IMPORTANT SAFEGUARDS

WARNING - TO AVOID DAMAGING DIGITAL TORQUE ADAPTER

• Never operate digital torque adapter when powered OFF. Always power adapter ON prior

to applying torque.

• Never use this digital torque adapter to loosen fasteners as damage may occur.

• Do not exceed the rated maximum torque value for the digital torque adapter as break-

age and/or a loss of accuracy could occur.

• Always verify the calibration of the digital torque adapter if you know or suspect its capac-

ity has been exceeded.

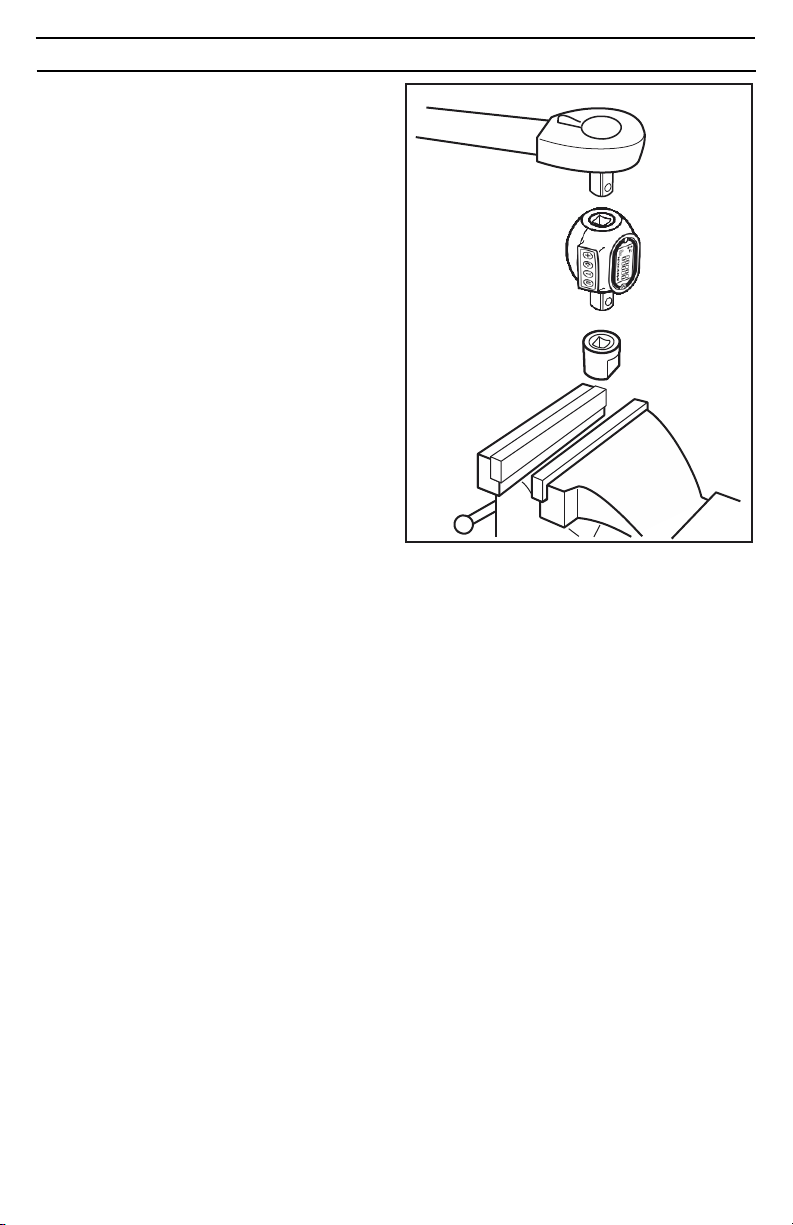

• Always pull - do not push - on the drive tool (ratchet) handle that is connected to the digi-

tal torque adapter.

• Adjust your stance to prevent a possible fall while applying torque.

• Apply torque slowly and grasp the center of the handle. Do not apply load to the end of

the handle.

• Avoid applying excessive torque, turn the ratchet slowly and steadily as you apply torque.

