FISBA READYBeam bio 1 Owner's manual

Technical Instruction

FISBA READYBeamTM

A compact multi-wavelength laser module

October 2021

Content

1 Safety 4

1.1 Explanation of symbols 4

1.1.1 General safety instructions 4

1.1.2 Laser safety 4

1.1.3 Laser area 4

1.2 Warning and information labels 6

1.3 Correctandspecieduseoftheunit 6

1.4 Warranty conditions 7

1.4.1 Limits of the warranty 7

2 Technical system 7

2.1 Laser module 7

2.2 Installation and commissioning 8

2.2.1 Unpacking and checking for visible damage 8

2.2.2 Installation 8

2.2.3 Operating the FISBA READYBeamTM 8

2.2.4 Software Setup 8

2.2.5 Software interface 9

2.2.6 Modulation mode 10

Appendix 12

Data sheet 14

4

1 Safety

1.1 Explanation of symbols

This symbol is used for all points in these operating instructions to which special

attention is to be paid so that all directives, regulations, instructions and the correct

work sequence are observed, and to prevent minor or serious damage to the laser

system or plant.

1.1.1 General safety instructions

The operating instructions and the safety instructions are to be read and observed

prior to installation and commissioning! The operating instructions must be read,

understood and followed by the operators responsible for the unit. Along with the

in structions in these operating instructions, also observe the generally applicable

safety and accident prevention regulations! All work on installation and commissioning

as well as all maintenance is to be performed by appropriately qualied personnel.

National accident prevention regulations, EN and IEC standards are to be observed.

Appropriately qualied personnel in the context of these basic safety instructions are

persons who are familiar with the tting, installation, placing in operation and operation

of the product and have qualications appropriate to their task.

1.1.2 Laser safety

The unit is a class 3B laser device. Both the direct beam and its reections from

di ffuse reective surfaces are dangerous.The unit emits strong power beams in the

visible spectral range (approx. 400 nm to 700 nm, for more detailed information see

the data sheet, page 14). The radiation can cause irreversible damage to the eyes if the

necessary protective measures are not taken.

1.1.3 Laser area

The laser area is the area in which the values for the maximum permissible irradiation

can be exceeded. Here the possibility of unintentional deection of the laser beam is

also to be taken into account. If operational equipment other than that given in this

manual or another procedure is used, dangerous exposure to the radiation may result.

Laser system screened inside a protective cover

By using suitable screening it can be ensured that people are not exposed to the laser

radiation. In this way the laser class is reduced and it is possible to work with the

closed arrangement without additional limitations or further measures.

5

However, in this case the following requirements apply to the protective cover:

· The protective cover must be appropriate to adequately shield the laser

radiation. It is therefore necessary to use laser safety glass or laser safety

lm for viewing windows.

· The cover itself as well as any doors or aps in the cover must be protected

using the interlock circuit that automatically shuts down and inhibits the laser

immediately on intentional or unintentional opening.

If the interlock circuit is disabled for service or maintenance work on the system with

the cover open, the laser area is enlarged again and the regulations in the next section

“Presence of persons in the laser area” apply.

Presence of persons in the laser area

In the laser area, people are subject to hazards, in particular ocular. Therefore the

follow ing measures must be taken and the following safety regulations observed:

· The room must have an emergency exit.

· The room must be optically screened from the environment (e.g. laser safety

lm on the windows).

· The laser area is to be kept as small as possible, to be bounded by suitable

screening and protected against access by unauthorized persons. The num-

ber of persons in the laser area should be reduced to the minimum.

· There must be a warning device on all entrances to the room that indicates

the laser radiation hazard.

· If the entry doors are not protected using the interlock circuits, opening the

doors easily from the outside must be impossible to prevent thoughtless

entry.

· All persons who are in the laser area during operation must be informed

about the dangers of the laser radiation.

· Laser safety glasses/goggles must be worn in the laser area. The operating

organisation must ensure that suitable safety glasses/goggles are available.

The glasses/goggles are selected in accordance with DIN EN 207. Please see

the data sheet on the unit for the actual wavelength of your laser. Herein-

after, the term safety glasses is always used to refer to suitable laser safety

glasses/goggles. Caution: in some circumstances your laser safety glasses/

goggles may not protect you from a powerful red pilot beam.

