6

EASy Reference Guide - S38SX

Service Bulletin

Calculating the Outrigger Load

After you nd an appropriate spot to set up the unit, you

must provide a stable base for the outriggers. If the site

you have chosen does not have stable soil conditions,

select a dierent site. Under no circumstances should

you compromise the stability of the unit by setting up on

unstable soil.

The following chart can be used as a guideline to help

you determine the load-bearing capacity of various soil

types. If you do not know what type of soil is on your job

site, the site manager may be able to tell you.

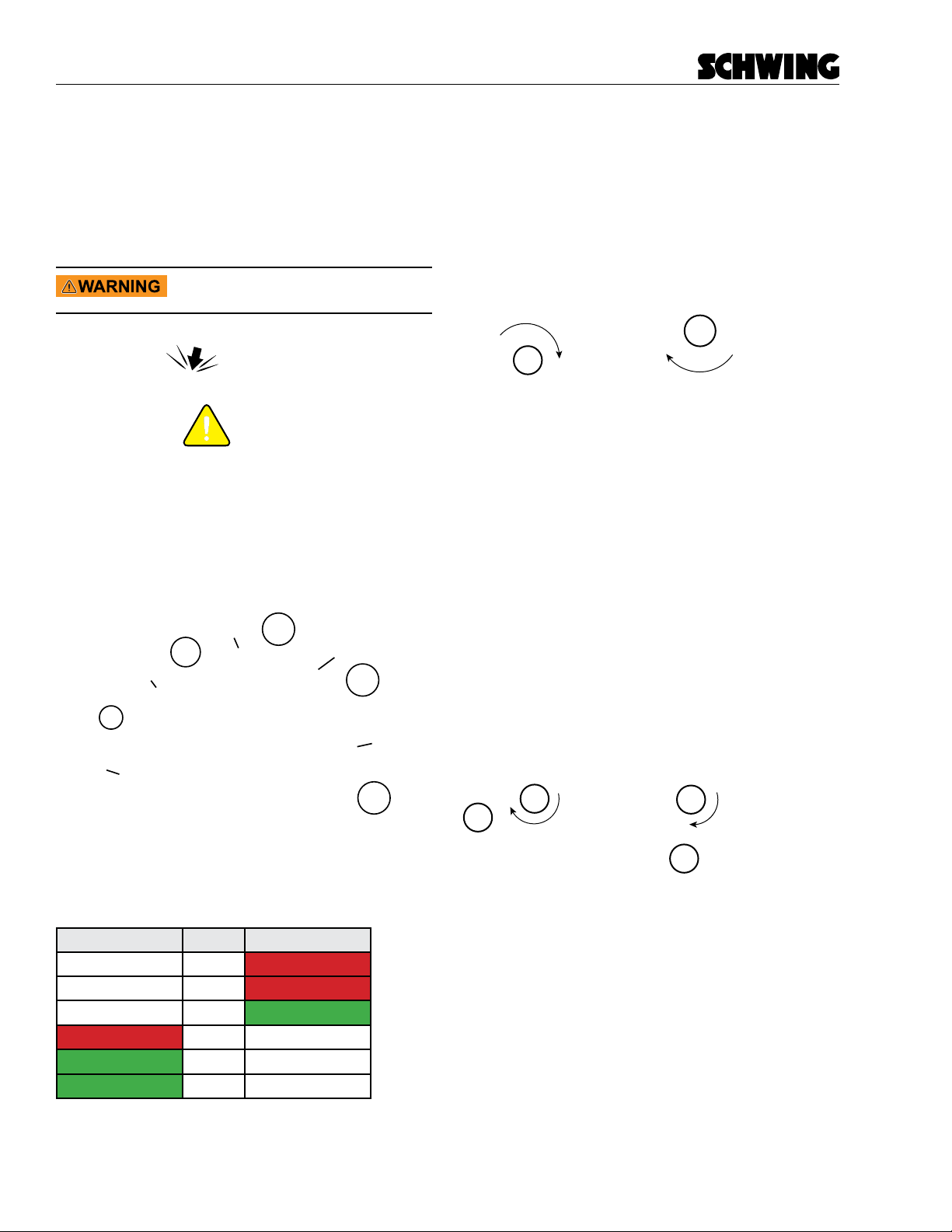

Soil Type PSI

Virgin ground 22

Asphalt 29

Compressed, crushed stone 36

Clay/silt soil, rm 43

Mixed granular soil 51

Firm, compacted gravel 58

Firm, compacted gravel (more compacted) 72

Firm, compacted gravel (more compacted,

class V)

109

Brittle, weathered rock 145

To determine the load your outriggers will impose on

the soil, divide the total force of the outrigger (shown on

a decal on the outrigger leg) by the number of square

inches of soil contact:

Soil pressure (PSI) = total outrigger force (lbs) ÷ area

of soil contact (sq. in.)

total outrigger force (lbs) =Soil pressure (PSI)

area of soil contact (sq. in.)

