2

Contents

About this guide..........................................................................................................................................................................................3

Safety instructions...................................................................................................................................................................................3

Why use of oil mist detector........................................................................................................................................................................4

The basics- and advantages of our Oil Mist Detectors.............................................................................................................................4

Class Approval........................................................................................................................................................................................4

Engine Protection Partner AS –the largest service partner worldwide! ...................................................................................................5

Repair and service department...................................................................................................................................................................6

Exchange pool (EXP) for all systems..........................................................................................................................................................7

Our Products..............................................................................................................................................................................................9

Visatron VN/87plus .................................................................................................................................................................................9

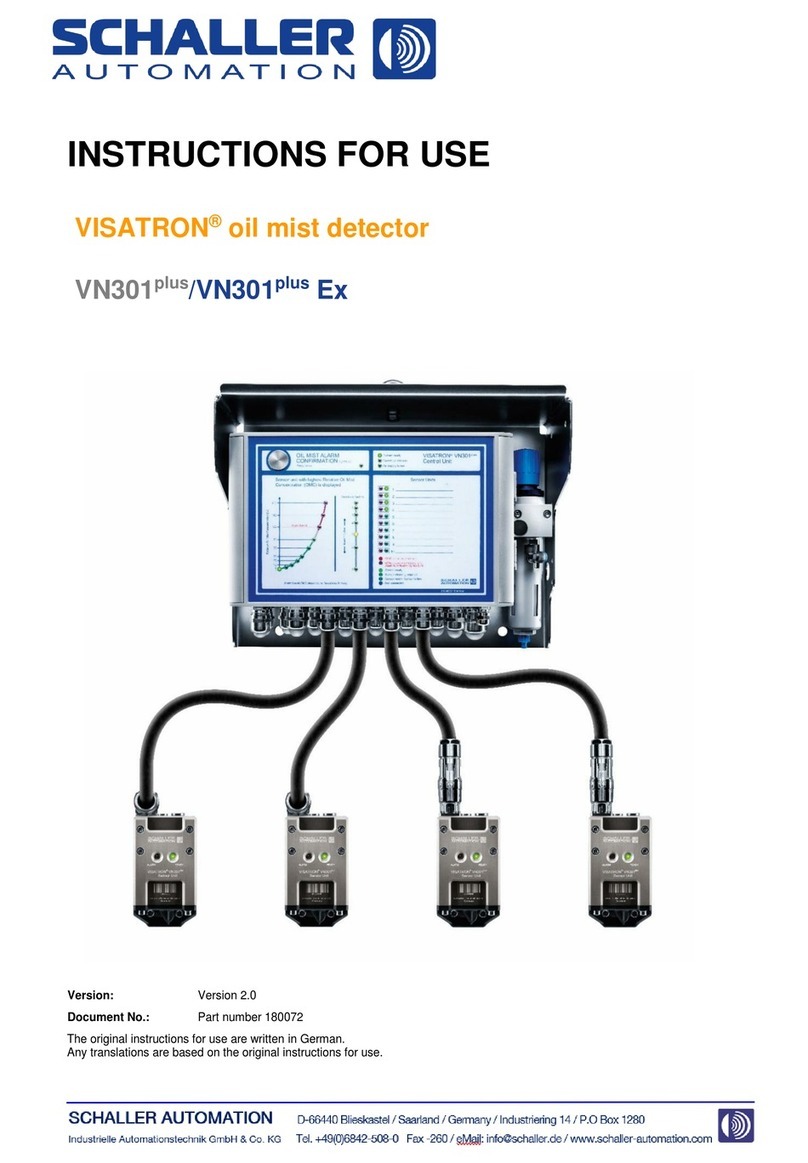

Visatron VN301plus ................................................................................................................................................................................9

Visatron VN2020...................................................................................................................................................................................10

Visatron VN/87 EMC.............................................................................................................................................................................10