· There must not be any potentially explosive substances in the laser area.

Easily inammable substances may catch re.

· Glossy reective equipment must be either removed from the laser area or

covered. Windows and reecting walls are also to be covered with material

with low inammability.

6

1.2 Warning and information labels

The following warning labels are tted to laser and processing head:

The READYBeam is an OEM certied laser. Please be advised that it has no dedicated

Key Switch. If operated via PC with the software installed, be cautioned that sudden-

ly unplugging it during “Lasing,” will cause it to emit radiation when plugged in the

next time. Always make sure to turn it to the “off” position prior to shutting down the

computer.

1.3 Correctandspecieduseoftheunit

It is forbidden to commission the laser system until it has been ensured that the

ma chine or plant in which the laser system has been tted complies with the appli-

cable safety regulations. The organisation operating the plant is solely liable for any

damage caused by incorrect use of the unit. The organisation operating the system is

respon sible for the correct conditions in relation to operation, maintenance and repair.

The only personnel to be tasked with operation, maintenance and repair are personnel

who have been adequately instructed in the function of the laser system and who

have also been instructed specically on the dangers and risks of incorrect handling of

the system.

7

1.4 Warranty conditions

The warranty period is 12 months from delivery. The warranty covers the entire laser

module. The warranty will become void on the

· unauthorized opening of the unit‘s components

· operation of the unit in an unauthorized conguration

· improper use, storage or transport (e.g. vibration, temperature shock, the

action of frost)

1.4.1 Limits of the warranty

No warranty of the suitability of the product for specic applications is provided.

FISBA is not liable for indirect, direct or consequential damages caused by the use of

this product.

2 Technical system

The laser module emits laser radiation with different wavelengths. Combination of

different laser diodes can emit radiation in the UV, VIS and/or NIR range. The different

combinations are documented within the data sheet, see page 14.

