SeaCom Rolltrailer User manual

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 1 / 21

O P E R A T I N G

M A N U A L

- Original -

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 2 / 21

Product

Seacom Rolltrailer

RT 80’ 150t

Serial no.

A 5502 / 1-7

Drawing no.

06.01.8082

Customer

Atlantic Container Line

ACL AB

S-403 36 Gothenburg

Supplier

Transport Systems Seacom AG

Berbiceweg 5

CH –8212 Neuhausen

Tel. +41 (0) 52 632 04 00

Fax +41 (0) 52 632 04 09

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 3 / 21

Table of contents

1. CE-DECLARATION OF CONFORMITY

2. PREFACE

3. RESIDUAL RISK

4. SPECIFICATION

5. OPERATING INSTRUCTIONS

6. SERVICE MANUAL

7. SPARE PART LIST

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 4 / 21

1 CE DECLARATION OF CONFORMITY

Transport Systems Seacom AG

Neuhausen, Schweiz

EG-Konformitäts-Erklärung

EC Declaration of Conformity

im Sinne der EG-Richtlinie Maschinen 2006/42/EG, Anhang II A

in the sense of EC Machinery Directive 2006/42/EC, annex II A

Produktbezeichnung:

Product:

Rolltrailer 80’ 150t

24,3x3,0x1,05/1,15m

STS-Nummer:

STS-Number:

A 5502 / 1-7

06.01.8082

Hersteller:

Manufacturer:

Transport Systems Seacom AG

Berbiceweg 5

CH –8212 Neuhausen

Der Hersteller deklariert, dass das bezeichnete

Produkt in Übereinstimmung mit folgender

Richtlinie entwickelt, konstruiert und gefertigt

wurde:

The manufacturer declares that the above men-

tioned product is developed, designed and

manufactured according to:

EG-Maschinen Richtlinien (2006/42/EG)

EC Machinery Directive (2006/42/EC)

Folgende harmonisierte Normen sind ange-

wandt:

The following national standards, directives and

specifications have been applied:

EN ISO 12100-1/ -2 (Sicherheit von Maschinen -

Grundbegriffe, allgemeine Gestaltungsleitsätze)

/ (Safety of machinery - Basic concepts, general

principles)

EN ISO 14121-1 (Sicherheit von Maschinen -

Risikobeurteilung) / (Safety of machinery - Risk

assessment)

EN 287-1 (Prüfung von Schweißern - Schmelz-

schweißen - Teil 1: Stähle) / (Qualification test of

welders - Fusion welding - Part 1: Steels)

Neuhausen, 22. July 2011

Heinz Althammer

Trailer Systems Seacom AG

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 5 / 21

2 PREFACE

Please read this documentation carefully in order to avoid accidents. This way you can make sure

that all warranty conditions are complied with and the trailer will be working well at any time.

HOW TO USE THE TRAILER CORRECTLY

The trailer is produced for internal transport only.

Please do not exceed the max. capacity stated on the type plate.

Damages caused by overloading are not covered by warranty.

Please observe the following operating instructions carefully.

The trailer may only be operated, maintained and repaired by trained persons.

Unauthorized modifications of the trailer will lead to expiry of warranty.

All rules and regulations for accident preventions have to be adhered to.

WARRANTY

Any warranty claims can only be considered, if all service and maintenance works has been

carried out on schedule. The operator has to keep records about all maintenance and repair

works.

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 6 / 21

3 RESIDUAL RISK

Danger

of getting caught or crushed during the coupling by the trailer.

Persons that are near the trailer during hitching and unhitching can get caught

or run over.

It needs to be ensured that no persons are in the danger area during

the coupling operation.

Warning

Dangers from overloading.

An overload of the trailer can cause major damages to the trailer and endan-

ger persons.

The load limitations must be observed.

Warning

Dangers from collision.

Parts of the load that extend over the cargo bed can collide with the surround-

ings, cause damage and endanger persons.

Before the transport, the driver must make sure that no collision is

possible.

Warning

Danger of getting caught or crushed by the trailer.

