Sea-Bird Electronics SBE 63 User manual

SBE 63

Digital Optical Dissolved Oxygen Sensor

User’s Manual

Sea-Bird Electronics, Inc.

13431 NE 20th Street

Bellevue, Washington 98005 USA

Telephone: 425/643-9866

Fax: 425/643-9954 Manual Version #005, 04/15/13

E-mail: seabird@seabird.com Firmware Version 3.0.1 and later

Website: www.seabird.com SeatermV2 version 2.2.6 and later

Optional Sensor Mount for

installation on SeaCAT CTD

SBE 63 DO Sensor

(plastic housing)

SBE 63 DO Sensor

(titanium housing)

2

Limited Liability Statement

Extreme care should be exercised when using or servicing this equipment. It should be used or serviced

only by personnel with knowledge of and training in the use and maintenance of oceanographic

electronic equipment.

SEA-BIRD ELECTRONICS, INC. disclaims all product liability risks arising from the use or servicing

of this system. SEA-BIRD ELECTRONICS, INC. has no way of controlling the use of this equipment

or of choosing the personnel to operate it, and therefore cannot take steps to comply with laws

pertaining to product liability, including laws which impose a duty to warn the user of any dangers

involved in operating this equipment. Therefore, acceptance of this system by the customer shall be

conclusively deemed to include a covenant by the customer to defend, indemnify, and hold SEA-BIRD

ELECTRONICS, INC. harmless from all product liability claims arising from the use or servicing of

this system.

Manual revision 005 Declaration of Conformity SBE 63

3

Declaration of Conformity

Manual revision 005 Table of Contents SBE 63

4

Table of Contents

Limited Liability Statement ............................................................................2

Declaration of Conformity ..............................................................................3

Table of Contents .............................................................................................4

Section 1: Introduction ....................................................................................5

About this Manual ............................................................................................ 5

Quick Start ........................................................................................................ 5

Unpacking SBE 63............................................................................................ 6

Section 2: Description of SBE 63 ....................................................................7

System Description ........................................................................................... 7

Specifications.................................................................................................... 8

Dimensions and Connector ............................................................................... 9

Section 3: Preparing SBE 63 for Deployment .............................................10

Software Installation ....................................................................................... 10

Power and Communications Test ................................................................... 10

Test Setup .................................................................................................10

Test ...........................................................................................................11

Section 4: Deploying and Operating SBE 63 ...............................................16

Sampling Modes ............................................................................................. 16

Polled Sampling........................................................................................16

Autonomous Sampling .............................................................................18

Command Descriptions................................................................................... 20

Data Formats................................................................................................... 27

Deployment..................................................................................................... 29

Integration with SeaCAT CTD

(SBE 16plus V2, 16plus-IM V2, or 19plus V2) .......................................29

Integration with MicroCAT CTD

(SBE 37-SMP-ODO, 37-IMP-ODO, 37-SIP-ODO).................................30

Recovery ......................................................................................................... 31

Section 5: Routine Maintenance and Calibration .......................................32

Corrosion Precautions..................................................................................... 32

Connector Mating and Maintenance ............................................................... 32

Sensor Maintenance ........................................................................................ 33

Sensor Calibration........................................................................................... 34

Section 6: Troubleshooting............................................................................35

Problem 1: Unable to Communicate with SBE 63.......................................... 35

Problem 2: Unreasonable Data ....................................................................... 35

Glossary ..........................................................................................................37

Appendix I: Functional Description .............................................................38

Appendix II: Installation/Removal from Optional Sensor Mount ............42

Appendix III: Command Summary .............................................................43

Appendix IV: Replacement Parts.................................................................44

Appendix V: Manual Revision History ........................................................45

Index................................................................................................................46

Manual revision 005 Section 1: Introduction SBE 63

5

Section 1: Introduction

This section includes a Quick Start procedure, and photos of a standard

SBE 63 shipment.

About this Manual

This manual is to be used with the SBE 63 Digital Optical Dissolved Oxygen

Sensor. It is organized to guide the user from installation through operation

and data collection. We’ve included detailed specifications, command

descriptions, maintenance and calibration information, and helpful notes

throughout the manual.

Sea-Bird welcomes suggestions for new features and enhancements of our

products and/or documentation. Please contact us with any comments or

Monday through Friday, 0800 to 1700 Pacific Standard Time (1600 to 0100

Universal Time) in winter and 0800 to 1700 Pacific Daylight Time (1630 to

0000 Universal Time) the rest of the year.

Quick Start

Follow these steps to get a Quick Start using the SBE 63.

