4

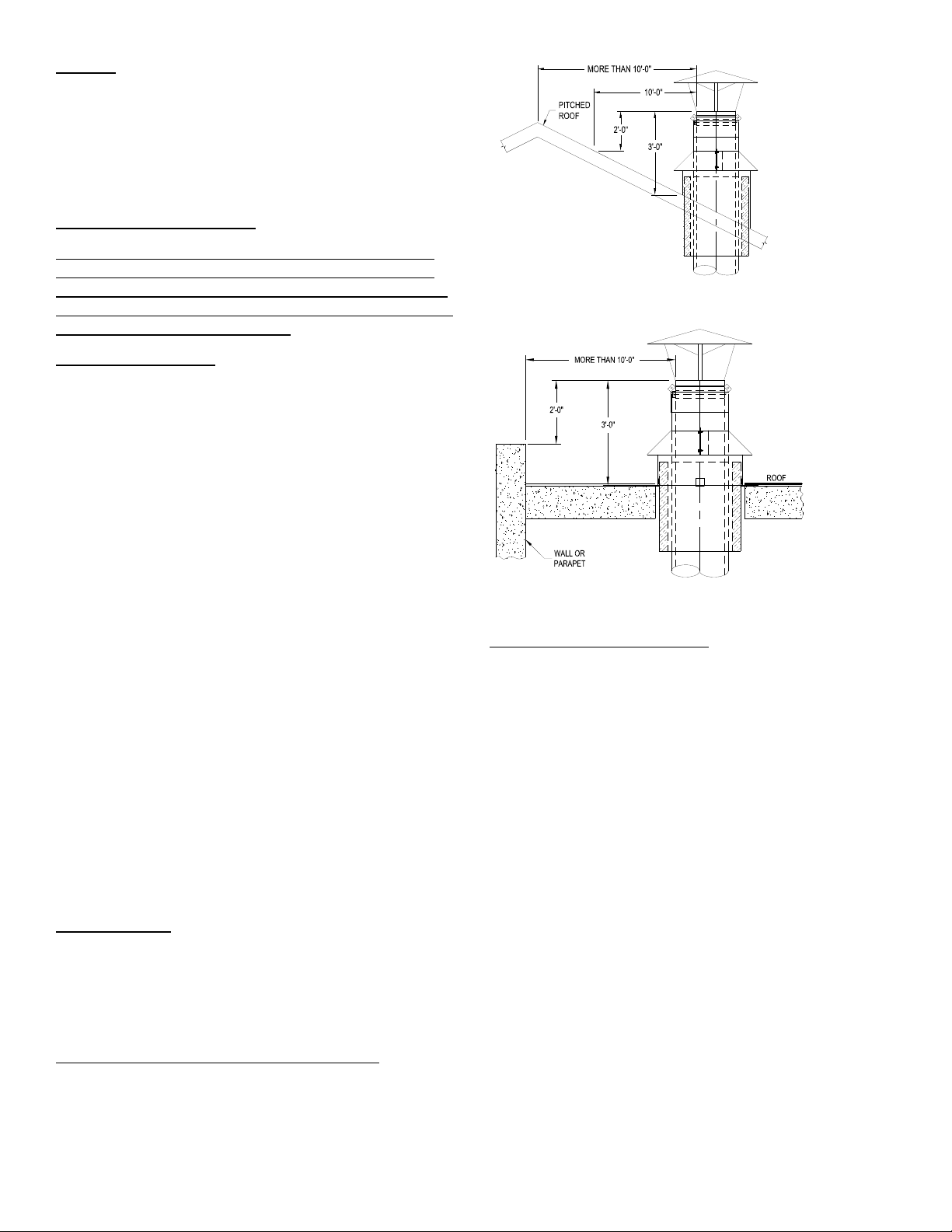

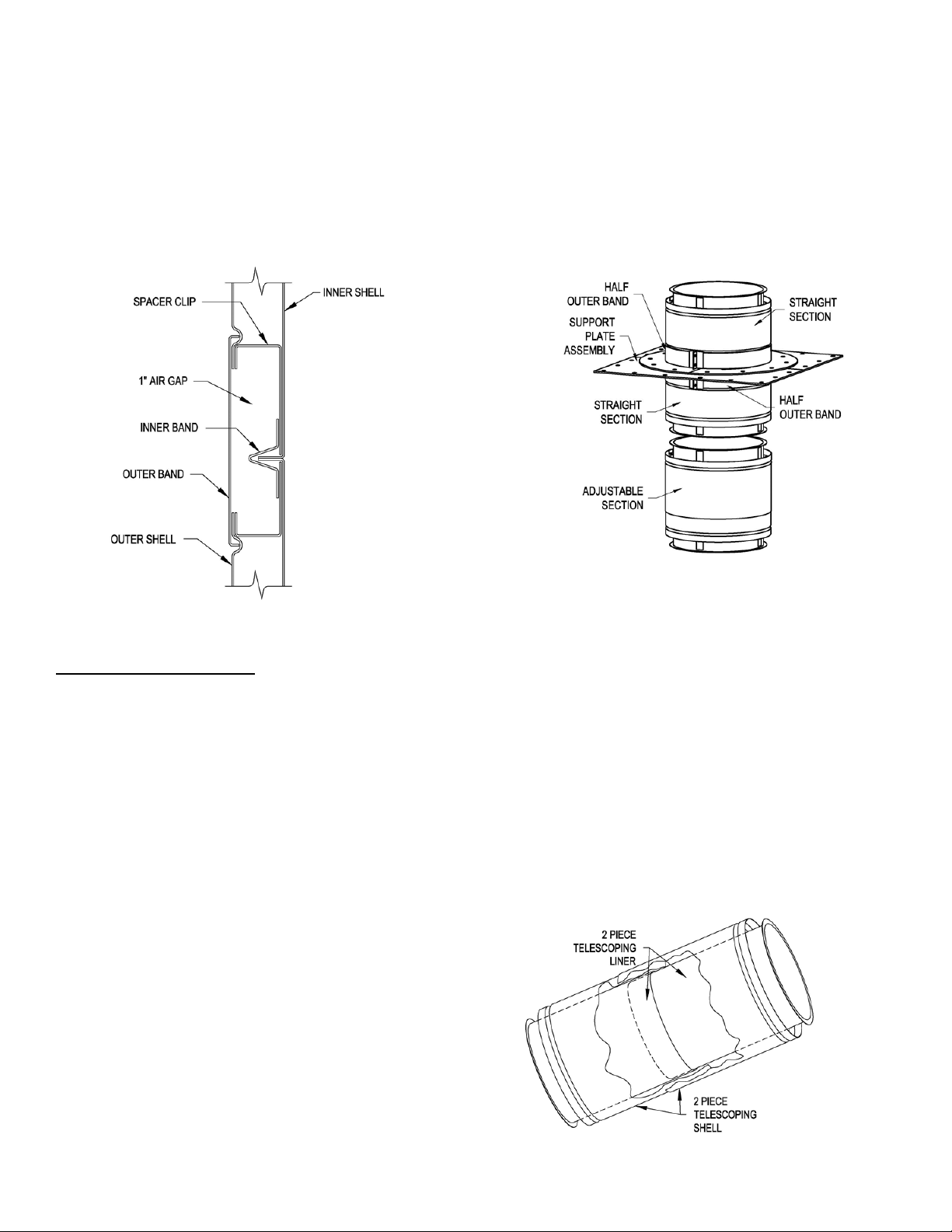

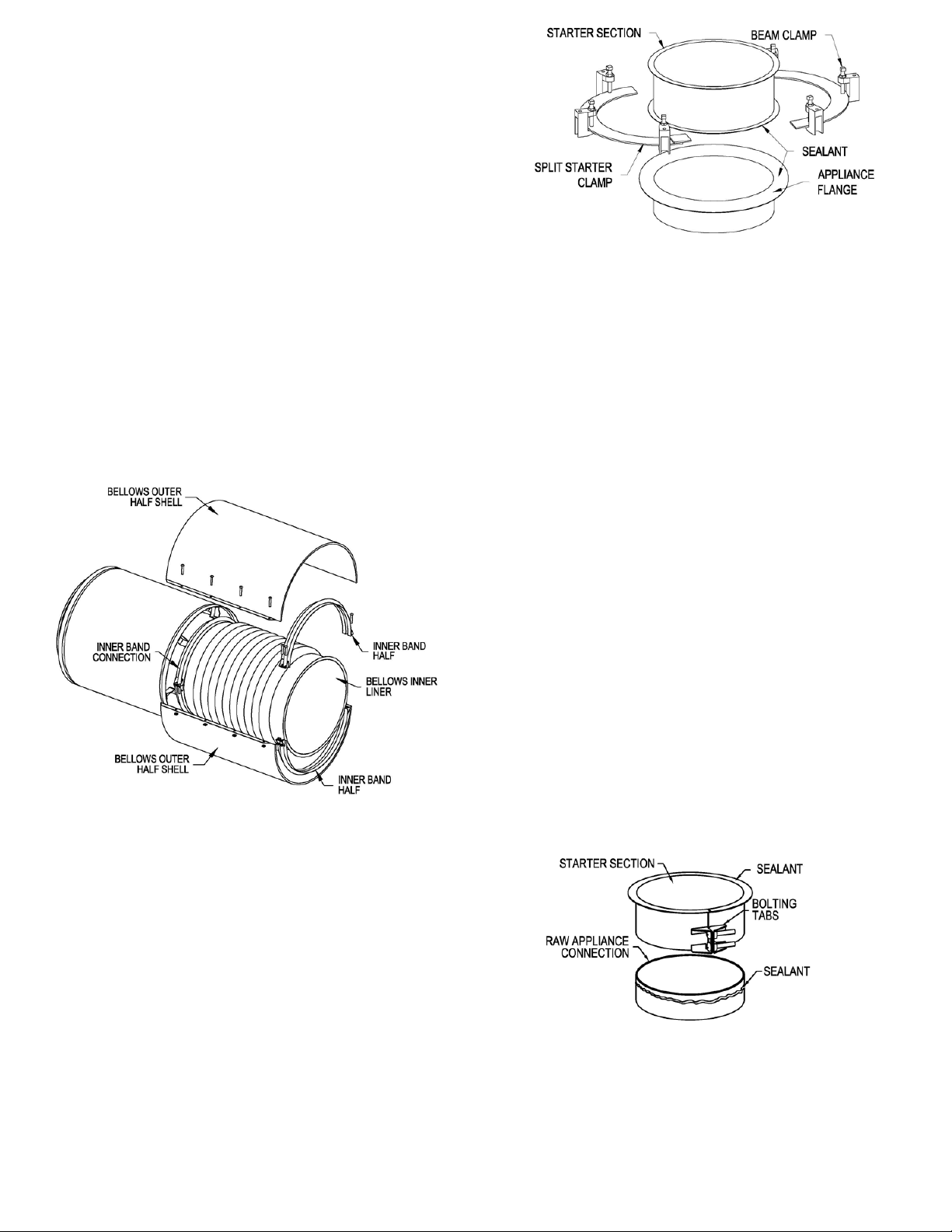

CLEARANCES AND ENCLOSURES

CAUTION – DO NOT ENCLOSE IN A CHASE OR

PASSAGEWAY MADE FROM WOOD OR ANY

OTHER COMBUSTIBLE MATERIAL. DO NOT

PLACE ANY TYPE OF INSULATION OR

COMBUSTIBLE MATERIALS IN THE REQUIRED

CLEARANCE SPACES SURROUNDING THE

CHIMNEY.

These chimneys are intended to be installed unenclosed or

with non-combustible enclosures. Schebler Chimney

Models SW, PA, P1, P2, P2A and P4 are not for use in one

or two-family dwellings.

If the chimney passes through any zone or story of a

building above that on which the connected appliance is

located, it is to be enclosed in non-combustible

construction having a fire rating equal to or greater than

that of the floor or roof assemblies through which it

passes. NOTE: Always check with the Authority Having

Jurisdiction for material with an appropriate fire rating. If

a portion of the chimney passes between a dropped ceiling

and roof, that portion is to be enclosed in a fire rated

enclosure or proper clearance to combustibles are

maintained. Chimneys are not intended to pass through

combustible walls. Any wall through which the chimney

passes must be of non-combustible construction unless

proper clearance to combustibles are maintained.