Danger when driving on inclines: The trailer or the cargo can slide away or tip,

especially when:

the trailer is loaded to maximum

the load has a high centre of gravity

the road surface is uneven or slippery (dirt, ice)

the speed is too high

braking or accelerating suddenly

The road surface should be paved well enough. Speed should be reduced on

inclines and driven with greatest caution. The cargo's centre of gravity should

lie in the middle of the loading area if possible. Adapt the speed to the condi-

tions.

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 7 / 21

Danger

of getting caught by the trailer.

Persons situated in front or close next to the moving trailer are in danger of

being caught and crushed by it.

As long as the trailer is moving, the driver must ensure that no persons

are situated in the danger area of the trailer.

Warning

Danger during maintenance.

Danger of injury from improper operation and maintenance.

All specifications concerning operation, inspection and maintenance must be

observed. In case of doubt, the supplier needs to be consulted.

Danger

during maintenance on a jacked up trailer.

The trailer needs to be sufficiently supported before maintenance and secured

against rolling away.

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 8 / 21

4 SPECIFICATION

Load capacity

150

t

Dead weight

approx.

30,6

t

Maximum speed

fully laden

6

km/h

empty

16

km/h

Platform length

approx.

24.300

mm

Platform width

approx.

3.000

mm

Platform height front/rear

approx.

1.050/1.150

mm

Total length

incl. gooseneck approx.

27.400

mm

Coupling height

1.350

mm

Rear overhang

8.400

mm

Axle load

4x 35,8

t

Fifth wheel load

37,5

t

Fixed gooseneck

with king pin standard

2”

Axle

2

pcs

Tyres

solid rubber

28x10x22

number of tyres

16

pcs

Brakes

air brake system

Loading platform

steel plate

10

mm

Accessories

lashing rail in the platform

D-Rings in front and rear

Finish

dry thickness

approx. 100/120

my

Colour (oxide red)

RAL 3009

Measurements and weight may vary slightly.

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 9 / 21

5 OPERATING INSTRUCTIONS

Intended use

The rolltrailer's intended use is for internal transport.

The driver of the tractor has to inspect the rolltrailer for detectable faults before the start of

operation.

Coupling

Reverse the truck towards the front of the rolltrailer, take care that the middle of the fifth wheel

is directing towards the king pin of the fixed gooseneck.

Then lift the fifth wheel coupling so that it is parallel to and under the gliding plate of the fixed

gooseneck.

Reverse the truck carefully till resistance is felt and fifth wheel has locked with king pin.

Make sure that the coupling is firmly engaged with the rolltrailer.

Connect brake lines.

Lift the rolltrailer until the front of it is approximately 100 –150 mm over the ground.

Driving

The rolltrailer shall only be towed by suitable towing vehicles with a fifth wheel lifting capacity

of at least 37,5 t and a lifting height of at least 750 mm.

The transport of persons is not permitted.

The road surface should be in reasonable condition, and without obstacles.

In any case, the prescribed speeds and safety regulations must be observed.

The maximum permitted speed, straight ahead with full load of 150 t is 6 km/h.

In curves the speed should be reduced appropriately.

When reversing, seek a guide, if visibility is insufficient.

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 10 / 21

Loading

Make sure that the rolltrailer is parked on horizontal ground.

The weight of the cargo put on the rolltrailer shall not exceed the maximum capacity.

Distributed load

To avoid overloading always ensure that the centre of gravity of the load is as close to the

centre of the load area of the rolltrailer as possible (see the following loading scheme).