98419619

43,800 LBS

195 (KN)

MAX. OUTRIGGER LOAD

Figure 15

Outrigger load decal (located on outrigger leg)

Outrigger Calculations

The front outrigger decal on the S38SX shows a max-

imum force of 43,800 lbs. The steel outrigger pads are

9.4 inches in diameter (70 sq in.). Dividing 43,800 by 70

gives a soil pressure of 626 PSI:

43,800 (lbs) =626 (PSI)

70 (sq. in.)

As you can see from the Soil Type chart, the steel

pads are not big enough to be used by themselves on

any of the soil types listed. This is why the unit comes

equipped with dunnage pads The pads are approxi-

mately 24” by 24” (576 sq in.). Now divide the maximum

force of 43,800 by 576:

43,800 (lbs) =76 (PSI)

576 (sq. in.)

The pressure of 76 PSI is suitable for rm, compacted

gravel (more compacted, class V). If you had to set up

on virgin ground, asphalt, or one of the other soil types

listed, you would need to use additional cribbing.

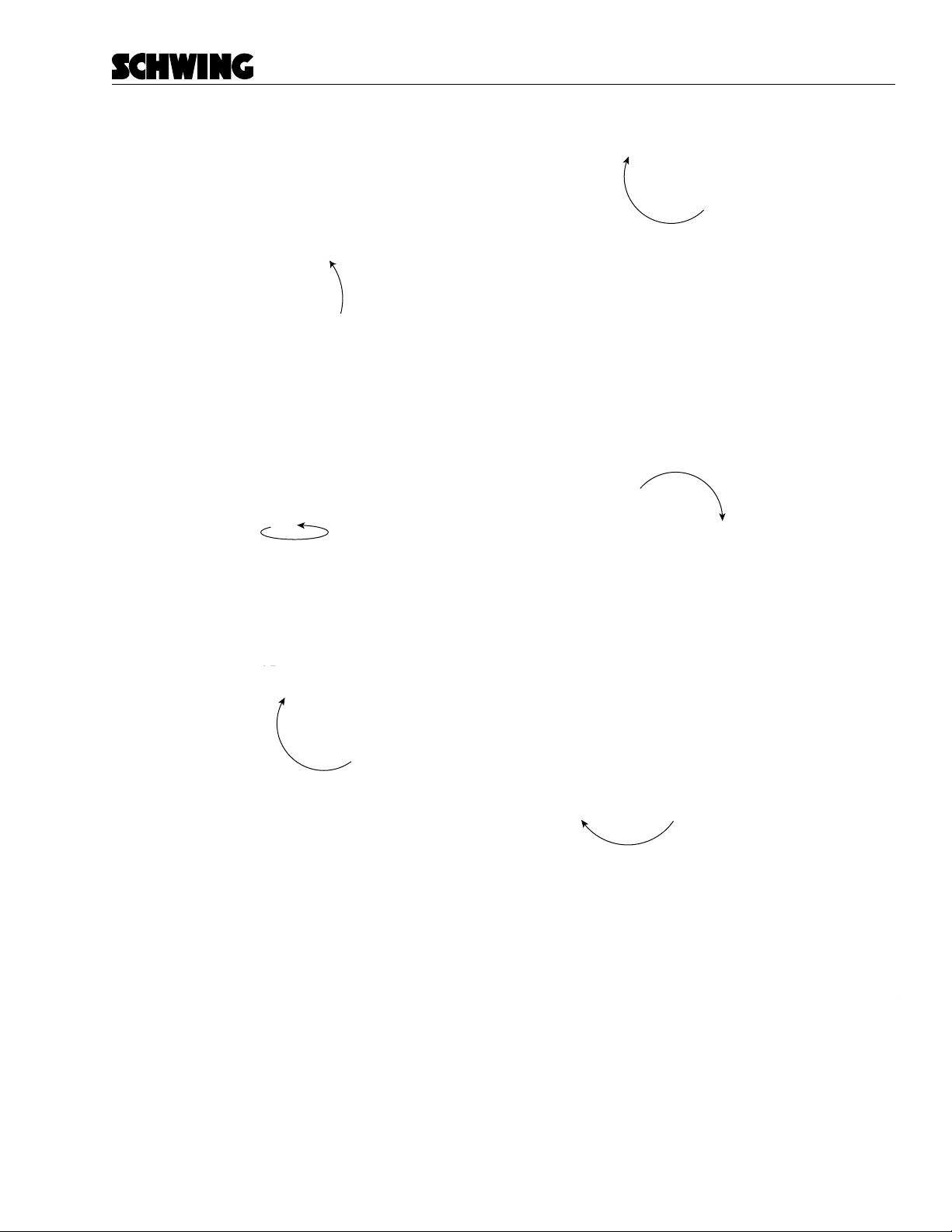

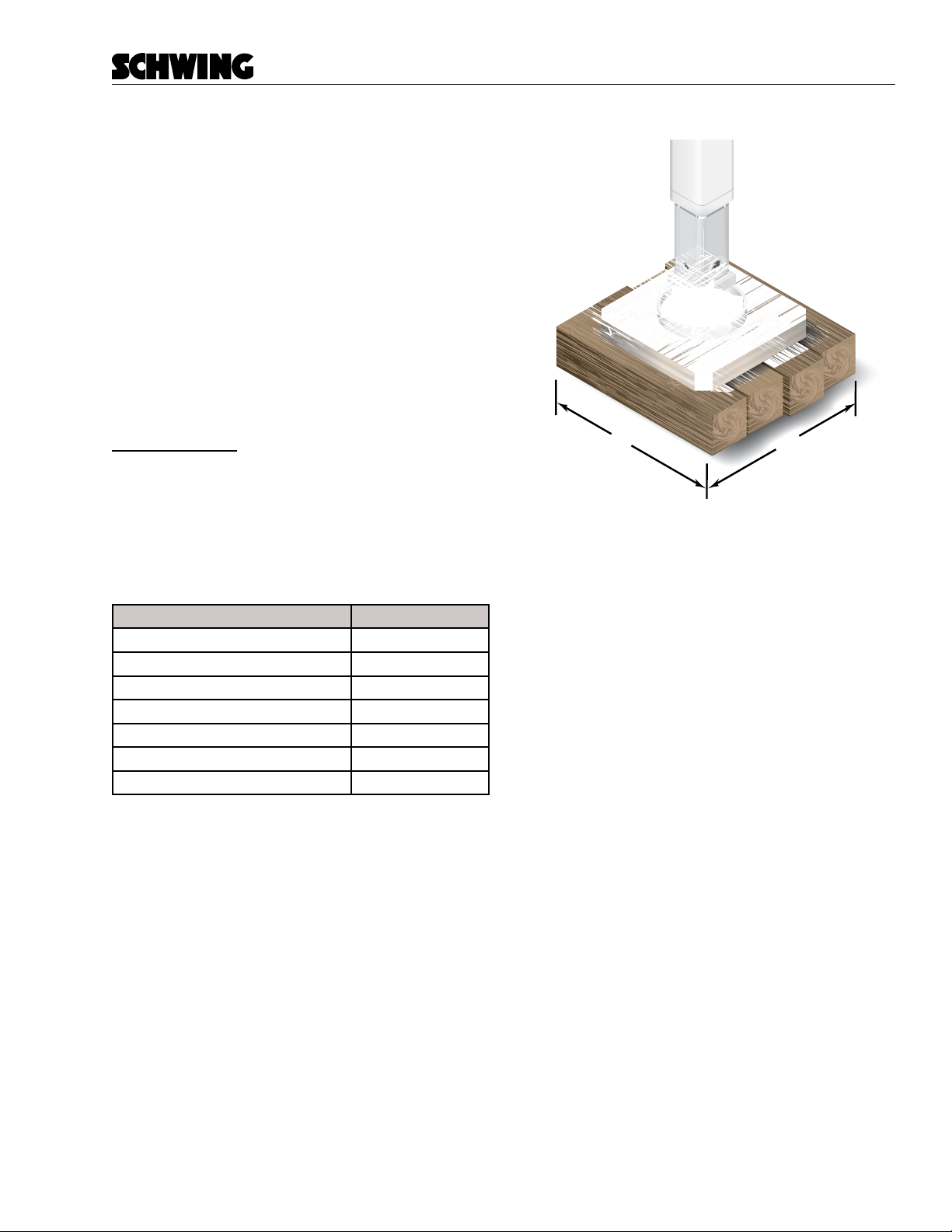

24”

24”

Figure 16

Dunnage Pads provided with unit.