The manual provides step-by-step details for performing each task:

1. Perform pre-check procedures (see Section 3: Preparing SBE 63

for Deployment):

A. Test power and communications.

2. Deploy the SBE 63 (see Section 4: Deploying and Operating SBE 63):

A. Establish setup and operating parameters.

B. Check status (GetSD) and calibration coefficients (GetCC) to verify

setup.

C. Install I/O cable connector and locking sleeve, and mount SBE 63.

D. Deploy SBE 63.

Manual revision 005 Section 1: Introduction SBE 63

6

Unpacking SBE 63

Shown below is a typical SBE 63 shipment.

Software, and Electronic Copies of

Software Manuals and User Manual

OR

Optional sensor mount for installation on

SBE 16plus V2, 16plus-IM V2, or 19plus V2

SBE 63 (plastic housing)

SBE 63 (titanium housing)

Manual revision 005 Section 2: Description of SBE 63 SBE 63

7

Section 2: Description of SBE 63

This section describes the functions and features of the SBE 63, including

specifications and dimensions.

System Description

The SBE 63 is an easy-to-use, light, compact instrument ruggedly made of

titanium and other low-maintenance (plastic) materials, designed to be

incorporated into oceanographic sensing systems at depths up to 600 or

7000 meters (1960 or 23,000 feet). Commands sent to the SBE 63 provide

status display, data acquisition setup, and diagnostic tests. Its data is

telemetered by its internal, 3-wire, RS-232C interface. The SBE 63 has no

sample memory or internal batteries.

The SBE 63 samples in two modes:

•Autonomous sampling –The SBE 63 samples at pre-programmed

intervals of 1 to 32,767 seconds. It can be set to average up to

255 measurements per sample, and transmits the averaged data.

The SBE 63 can be programmed to begin autonomous sampling when

power is applied or on command.

•Polled sampling – On command, the SBE 63 takes one sample and

transmits the data.

The SBE 63 outputs raw or converted (ASCII engineering units) data in one of

a number of formats, for compatibility with existing CTDs.

Each SBE 63 is calibrated individually in a temperature-controlled bath.

Bath temperatures are varied at each of 4 oxygen values, providing a

comprehensive 24-point calibration. Two reference sensors in each bath are

standardized against Winkler titrations. Response time tests are conducted on

each sensor, using gas. Salinity and pressure impacts on sensor response are

each checked at two separate points.

The SBE 63 is designed for use in a CTD's pumped flow path. Water does not

freely flow through the plumbing between samples, allowing anti-foul

concentration inside the system to maintain saturation and eliminating

exposure of the sensor to light, maximizing bio-fouling protection. The

elapsed time between the CTD and associated oxygen measurement is easily

quantified, and corrected for in post-processing.

Configuration options:

•With the optional sensor mount, the SBE 63 can be plugged into the

RS-232 auxiliary sensor connector of the SBE 16plus V2, 16plus-IM V2,

or 19plus V2 SeaCAT CTD. Configuration choices include a 600-meter

plastic housing or 7000-meter titanium housing, and an XSG or

wet-pluggable MCBH connector.

•The SBE 63 with a 600-meter plastic or 7000-meter titanium housing can

be integrated into an SBE 37 MicroCAT (37-IMP-ODO, 37-SMP-ODO,

or 37-SIP-ODO).

•On an SBE 41 (Argo float) CTD, the SBE 63 has a 7000-meter titanium

housing. The SBE 63 is physically integrated with the CTD; however,

electronic operation of the SBE 63 requires an RS-232 interface in the

float controller.

SBE 63 (plastic housing)

SBE 63 (titanium housing)

Manual revision 005 Section 2: Description of SBE 63 SBE 63

8

The SBE 63 is supplied with a powerful Windows software package,

Seasoft V2, which includes:

•SeatermV2 - terminal program for communication and data retrieval.

SeatermV2 is a launcher, and launches the appropriate terminal program

for the selected instrument (Seaterm232 for RS-232 instruments such as

this SBE 63).

•Seasave V7 – program for acquiring, converting, and displaying real-time

or archived raw data.

•SBE Data Processing – program for calculation and plotting of

conductivity, temperature, pressure, auxiliary sensor data (such as

dissolved oxygen), and derived variables such as salinity and sound

velocity.

