42

5

3Operating

EN Wall, ceiling and floor grinding machine WDS 250

WDS250‐en‐220909

9

3.2 Operating

The grinding machine was put into operation

(!Chapter 3.1, Page 7).

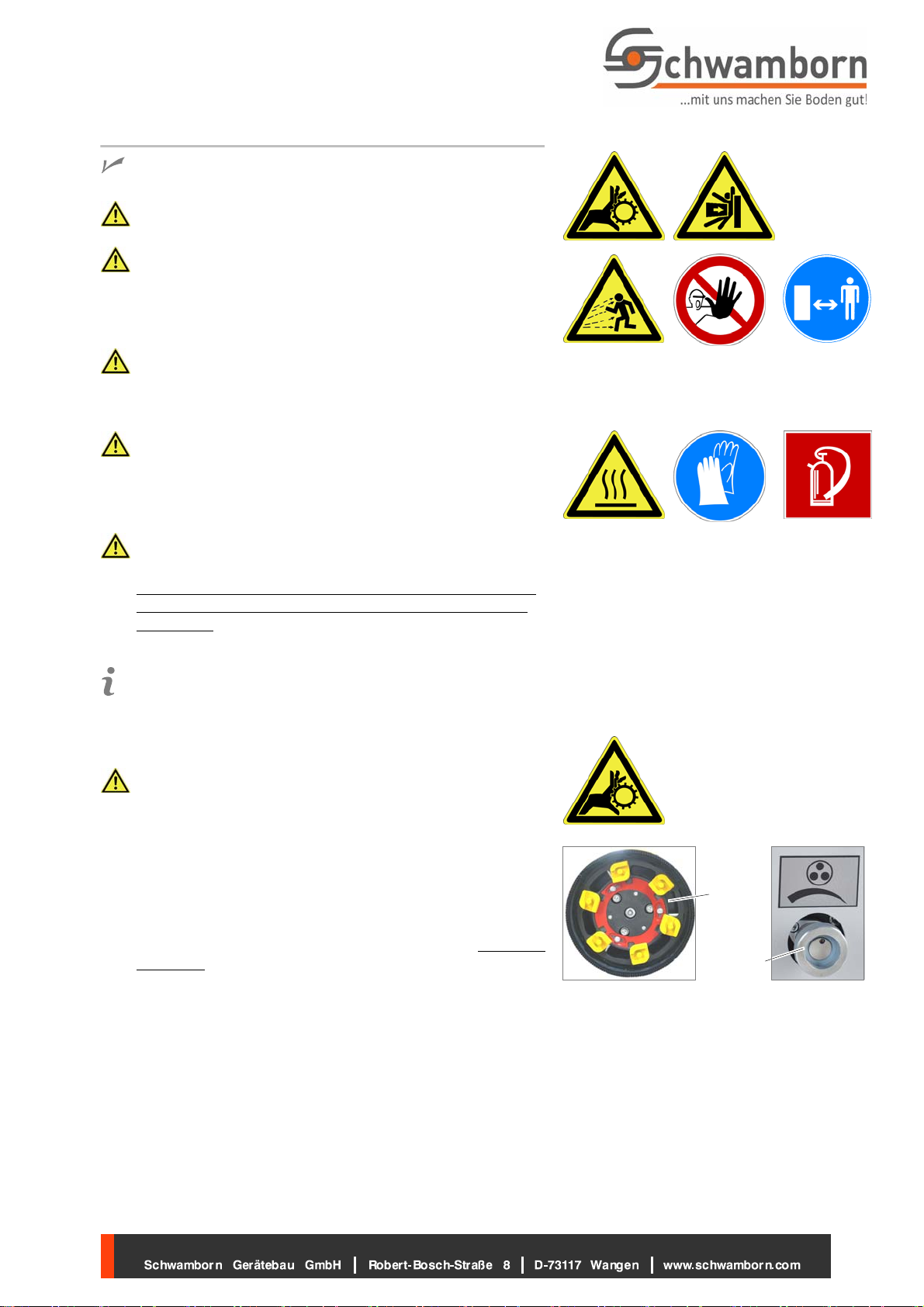

Risk of injury from inadvertent starting and movement of

the grinding machine or guiding machine!

Risk of injury from loose parts!

During operation, loose parts (stones / removed material /

broken components / tools etc.) can be flung out!

Keep at least 5 m safety distance from the grinding ma

chine and from the guiding machine!

The operating and maintenance personnel responsible for

the grinding machine must ensure that no one can enter

the grinding machine’s danger zone during operation or

maintenance work!

Risk of injury and fire hazard from hot surfaces on the ma

chine housing, tool mounts and grinding tools!

Wear protective gloves!

Have suitable fire extinguishers on hand!

Work with the greatest care and caution!

The dust cover ring must always contact the surface being

machined during operation (!Chapter 4.5, Page 16)!

GG" The manufacturer of the grinding machine urgently recom

mends practising the grinding of walls, ceilings and floors

sufficiently.

1. Switch the guiding machine on.

When the grinding machine is switched on at the controller of

the guiding machine, the contact pressure of the grinding

machine head is applied by the hydraulic control system and

is not operated via operating elements of the guiding

machine.

Risk of injury from rotating machine parts!

Work with care!

2. Switch on the tool rotation and the contact pressure using

the remote control of the guiding machine

(!operating manual of the guiding machine, chapter

Operation of double‐acting hydraulic tools

).

3. Measure the speed of the gear disc [42] with a suitable mea

suring instrument.

GG" The maximum speed of the gear disc was set to maximum

2000 rpm when the guiding machine was adapted to the

grinding machine. This preset hydraulic volume flow of the

guiding machine may not be changed!

When the guiding machine is changed, the maximum speed

must be reset to 1800 rpm .... 2000 rpm.

4. Use the controller [5] to set the desired gear disc speed if

necessary.The manufacturer of the grinding machine can

gladly provide corresponding recommendations.