6

Table of Contents

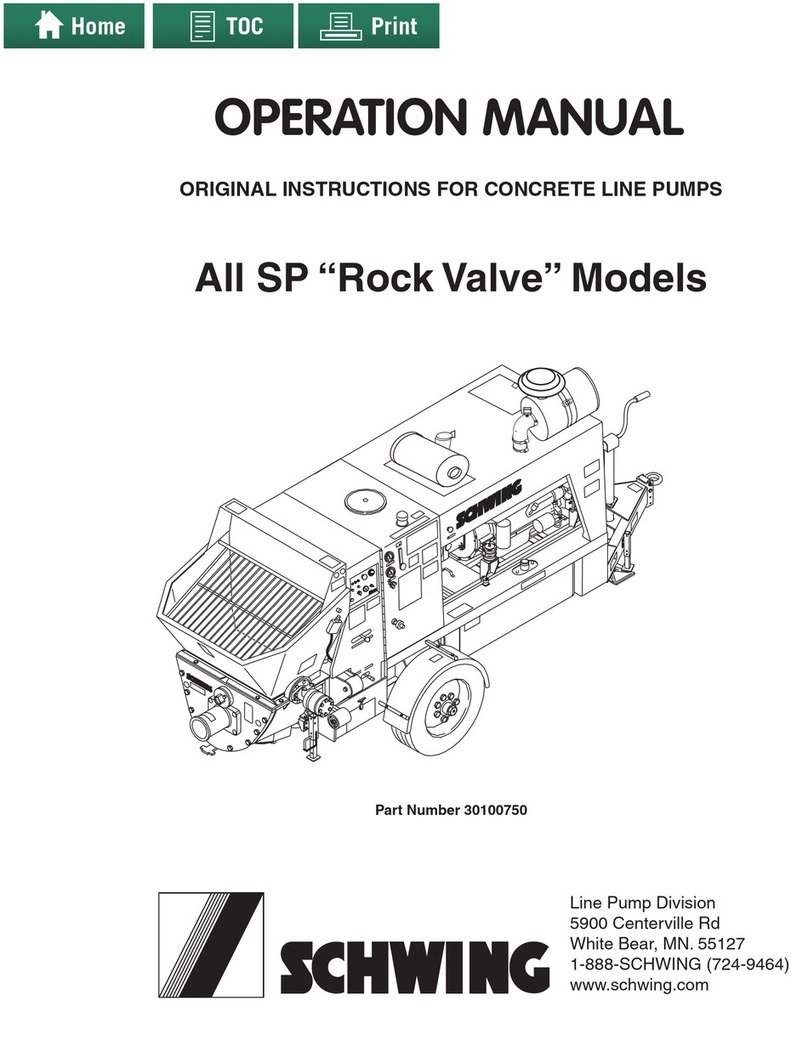

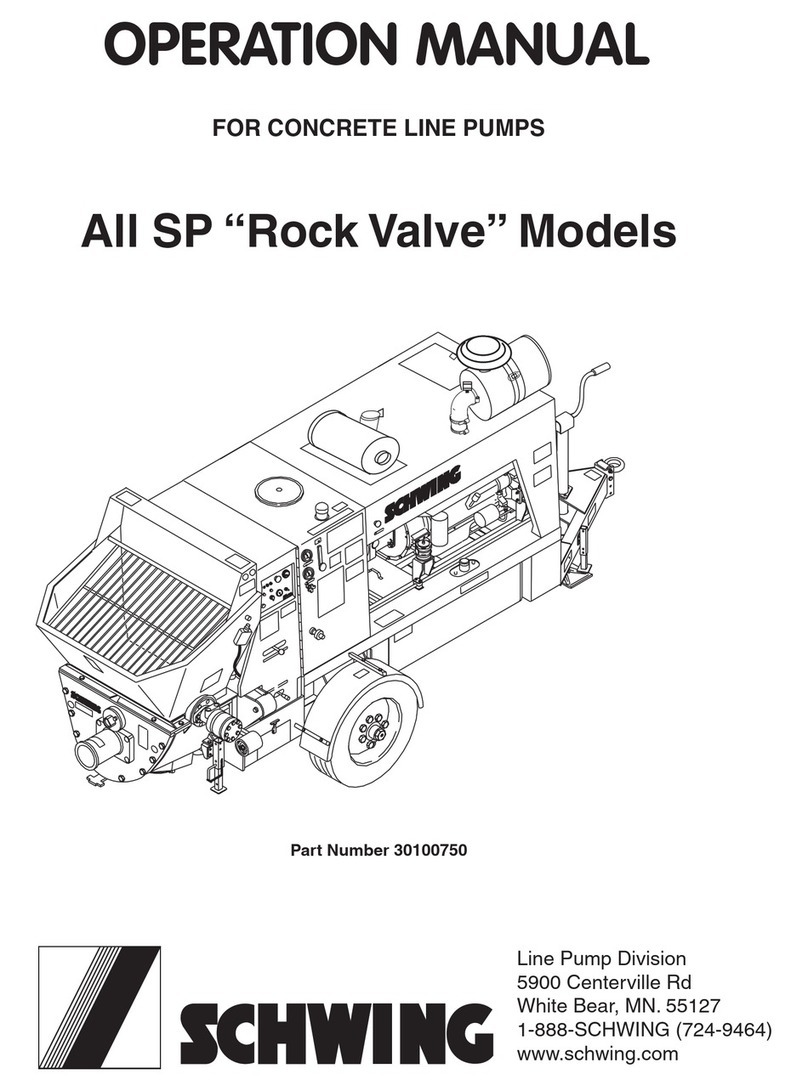

SP 500 / 750-15 / 750-18 / 1000 / 1250 Operation Manual

Operation.................................................. 61

Preparing for the Job........................................63

Personal Protection .......................................63

Pipeline and Clamps......................................63

Tools and Accessories...................................63

Tow Vehicle....................................................64

Tow Vehicle Pre-Check..................................64

Stationary Pump Pre-Check ..........................64

Attaching the Tow Hitch .................................65

Towing the Stationary Pump..........................66

Machine Loading/Unloading.............................67

Lifting with a Crane........................................67

Lifting with a Forklift.......................................67

Loading on a atbed trailer............................67

Unit Setup.........................................................67

Selecting the setup location ..........................67

Laying out the pipeline...................................68

Machine Preparation .....................................68

Starting the Machine.........................................70

Checking the machine...................................70

Shutting the Machine Down..............................71

Lubricating Slurry..............................................71

Lubricating the pipeline..................................71

Controlling the Concrete Pump ........................74

Stroke Limiter ................................................74

Cable Remote................................................74

Wireless Remote (Optional) ..........................75

Safe pairing of Transmitter to Receiver .........75

Pumping the Job...............................................77

Time constraints ............................................78

Cold conditions ..............................................78

Delays............................................................78

Keep the water box full ..................................78

Blockages......................................................79

Cleanout ...........................................................80

Clean the waterbox........................................83