Specifications

Measurement

Range

120% of surface saturation in all natural waters,

fresh and salt

Initial Accuracy Larger of ±3 µmol/kg (equivalent to 0.07 ml/L or 0.1 mg/L)

or ±2%

Resolution 0.2 µmol/kg

Sample-Based

Drift < 1 µmol/kg / 100,000 samples (20 °C)

Response Time

(

τ

, 63%

response)

< 6 sec (20 °C)

Sampling

Speed 1 Hz (1 sample/sec)

Calibration

Each sensor fully and individually calibrated

(0 – 450 µmol/kg oxygen, 0 – 30 °C, 0 – 35 psu,

0 – 2000 dbars)

8 coefficients plus 4 temperature compensation

coefficients

Input Power 6 - 24 VDC, 35 mA (0.08 J/sample)

Output Signal RS-232, 600-115,200 baud (user-selectable),

8 data bits, no parity, 1 stop.

Depth rating,

housing, and

weight (in air)

Sensor:

600 m (1960 ft) plastic housing: 245 g (0.54 lbs)

7000 m (16,400 ft) titanium housing: 270 g (0.60 lbs)

Optional sensor mount for use with

SBE 16plus V2, 16plus-IM V2, or 19plus V2:225 g (0.50 lbs)

Notes:

•Help files provide detailed

information on the software.

•A separate software manual on CD-

ROM contains detailed information

on the setup and use of Seasave V7

and SBE Data Processing.

•Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

Manual revision 005 Section 2: Description of SBE 63 SBE 63

9

Dimensions and Connector

SBE 63 sensor installed in sensor

mount, for use with RS-232

auxiliary sensor channel on CTD

(SBE 16plus V2, 16plus-IM V2, or

19plus V2 SeaCAT)

SBE 63 sensor for integration with

SBE 37 ODO MicroCAT (600 m or 7000 m housing), or

SBE 41 (Argo) CTD (7000 m housing)

Manual revision 005 Section 3: Preparing SBE 63 for Deployment SBE 63

10

Section 3:

Preparing SBE 63 for Deployment

This section describes installing software and testing power and

communications.

Software Installation

Seasoft V2 was designed to work with a PC running Windows XP service

pack 2 or later, Windows Vista, or Windows 7.

If not already installed, install SeatermV2 and other Sea-Bird software

programs on your computer using the supplied software CD:

1. Insert the CD in your CD drive.

2. Install software: Double click on SeasoftV2.exe. Follow the dialog box

directions to install the software. The installation program allows you to

install the desired components. Install all the components, or just install

SeatermV2, Seasave V7, and SBE Data Processing.

The default location for the software is c:\Program Files\Sea-Bird. Within that

folder is a sub-directory for each program.

Power and Communications Test

The power and communications test will verify that the system works,

prior to deployment.

Test Setup

1. Remove dummy plug (if applicable):

A. By hand, unscrew the locking sleeve from the SBE 63’s bulkhead

connector. If you must use a wrench or pliers, be careful not to

loosen the bulkhead connector instead of the locking sleeve.

B. Remove the dummy plug from the SBE 63’s I/O bulkhead connector

by pulling the plug firmly away from the connector.

2. Standard Connector - Install the I/O cable connector, aligning the raised

bump on the side of the connector with the large pin (pin 1 - common) on

the SBE 63 sensor mount. OR

MCBH Connector – Install the I/O cable connector, aligning the pins.

3. Connect the I/O cable connector to your computer’s serial port.

4. Connect the I/O cable connector’s red (+) and black (-) wires to a power

supply (6 – 24 VDC).

Notes:

•Help files provide detailed

information on the software.

•It is possible to use the SBE 63

without the SeatermV2 terminal

program by sending direct

commands from a dumb terminal or

terminal emulator, such as Windows

HyperTerminal.

•Sea-Bird supplies the current

version of our software when you

purchase an instrument. As software

revisions occur, we post the revised

software on our FTP site. See our

website (www.seabird.com) for the

latest software version number, a

description of the software changes,

and instructions for downloading the

software from the FTP site.

I/O cable

Locking sleeve

Note:

SBE 63 integrated with a MicroCAT

(37-SMP-ODO, IMP-ODO, SIP-ODO):

See the MicroCAT manual for

information on communicating with the

SBE 63 through the MicroCAT.

Manual revision 005 Section 3: Preparing SBE 63 for Deployment SBE 63

11

Test

1. Double click on SeatermV2.exe. The main screen looks like this:

SeatermV2 is a launcher. Depending on the instrument selected, it

launches Seaterm232 (RS-232 instruments), Seaterm485 (RS-485

instruments), or SeatermIM (inductive modem instruments).

2. In the Instruments menu, select SBE 63 Dissolved Oxygen Sensor.

Seaterm232 opens; the main screen looks like this:

•Menus – For tasks and frequently executed instrument commands.

•Send Commands window – Contains commands applicable to your

SBE 63. The list appears after you connect to the SBE 63.

