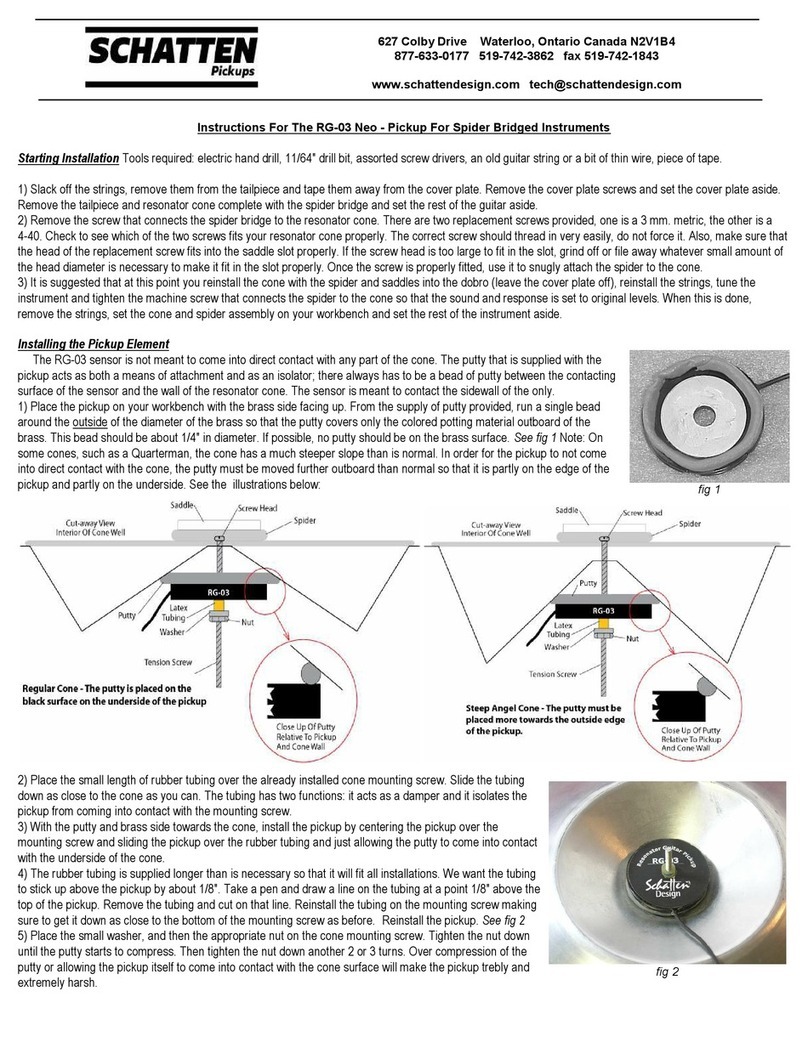

2) Place the small length of rubber tubing over the already installed cone

mounting screw. Slide the tubing down as close to the cone as you can.

The tubing has two functions: it acts as a damper and it isolates the

pickup from coming into contact with the mounting screw.

3) With the putty and brass side towards the cone, install the pickup by

centering the pickup over the mounting screw and sliding the pickup over

the rubber tubing and just allowing the putty to come into contact with

the underside of the cone.

