4 5

AE701/AE5702/AE5703

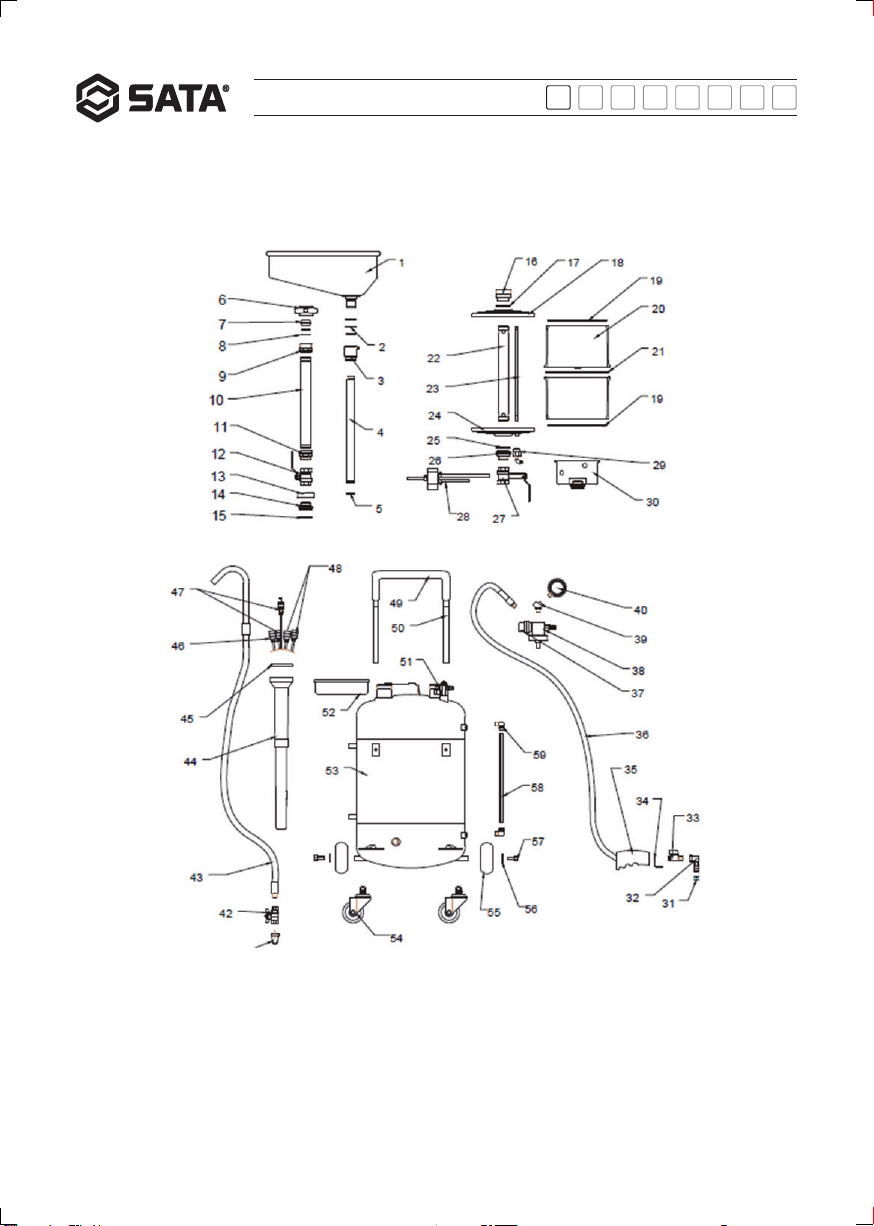

AE5701、AE5702、AE5704 Oil Drainer Parts list

No. Part No. Name No. Part No. Name No. Part No. Name

1 AE5701-5 Oil funnel 21 AE5701-25 O seal ring 41 AE5701-45 Oil draining

bend tube

2 AE5701-6 O seal ring 22 AE5701-26 Central oil

tube 42 AE5701-46 Ball valve

3 AE5701-7 Connecting

nut 23 AE5701-27 Metal air tube 43 AE5701-47 Oil draining

hose

4 AE5701-8 Inner lifting

support 24 AE5701-28 Lower cover 44 AE5701-48 Suction probe

holder

5 AE5701-9 O seal ring 25 AE5701-29 O seal ring 45 AE5701-49 Cover

6 AE5701-10 Locking nut 26 AE5701-30 Lower cover

nut 46 AE5701-50 5 suction

probe

7 AE5701-11 Locking ring 27 AE5701-31 Ball valve 47 AE5701-52 6 suction

probe

8 AE5701-12 O seal ring 28 AE5701-32 Valve part 48 AE5701-53 8 suction

probe

9 AE5701-13 Joint 29 AE5701-33 Air connecting 49 AE5701-54 Handle pad

10 AE5701-14 Outer lifting

support 30 AE5701-34 Valve body