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 11 / 21

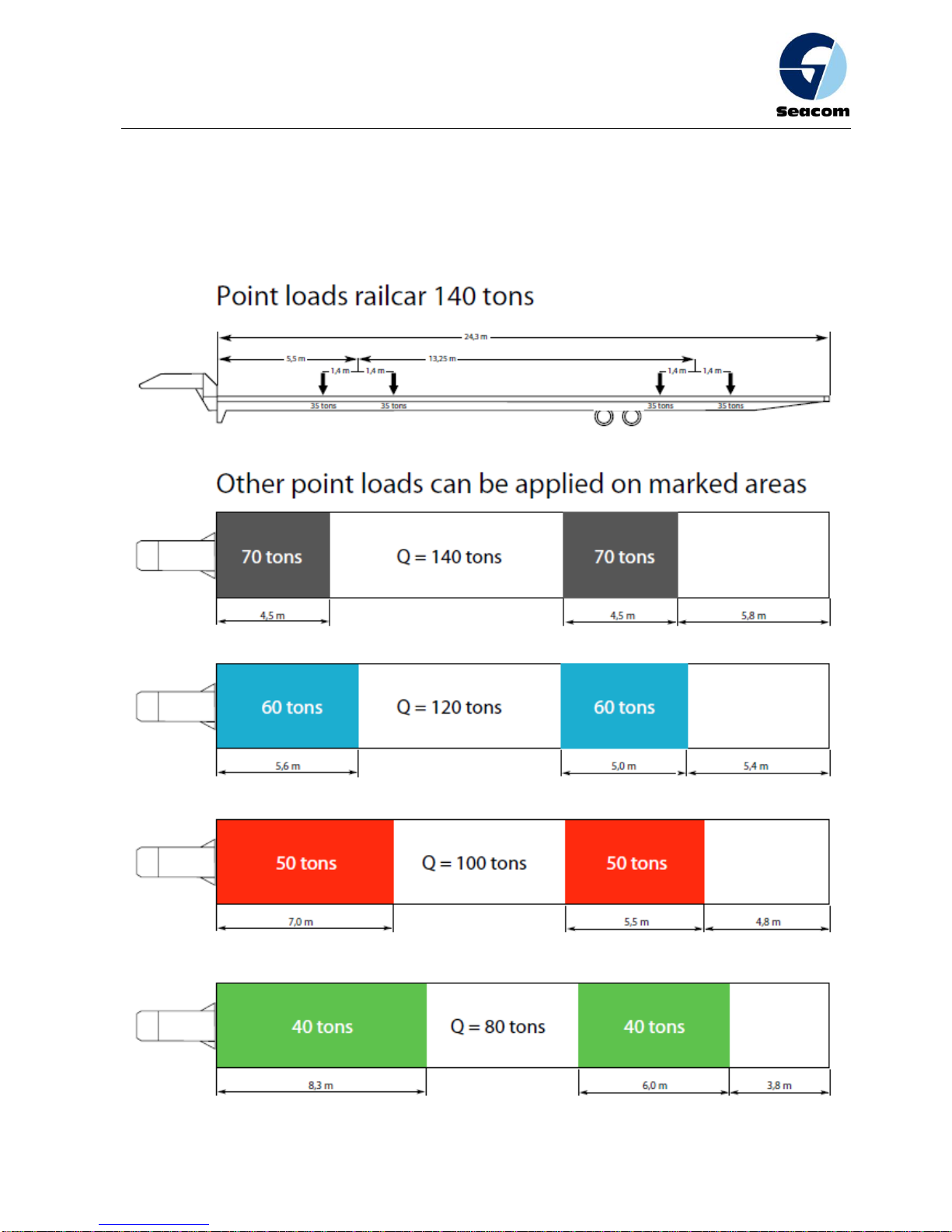

Pointed load

For the distribution of the load see the following scheme.

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 12 / 21

6 SERVICE MANUAL

General information

The trailer is a simple and solid construction. The following inspections and maintenance tasks

should be done at regular intervals in order to ensure a trouble free and safe operation. Faulty parts

need to be replaced in time. They need to meet the specified requirements of the supplier and the

pertinent safety regulations.

Wheel set

Inspect the wheel sets regularly (in about 6–month intervals) for external damages.

Tyres

Inspect the tyres for mechanical damages (about once a month).

Wheels

Check the wheels regularly:

1. Does the wheel turn without noise and without axial movement?

2. If there is a noticeable noise, then dismount the wheel and check the ball bearings; if necessary

replace them.

Frame

The frame and the welding points should be checked regularly. The frame construction consists of

structural steel and can be repaired by qualified repair technicians in case of damages. In case of

questions, call your supplier.

Lubrication

Greasing point

Number

Greasing interval

Rocker arm bearing

2

3 month

Swivel axle bearing

4

3 month

The lubrication intervals depend on the operational conditions of the trailer: If the conditions are

rough, then more frequent lubrication is needed.

