Trimline Car and Sling Overview

Vertical Express 7

Overview

The Trimline®Elevator is designed to meet EN81 standards.

This is a list of major Trimline Elevator components, functional descriptions, and an overview of

some critical adjustments and maintenance information. See Figure 1 on page 8.

• Brace Rods - The rods that support and connect the corners of the platform to the stiles. They

help hold the platform level, and are attached to the platform by means of an isolation mount.

• Brace Rod Isolation Mount - The bracket that connects the bottom end of the brace rod to the

side of the platform.

• Brace Rod Isolation Pad - The neoprene isolation pad placed between the end of the brace rod

and the platform mounting bracket.

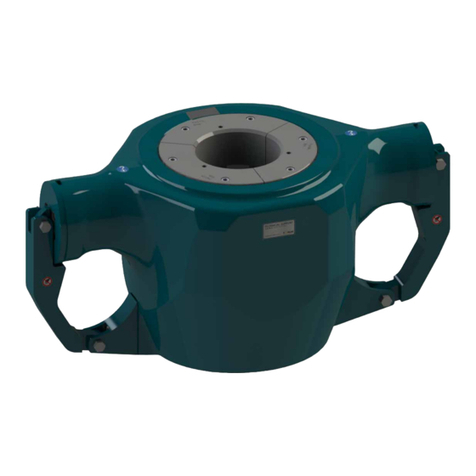

• Car Sling - The main structural members of the elevator car. They consist of the safety plank,

the stiles, and the crosshead.

• Compensation Chain - The chain connected to the bottom of the platform on one end and to

the counterweight assembly on the other end to compensate for the weight of the hoist cable

as the elevator moves through the hoistway.

• Crosshead - The structural member at the top of the sling. The crosshead is made of formed

channel.

• Governor Rope Stile Bracket - The bracket bolted to the stile that attaches the governor rope to

the car and guides the governor rope to the governor rope lever.

• Hitch Plate Assembly - The attachment point of the hoist ropes to the car sling, bolted under

the crosshead. It contains the loadweigher mechanism.

• Platform - The rectangular surface on which the elevator cab is built. The platform must be

installed square and level to provide a basis for the rest of the elevator cab.

• Platform Isolation Pad - The neoprene isolation pad placed between the safety channel and the

platform joist. It is the main part of the car noise isolation system.

• Platform Retainer Bracket - The bracket that constrains the platform’s movement from front to

back in the car sling. It also provides a mounting point for the stile isolation pad.

• Roller Guide Mount - The plate bolted to the ends of the crosshead channels for mounting roller

guides. It has a universal hole pattern for both the roller guides and the temporary guide

shoes.

• Safety Plank - The bottom member of a traction elevator sling. The safety plank houses the

devices necessary to stop the elevator in an emergency situation as well as provide a structural

foundation for the elevator cab.

• Stile - The vertical members of the sling that connect the safety plank to the crosshead.

• Stile Isolation Pad -The neoprene pad that is placed between the side of the platform and the

stile to prevent metal to metal contact between the two members. It is held in place by the Plat-

form Retainer Bracket.

Specifications

• Maximum Speed: 1200 fpm

• Maximum Capacity: 5000 lb.