Preparing for travel........................................83

External Cleaning .............................................84

High Pressure Washer...................................84

Use of Cleaning Agents.................................84

Protecting New Paint.....................................84

Special Pumping Situations..............................85

Quick cleanout...............................................85

Cold-weather pumping ..................................85

Emergency Procedures....................................87

Emergency Override Button ..........................87

Loss of Radio/Cable remote..........................87

Optional Equipment..........................................88

Hydraulic Outriggers......................................88

Hopper Vibrator .............................................88

Auto Greaser .................................................88

Maintenance............................................. 89

Hoses and Fittings............................................91

Torque specications .....................................91

Welding precautions......................................91

Adjusting relief valves....................................91

Removing safety devices...............................92

Lock Out - Tag Out procedure .......................92

Replacing the hydraulic pump .......................92

Hydraulic Oils ...................................................93

General information .......................................93

Specic information .......................................93

“Industrial” gear lubricant codes ...................93

Vehicle gear box oil codes.............................93

Hydraulic Oil Recommendations ...................94

Biodegradable Hydraulic Oils ...........................94

Filtration............................................................95

General information .......................................95

Specic information .......................................95

Bypass Check valve ......................................96

Scheduled Maintenance...................................97

Maintenance Chart ........................................97

Daily maintenance............................................98

Weekly maintenance ......................................101

Monthly maintenance .....................................103

Semi-annual maintenance .............................104