Introduction

Operation Manual - Line pumps10

revDate

Introduction

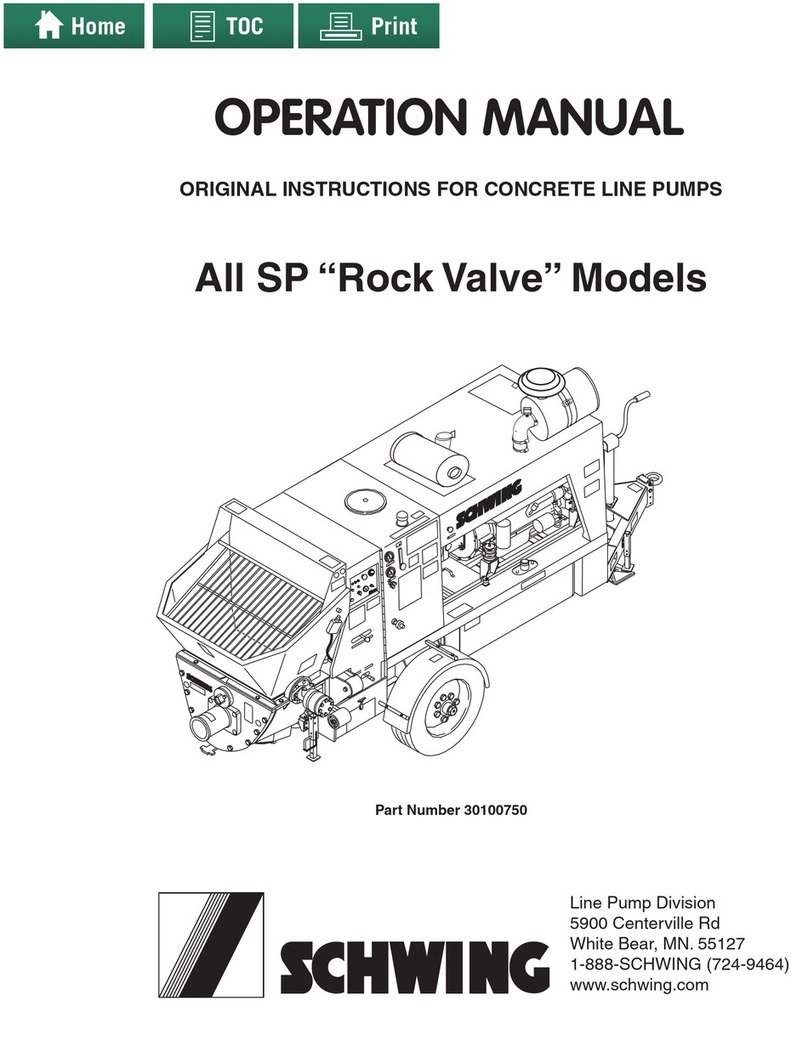

This operation manual contains unit specifications,

product overview information, the safety manual,

operation information, and maintenance information

for your concrete pump unit.

Manufacturer’sStatement

The information contained in the operation manual is

absolutely necessary for the safety, proper setup,

operation, maintenance, and servicing of your concrete

pump. By learning this information and practicing it

every day, you can expect that your concrete pump unit

will give you efficient and reliable service year after

year.

For your own benefit and safety, read the information in

this manual, and follow the instructions to the letter.

Before you operate your concrete pump for the first

time, you should read the operating instructions several

times through. We recommend that you keep a copy

with the concrete pump for quick reference while on

the job site. The general knowledge must be in place

before you arrive on the job site. Any and all persons

who operate a concrete pump must be familiar with the

operating instructions. Even a temporary operator (for

example, if the normal operator is ill or on vacation)

must be familiar with the operation instructions. It

stands to reason that a person who has not operated a

particular concrete pump before will not know how to

safely operate that concrete pump. The machine is built

to the latest technology and safety regulations, but it

may still be dangerous to people and property if it is

operated, maintained, repaired, or used incorrectly.

The illustrations contained in this manual are intended

to clarify text passages. They may look slightly

different from your unit, but this has only been allowed

if it does not fundamentally change the factual

information.

Technical modifications that are made to units will be

documented in each new edition of the operation

manual.

Safety alert symbol and signal word

explanation

The triangle with the exclamation point inside is used

to alert you to an important safety point and is called a

safety alert symbol

. One of the following signal words

will appear after the safety alert symbol:

• If the safety alert symbol is followed by the

signal word

DANGER

, it indicates a

hazardous situation which, if not avoided,

WILL

lead to

death or serious injury.

• If the safety alert symbol is followed by the

signal word

WARNING

, it indicates a

potentially hazardous situation which, if not

avoided,

COULD

result in

death or serious

injury.

• If the safety alert symbol is followed by the

signal word

CAUTION

, it indicates a

potentially hazardous situation which, if not

avoided,

MAY

result in

minor to moderate

injury.

• The signal word

CAUTION

used without the

safety alert symbol means the point addresses

a hazard which

COULD

cause

damage to

equipment or property.

WARNING

Improper setup / operation creates

hazards. Do not operate thismachine

without training. Understand the

warningsin safety manualsand on

decals.

000099.eps

Danger

Warning

Caution