4|

Contents

Racks. . . . . . . . . . . . . . . . . . . . . . . 3

Quartz Vessels. . . . . . . . . . . . . . . . . . . 3

Accessories . . . . . . . . . . . . . . . . . . . . 3

Teon®Vessels. . . . . . . . . . . . . . . . . . . 3

Power and Connections . . . . . . . . . . . . . . 3

1 Introduction 6

Unpacking . . . . . . . . . . . . . . . . . . . . 6

Inspection . . . . . . . . . . . . . . . . . . . . 6

Instrument Description . . . . . . . . . . . . . . 6

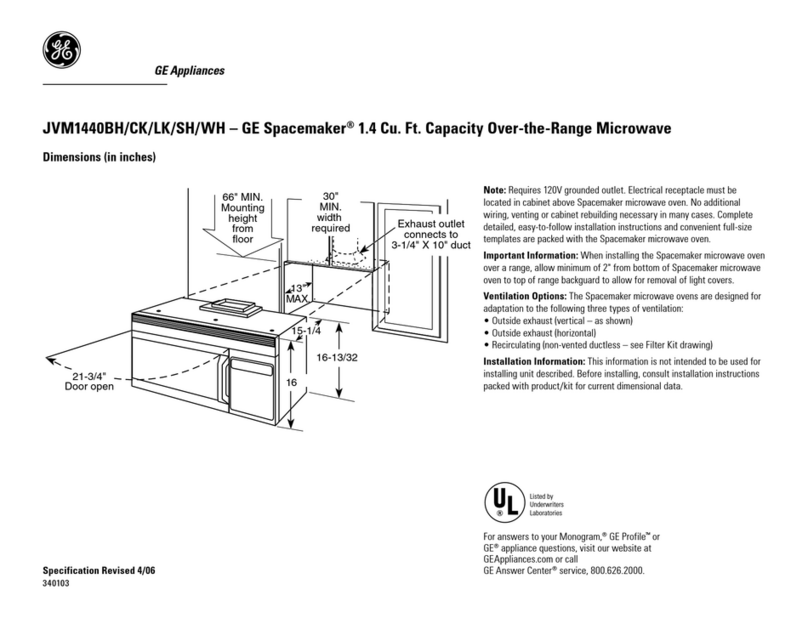

2 Installation 7

3 Cautions, Notes and Symbols 8

Cautions,Warnings and Notes

are included throughout this manual . . . . . . . . 8

4 Racks & Vessels 9

5 Operation 10

Software . . . . . . . . . . . . . . . . . . . . 11

Module Tab . . . . . . . . . . . . . . . . . . . 12

Digestion Tab . . . . . . . . . . . . . . . . . . 16

Methods Tab . . . . . . . . . . . . . . . . . . 17

Reports Tab . . . . . . . . . . . . . . . . . . . 19

Utilities Tab . . . . . . . . . . . . . . . . . . . 20

Diagnostic Tab . . . . . . . . . . . . . . . . . 22

Operation. . . . . . . . . . . . . . . . . . . . 22

Logout Tab . . . . . . . . . . . . . . . . . . . 23

6Cleaning / Maintenance of System 24

Cleaning of Vessels . . . . . . . . . . . . . . . 24

Cleaning of Teon®Liners, Caps

and Safety Pressure Caps . . . . . . . . . . . . . 24

Pressure . . . . . . . . . . . . . . . . . . . . 24

Cleaning the Cavity . . . . . . . . . . . . . . . 24

Cleaning the screen of the Controller . . . . . . . 24

7 Warranty & Safety Information 25

Toxic or hazardous substances and elements . . . . 26

8 Specications 27

Modual Indicator . . . . . . . . . . . . . . . . 28

Running display messages . . . . . . . . . . . . 29

9 Troubleshooting 30

Safety Messages. . . . . . . . . . . . . . . . . 30