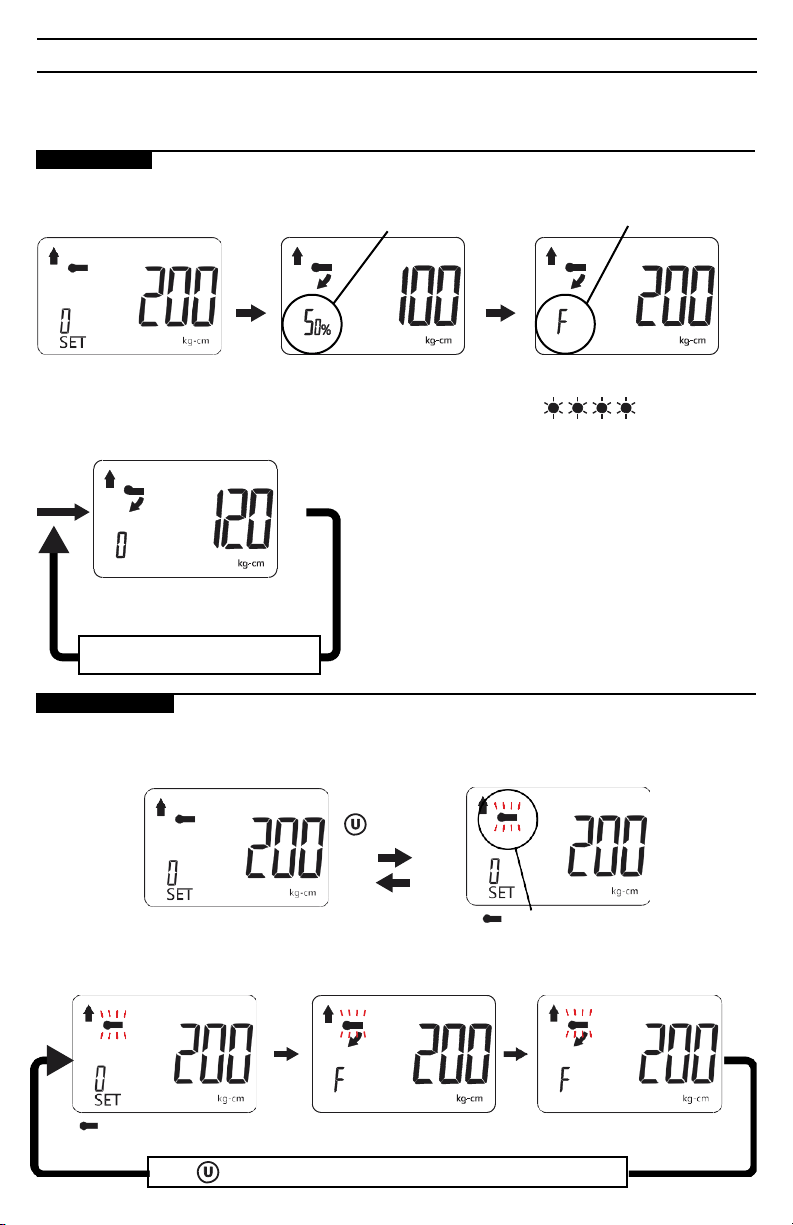

Pay attention to the LED light and sound indicators.

• Never submerge the digital torque adapter in water or any other liquid.

• If the tool gets wet, immediately wipe it dry with a soft, clean towel.

• Do not expose this wrench to dust or sand as this could cause serious damage.

• Use the digital torque adapter only for its intended purpose as described in this manual.

• Do not use the digital torque adapter if it is not working properly or if it has suffered any

damage.

• Do not disassemble the digital torque adapter.

• Do not expose the digital torque adapter to extreme temperatures, humidity, direct sun-

light.

• Do not shake violently or drop digital torque adapter.

• Do not use this tool as a hammer.

• Position batteries in proper polarity.

• Do not mix batteries of different type.

• Never clean the digital torque adapter with soap or solvents.

• Use a soft, dry, clean cloth to clean the digital torque adapter and LCD panel.

