1.Grounding outlet to avoid accidental electric shock or fire disaster.

2.Do not attempt to repair the product yourself. Do not open th e power box indiscriminately to

avoid electric shock.

3.Please an the independent mains jack socket. Make sure the proper plug with outlet. Loose

connection will result in overheating, electric shock, or even fire disaster.

4.Do not pull out the plug when it is operating. Do not drag the wire to plug the outlet.

5.Do not damage the wires or use the undesignated wires. Do not try to extend the wires or attach

wires at the middle by yourself. Improper handling of wires will result in fire or electric shock.

6.Plug the outlet with wet will get risk of electric shock.

7.Do not put fingers, rods or other kinds of foreign bodies into the inlet or outlet of air.

8.In case of malfunction or burning smell, the unit must be immediately unplug and ceased for

further checking, or use a circuit breaker to cut off the power supply. Continuance of abnormal state

will result in fire caused by overheating.

9.The electric power supply must be cut off under following situations:

9.1.When opening the door of power box. Without cutting off power supply, the opening of the door

will probably result in electric shock.

9.2.When replacing the fuse. Replacing the fuse without cutting off the power supply will probably

result in electric shock.

9.3.When the malfunction occurs. Mishandling will result in the further damage of the equipment or

accidental injury.

9.4.When not using for a long period of time. The dust accumulated on the outlet may leads to fire

cause by electric leakage.

9.5.When moving the equipment. Moving the equipment connected with power supply will

probably result in electric shock.

Danger! (Warnings against likely injury or death.)

Please be sure to follow the instructions, which are

really important for your safety.

Safety instruction!

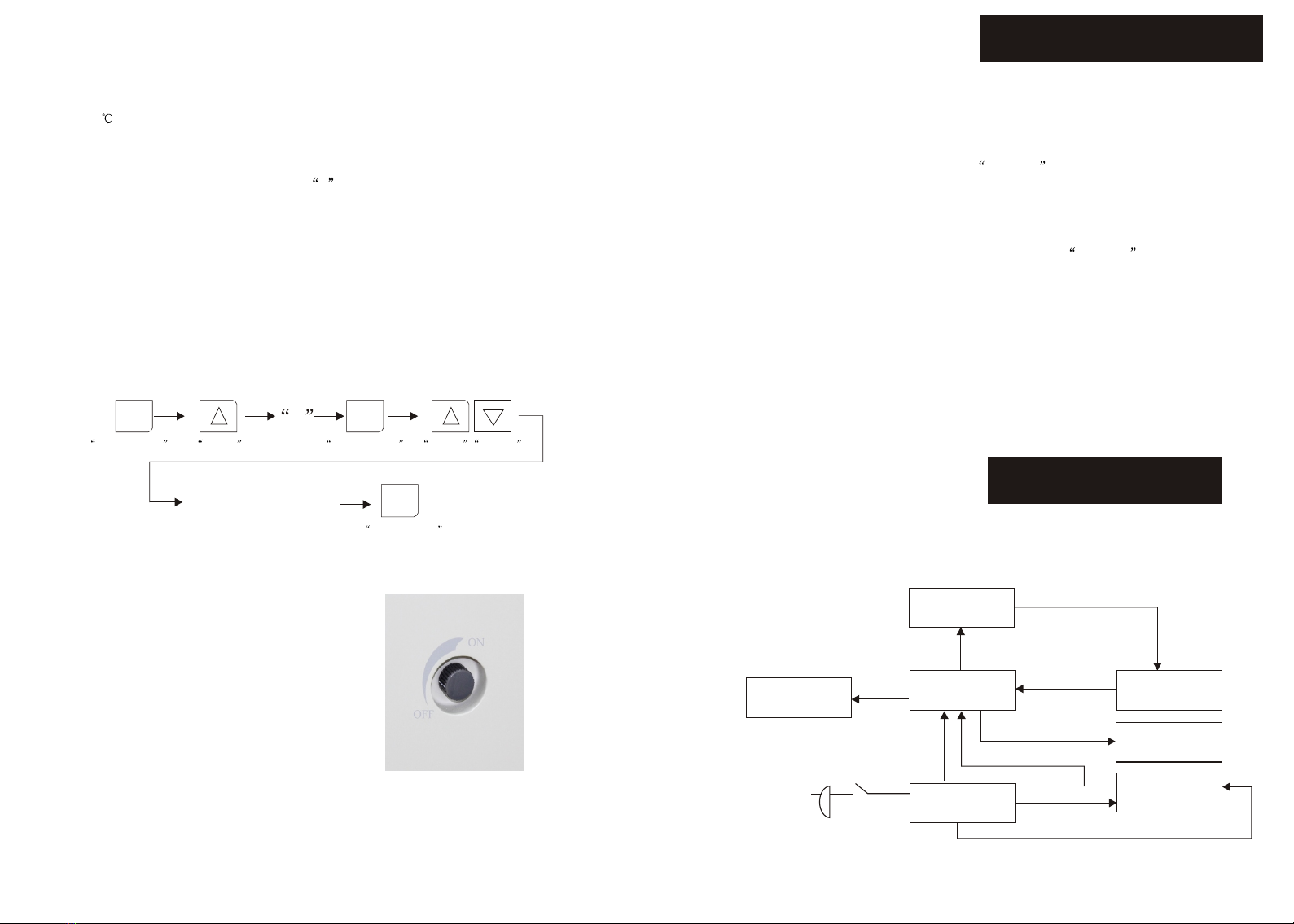

1.The unit must be placed horizontally on solid, flat floors.

