2

1. Safety _______________________________________________________________________ 4

1.1 Danger ___________________________________________________________________ 4

1.2 Warning __________________________________________________________________ 5

1.3 Earthing and earth fault protection ___________________________________________ 5

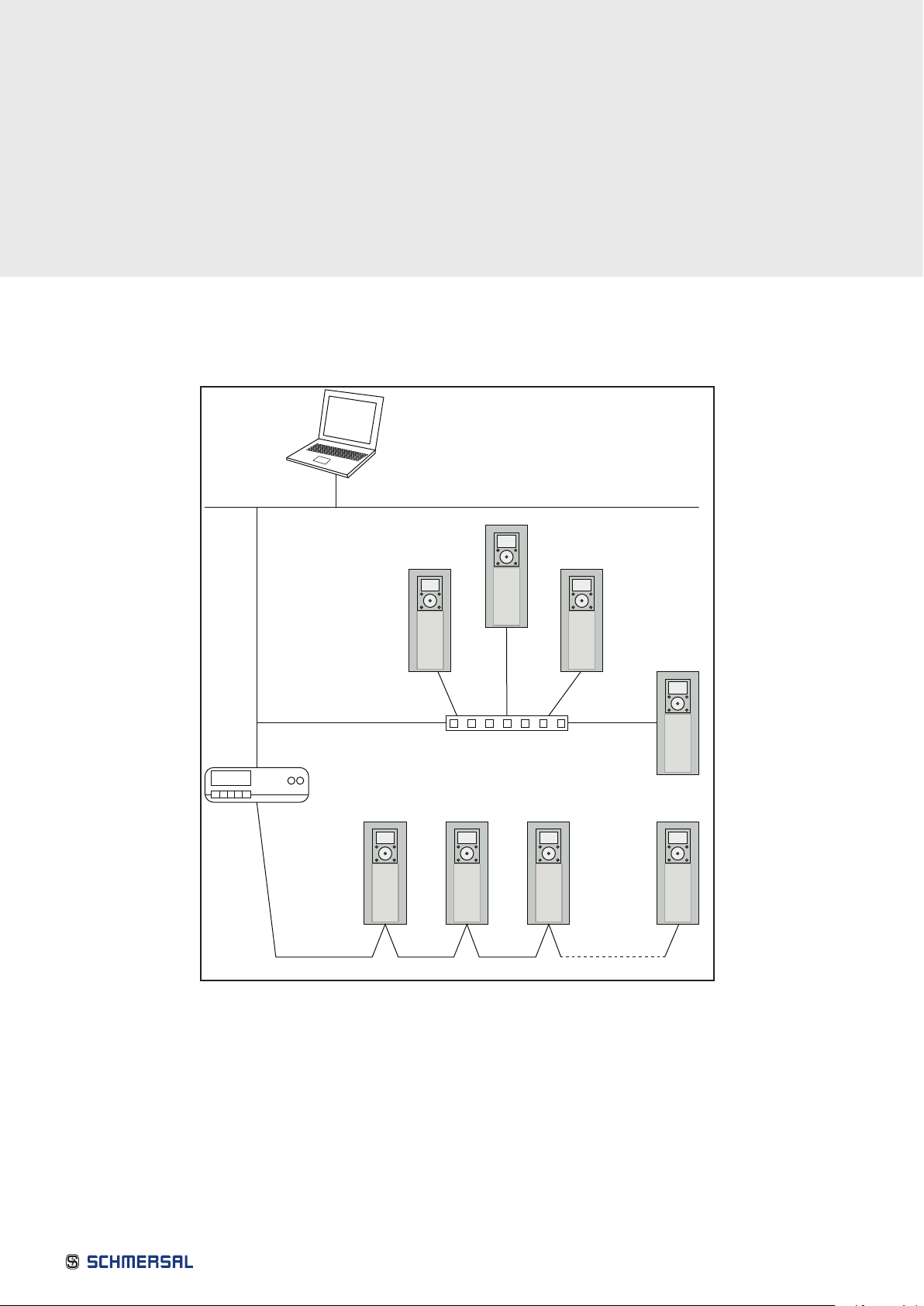

2. Modbus - General Info ________________________________________________________ 6

3. Modbus Technical Data _______________________________________________________ 8

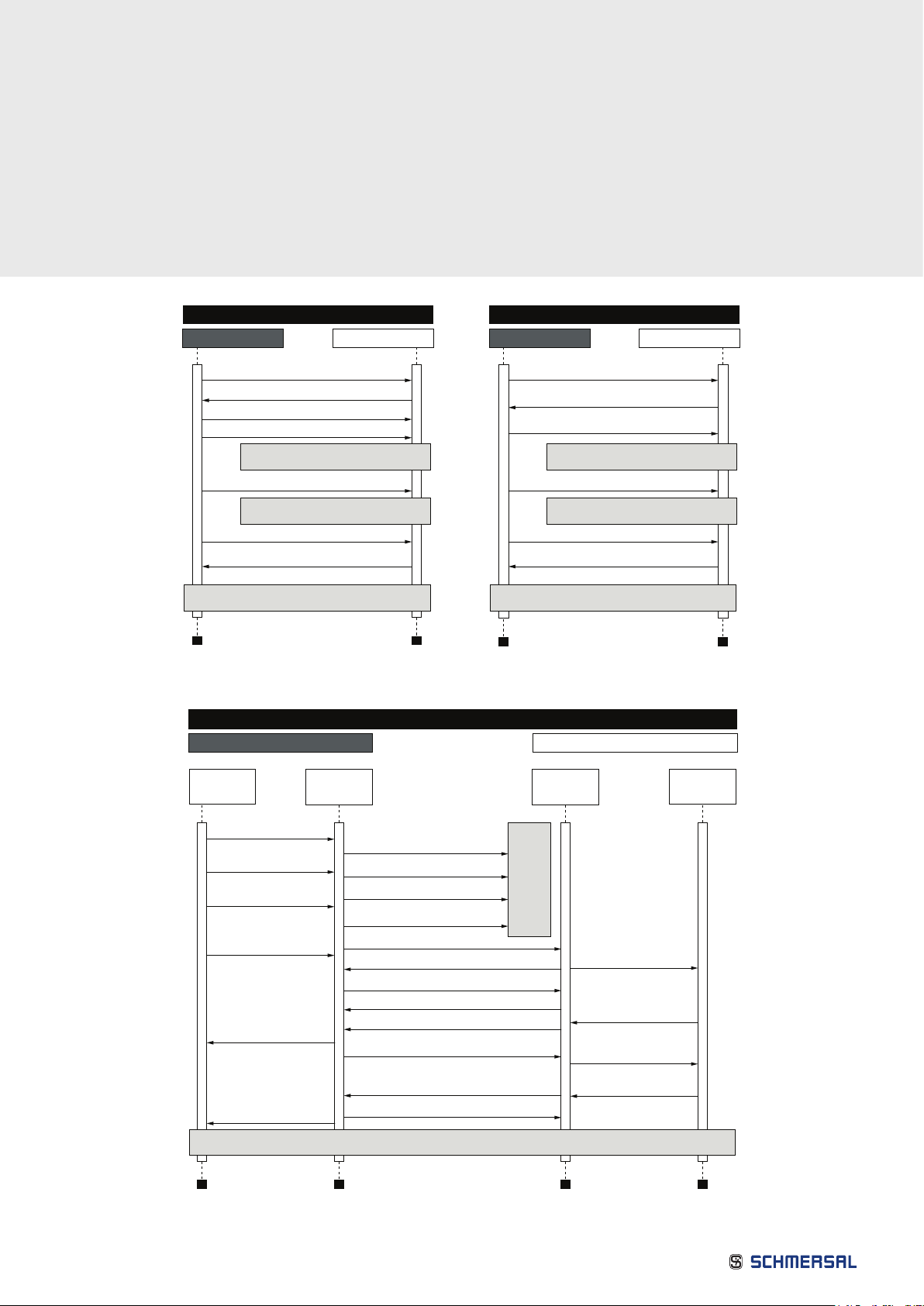

3.1 Modbus RTU Protocol _____________________________________________________ 8

3.2 Modbus TCP Protocol _____________________________________________________ 8

3.3 Modbus UDP vs TCP ______________________________________________________ 8

3.4 Connections and Wiring ____________________________________________________ 11

3.5 ACD (Address Conflict Detection) in Ethernet Network _________________________ 11

4. Installation ___________________________________________________________________ 12

4.1 Installation in Praxi®100 Family AC Drives ____________________________________ 12

4.1.1 Prepare for use Through Ethernet______________________________________ 13

4.1.2 Prepare for use Through RS485 _______________________________________ 15

