Operating manual for the VISATRON VN2020 V2.0 12/2021 EN

Page 5of 106

SCHALLER AUTOMATION 66440 Blieskastel / Saarland / Germany / Industriering 14 / P.O. Box 1280

Industrielle

Automa

tionstechnik

Gm

bH

&

Co.

KG

Tel. +49(0)6842-508-0/ Fax -260 / Email: inf[email protected]e / www.schaller-automation.com

7.8. Installing the electrical connecting cable..........................................................39

7.9. Installing the Remote Indicator (optional).........................................................43

7.10. Starting up for the first time..............................................................................45

7.10.1.Setting the negative pressure at the measuring head ......................................45

7.10.2.Connecting the power supply...........................................................................48

7.10.3.Setting the sensitivity of the oil mist detector....................................................48

7.10.4.Function test during startup..............................................................................49

7.10.5.Checklist for startup.........................................................................................50

8. Operation and application................................................................................51

8.1. Display and alarm reset ...................................................................................51

8.2. Error diagnosis and troubleshooting.................................................................52

8.2.1. Error code –All LEDs off..................................................................................53

8.2.2. Error code 02 –Electronic module faulty..........................................................53

8.2.3. Error code 03 –Supply pressure measurement faulty......................................53

8.2.4. Error code 04/16 - Measured value too high/Measured value too low..............53

8.2.5. Error code 06 –Supply voltage not within permissible range ...........................53

8.2.6. Error code 07 –Reset button faulty..................................................................53

8.2.7. Error code 08 –Electronics temperature too high (> 75 °C).............................53

8.2.8. Error code 09 –Electronics temperature too low (< 0 °C) ................................53

8.2.9. Error code 10 –Ambient temperature too high (> 70 °C) .................................53

8.2.10.Error code 11 –Ambient temperature too low (< 0 °C).....................................54

8.2.11.Error code 12/17 –Internal memory checksum error .......................................54

8.2.12.Error code 13 –Optical sensor dirty –cleaning required..................................54

8.2.13.Error code 14 –Supply pressure too low .........................................................54

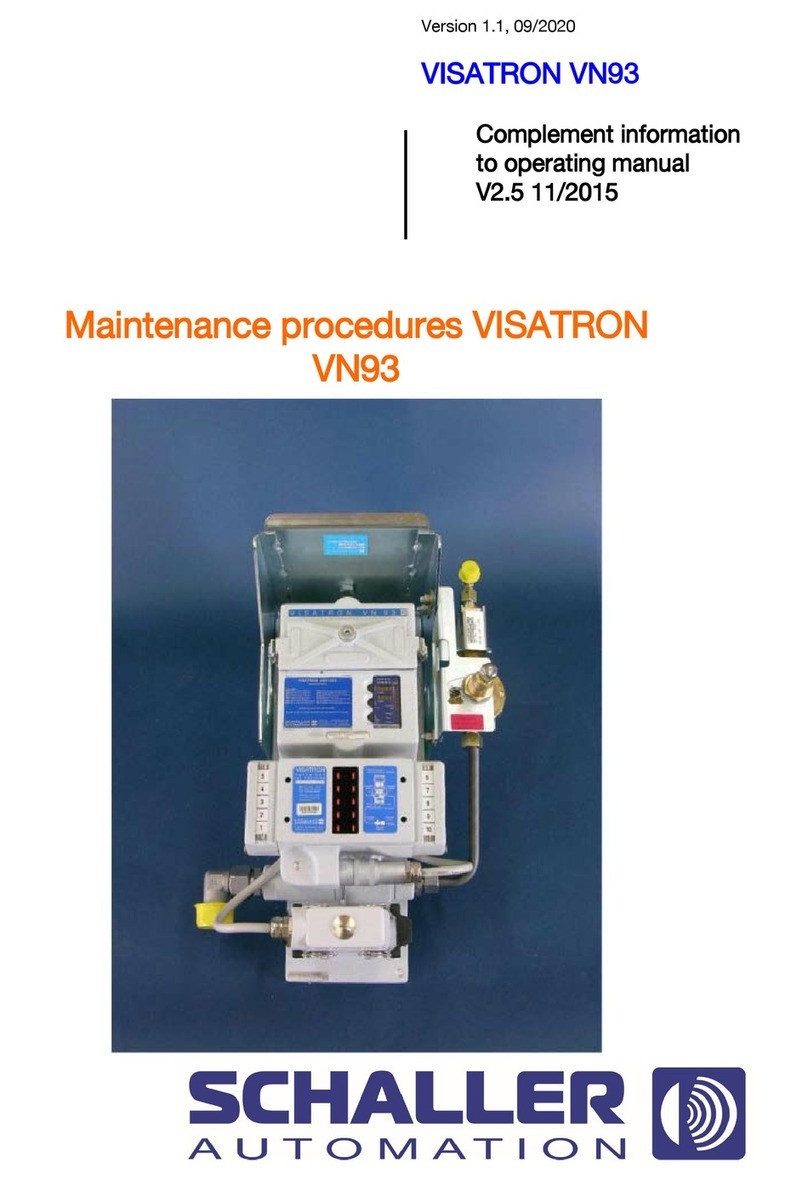

9. Maintenance and repair ...................................................................................55

9.1. Maintenance....................................................................................................55

9.1.1. Maintenance cycles for reliable operation........................................................55

9.1.2. Maintenance by the operator ...........................................................................57

9.1.3. Cleaning the light path (4,000 h)......................................................................57

9.1.4. Function test with smoke tube..........................................................................60

9.1.5. Replacing the filter of the filter control valve.....................................................63

9.1.6. Replace connection box seal...........................................................................64

9.1.7. Inspection of the oil mist detection system (16,000 h)......................................68

10. Repair..............................................................................................................68

10.1. Repair by the operator .....................................................................................68

10.1.1.Replacing the measuring head.........................................................................68

10.1.2.Replacing the terminal box...............................................................................72