Schindler 3100/3300/6300 J 43402603 / 01 4/269

Copyright © 2017 INVENTIO AG

4.8 Maintenance Plan - Guideline. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

4.9 Bionic Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.9.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

4.9.1.1 Bionic 7 Main Components. . . . . . . . . . . . . . . . . . . . . . 82

4.9.1.2 Bionic 7 Bus System. . . . . . . . . . . . . . . . . . . . . . . . . . . 83

4.9.1.3 User Interface (HMI). . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4.9.1.4 Elevator Status (Indication on HMI) . . . . . . . . . . . . . . . 86

4.9.1.5 Buttons Navigation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

4.9.2 Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.9.2.1 LED Interpretation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

4.9.2.2 Access to Control Parameters (Menu 40). . . . . . . . . . . 90

4.9.3 Reset and Synchronization Travel . . . . . . . . . . . . . . . . . . . 93

4.9.3.1 Reset Procedure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

4.9.3.2 Synchronization Travel . . . . . . . . . . . . . . . . . . . . . . . . . 95

4.9.4 Fixtures Keypad Configuration . . . . . . . . . . . . . . . . . . . . . . 96

4.9.4.1 FI GS100 COP Configuration. . . . . . . . . . . . . . . . . . . . 96

4.9.4.2 FI GS100 LOP Configuration . . . . . . . . . . . . . . . . . . . . 97

4.9.5 Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

4.9.6 EN81-20/50 Door Bypassing Function . . . . . . . . . . . . . . . . 167

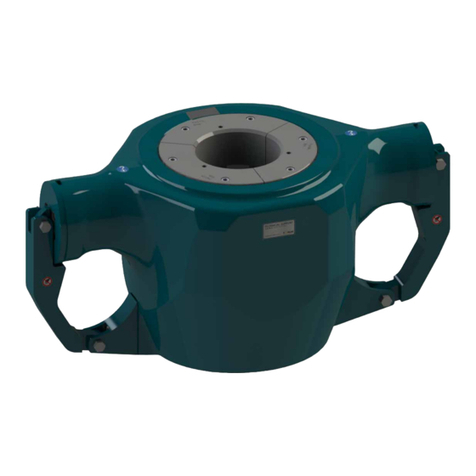

4.10 Machine Brake Leroy-Somer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

4.10.1 Overview Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

4.10.2 Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

4.10.2.1 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 171

4.10.2.2 Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 172

4.10.2.3 Brake Test During Maintenance . . . . . . . . . . . . . . . . . . 173

4.10.2.4 Machine and Brake Replacement Tests. . . . . . . . . . . . 176

4.11 Mechanical Hoistway Components. . . . . . . . . . . . . . . . . . . . . . . . . . . 183

4.11.1 STM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183

4.11.1.1 Overview Information . . . . . . . . . . . . . . . . . . . . . . . . . . 183

4.11.1.2 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 183

4.11.1.3 Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 183

4.11.2 Buffers P+S. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

4.11.2.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

4.11.2.2 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 191

4.11.2.3 Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 191

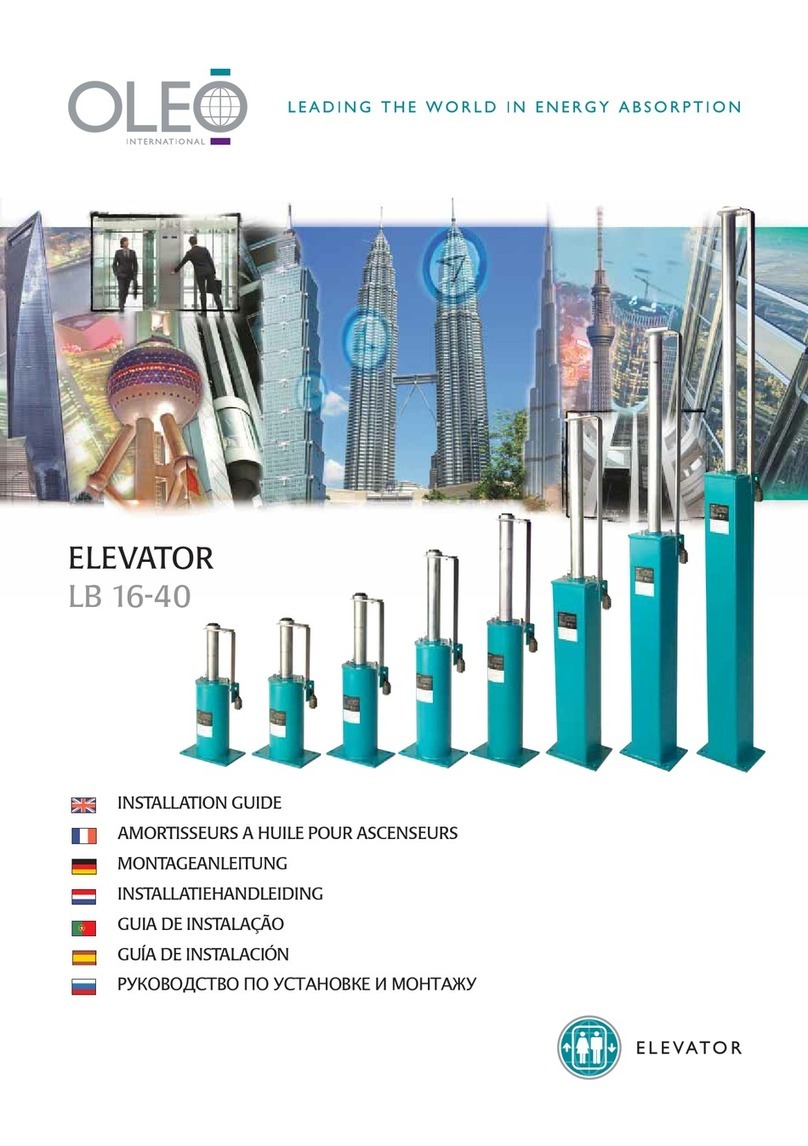

4.11.3 Buffer OLEO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4.11.3.1 Overview Information . . . . . . . . . . . . . . . . . . . . . . . . . . 192

4.11.3.2 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.11.3.3 Maintenance Check . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.11.3.4 Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 194

4.11.4 SA GBP 201 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

4.11.4.1 Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195

4.11.4.2 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 195

4.11.4.3 Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 196

4.11.4.4 Periodic Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200

4.11.4.5 Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

4.11.4.6 Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

4.12 Car Door . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4.12.1 Varidor 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4.12.1.1 Overview Information . . . . . . . . . . . . . . . . . . . . . . . . . . 204

4.12.1.2 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 207

4.12.1.3 Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 208

4.12.2 Sematic 2000 C-MOD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 218

4.12.2.1 Overview Information . . . . . . . . . . . . . . . . . . . . . . . . . . 218

4.12.2.2 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 219

4.12.3 Wittur Fine Line. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 220

4.12.3.1 Overview Information . . . . . . . . . . . . . . . . . . . . . . . . . . 220

4.12.3.2 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 221

4.12.4 FEP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

4.12.4.1 Overview Information . . . . . . . . . . . . . . . . . . . . . . . . . . 222

4.12.4.2 Maintenance Task List . . . . . . . . . . . . . . . . . . . . . . . . . 223

4.12.4.3 Maintenance Checks . . . . . . . . . . . . . . . . . . . . . . . . . . 224