A. GENERAL INFORMATION

I Warnings and Note

WARNING¢INDICATES ADEFINITE RISK OF EQUIPMENT DAMAGE

OR DANGER TO PERSONNEL. FAILURE TO OBSERVE AND FOLLOW PROPER

PROCEDURES COULD RESULT IN SERIOUS OR FATAL INJURY TO PERSONNEL,

SIGNIFICANT PROPERTY LOSS, OR SIGNIFICANT EQUIPMENT DAMAGE.

NOTE¢ INDICATES THAT ADDITIONAL INFORMATION IS PROVIDED

ABOUT THE CURRENT TOPICS. THIS TECHNICAL DOCUMENTATION CONTAINS

INSTRUCTIONS ON SAFETY, INSTALLATION, OPERATION AND MAINTENANCE

FOR THE FORUM B + V OIL TOOLS TOOL. ITMUST BE STUDIED BEFORE

WORKING WITH THE TOOL.

II Intended use of this manual

This manual is intended for use by field service,

engineering, installation, operation, and

Forum B + V Oil Tools personnel. Every effort has been

made to ensure the accuracy of the information contained

herein. Forum B + V Oil Tools GmbH, will not be held

liable for errors in this material, or for consequences

arising from misuse of this material. Anyone using service

procedures or tools, whether or not recommended by

Forum B + V Oil Tools GmbH, must be thoroughly satisfied

that neither personal safety nor equipment safety will be

jeopardized.

III Intellectual property

All rights retained. No part of this document may be

reproduced in any form (print, photocopy, microfilm or

any other procedure) or be processed using an electronic

system without written approval of Forum B + V Oil Tools

GmbH. All information contained in this manual is

based upon the latest product information available at

any time of printing. Dependent on ongoing technical

improvements (ISO 9001) “Forum B + V Oil Tools GmbH”

reserves the right to change the design and specifications

without announcement. The values specified in this

manual represent the nominal values of a unit produced in

series. Slight deviations in the case of the individual devices

are possible.

NOTE¢INTHE EVENT OF PROBLEMS THAT CANNOT BE SOLVED WITH

THE AID OF THIS MANUAL, PLEASE CONTACT ONE OF THE ADDRESSES LISTED

BELOW.

IV Intend of use

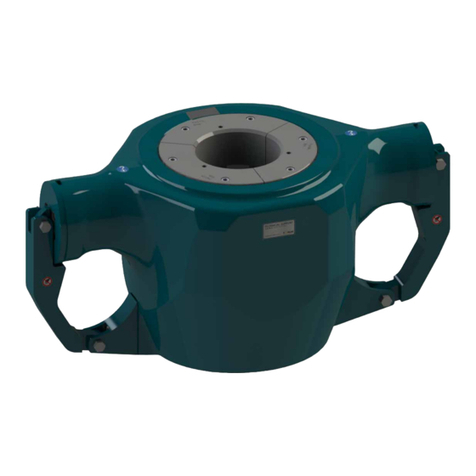

The Forum B + V Oil Tools SDL Side Door Elevators is

designed to be used for vertical pipe and is hanging in

links. It conduces as an association between the Top Drive,

the two Links and the pipes. The load capacity of the

elevator is designated by the elevator make and is limited

in vertical direction only. The elevator is also available for

hydraulic operation in the SDL-H type series .

The operation of the SDL is allowed for its intended use

only. Additionally the intended use covers the compliance

and observance of all procedures and safety notes of this

manual as well as performing all necessary maintenance

work in the given intervals.

V Improper / Unsafe Use

The tool must only be used for the designated purpose.

When using the tool, the rated load must never be

exceeded (refer to„1.5 Technical Data“ on page 15).

- Lower ears load-rated to 5 tons for attaching slings/

single joint option.

VI Limited Warranty

The warranty provided will be void if the tool is either:

Forum or serviced by a service facility which was not

authorised by Forum B + V Oil Tools GmbH.

Replacement parts not manufactured by

Forum B + V Oil Tools Forum GmbH are used.

Modifications were made to the tool which were not

approved by Forum B + V Oil Tools GmbH.

VII Conformity

The SDL Side Door Elevators satisfies all requirements in

applicable directives and standards. A sample of the EC

Declaration of Conformity is given in the appendix.

NOTE¢THIS OPERATING MANUAL IS APART OF THE TECHNICAL

DOCUMENTATION FOR THE SDL SIDE DOOR ELEVATORS.

The EC Declaration of Conformity is delivered together

with the SDL Side Door Elevators.

Keep these instructions and the associated documents for

later use.

VIII Operational Environment

The SDL is designed and constructed for use in the drilling

industry on ships and platforms. The tool complies with

the Machinery Directive 2006/42/EC. The machine is

approved for operation in explosion hazard areas.

For machines containing any hydraulic powered parts,

the directive 2014/34/EC “Equipment and protective

systems in potentially explosive atmospheres” applies. The

corresponding ATEX certificates are present in the Data

book. The Classification according to CE (with reference to

the ATEX guideline) is as followed:

II 2G IIB T5 for hydraulic and pneumatic tools

or

II 2G IIB T6 for manual tools

with

CE- marking (with reference to the ATEX guideline)

Marking of the equipment for the Ex- range

II Equipment Group (II)

2 Equipment Category

GFor explosive mixtures of air and combustible gases, mists or

vapors (G)

IIB Categorie for Gases

T5/T6 Temperature class

5

04-2016 PN: 651520-Y-BC-D - Revision: 10 SDL

Operating Instructions