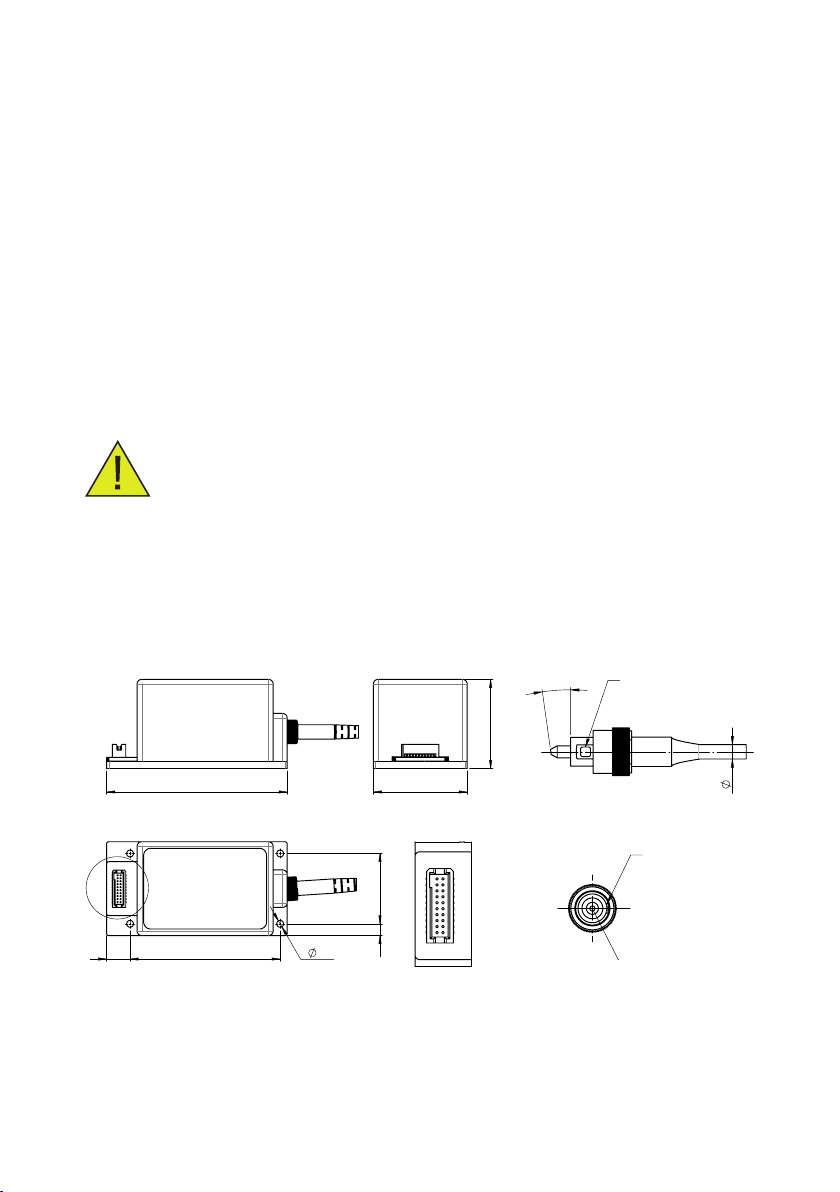

2.1 Laser module

Dimensions of the laser module in mm:

77 40

37

10 64

5

30

2.9

A

A

01

20 19

02

Pin assignment Samtec SFSD-10-28G24.00SR

01

VIN red N

11

RS485B

02

VIN red P

12

RS485A

03

VIN green N

13

GND

04

VIN green P

14

GND

05

VIN blue N

15

GND

06

VIN blue P

16

GND

07

GND

17

+12V...+24V

08

Enable red

18

+12V...+24V

09

Enable green

19

+12V...+24V

10

Enable blue

20

+12V...+24V

CAD-System: SolidWorks

00.237.83-010

SAP Material:

A4

Format

Format

www.fisba.com

1:1

Massstab

/ Scale

Werkstoff

Material

Änderungs-Nr.

Revision no.

Benennung

/ Description

1 / 1

Blatt / Anz

Sheet / no. of

Zeichnungs-Nr.

/ Drawing no.

Freigegeben

Approved

Erstellt

Prepared

READYBeam BIO

Streng vertraulich. Alle Rechte vorbehalten. Die Vervielfältigung

und die Verarbeitung mit elektronischen Systemen ist ohne

schriftliche Genehmigung der FISBA AG nicht gestattet.

Revision

Revision

+

E-18006

Gewicht

Weight

130.13 g

Geändert

Modified

Strictly confidential. All rights reserved. Reproduction and

processing of data in electronic systems or in any form whatever

is not permitted without written authority of FISBA AG.

Status

Status

in Bearbeitung

Oberfläche

Surface

Dimension nach Oberflächenbehandlung

Dimensions after surface treatment

Kanten gebrochen 0.1...0.2x45°

Edges chamfered 0.1...0.2x45°

Allgemeintoleranzen nach ISO2768-fH

General tolerances according to ISO2768-fH

Toleranz-Grundsatz nach ISO8015

Tolerancing ISO8015

Alle Masse in mm

All dimensions in mm

FC Connector Key

Laser Exit Aperture

8°

3

FC Connector Key

Narrow Key

Slow Axis Alignment

Polarisation Direction

FC Connector Key

Laser Exit Aperture

8°

3

FC Connector Key

Narrow Key

Slow Axis Alignment

Polarisation Direction

Connector: Samtec SFSD-10-28G24.00SR

Pin assignment: documented in the appendix (Table 1 on page 12)

8

2.2 Installation and commissioning

Note that the laser module with electronic driver is not a product for direct use.

Security elements, such as interlock, and emergency switch are not included in

the laser module. If the laser module is used as part of system or product, then the

responsibility for safety lies with the product development team of the product.

When operating the laser module, the laser safety regulations must be observed.

2.2.1 Unpacking and checking for visible damage

Check the completeness of the delivery and check that all the items supplied are in

good condition. In case of errors please contact FISBA AG (readybeam@sba.com).

If possible, keep the packaging in which the laser system was supplied. It will then

be possible to pack the unit in its original packaging and transport it safely in case of

repair.