•Command/Data Echo Area – Title bar of this window shows

Seaterm232’s current comm port and baud rate. Commands and the

SBE 63 responses are echoed here. Additionally, a command can be

manually typed or pasted (ctrl + V) here. Note that the SBE 63 must

be connected and awake for it to respond to a command.

•Status bar – Provides connection, script, and capture status

information.

Notes:

•You can use any terminal

program to set up the SBE 63;

set it to 8 data bits, no parity,

1 stop bit, and 9600 baud (default

SBE 63 baud rate). Instructions

here are for using SeatermV2.

•See SeatermV2’s Help files.

Note:

See Seaterm232’s Help files.

Capture

status

Status –

Connecting,

Ready, etc.

Status Bar

Command/Data Echo Area

Send Commands

Window

Menus

Manual revision 005 Section 3: Preparing SBE 63 for Deployment SBE 63

12

Following is a description of the menus:

Menu

Description

Equivalent Command*

File

•Load command file – opens selected .XML

command file, and fills Send Commands

window with commands

•Unload command file – closes command

file, and removes commands from Send

Commands window

•

Exit - Exit program.

—

Communications

•Connect – connect to comm port

•Disconnect – disconnect from

comm port

•Configure – Establish communication

parameters (comm port and baud rate).

•Disconnect and reconnect – may be useful

if SBE 63 has stopped responding

—

Command

•Abort – interrupt and stop SBE 63

response

•Send stop command

Remaining menu items are not applicable to

SBE 63

•(press Esc key)

•Stop

Capture

Capture SBE 63 responses on screen to file,

to save real-time data or use for diagnostics.

File has .cap extension.

Click Capture again to turn off capture.

Capture status displays in Status bar.

—

Upload

Not applicable to SBE 63

—

Tools

•Diagnostics log - Keep a diagnostics log.

•Convert .XML data file – not applicable to

SBE 63

•Send script – Send XML script to SBE 63.

May be useful if you have a number of

SBE 63s to program with same setup.

—

*See Command Descriptions in Section 4: Deploying and Operating

SBE 63.

Manual revision 005 Section 3: Preparing SBE 63 for Deployment SBE 63

13

3. If this is the first time Seaterm232 is being used, the Serial Port

Configuration dialog box displays:

Make the desired selections, and click OK.

4. Seaterm232 tries to automatically connect to the SBE 63. As it connects,

it sends GetHD and displays the response, which provides factory-set

data such as instrument type, serial number, and firmware version.

Seaterm232 also fills the Send Commands window with the correct list

of commands for your SBE 63.

If there is no communication:

A. In the Communications menu, select Configure. The Serial Port

Configuration dialog box appears. Select the Comm port and baud

rate for communication, and click OK. Note that the factory-set baud

rate is documented on the Configuration Sheet. .

B. In the Communications menu, select Connect (if Connect is grayed

out, select Disconnect and reconnect). Seaterm232 will attempt to

connect at the baud specified in Step A, but if unsuccessful will then

cycle through all other available baud rates.

C. If there is still no communication, check cabling between the

computer and SBE 63, and try to connect again.

D. If there is still no communication, repeat Step A with a different

comm port, and try to connect again.

After Seaterm232 displays the GetHD response, it provides an S> prompt

to indicate it is ready for the next command.

Note:

Seaterm232’s baud rate must be the

same as the SBE 63 baud rate (set

with SetBaud=). Baud is factory-set

to 9600, but can be changed by the

user (see Command Descriptions in

Section 4: Deploying and Operating

SBE 63). Other communication

parameters – 8 data bits, 1 stop bit,

and no parity – cannot be changed.

Computer COM port and baud rate for

communication between computer and

SBE 63. Seaterm232 tries to connect at

this baud rate, but if unsuccessful will

cycle through all available baud rates.

Update COM Port pulldown to

include connected USB ports.

Manual revision 005 Section 3: Preparing SBE 63 for Deployment SBE 63

14

Taking a look at the Send Commands window:

You can use the Send Commands window to send commands, or simply type

the commands in the Command/Data Echo area if desired.

Click on desired command

description in list.

Help box describes

selected command in more

detail.

Enter any command

arguments (such as

desired output format) in

this box.

Click Execute when ready

to send selected

command.

This box

shows selected

command.

