TB-9115 Page 1 of 6 © 2023 DESCO INDUSTRIES INC

Employee Owned

Desco Asia - 193-12 Yachimata-i, Yachimata-shi, Chiba, 289-1143, Japan

Phone: +81 43-309-4470 • Website: DescoAsia.com

975 Ionized Air Blower

Installation, Operation, and Maintenance

June 2023

Description

The SCS 975 Ionized Air Blower is used for neutralizing

electrostatic charges on insulators and ungrounded

conductors. Its fast discharge times (< 1 second at 12

inches) and ±10 volt offset voltage exceed the required

limits of ANSI/ESD S20.20 and ESD TR53. The 975

Ionized Air Blower monitors its offset voltage (balance),

and it alarms when emitter cleaning is required. A

built-in automatic emitter point cleaner periodically

brushes away dust and minimizes maintenance. The

emitters may be accessed for thorough cleaning with

the use of a single thumb screw. The 975 Ionized Air

Blower features a powder coated steel enclosure,

multi-mount stand, and terminal block with alarm output

for machine integration.

The SCS 975 Ionized Air Blower operates on

Steady-state DC. Steady-state DC systems consist of

separate negative and positive ion emitters connected

by a pair of high-voltage cables to their respective

high-voltage power supplies. DC power is constantly

applied to the emitter points. The ionizer utilizes

sampling from its inner fan grill to continuously adjust

the output and maintain its offset voltage.

USER GUIDE TB-9115

“The primary method of static charge control is direct

connection to ground for conductors, static dissipative

materials, and personnel. A complete static control

program must also deal with isolated conductors

that cannot be grounded, insulating materials (e.g.,

most common plastics), and moving personnel who

cannot use wrist or heel straps or ESD control flooring

and footwear. Air ionization is not a replacement for

grounding methods. It is one component of a complete

static control program. Ionizers are used when it is not

possible to properly ground everything and as backup

to other static control methods. In clean rooms, air

ionization may be one of the few methods of static

control available.” [ESD Handbook ESD TR20.20

Ionization, section 5.3.6.1 Introduction and Purpose /

General Information]

The 975 Ionized Air Blower and its accessories are

available as the following item numbers:

Item Description

975A Ionized Air Blower with North America

Power Adapter

975N Ionized Air Blower without Power Adapter

975P North America Power Adapter

Packaging

1 Ionized Air Blower

1 Ground Wire

1 Power Adapter (975A only)

1 North America Power Cord (975A only)

1 Certificate of Calibration

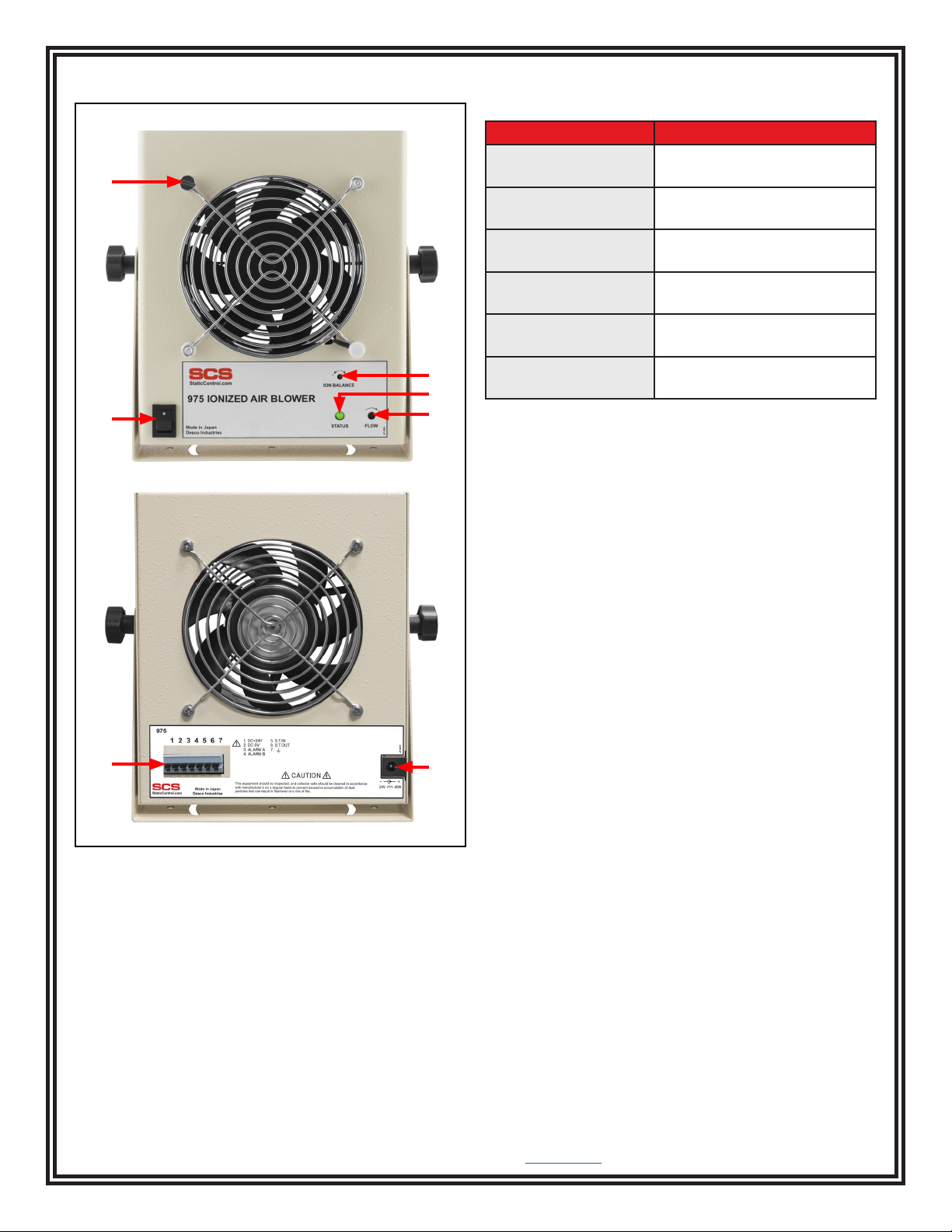

Figure 1. SCS 975 Ionized Air Blower

Made in Japan