• Do not apply excessive force to the LCD display panel.

• Store in a clean dry place.

• Keep this tool away from magnets.

PRODUCT SPECIFICATIONS

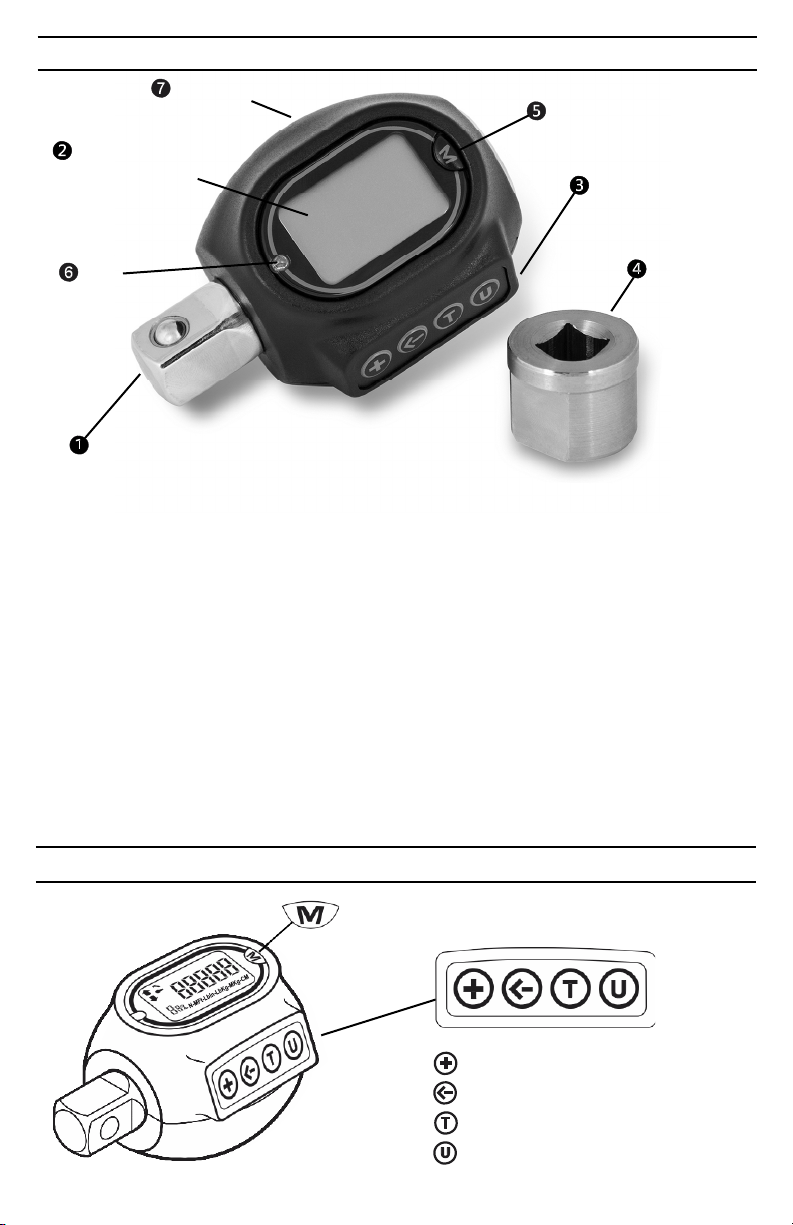

Drive size: 3/8 or 1/2 inch (depending of reference#)

Accuracy:

CW: ± 1%

CCW (4-39Nm) ± 4%

CCW (40-203Nm) ± 2%

Mem

o

ry

p

resets:

10

Display resolution: 0.1 Nm

Operation mode: Peak/Trace

Unit selection: kg-cm, kg-m, lb-in, lb-ft, N-m

Battery: (1) DC 3V, CR2032

Ambient temperature range:

Operating: -10°C – 60°C (13.9°F – 139.9°F)

Storage: -20°C - 70°C (-4°F – 157.9°F)

Auto shut-off: 80 seconds

Torque range: 4-203 Nm