cover 50 AE5701-55 Handle

11 AE5701-15 Joint 31 AE5701-35 O seal ring 51 AE5701-56 Air inflow part

12 AE5701-16 Ball valve 32 AE5701-36 Oil suction

head 52 AE5701-57 Tool tray

13 AE5701-17 Base inner

ring 33 AE5701-37 Ball valve 53 AE5701-58 Oil tank

14 AE5701-18 Nut

connection 34 AE5701-38 Oil suction

hook 54 AE5701-59 Steering

wheel

15 AE5701-19 O seal ring 35 AE5701-39 Handle bar 55 AE5701-60 Directional

wheel

16 AE5701-20 Upper cover

nut 36 AE5701-40 Suction hose 56 AE5701-61 Washer

17 AE5701-21 O seal ring 37 AE5701-41 Silencer 57 AE5701-62 Screw

18 AE5701-22 Upper cover 38 AE5701-42 Generator

part 58 AE5701-63 Level

indicator

19 AE5701-23 O seal ring 39 AE5701-43 T- joint 59 AE5701-64 Bend head

20 AE5701-24 Measuring

cup 40 AE5701-44 Vacuum

gauge

ESPT JARUEN DE KO

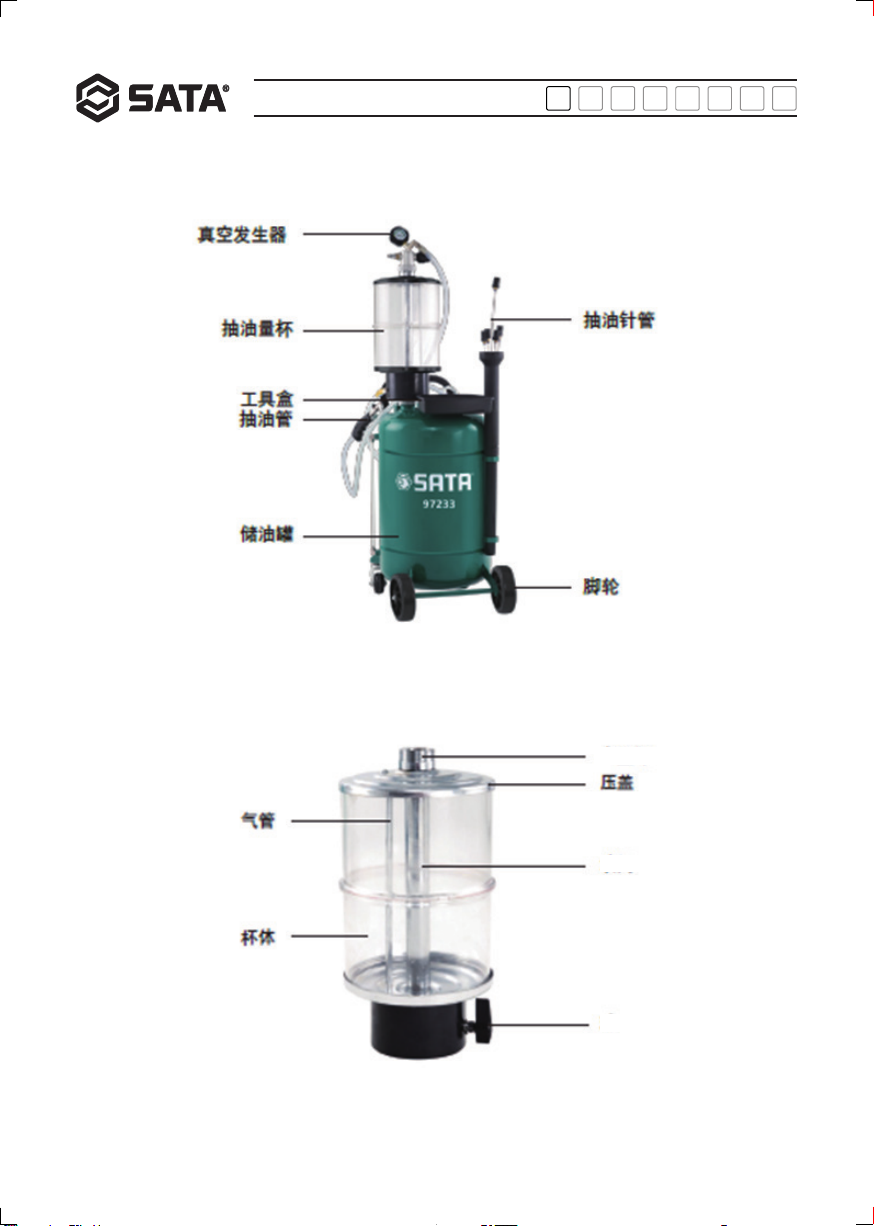

中文

AE5701_AE5702_AE5704八国-200621.indd 5AE5701_AE5702_AE5704八国-200621.indd 5 2020/6/23 19:05:222020/6/23 19:05:22