4.2 Installation in Praxi®100 x __________________________________________________ 19

4.2.1 Prepare for use Through Ethernet______________________________________ 19

4.2.2 Prepare for use Through RS485 _______________________________________ 20

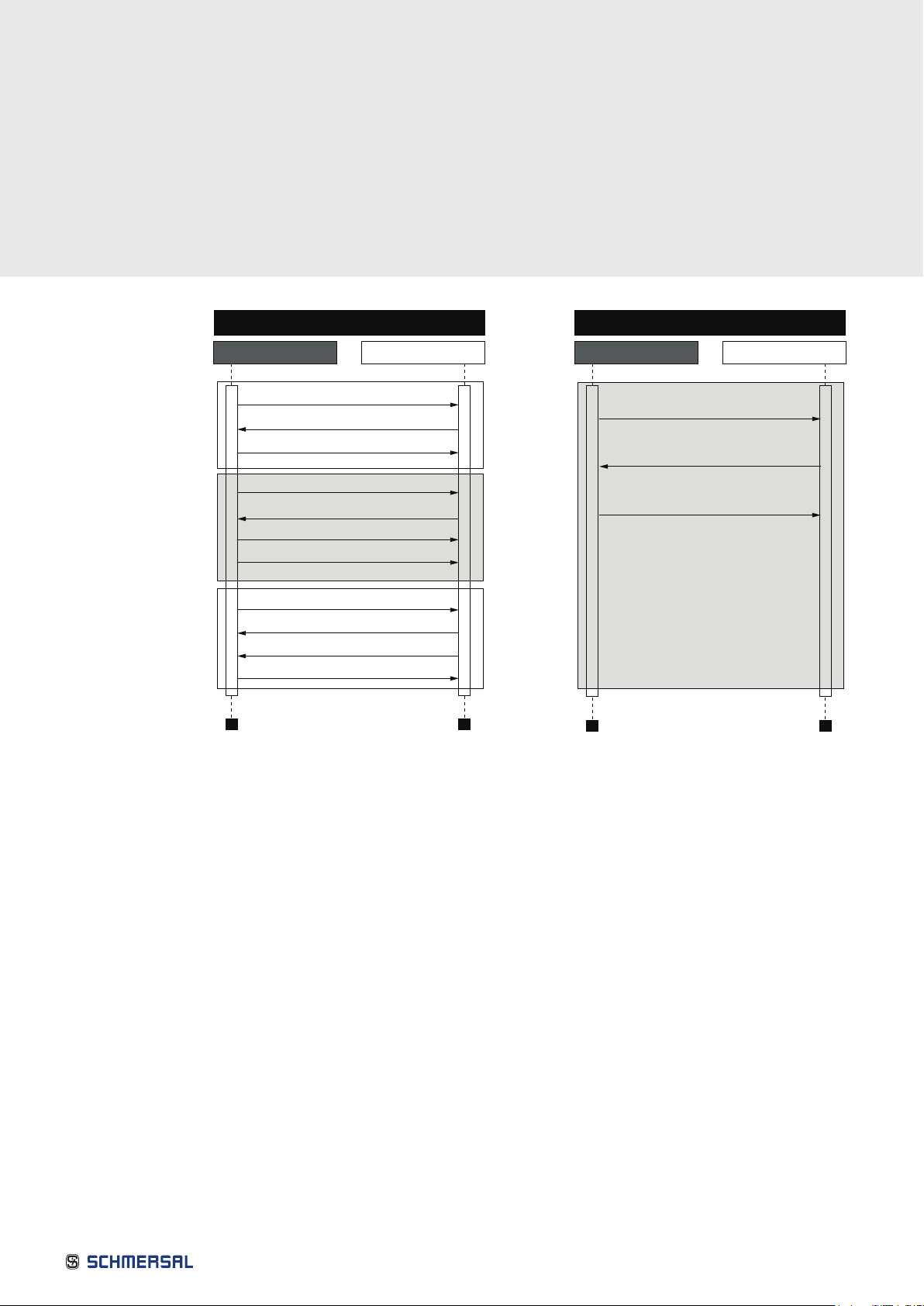

5. Fieldbus Parametrization _____________________________________________________ 22

5.1 Fieldbus Control and Basic Reference Selection_______________________________ 22

5.1.1 Torque Control Parametrization________________________________________ 22

5.1.2 Enabling Modbus Protocol____________________________________________ 23

5.2 Modbus RTU Parameters and Monitoring Values (M5.8.3) ______________________ 23

5.2.1 Slave Address_______________________________________________________ 24

5.2.2 Baud Rate __________________________________________________________ 24

5.2.3 Parity Type__________________________________________________________ 24

5.2.4 Stop Bits ___________________________________________________________ 24

5.2.5 Communication Timeout _____________________________________________ 24

5.2.6 Operate Mode_______________________________________________________ 24

5.2.7 IDMap IDs __________________________________________________________ 25

5.2.8 Fieldbus Protocol Status _____________________________________________ 25

5.2.9 Communication Status _______________________________________________ 25

5.2.10 Illegal Functions ____________________________________________________ 26

5.2.11 Illegal Data Address_________________________________________________ 26

5.2.12 Illegal Data Values __________________________________________________ 26

5.2.13 Slave Device Busy __________________________________________________ 26

5.2.14 Memory Parity Error ________________________________________________ 26

5.2.15 Slave Device Failure ________________________________________________ 26

5.2.16 Last Fault Response ________________________________________________ 26

5.2.17 Control Word_______________________________________________________ 26

5.2.18 Status Word _______________________________________________________ 26

5.3 Modbus TCP/UDP Parameters and Monitoring Values _________________________ 27

5.3.1 Ethernet Common Settings (M5.9.1) ___________________________________ 27

5.3.2 IP Address Mode ____________________________________________________ 27

5.3.3 Fixed IP Address ____________________________________________________ 27

5.3.4 Fixed Subnet Mask __________________________________________________ 28

5.3.5 Fixed Default Gateway _______________________________________________ 28

5.3.6 Active IP Address, Subnet Mask and Default Gateway ___________________ 28

Table of Contents