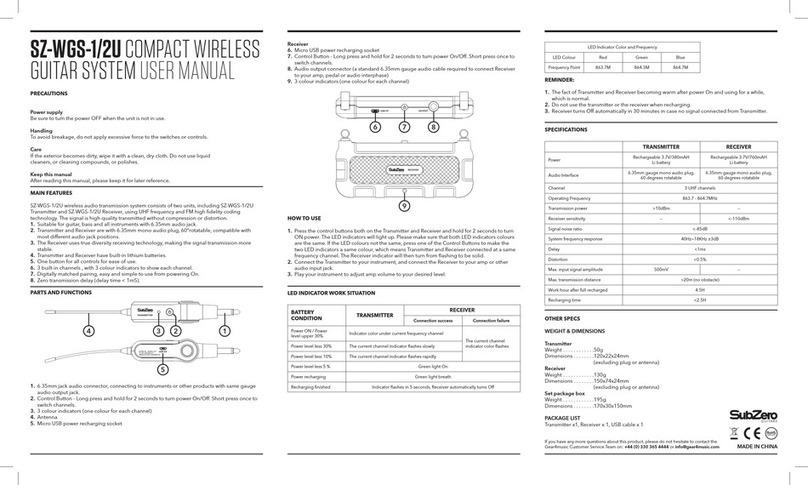

4) The rubber tubing is supplied longer than is necessary so that it will fit

all installations. We want the tubing to stick up above the pickup by

about 1/8". Take a pen and draw a line on the tubing at a point 1/8"

above the top of the pickup. Remove the tubing and cut on that line.

Reinstall the tubing on the mounting screw making sure to get it down as

close to the bottom of the mounting screw as before. Reinstall the

pickup. See fig 2

5) Place the small washer, and then the appropriate nut on the cone

mounting screw. Tighten the nut down until the putty starts to compress. Then tighten the nut down another 2 or 3

turns. Over compression of the putty or allowing the pickup itself to come into contact with the cone surface will make

the pickup trebly and extremely harsh.

M Condenser Microphone Installation:

1) The suggested mounting position for the microphone is as

shown, just below the cut for the lip of the cone. The mic will be

generally be placed 3/8" down from that cut.

2) Both putty and 3M VHB mounting tape is supplied for installing

the microphone. The suggested method of mounting the mic is to

use the supplied putty.

3) Roll up a small ball of the putty (about 3/8" in diameter) and

spread it out evenly on the flat surface of the microphone mount.

Press the microphone mount firmly against the side wall of the well.

It may be necessary to press the assembly against the wall several

times over ten or fifteen minutes until the putty takes a set.

4) If the wall surface is clean and smooth, the VHB may be used for

mounting if desired. Alternatively, a small screw may be used to

affix the mic to the wall using the small hole in the mount.

Installing the Jack

Note: You have the option of permanently installing the supplied jack as an endpin jack, as a side jack or, if you

don’t wish to drill a hole through the butt or side of the instrument, the jack may be hung from an existing tailpiece

screw or strap button.

For endpin jack use

1) Remove the existing strap button. If the strap button screw also functioned to hold the tailpiece in place, then

reinstall the screw without the strap button.

2) Measure the actual depth of your resonator cone (it is generally in the range of 2""). Allowing for the amount that

the resonator cone is recessed into the top (usually about 1/8" to 1/4"), add that to the depth figure for the cone

(usual total 2 1/4"). Add extra 1/2" for clearance and measure down from the top of the instrument about 2 3/4".

3) Drill a pilot hole through the end block approximately 3/16" in diameter in the area you wish to place the end pin

jack.

4) Using a fluted burr, chamfer the edges of the hole so that you will not damage the finish of the instrument when

you use the larger sizes of bits required.

5) Drill through the guitar end block using a 3/8" bit and re-chamfer the hole. Repeat drilling with a 31/64" bit to

complete the drilling operations.

7) Remove the Outer strap button, and the small nut and washer from the endpin jack or preamp. Reach inside the

instrument and poke the endpin jack part through the drilled hole in the end block. The jack should protrude

approximately 5/16" outside the guitar. Reinstall the flat washer and small nut.

8) Insert a small allen wrench or other small round (like a drill bit) through the 2 holes in the end of the endpin jack

to keep the jack assembly from rotating; tighten the small nut.

For side jack use

1) Drill a 3/8" diameter hole in the side wall of the instrument where you want to mount the jack.

2)Remove the outer strap button, small nut and washer from the endpin jack. Reach inside the instrument and poke

the jack through the drilled hole in the side. Reinstall the flat washer and nut and tighten the jack.

fig 2