2036532 SEMI-FIXEDU.R,lK OHtl(B)

T2202 614 0504114 I. F. T.Ffl

T2203 614 0293906 MX COIL, FH

T2301 614 0277845 CHOKE ,TRAP

T2302 614 0277845 CHOKE eTRAP

X2401 6142040317 CRYSTAL .7-2!IHZ

UNER FRtiNT P. C. B6ARD ASSY

REF.NO. PART NO. DESCRIPTION

72 614 229 9517 ASSY.PCB.DISP/SW

614227 1872 MOUNT-E.FL

CN295 614 221 9102 SOCKET.10P.TO NAIN PCB

CN296 614221 9126 SOCKET.12P.TO MAIN PCB

CT241 6140076332 TRIMIIER,30PF(GR),CLOCK

D2402 4070079904 OIODE GNAO1

D2403 4070079904 DIODE GMAO1

D2404 4070079904 OIOOE GMAO1

D2405 4070079904 OIODE GMAO1

02406 407 0079904 OIOOE GflAOl

D2407 407 007 9904 OIODE GIIAO1

D2408 407007 9904 DIODE GNAO1

02420 407 0079904 DIODE GMAO1

FL241 614 2267561 FLUORESCENT TUBE .FOR TUNER

IC242 410 112-7406 XC HD404728A34S

L2401 6140284256 FILTER,100UH.CHOCK(RIPPLE)

Q2451 405 003 5302 TR 2S01317-T

OR 405 0035401 TR 2S01317-U

R4241 614 2180433 RESISTOR 100K X5

S2401 6142205655 SWITCH .TACT .CLE6R

S2402 614 220 5655 SWITCH .TACT.SLEEP

S2403 614 2205655 SWITCH,TACT .WAKE UP

S2404 614 2205655 SWITCH, TACT .TDIER

S2405 614 2205655 SWITCH .TACT>CLOCK

S2406 614 2205655 SWITCH. TACT .BANO

S2407 614 2205655 SWITCH .TACT.SET

S2408 614 220 5655 SWITCH. TACT JIEtlORY

S2409 6142205655 SWITCH .TACT .UP

S241O 6142205655 SWITCH-TACT }DOWN

S2441 407 138 4700 PHOTO CONNECTOR ,REMOCON RECIEUER

X2402 6142293294 RESONATOR.4.19MHZ

‘.\,

–5–

“i

:.:..”.”

!----