Startup 9

6 Startup

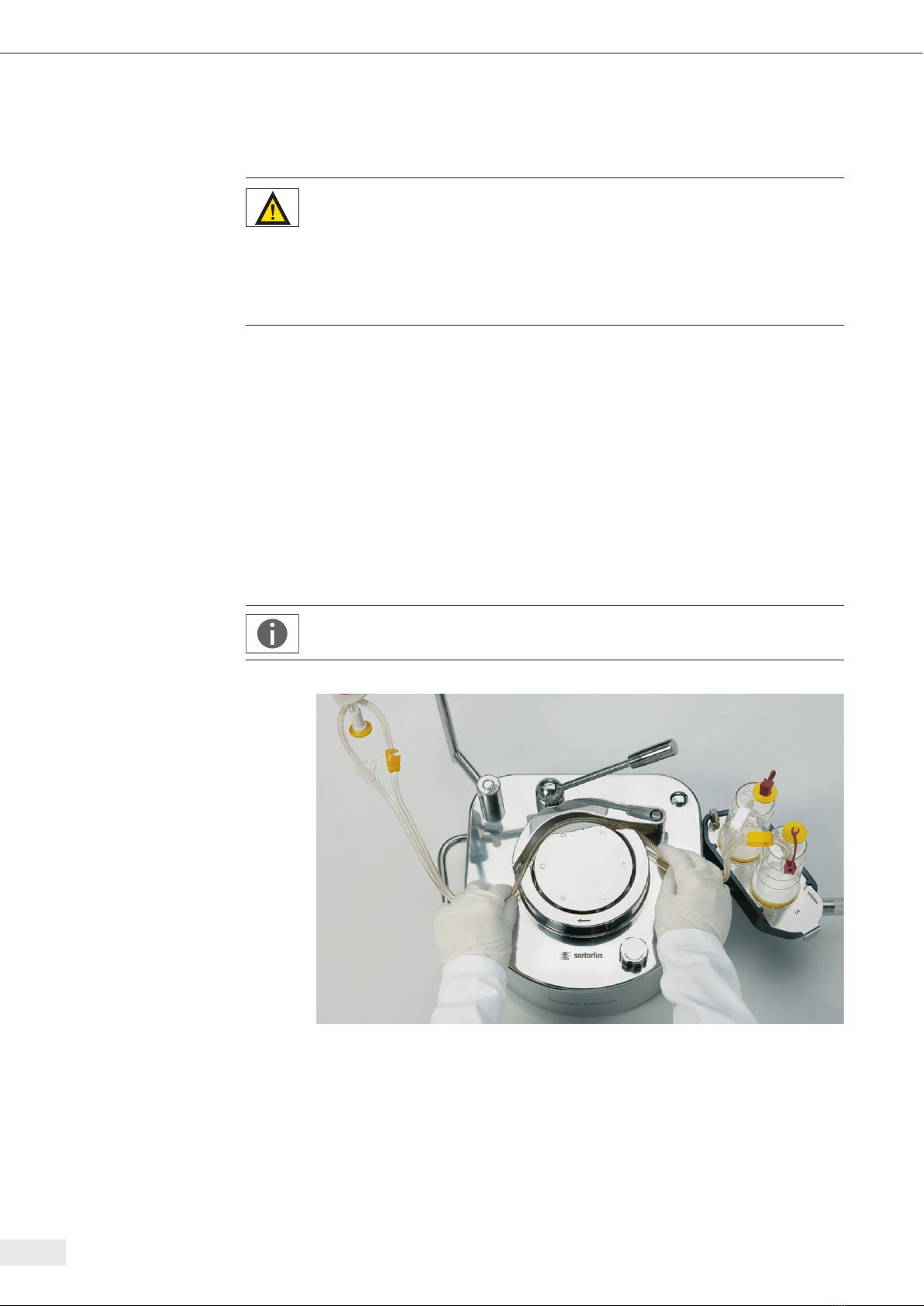

Set up the Sterisart®universal pump ergonomically in a suitable area (cleanroom,

laminar flow work bench, isolator).

Before initial start-up, the accessories supplied must be assembled on the Sterisart®

Universal pump. Please proceed in the following order:

– At the back left, push the support rod (Fig.1, 7) onto the pin of the upper part of the

pump until it is firmly in place. The holes in the foot of the support rod allow the

positioning of the support rod to be altered.

– Fasten the bottle holder (Fig. 1, 8) and the fastening arm (Fig. 1, 9) to the support

rod. If necessary, attach the ampoule breaker (Fig. 1, 10) beforehand.

– Insert the bow (Fig. 1, 4) and the clamping lever (Fig. 1, 3) on the corresponding

bolts on the top of the pump. The lever is jacketed in a plastic sleeve, which can be

removed for cleaning. If signs of wear appear on this sleeve after it has been in use

for some time, it can be re-ordered as a spare part (see chapter “Ordering informa-

tion for the Sterisart®Universal Pump”).

– After connecting the drain tubing to the barb (Fig. 1, 12) of the container for drain-

ing (Fig. 1, 11); attach the container for draining to the appropriate bolts on the

right handle (Fig. 1, 5). The container for draining and the cover plate are attached

by moving the tilting lock.

– Fasten the end of the drain tubing to the appropriate drain.

Very Important Note!

Always make sure that there is a sufficient liquid level differential (> 5 cm) bet-

ween the container for draining and the drain. This makes safe drainage possible

and prevents backflow into the container for draining. Make sure that the drain

tubing is kept lower than the pump to prevent the drain pan from overflowing.

Treat the waste as a biohazard. Only dispose of it in accordance with current

regulations.

– Plug the foot switch into the designated socket located on the rear panel (see Fig. 2,

4). Fasten the plug to the socket by turning it clockwise.

– Plug the power cable into the male power socket on the back of the Sterisart®

Universal pump and into a grounded electrical outlet (Fig. 2, 3).

– Use the On|Off switch (Fig. 2, 2) at the rear side of the Sterisart®Universal pump to

turn it on.