Manual revision 005 Section 3: Preparing SBE 63 for Deployment SBE 63

15

5. Display SBE 63 setup and hardware information by typing GetHD and

pressing the Enter key. The display looks like this:

<HardwareData DeviceType = 'SBE063' SerialNumber = '0013'>

<Manufacturer>Sea-Bird Electronics, Inc.</Manufacturer>

<FirmwareVersion>3.0.1</FirmwareVersion>

<FirmwareDate>Apr 9 2013 10:30:28</FirmwareDate>

<CommandSetVersion>1.2</CommandSetVersion>

<MFGDate>04142</MFGDate>

<PCBAssembly>41755</PCBAssembly>

<PCBSerialNum>00013</PCBSerialNum>

<PCBAssembly>41756</PCBAssembly>

<PCBSerialNum>00013</PCBSerialNum>

<FilmSerialNum>00077</FilmSerialNum>

<Supply Voltage>8.63</Supply Voltage>

<LoaderVersion>SBE 63 FirmwareLoader V 1.0</LoaderVersion>

<CalibrationDate>04826</CalibrationDate>

<HardwareConfig>

<BaudRate>009600</BaudRate>

<BlueOnTime>0000000</BlueOnTime>

<SampleAvg>002</SampleAvg>

<SampleInterval>00004</SampleInterval>

<BootDelay>001</BootDelay>

<OutFormat>01</OutFormat>

<AnalogGain>2</AnalogGain>

<AnalogOffset>00</AnalogOffset>

<AutoRun>0</AutoRun>

<BlueTupdate>0</BlueTupdate>

<SerPause>1</SerPause>

<Echo>1</Echo>

<Flags>0x0023</Flags>

</HardwareConfig>

</HardwareData>

6. Command the SBE 63 to take a sample by typing TS and pressing the

Enter key. The display looks like this (if SBE 63 is set up with

SetFormat=1):

16.411,0.550736,5.980,25.0011

where 16.411 = raw phase delay

0.550736 = raw thermistor voltage

5.980 = converted oxygen in ml/l

25.0011 = temperature in deg C

The SBE 63 is ready for programming and deployment.

Manual revision 005 Section 4: Deploying and Operating SBE 63 SBE 63

16

Section 4: Deploying and Operating SBE 63

This section provides instructions for deploying the SBE 63. It includes:

•Sampling modes, including example sets of commands

•Command descriptions

•Data output formats

•Deployment

•Recovery

Sampling Modes

The SBE 63 has two sampling modes for obtaining data:

•Polled Sampling

•Autonomous Sampling

Shown below are descriptions and examples of the two sampling modes. Note

that the SBE 63’s response to each command is not shown in the examples.

Review the operation of the sampling modes and the commands described in

Command Descriptions before setting up your system.

Polled Sampling

On command (TS or TSR), the SBE 63 takes one sample of data and transmits

the data.

Examples continued on next page

Example 1: Polled Sampling (user input in bold).

Set up to wait for a command upon power up (SetAutoRun=0). Set up to

echo commands (SetEcho=1), output converted oxygen and temperature

data (SetFormat=0), and average 2 measurements/sample (SetAvg=2).

Verify setup with status (GetHD) command. Remove power.

(Apply power, then select Connect in Seaterm232’s Communications

menu to connect and wake up.)

S>SETAUTORUN=0

S>SETECHO=1

S>SETFORMAT=0

S>SETAVG=2

S>GETHD (to verify setup)

(Remove power.)

When ready to take a sample (repeat as desired): apply power, establish

communications with SBE 63, command it to take a sample and output

data in format established with SetFormat=, and remove power.

(Apply power, then select Connect in Seaterm232’s Communications

menu to connect and wake up.)

(Before first sample, click Capture menu to capture data to a file –

Seaterm232 requests file name for data to be stored.)

S>TS

(Remove power.)

Notes:

•Sea-Bird ships the SBE 63 with

SetAutoRun=0 (it will not

automatically start sampling when

power is applied). If you previously

sent SetAutoRun=1 (it

automatically started sampling

when power was applied), press the

Esc key to stop sampling. You will

then be able to send commands to

change the setup.

•SBE 63 response to commands is

not shown in examples.

Note:

Separate software manuals and

Help files contain detailed

information on installation, setup,

and use of Sea-Bird’s software.

Manual revision 005 Section 4: Deploying and Operating SBE 63 SBE 63

17

Example 2: Polled Sampling with SBE 16plus V2 (user input in bold).

Set up to wait for a command upon power up (SetAutoRun=0). Set up to

echo commands (SetEcho=1), average 2 measurements per output sample

(SetAvg=2), and output data in a format compatible with 16plus V2

(SetFormat=1). Set SBE 63 baud rate to same baud as 16plus V2 (assume

9600 baud for this example). Verify setup with status (GetHD) command.

Remove power.

(Apply power to SBE 63, then select Connect in Seaterm232’s

Communications menu to connect to and wake up SBE 63.)