Chimneys installed in open rooms or fully ventilated areas

on the same story as the equipment connected to it shall

have a minimum clearance to combustibles as shown in

the following tables: Refer to grease duct section for

applications and clearances.

Clearances to non-combustibles shall be as necessary for

installation, inspection and maintenance.

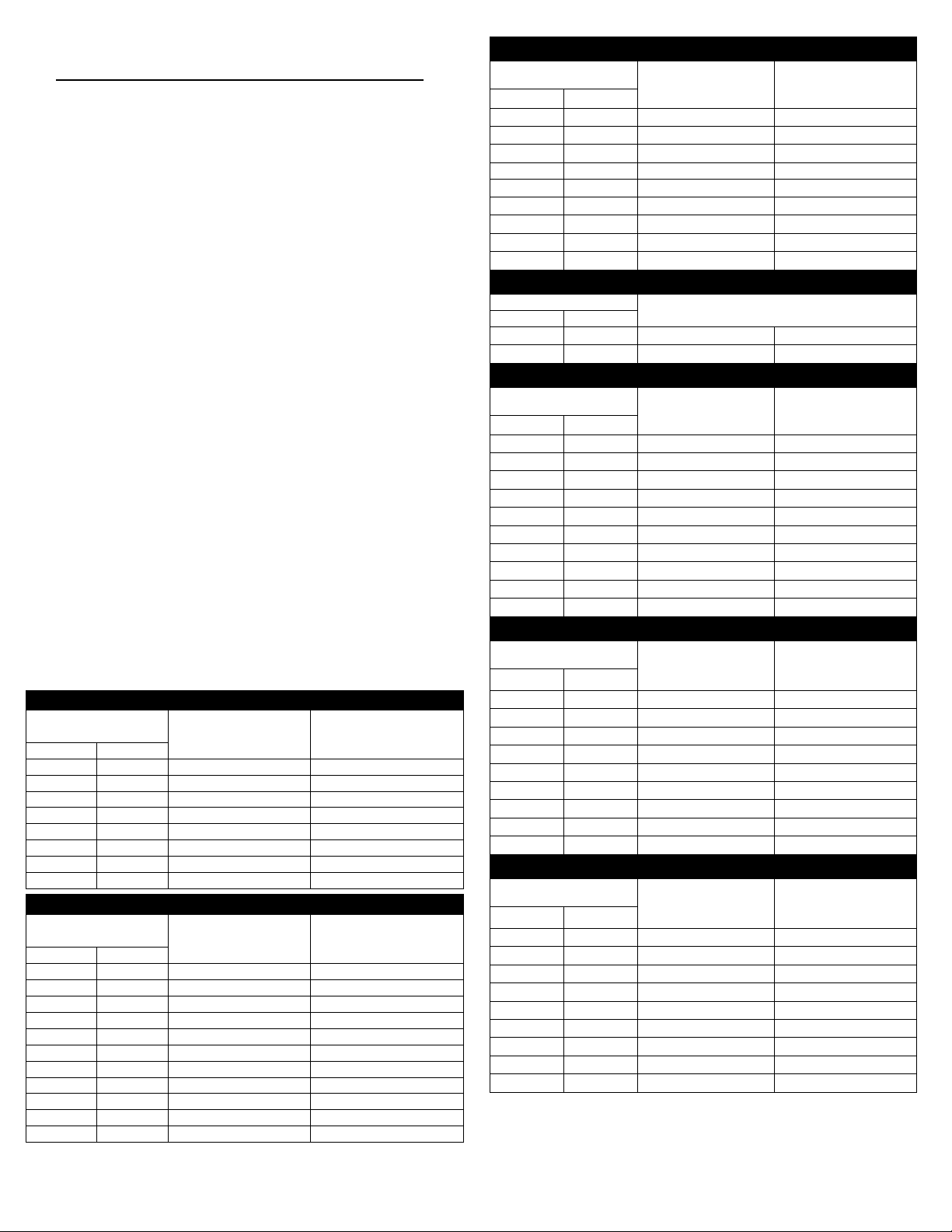

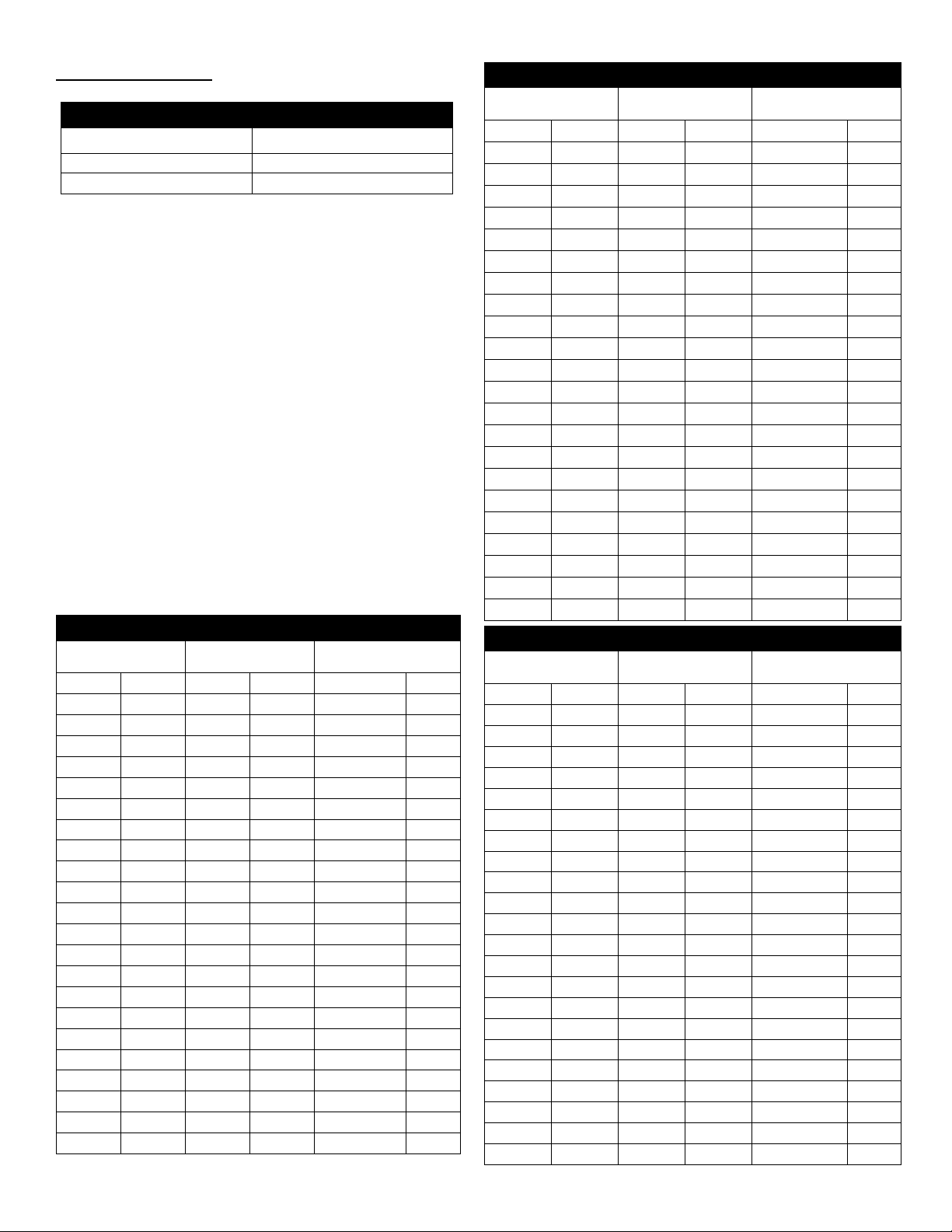

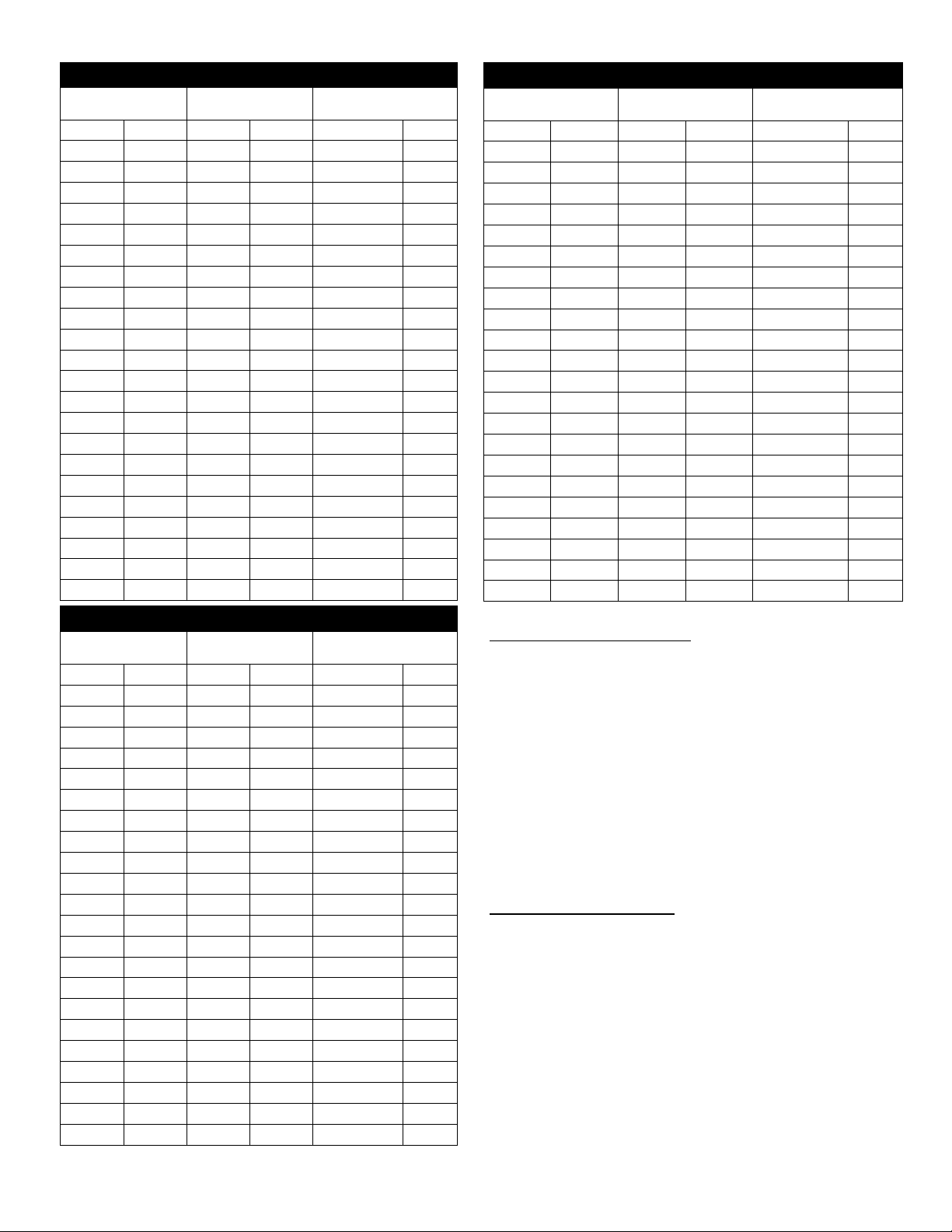

MODEL SW CHIMNEY CLEARANCES

Inside Diameter Building Heating

Appliance (1000°F)

(560°C) Chimney

1400° Fahrenheit

(760°C) Chimney

inches mm

5-6 127-152 18” (457mm) 18” (457mm)

7-16 178-406 18” (457mm) 18” (457mm)

17-20 431-508 18” (457mm) 18” (457mm)

21-24 533-610 18” (457mm) 18” (457mm)

25-28 635-711 18” (457mm) 18” (457mm)

29- 32 736-813 18” (457mm) 18” (457mm)

33- 36 838-914 18” (457mm) 18” (457mm)

41- 48 1041-1219 18” (457mm) 18” (457mm)

MODEL PA CHIMNEY CLEARANCES

Inside Diameter Building Heating

Appliance (1000°F)