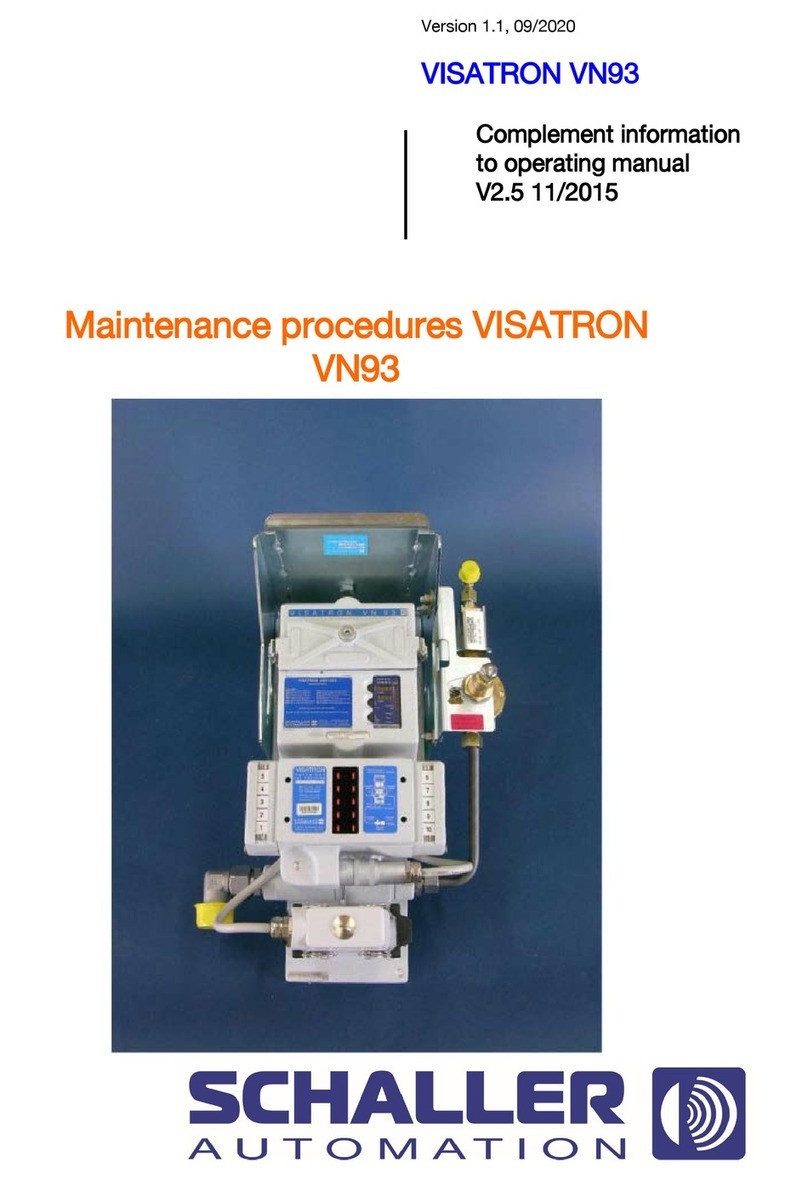

Visatron VN/93......................................................................................................................................................................................11

Wire break resistance for oil mist alarm ....................................................................................................................................................12

Wire break resistance for VN/87 EMC...................................................................................................................................................12

Wire break resistance for VN/87plus.....................................................................................................................................................13

Wire break resistance for VN/93............................................................................................................................................................13

Wire break resistance for VN/2020........................................................................................................................................................14

Alarm diagram for VN/87 EMC, VN/87plus & VN/93..............................................................................................................................14

How to test the alarm system....................................................................................................................................................................15

Maintenance Schedules ...........................................................................................................................................................................16

Maintenance Schedule Visatron VN/87 EMC & VN/87plus....................................................................................................................16

Maintenance Schedule Visatron VN/93.................................................................................................................................................20

Visatron VN2020...................................................................................................................................................................................23

Troubleshooting........................................................................................................................................................................................27

Visatron VN/87 EMC.............................................................................................................................................................................27

Visatron VN/87plus ...............................................................................................................................................................................27

Visatron VN/93......................................................................................................................................................................................27

Visatron VN2020...................................................................................................................................................................................27

Spare Parts ..............................................................................................................................................................................................28

Visatron VN115/87 EMC.......................................................................................................................................................................28

Visatron VN115/87plus .........................................................................................................................................................................29

Visatron VN115/93................................................................................................................................................................................30

Visatron VN116/87 EMC.......................................................................................................................................................................31

Visatron VN116/87plus .........................................................................................................................................................................32

Visatron VN116/93................................................................................................................................................................................33

Visatron VN215/87 EMC.......................................................................................................................................................................34

Visatron VN215/87plus .........................................................................................................................................................................35

Visatron VN215/93................................................................................................................................................................................36

Visatron VN2020...................................................................................................................................................................................37

Visatron VN301plus ..............................................................................................................................................................................38

Part- & Kit Database.................................................................................................................................................................................39