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 13 / 21

Brake system

Check correct function of brakes every week

Adjust brake if necessary

Replace damaged or worn out parts

Check line filters behind couplings at front side of trailer every month and clean filter insert from

dust if necessary

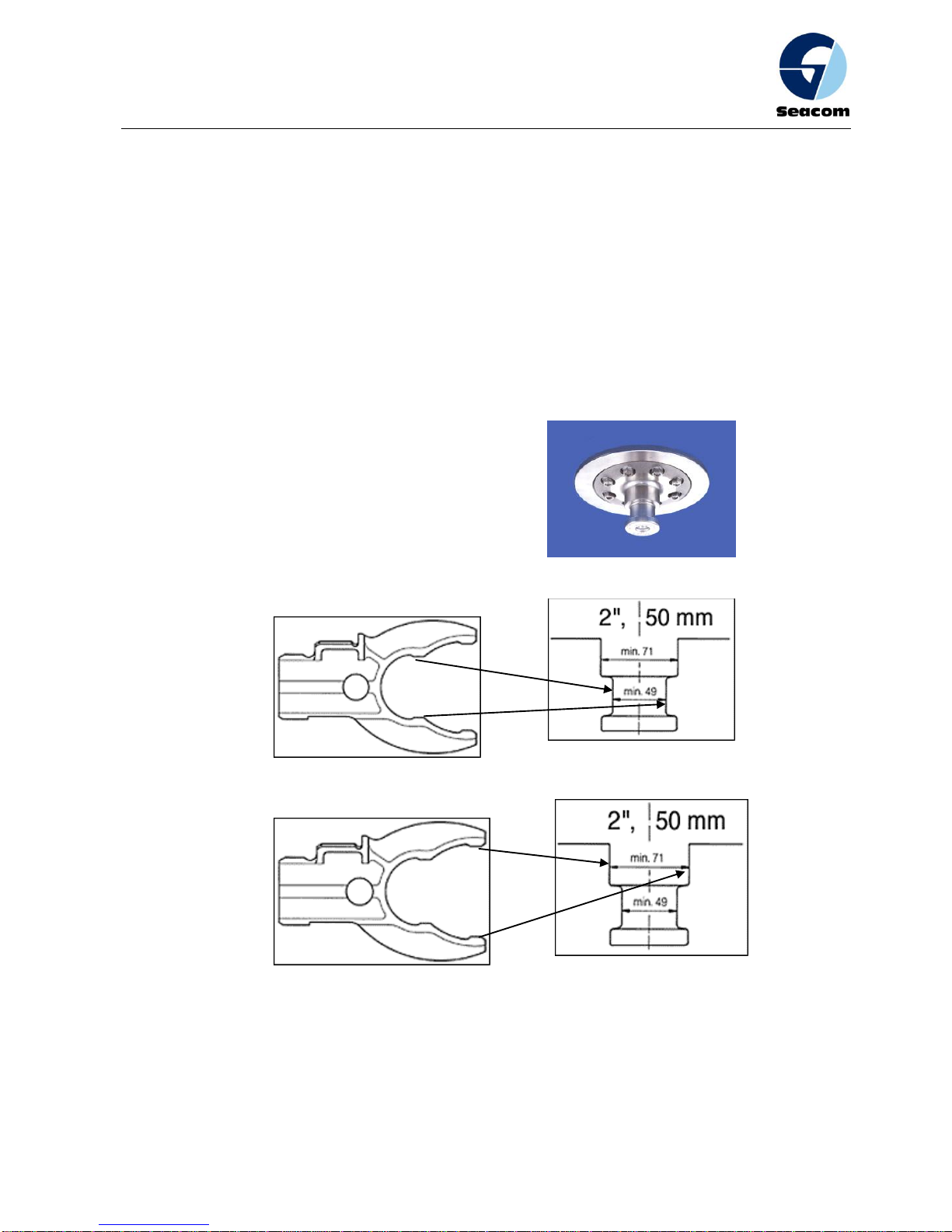

King pin

1. Inspect king pin regularly (approx. in 1 months intervals)