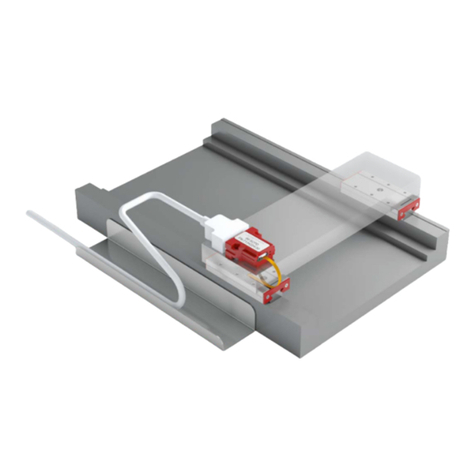

2.2.2 Installation

The laser module can be mounted with screws on a at bottom plate. The bottom

plate should be cooled and the heat transfer should be at least 7W to hold the module

on a stable operating temperature. The laser module READYBeam is TEC-controlled.

Incorrect cooling effects the laser power and can destroy the laser diodes. During

assembly of the laser module on a plane cooling surface, attention is required so that

no tension can apply to the casing. Tension inuences the beam quality very strongly.

The connection must be handled carefully.

2.2.3 Operating the FISBA READYBeamTM

· The safety regulations must be carefully observed

· A power supply between +12 and +24V with max. 4 Ampere is needed

to start the READYBeam

· FISBA READYBeamTM can be started digital with the software application

and RS485 interface or analog based controlled

2.2.4 Software Setup

· Visit sba.com/readybeam-software to download the software

· Unpack the les from downloaded folder

· Start “RGB Service Software Setup.msi” and follow the

installation instructions

· You need an USB - RS485 interface cable for the digital operating mode

See the details in the appendix (Figure 1 on page 13)

9

· Connect the USB plug to your laptop and the RS485 plug to the laser module

interface cable

· Connect the power supply to the interface cable

· Connect the interface cable to the laser module connector

· Start the READYBeam software

· Now it is possible to control the lasers via the software

2.2.5 Software interface

The software interface allows a fast start up of the READYBeam with all main

functions.

· Connect power supply

· Connect RS485 interface cable

· Connect the interface cable to the READYBeam

· Switch On +12/+24V Power

· Start software

· Wait 1 minute for temperature stabilization

1. Set Modulation Mode: choose “Digital”

2. Set Power Value 1 (red), Power Value 2 (green) and Power Value 3 (blue):

values in % of the max. laser power

3. Switch the Laser on/off with Digital Enable 1, 2 or 3

4. Enter the command with “WriteCong”Button

The READYBeam software is provided for download at:

sba.com/readybeam-software

10

2.2.6 Modulation mode

On the Interface, the three channels can be set as either on “Digital” to control

On/Off modulation via software with a maximum pulse frequency of 100 Hz, or

to “Analog” for external control in On/Off mode or continuous waveform modulation.

11

Software Control External Control

Digital

On/Off

modulation

Up to 100Hz

Analog

On/Off

modulation

Up to 1M Hz

Continuous

waveform

Up to 20kHz

On/Offmodulation

On/Off modulation is best when the operator wants fast and accurate modulation with

discrete signals. Digital modulation is possible with two options. Option one is over

the SW up to 100Hz. Option two over a 0-3.3V TTL input signal up to 1MHZ. For digital

modulation over SW, choose “Digital” from the “Modulation Mode” drop-down menu

on the main screen and set “Pulse Enable” to ON and set “On Time “ and “Off Time”.

The unit of On and Off Time is ms. For digital modulation over TTL input signal, choose

“Analog” from the “Modulation Mode” drop-down menu on the main screen and use

a function generator or a similar external signal source for the 0-3.3V TTL input Signal.

A function generator, or similar external signal source, is needed to drive the modula-

tion.

Continuous waveform

To modulate the laser power choose “Analog” from the “Modulation Mode” drop-

down menu. The signal is calibrated from 0.33V to 3.3V. This corelates with 10% to

100% of laser power. Below 0.33V the laser power is not longer linear and below the

threshold current the laser is no longer in lasing mode. A function generator, or similar

external signal source, is needed to drive the modulation.

