Operation Manual VISATRON® VN115/87plus EX 06/2016

Page 2

SCHALLER AUTOMATION D-66440 Blieskastel / Saarland / Germany / Industriering 14 / P.O Box 1280

Industrielle Automationstechnik GmbH & Co. KG Tel. +49(0)6842-508-0/ Fax -260 / eMail: info@schaller.de / www.schaller.de

About this Manual

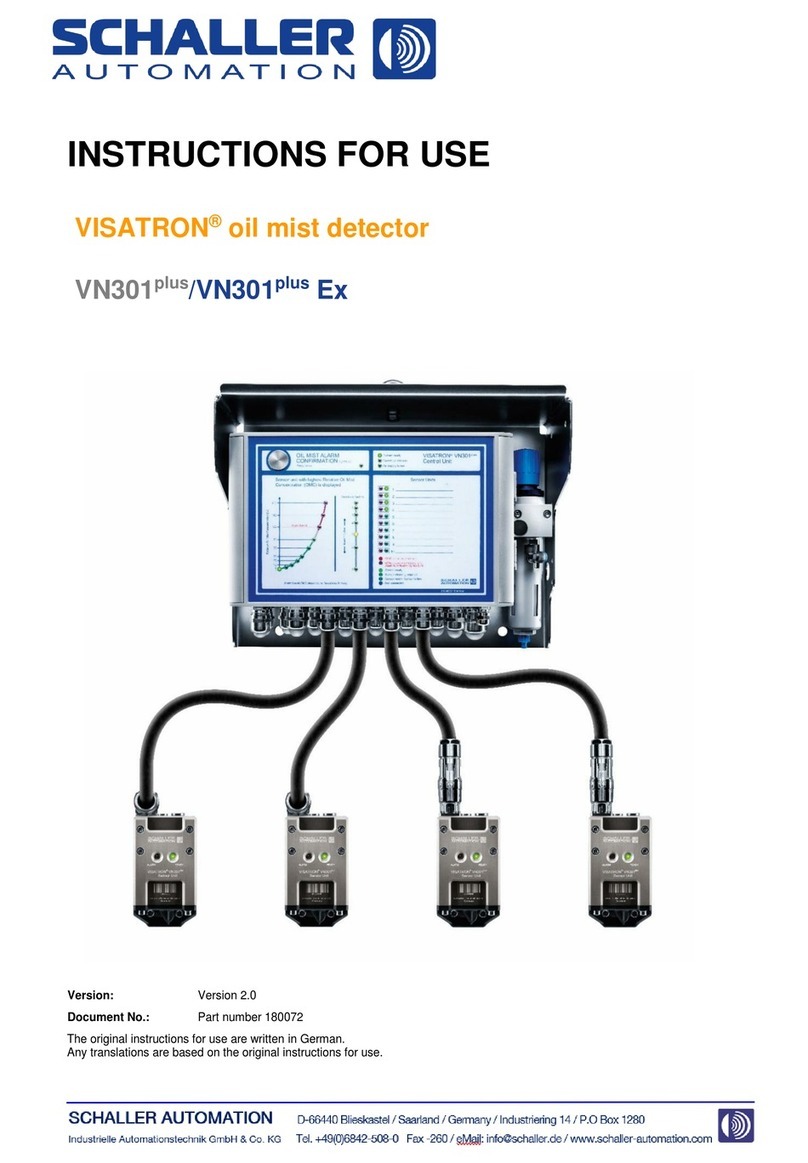

This operation manual was designed to answer your questions concerning the

handling, operation and maintenance of the Oil Mist Detector (OMD) VISATRON®

VN115/87plus EX. It contains no details about repairs.

The operating instructions are applicable for:

VN115/87plus EX

Should you encounter any interruption or breakdown of your VISATRON® OMD

device during operation, please contact your local representative (refer to chapter

10 ‘Service Partners’) or Schaller Automation, Industrielle Automationstechnik

GmbH & Co. KG directly. The repair of OMD devices should be carried out by

Schaller Automation directly. You can expect safe and reliable operation of your

OMD only when the device is operated in accordance with this manual.

Please take note of the following:

Please read this manual thoroughly and acquaint yourself with the correct

installation, operation and maintenance of your VISATRON® VN115/87plus EX

device.

Installations of the VISATRON® VN115/87plus EX devices have to be in

accordance to the IACS UR M10 if applicable.

Use the VISATRON® VN115/87plus EX devices only for the purpose described in

the operation manual.

Incorrect maintenance and handling errors may cause possible device failure or

an unsafe operating environment.

The VISATRON® VN115/87plus EX devices may only be used by authorised

staff.

This operation manual must be available at the place of installation at all times.

Terms and conditions of sale

The standard terms and conditions of sale of SCHALLER AUTOMATION shall apply to

all VISATRON® and related products.

SCHALLER AUTOMATION Industrielle Automationstechnik GmbH & Co. KG warrants

that under proper use, handling and maintenance OMD VISATRON® VN115/87plus

EX is free from defects in material, design and/or workmanship. Claims of

buyers/operators, in particular compensation for damage, which does not arise at

OMD VISATRON® VN115/87plus EX itself or for natural wear and tear of

consumable supplies, e.g. filters etc., are excluded. SCHALLER AUTOMATION

Industrielle Automationstechnik GmbH & Co. KG is not responsible for defects,

which arise as a result of:

a) natural wear and tear, improper commissioning, improper use/handling, use of

unsuitable power supply, welding processes on the engine as well as non-

observance of commissioning, installation, operating and service instructions as

given in this Operation Manual