(560°C) Chimney

1400Fahrenheit

(760°C) Chimney

inches mm

5-6 127-152 6” (152mm) 7” (178mm)

7-12 178-305 7” (178mm) 8” (203mm)

13-16 330-406 8” (203mm) 9” (229mm)

17-20 431-508 9” (229mm) 10” (254mm)

21-24 533-610 10” (254mm) 11” (279mm)

25-28 635-711 11” (279mm) 12” (305mm)

29-32 736-813 12” (305mm) 13” (330mm)

33-36 838-914 13” (330mm) 14” (356mm)

37-40 940-1016 14” (356mm) 15” (381mm)

41-44 1041-1118 15” (381mm) 16” (406mm)

45-48 1143-1219 18” (457mm) 20” (508mm)

MODEL P1 UL 103 CHIMNEY CLEARANCES

Inside Diameter Building Heating

Appliance (1000°F)

(560°C) Chimney

1400Fahrenheit

(760°C) Chimney

inches mm

6-14 152-356 1” (25mm) 1” (25mm)

15-20 381-508 2” (51mm) 2” (51mm)

21-24 533-610 3” (76mm) 3” (76mm)

25-28 635-711 4” (102mm) 4” (102mm)

29-33 736-838 5” (127mm) 5” (127mm)

34-38 864-965 6” (152mm) 6” (152mm)

39-41 991-1041 7” (178mm) 7” (178mm)

42-45 1067-1143 8” (203mm) 8” (203mm)

46-48 1168-1219 9” (229mm) 9” (229mm)

MODEL P1 UL 103HT CHIMNEY CLEARANCES

Inside Diameter 1400Fahrenheit (760°C) Chimney

inches mm

5-12 127-305 1” (25mm)

13-24 330-610 2” (51mm)

MODELS P2 CHIMNEY CLEARANCES

Inside Diameter Building Heating

Appliance (1000°F)

(560°C) Chimney

1400Fahrenheit

(760°C) Chimney

inches mm

5-6 127-152 1/2” (13mm) 1/2” (13mm)

7-10 178-254 1” (25mm) 1” (25mm)

11-14 279-356 2” (51mm) 2” (51mm)

15-18 381-457 3” (76mm) 3” (76mm)

19-24 483-610 4” (102mm) 4” (102mm)

25-28 635-711 5” (127mm) 5” (127mm)

29-32 736-813 6” (152mm) 6” (152mm)

33-36 838-914 7” (178mm) 7” (178mm)

37-40 940-1016 8” (203mm) 8” (203mm)

41-48 1041-1219 9” (229mm) 9” (229mm)

MODEL P2A CHIMNEY CLEARANCES

Inside Diameter Building Heating

Appliance (1000°F)

(560°C) Chimney

1400° Fahrenheit

(760°C) Chimney

inches mm

5-6 127-152 1” (25mm) 2” (51mm)

7-16 178-406 2” (51mm) 3” (76mm)

17-20 431-508 3” (76mm) 4” (102mm)

21-24 533-610 4” (102mm) 5” (127mm)

25-28 635-711 5” (127mm) 6” (152mm)

29- 32 736-813 6” (152mm) 7” (178mm)

33- 36 838-914 7” (178mm) 8” (203mm)

37- 40 940-1016 8” (203mm) 9” (229mm)

41- 48 1041-1219 11” (279mm) 12” (305mm)

MODEL P4 CHIMNEY CLEARANCES

Inside Diameter Building Heating

Appliance (1000°F)

(560°C) Chimney

1400° Fahrenheit

(760°C) Chimney

inches mm

5-6 127-152 1” (25mm) 2” (51mm)

7-16 178-406 2” (51mm) 3” (76mm)

17-20 431-508 3” (76mm) 4” (102mm)

21-24 533-610 4” (102mm) 5” (127mm)

25-28 635-711 5” (127mm) 6” (152mm)

29- 32 736-813 6” (152mm) 7” (178mm)

33- 36 838-914 7” (178mm) 8” (203mm)

37- 40 940-1016 8” (203mm) 9” (229mm)

41- 48 1041-1219 11” (279mm) 12” (305mm)