1.1-1

005.008.05-EN

STRUCTURE OF THE OPERATING

INSTRUCTIONS

The present operating instructions have a

modular structure and consist of seven

chapters. The operating instructions are

numbered by chapter title, as individual

chapters are interchangeable and partially

(e.g. safety manual) have their own, individual

numbering.

For ease of use, the beginning of each new

chapter is identified by a green page.

As some chapters may also be issued

separately, they are identified by their own

cover sheets.

THE SEVEN CHAPTERS OF THE

OPERATING INSTRUCTIONS

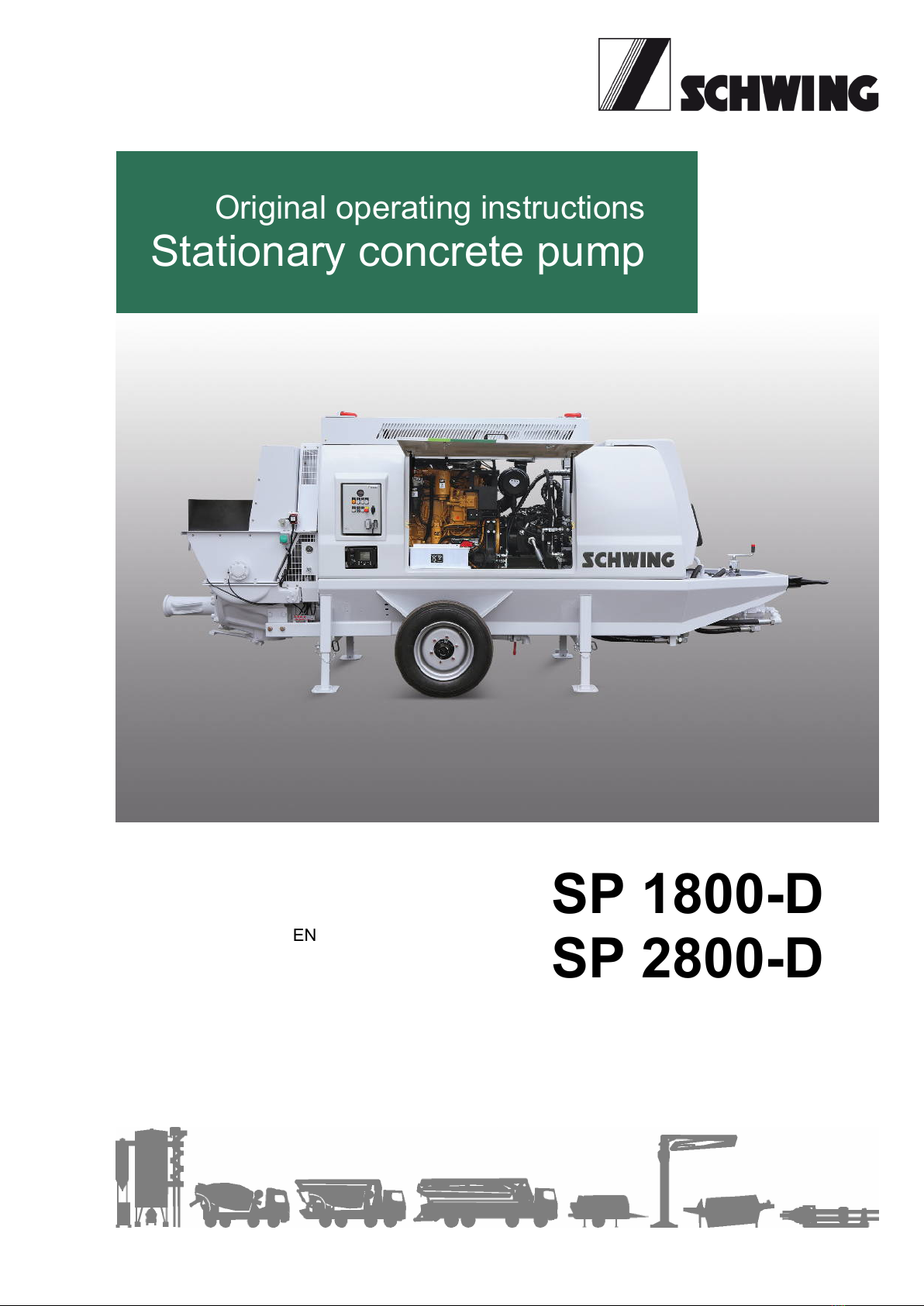

CHAPTER 1: INTRODUCTION

The first chapter of these operating

instructions is about familiarising yourself with

the machine. Here you will find - For example -

The technical data, a brief description, an

overview of the control and check devices, as

well as a description of the control systems

used.

CHAPTER 2: SAFETY

In the second chapter you will find our

SAFETY MANUAL. The safety manual is

prepared jointly by leading manufacturers of

concrete pumping and placing machines under

the auspices of the VDMA (Verband deutscher

Maschinen- Und Anlagenbauer/Association of

German Machinery and Equipment

Constructors). It is applicable without

restrictions to our machines and an integral

part of these operating instructions.

The safety manual contains essential safety

notices for the operation of the above-

mentioned machines and is used by all

collaborating companies.

Special safety and warning notices for your

SCHWING machine are provided in the

individual chapters of these operating

instructions.

CHAPTER 3: OPERATION

In the third chapter you will find descriptions of

all machine operating procedures, from

commissioning to working operation and

cleaning to decommissioning.

CHAPTER 4: MAINTEANCNE

In the fourth chapter you will find essential

information on when and how the machine

must be serviced, as well as information on

filling quantities and lubricants and operating

materials used.

CHAPTER 5: RADIO REMOTE CONTROL

In chapter 5, you will find operating instructions

for the remote control used. If alternative

remote controls are available for your machine,

all up-to-date variants are shown here. With

machines for which no radio remote control

was offered, this chapter is empty.

CHAPTER 6: SPECIAL EQUIPMENT

Chapter 6 provides information about special

equipment for your machine.

CHAPTER 7: APPENDIX

In the appendix you will find topics such as

organisation and administration.