2. All screws tightened?

3. Check wear of pin with gauge

4. If middle part of pin is less 49 mm then replace it

Gauge

5. If upper pin diameter less 71 mm then replace it

Gauge

6. To replace pin unlock screws,

7. Do not use the old screws

8. Replace pin and screws

9. Use torque wrench (190 Nm)

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 14 / 21

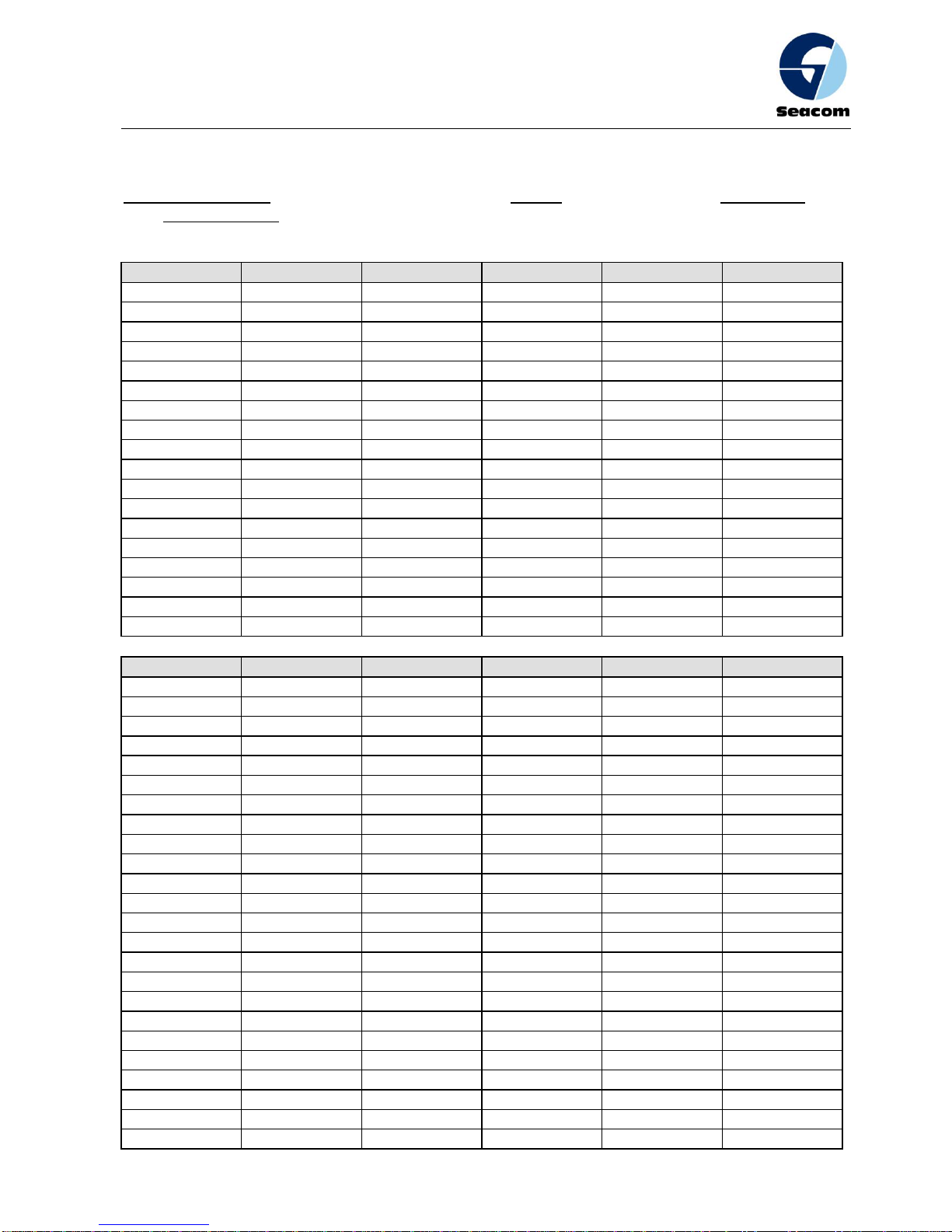

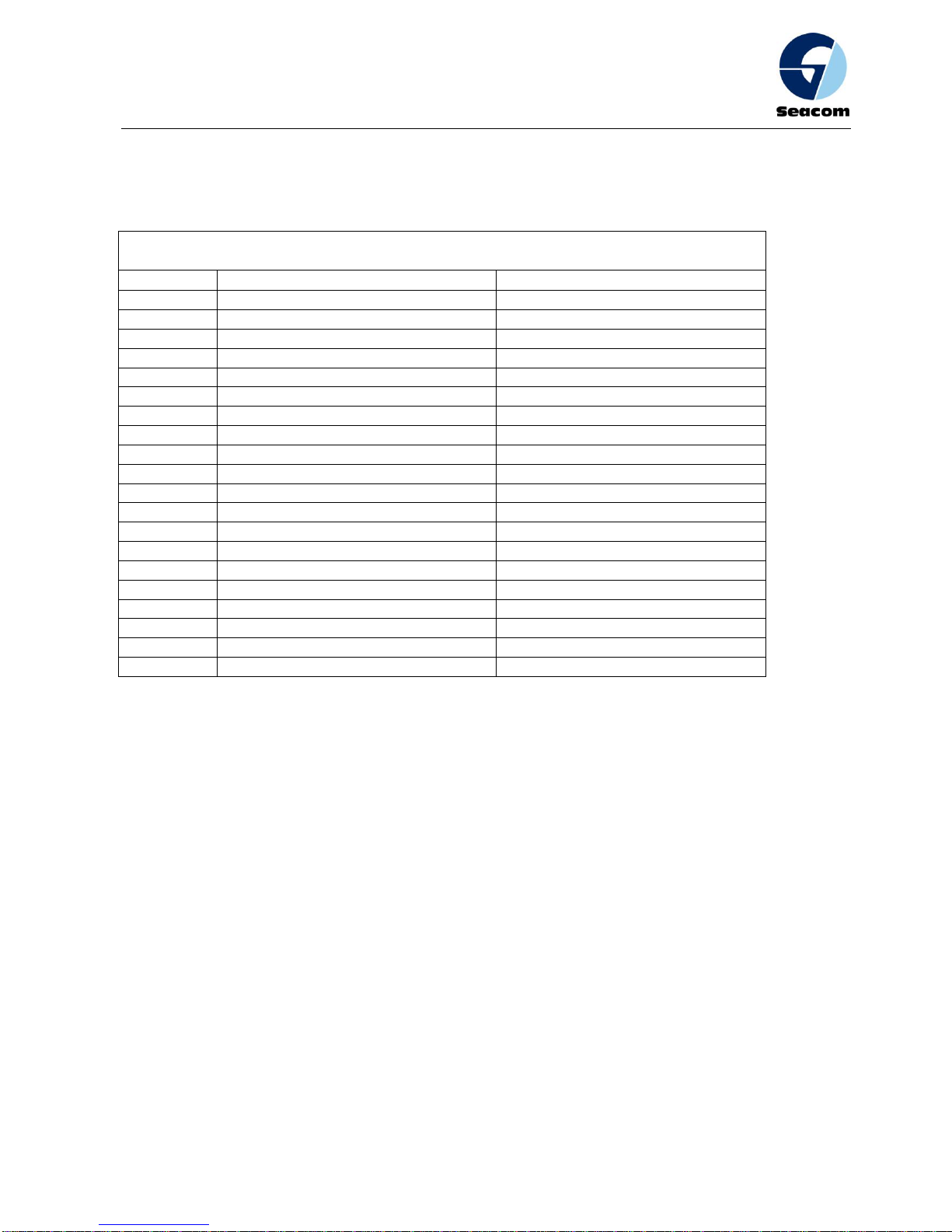

Tightening torque for screws and nuts

Screws and nuts need to be inspected regularly (monthly) or retightened.

Coefficient of friction: µ tot.= 0.12 for screws and nuts without reworking, as well as phosphated

nuts. Tighten by hand!

Tightening torques, if not specified otherwise, can be found in the following tables.