S>SETAUTORUN=0

S>SETECHO=1

S>SETAVG=2

S>SETFORMAT=1

S>SETBAUD=9600 (get message to re-enter baud)

SB>SETBAUD=9600

(In Seaterm232’s Communications menu, select Configure. Change baud

to 9600 and click OK. In Seaterm232’s Communications menu, select

disconnect and reconnect. You will now be communicating at new baud).

S>GETHD (to verify setup)

(Remove power from SBE 63.)

When ready to begin sampling: Connect SBE 63 to 16plus V2 RS-232

auxiliary sensor connector. Start autonomous sampling in 16plus V2 (see

16plus V2 manual). Each time SBE 16plus V2 takes a measurement, it

applies power to and requests a sample from SBE 63 using TS command.

When ready to stop sampling: Stop autonomous sampling in 16plus V2.

Example 3: Polled Sampling with SBE 41 (Argo float) CTD that is not

making continuous oxygen measurements (user input in bold).

Set up to wait for a command upon power up (SetAutoRun=0). Set up to

echo commands (SetEcho=1), output raw and converted oxygen and

temperature data (SetFormat=1), to average 2 measurements/sample

(SetAvg=2). Verify setup with status (GetHD) command. Remove power.

(Apply power, then select Connect in Seaterm232’s Communications

menu to connect and wake up.)

S>SETAUTORUN=0

S>SETECHO=1

S>SETFORMAT=1

S>SETAVG=2

S>GETHD (to verify setup)

(Remove power.)

When ready to begin sampling: Connect SBE 63 to SBE 41. Each time

SBE 41 takes an oxygen measurement, it applies power to and requests a

sample from SBE 63 using TS command.

Note:

When using the SBE 63 with an

SBE 16plus V2, 16plus-IM V2, or

19plus V2 CTD, the following setup in

the SBE 63 is required:

•SetBaud= to the baud rate set in the

CTD (1200 for the 16plus-IM V2)

•SetEcho=1

•SetFormat=1

•SetAvg=1 to 16; recommended

value is 2

•SetAutoRun=0

In the CTD, set:

•Pump mode to 2 (PumpMode=2).

•Delay before sampling

(DelayBeforeSampling=) to

25 sec at 15 °C to 40 sec at 0 °C

(linear interpolation between those

values). This provides enough time

for the SBE 63 to equilibrate after

pumping begins, before the

measurement is made.

In the CTD, the interval between

samples (SampleInterval=) must be

greater than or equal to the sum of the

times required to sample. Total time is

affected by the following:

- Minimum time required for CTD to

take a sample (≈ 2.5 sec).

- Time required for integration of

optional Quartz pressure sensor

(ParosIntegration=).

- Time required for CTD to take and

average NCycles= samples; samples

are taken 0.25 sec apart.

- Delay after providing power to

external sensors before sampling

(DelayBeforeSampling=); described

above.

- Delay after sampling before turning

off power to external sensors

(DelayAfterSampling=).

For the 16plus-IM V2, commands are

preceded by #ii (ii=ID).

Manual revision 005 Section 4: Deploying and Operating SBE 63 SBE 63

18

Autonomous Sampling

The SBE 63 does not have an internal (standby) real-time clock. Therefore,

once you start autonomous sampling, power to the SBE 63 must remain on for

autonomous sampling to continue at the specified interval.

SetAutoRun defines how sampling starts:

SetAutoRun=

To Start

Autonomous

Sampling

To Stop Autonomous Sampling

0(default)

Send Start.

•Turn off power, or

•Click Esc (stopping this way allows

you to then send commands to

check/modify the setup), or

•Send Stop (stopping this way allows

you to then send commands to

check/modify the setup).

1Turn on power.

Examples continued on next page

Example 1: Autonomous Sampling Setup for SetAutoRun=0 (user

input in bold).

Set up to wait for a command upon power up (SetAutoRun=0).

Set up to echo commands (SetEcho=1), take and output a sample every

10 sec (SetInterval=10), averaging 2 measurements per output sample

(SetAvg=2), and output converted oxygen and temperature data

(SetFormat=0). Verify setup with status (GetHD) command. Remove

power.

(Apply power, then select Connect in Seaterm232’s Communications

menu to connect and wake up.)

S>SETAUTORUN=0

S>SETECHO=1

S>SETINTERVAL=10

S>SETAVG=2

S>SETFORMAT=0

S>GETHD (to verify setup)

(Remove power.)

When ready to begin sampling:

(Apply power, then select Connect in Seaterm232’s Communications

menu to connect and wake up.)

S>START

When ready to stop sampling:

(Send Stop, click Esc, or remove power.)

Note:

Sea-Bird ships the SBE 63 with

SetAutoRun=0 (it will not

automatically start sampling when

power is applied). If you send

SetAutoRun=1, turn power off and

then on again to start sampling, or

send Start.