12

Appendix

Pin conguration and power values

Connector: Samtec SFSD-10-28G24.00SR

Enable Laser: low = 0V, high = 3.3V

Analog In: 0.33V … 3.3V --> 10% ...100% of Laser power

Power: +12V … + 24V max. 4A

Pin 1 is marked on the connector with arrow (not notch)

Pin 1 Analog In- Laser red

Pin 2 Analog In+ Laser red

Pin 3 Analog In- Laser green

Pin 4 Analog In+ Laser green

Pin 5 Analog In- Laser blue

Pin 6 Analog In+ Laser blue

Pin 7 Gnd

Pin 8 Enable Laser red

Pin 9 Enable Laser green

Pin 10 Enable Laser blue

Pin 11 RS 485 B

Pin 12 RS 485 A

Pin 13 Gnd

Pin 14 Gnd

Pin 15 Gnd

Pin 16 Gnd

Pin 17 Power +12V … +24V

Pin 18 Power +12V … +24V

Pin 19 Power +12V … +24V

Pin 20 Power +12V … +24V

Table 1

13

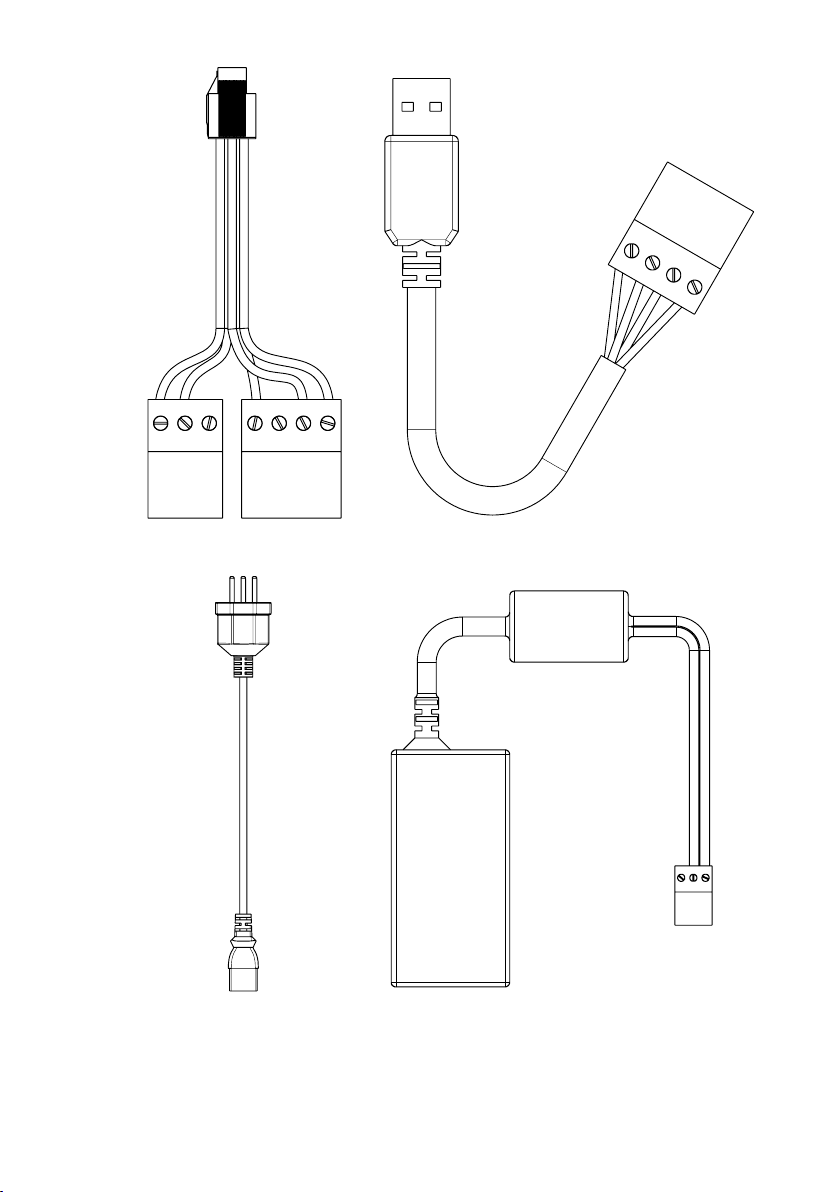

USB RS-485

Power RS-485

Module

Power

Power supply

Electric

Cable

Figure 1

14

Data sheet FISBA READYBeamTM

Technical Specications

FISBA READYBeam™

Technical specications

Wavelength 1)