Metric ISO standard thread DIN 13, sheet 13

Size

8.8

10.9

12.9

M4

2,8

4,1

4,8

M5

5,5

8,1

9,5

M6

9,5

14

16,5

M7

15

23

28

M8

23

34

40

M10

46

68

79

M12

79

115

135

M14

125

185

215

M16

195

280

330

M18

280

390

460

M20

390

560

650

M22

530

750

880

M24

670

960

1100

M27

1000

1400

1650

M30

1350

1900

2250

M33

1850

2600

3000

M36

2350

3300

3900

M39

3000

4300

5100

Metric ISO fine thread DIN 13, sheet 13

Size

8.8

10.9

12.9

M 8 x 1

24

36

43

M 9 x 1

36

53

62

M 10 x 1

52

76

89

M 10 x 1.25

49

72

84

M 12 x 1.25

87

125

150

M 12 x 1.5

83

120

145

M 14 x 1.5

135

200

235

M 16 x 1.5

205

300

360

M 18 x 1.5

310

440

520

M 18 x 2

290

420

490

M 20 x 1.5

430

620

720

M 22 x 1.5

580

820

960

M 24 x 1.5

760

1100

1250

M 24 x 2

730

1050

1200

M 27 x 1.5

1100

1600

1850

M 27 x 2

1050

1500

1800

M 30 x 1.5

1550

2200

2550

M 30 x 2

1500

2100

2500

M33 x 1.5

2050

2900

3400

M 33 x 2

2000

2800

3300

M 36 x 1.5

2700

3800

4450

M 36 x 3

2500

3500

4100

M 39 x 1.5

3450

4900

5700

M 39 x 3

3200

4600

5300

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 15 / 21

7 SPARE PARTS

7.1 GENERAL VIEW

Dwg. No. 06.01.8082

Item

Description

Part. No

1

King pin 2”