Manual revision 005 Section 4: Deploying and Operating SBE 63 SBE 63

19

Example 2: Autonomous Sampling Setup for SetAutoRun=1 for use

with power supply and logger.

Set up to start sampling when power is applied (SetAutoRun=1).

Set up to echo commands (SetEcho=1), take samples at 10-sec intervals

(SetInterval=10), average 2 measurements per output sample

(SetAvg=2), output converted oxygen and temperature data

(SetFormat=0), and set the delay before sampling to the minimum value

(SetBootDelay=). Verify setup with status (GetHD) command. Remove

power.

(Apply power, then select Connect in Seaterm232’s Communications

menu to connect and wake up.)

S>SETAUTORUN=1

S>SETECHO=1

S>SETINTERVAL=10

S>SETAVG=2

S>SETFORMAT=0

S>SETBOOTDELAY=1

S>GETHD (to verify setup)

(Remove power from SBE 63.)

When ready to begin sampling, connect SBE 63 to power supply and data

logger.

(Apply power – SBE 63 automatically begins sampling at 10-sec

intervals.)

When ready to stop sampling:

(remove power.)

Manual revision 005 Section 4: Deploying and Operating SBE 63 SBE 63

20

Command Descriptions

This section describes commands and provides sample outputs.

See Appendix III: Command Summary for a summarized command list.

When entering commands:

•Input commands to the SBE 63 in upper or lower case letters and register

commands by pressing the Enter key (0xD).

•Commands to enable a parameter can be entered with the argument as

Y or 1 for yes, and N or 0 for no (for example, SetAutoRun=y and

SetAutoRun=1 are equivalent; both enable automatic starting of sampling

when power is applied).

•The SBE 63 sends Command failed: Unknown command

if an invalid command is entered.

•If the SBE 63 does not return an S> prompt after executing a command,

press the Enter or Esc key to get the S> prompt.

•If the SBE 63 is transmitting data and you want to stop it, press the Esc

key or send Stop. Alternatively, remove power.

•All commands that change setup take effect immediately, and are

committed to nonvolatile storage (SBE 63 retains settings when power is

removed).

