Page 2 of 12

1. FCC Notice

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions: (1) this device may not cause harmful

interference, and (2) this device must accept any interference received,

including interference that may cause undesired operation.

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a

residential installation.

If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the

following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

Caution: Any changes or modifications in construction of this device which are

not expressly approved by the party responsible for compliance could void the

user’s authority to operate the equipment.

2. Tire Pressure Monitoring System (TPMS)

This system is a sensing device designed to measure and display tire

temperature and pressure, and to activate an alert to the driver when

pressure and temperature irregularities are detected. It is the responsibility of

the driver to react promptly and with discretion to alerts. Abnormal tire

inflation pressure should be corrected at the earliest opportunity.

Do not use any temporary re-sealing or re-inflation products containing

internal sealants or propellants in any tire assembly as these may adversely

affect the operation of the sensor/transmitter.

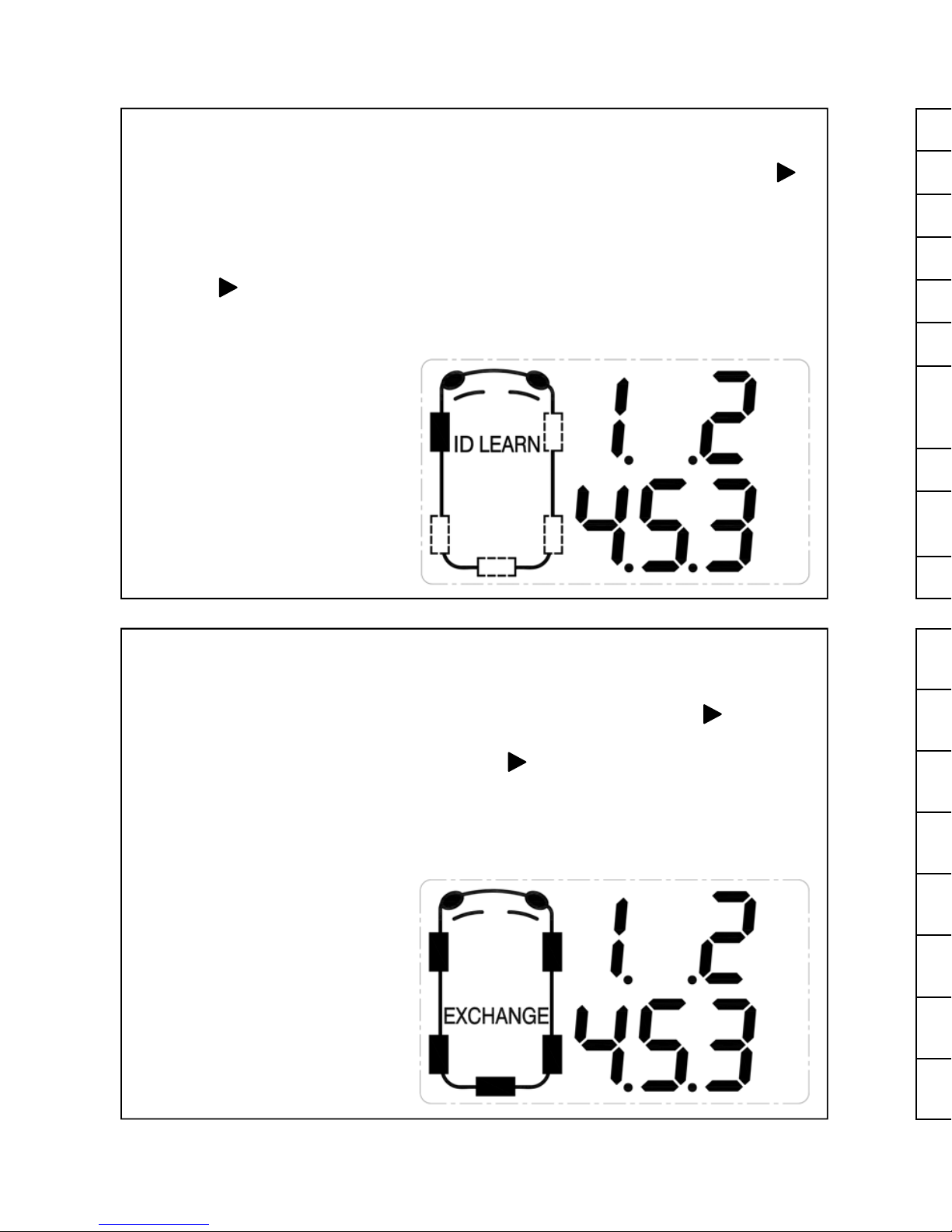

3. How It Works

Pressure and temperature information is transmitted by radio frequency to the

receiver and displayed on the LCD display. When an under-inflated,

over-inflated or over-heated tire is detected, the display will emit an audible

warning and activate a warning lamp to alert the driver. The icon for the tire

with the fault will be displayed along with the pressure and temperature. Each

sensor’s battery is also monitored, and an alert will activate if a sensor’s

battery is found to be low in charge. The receiver will turn on when a shock is

received and will automatically turn off after 5 minutes of no movement being

detected. The display will flash the last known data until next transmission is

received from that particular sensor.