2.The unit must be provided with sufficient clearance on all sides of the unit, at least 20cm.

3.Do not leave the unit in a location exposed to direct sunlight or near heater.

4.The unit must be kept faraway from source of electromagnetic interference.

5.When in normal operation, culture inside the incubator should be placed to the extent of which

the air flow inside the equipment is not affected to keep the temperature uniformity in the working

chamber.

6.Make sure the shelves inside the chamber is placed horizontally.

7.Open or close the door heavily will probably leads to the damage of the equipment.

8.When in operation, do not open the door indiscriminately which will affect the temperature

inside.

9.The exterior of equipment must be kept away from volatile, flammable, explosive liquids or

gases.10.Please keep the chamber clean. Regular cleaning is required.

Instructions to keep the normal life and proper

operations of the equipment!

Apart from the above warnings and instruction, there are

several other special reminder with a exclamation point

within a triangle, please read and follow. Any neglect will

probably lead to hidden trouble, serious damage, or

accidental injury.

Attention!

Attention!

Attention

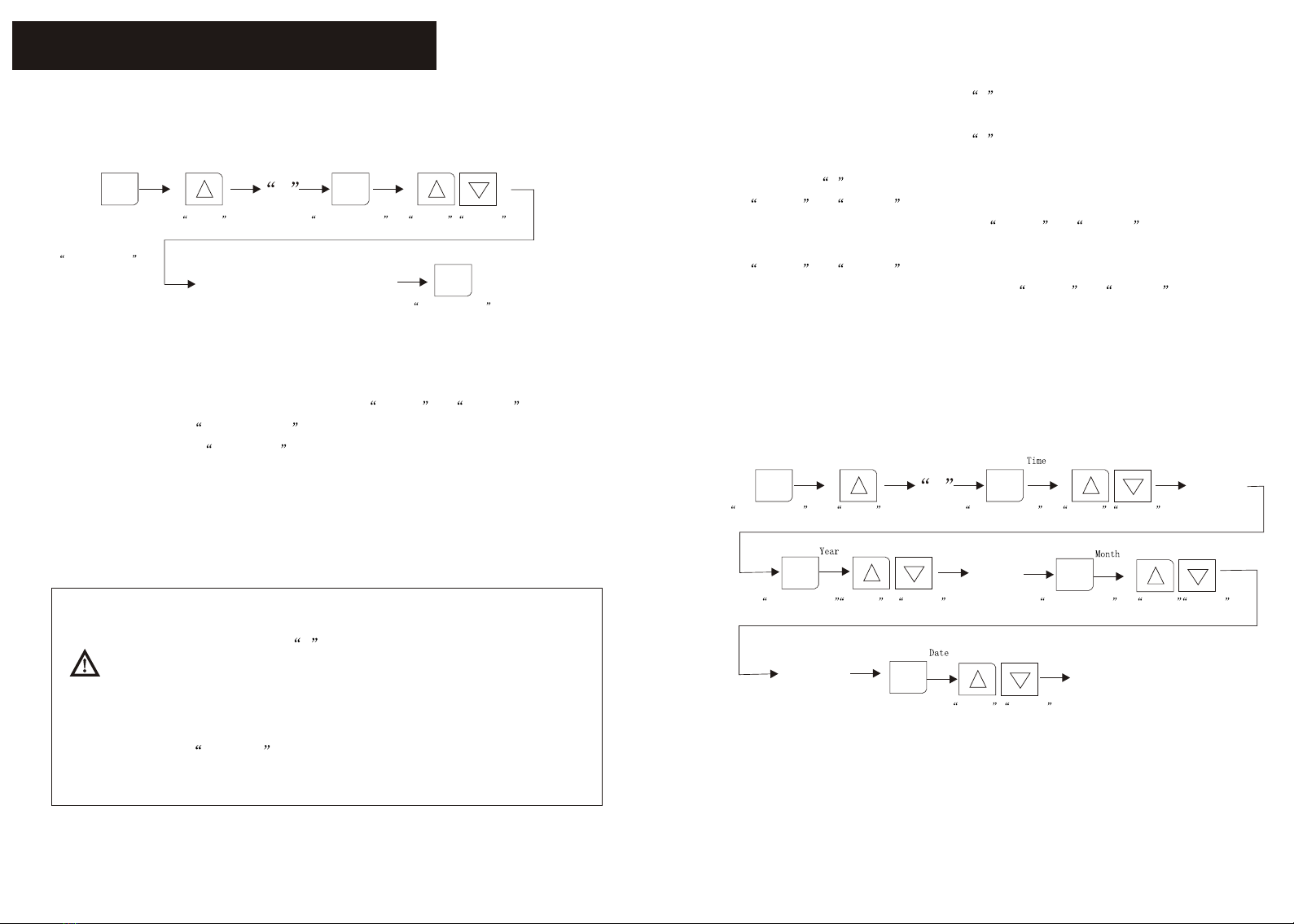

Please close the door immediately after take/put the sample,otherwise the

temperature control precision could the affected.

If the door had to be opened for a long time, please power off the unit.