Table of contents

Popular Accessories manuals by other brands

Treatlife

Treatlife SK50 instructions

Hally-Gally

Hally-Gally Piccolo 20.02.118 Assembly instructions

Gewiss

Gewiss Chorus GW 90 769 manual

PCB Piezotronics

PCB Piezotronics IMI SENSORS 649A04 Installation and operating manual

Bumbleride

Bumbleride car seat cover Product guide

Dometic

Dometic CK40D Hybrid operating manual

Honeywell

Honeywell RPW203A Mounting instruction

CONVEY-ALL

CONVEY-ALL 1635-FL Operator's manual

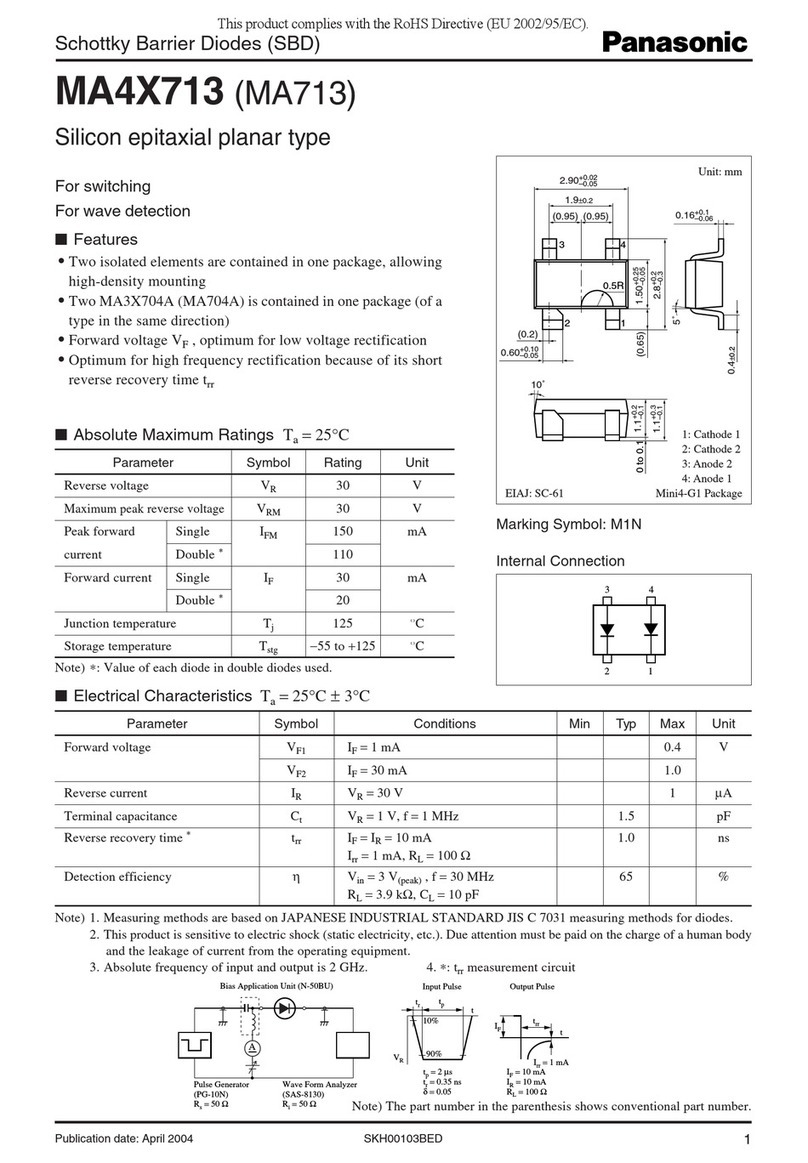

Panasonic

Panasonic MA4X713 (MA713) Specification sheet

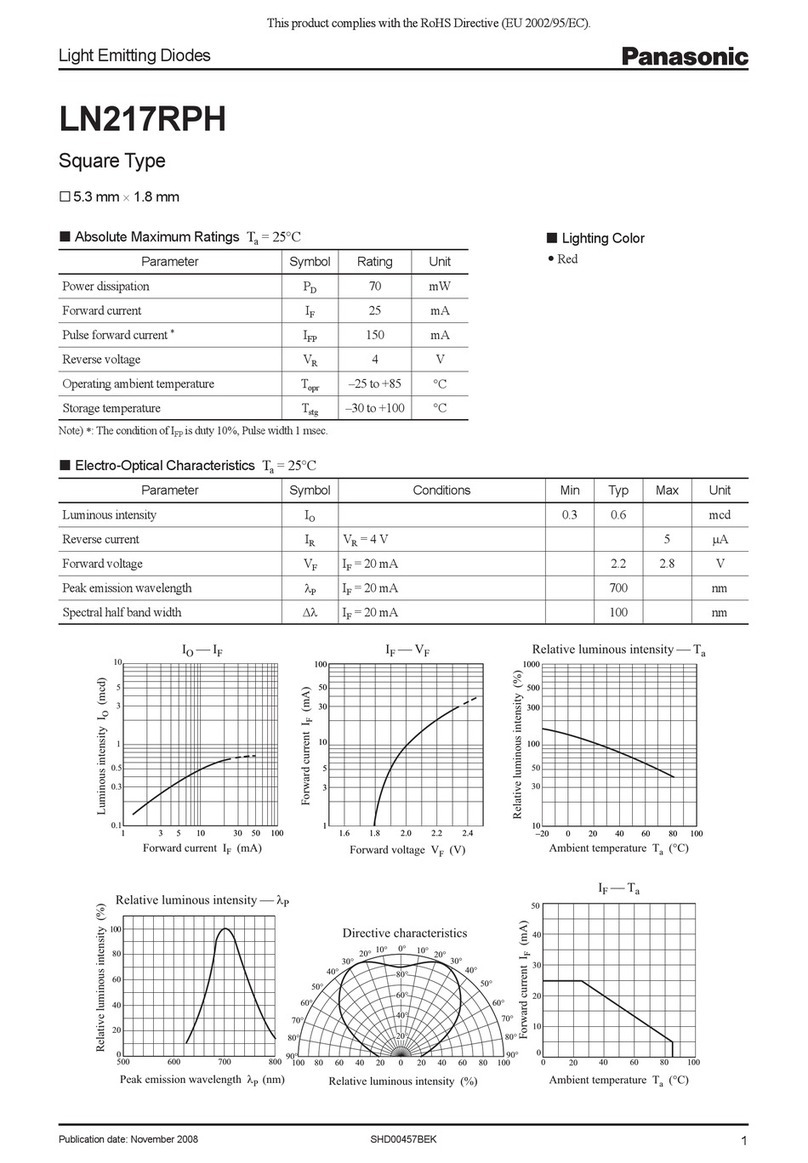

Panasonic

Panasonic Light Emitting Diodes LN217RPH Specifications

Endress+Hauser

Endress+Hauser ISEmax CAS40D operating instructions

Arctic Cove

Arctic Cove COOL CAVE MPK1180 Operator's manual