405 nm 450 nm 488 nm 520 nm 638 nm 660 nm

FISBA READY BeamTM bio 1 1006061 xxx

FISBA READY BeamTM bio 2 1008062 xxx

FISBA READY BeamTM ind 1 1006062 xxx

FISBA READY BeamTM ind 2 1007773 x x x

Output power calibrated values 2) 40 mW 40 mW 30 mW 30 mW 40 mW 40 mW

Power stability 8 h < 2%

Fiber type SM/PM, 3 µm core, end capped, APC Connector

Fiber cable length 1 m

Polarisation ratio 3) typ.17 dB

Spatial mode TEM 00

M2 < 1.1

Optical noise RMS, 20Hz – 20MHz typ. 0.2, max. 0.5 %

Laser operation modes CW, modulated

Digital modulation TTL input

Digital modulation frequencies 1 MHz

Digital rise time 10 – 90% 11 ns

Digital fall time 90 – 10% 11 ns

Analog modulation bandwidth 0 – 3.3 V input voltage

Analog modulation frequencies 20 KHz

Analog rise time 10 – 90% 12 µsec

Analog fall time 90 – 10% 12 µsec

Laser safety class 3B

Max. storage temperature range - 10° C to + 60° C

Operational temperature range + 15° C to + 40° C

Power consumption typ. 5 W, max. 12 W

Temperature stabilization internal TEC controlled

Communication interface RS 485

1)

Laser center wavelength tolerances: 405: 400 – 410nm ; 450: 440 – 460nm; 488: 486 – 490nm; 520: 515 – 530 nm; 638: 632 – 643nm; 660: 655 – 665nm

2)

linear calibrated power range from 10% to 100% (max)

3)

min.13dB, max. 26 dB

15

Denition of QR Code information

Specication1 Itemnumber

Specication2 Serialnumber

Specication3 Finalinspectiondate

CAD-System: SolidWorks

SAP Material:

A4

Format

Format

www.fisba.com

1:1

Massstab

/ Scale

Werkstoff

Material

Änderungs-Nr.

Revision no.

Benennung

/ Description

1 / 1

Blatt / Anz

Sheet / no. of

Zeichnungs-Nr.

/ Drawing no.

Freigegeben

Approved

Erstellt

Prepared

Streng vertraulich. Alle Rechte vorbehalten. Die Vervielfältigung

und die Verarbeitung mit elektronischen Systemen ist ohne

schriftliche Genehmigung der FISBA AG nicht gestattet.

Revision

Revision

Gewicht

Weight

99.09 g

Geändert

Modified

Strictly confidential. All rights reserved. Reproduction and

processing of data in electronic systems or in any form whatever

is not permitted without written authority of FISBA AG.

Status

Status

in Bearbeitung

Oberfläche

Surface

Dimension nach Oberflächenbehandlung

Dimensions after surface treatment

Kanten gebrochen 0.1...0.2x45°

Edges chamfered 0.1...0.2x45°

Allgemeintoleranzen nach ISO2768-fH

General tolerances according to ISO2768-fH

Toleranz-Grundsatz nach ISO8015

Tolerancing ISO8015

Alle Masse in mm

All dimensions in mm

READYBeam Front View - mit Labels

i

© FISBA AG

FISBA AG

FISBA Photonics GmbH

FISBA LLC

FISBA (Shanghai) Co., Ltd.

Rorschacher Str. 268

9016 St.Gallen

Switzerland

Schwarzschildstrasse 10

12489 Berlin

Germany

6296 E.Grant Rd Suite 150

Tucson, AZ 85712

United States

World Plaza, No. 855

9F Pudong South Rd.

Puong District

Shanghai City

China

sba.com |readybeam@sba.com

This manual suits for next models

7

Table of contents