Page 11 of 12

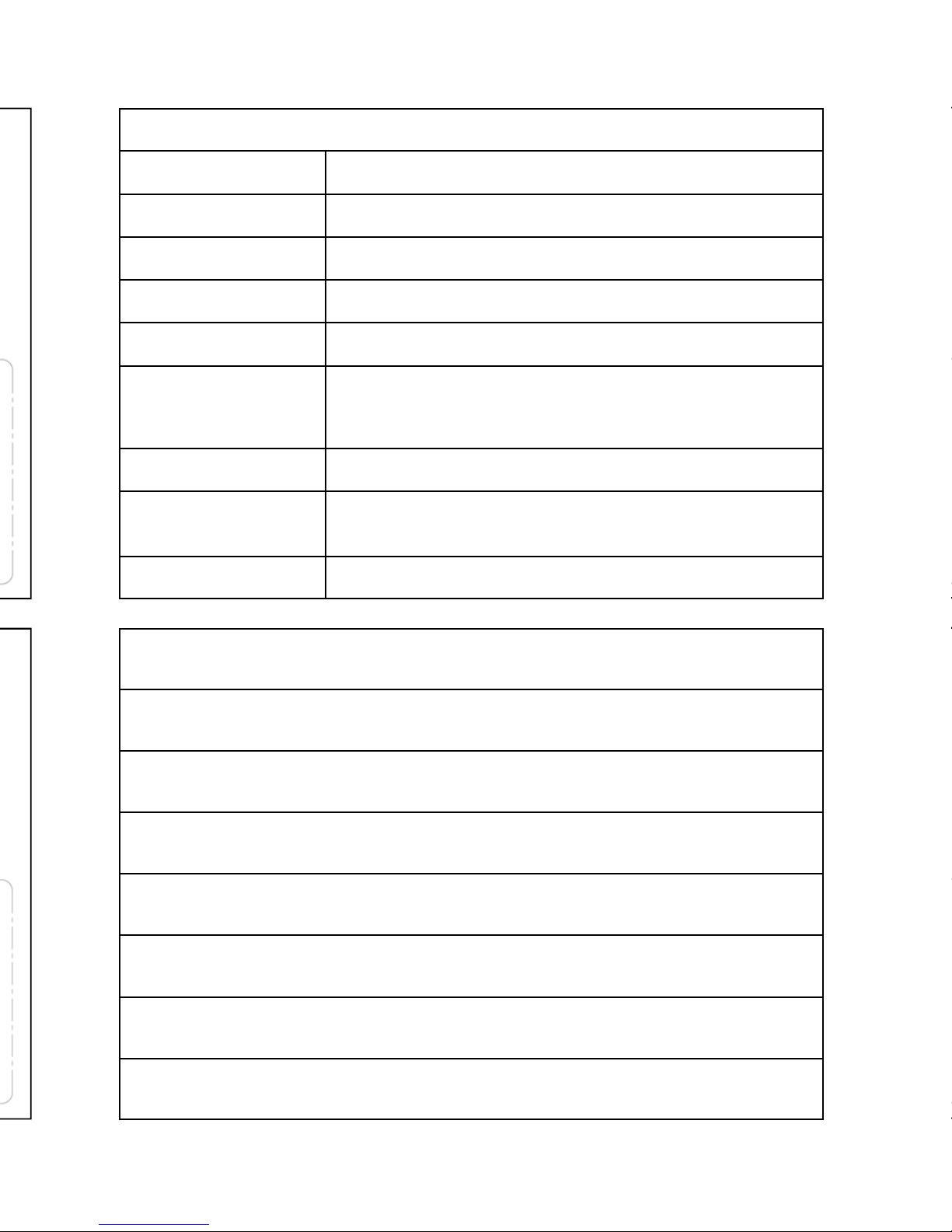

19. Parts List

Description Qty Part Number

Sensor (complete) 4 20154

Receiver (display) 1 20213

Wheel Sensor (Snap-in) 1 20214

Torx Screw (individual) 1 20562013

Valve (individual) 1 20522044

Hardware bag, inc. 1 20215

Cleaning Swab 1 20216

Top Dash Adhesive Strip 1 20217

Windscreen Adhesive Strip 1 20219

Windscreen Wedge Adaptor 1 20220

°C °F °C °F °C °F

-40 -40 20 68 80 176

-30 -22 30 86 90 194

-20 -4 40 104 100 212

-10 14

50 122

110 230

0 32 60 140 120 248

10 50

70 158

125 257

18. °C to °F Conversion Table