1723.1012

34

Screw M16x80 DIN933

06.01.8082.34

35

Washer B16 DIN127

06.01.8082.35

36

D-ring

06.01.8082.36

37

Wheel set 28x10x22

06.01.8082.37

38

Wheel set with brake 28x10x22

06.01.8082.38

39

Rocker beam

06.01.8082.39

40

Air brake system

06.01.8082.40

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 16 / 21

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 17 / 21

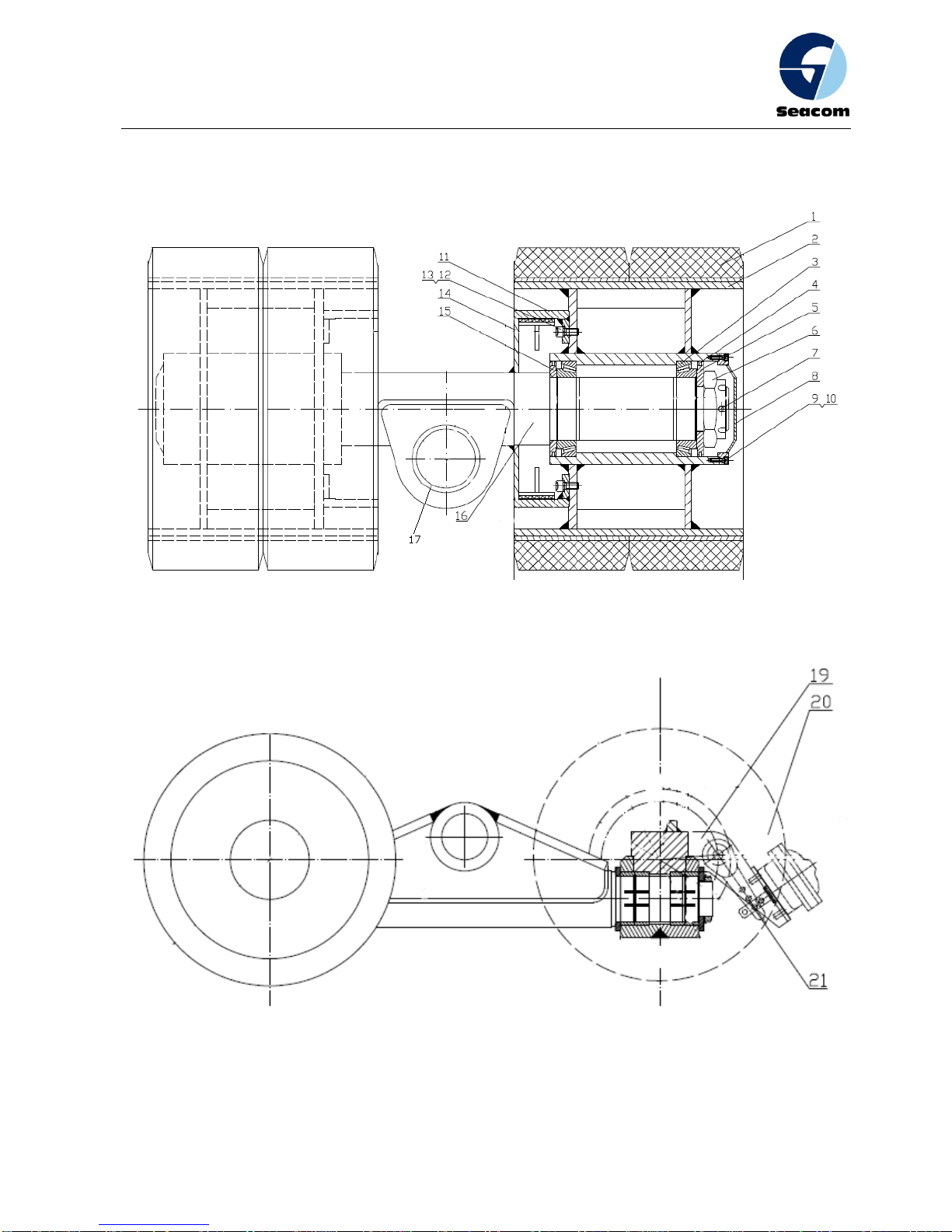

7.2 WHEEL SET 28X10X22

Dwg. No. 06.01.8082.37

Item

Description

Part. No

1

Tyre 28x10x22

1605.1038

2

Wheel body

06.01.8082.37.2

3

Taper roller bearing 32028

1410.0010

4

Fey ring FK6 d=210 ASD

1450.0211

5

Sealing washer

06.01.8082.37.5

6

Hornet nut M100x2

1356.0100

7

Split pin 13x160 DIN94

06.01.8082.37.7

8

Hub cap

06.01.8082.37.8

9

Screw M8x30 DIN912

06.01.8082.37.9

10

Washer B8 DIN127

06.01.8082.37.10

15

Sealing washer

06.01.8082.37.15

16

Axle

06.01.8082.37.16

17

Bush 150x130x80

06.01.8082.37.17

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 18 / 21

7.3 WHEEL SET WITH BRAKE 28X10X22

Dwg. No. 06.01.8082.38

Item

Description

Part. No

1

Tyre 28x10x22

1605.1038

2

Wheel body

06.01.8082.38.2

3

Taper roller bearing 32028

1410.0010

4

Fey ring FK6 d=210 ASD

1450.0211

5

Sealing washer

06.01.8082.38.5

6

Hornet nut M100x2

1356.0100

7

Split pin 13x160 DIN94

06.01.8082.38.7

8

Hub cap

06.01.8082.38.8

9

Screw M8x30 DIN912

06.01.8082.38.9

10

Washer B8 DIN127

06.01.8082.38.10

11

Brake

06.01.8082.38.11

12

Screw M16x35 DIN6912

06.01.8082.38.12

13

Washer B16 DIN127

06.01.8082.38.13

14

Brake d=400x80

1616.1008

15

Sealing washer

06.01.8082.38.15

16

Axle

06.01.8082.38.16

17

Bush 150x130x80

06.01.8082.38.17

19

Fastener

06.01.8082.38.19

20

Brake

06.01.8082.38.20

21

Screw M16x55 DIN931

06.01.8082.38.21

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 19 / 21

Transport Systems Seacom AG

A 5502 / Rolltrailer 80’ 150t Page 20 / 21

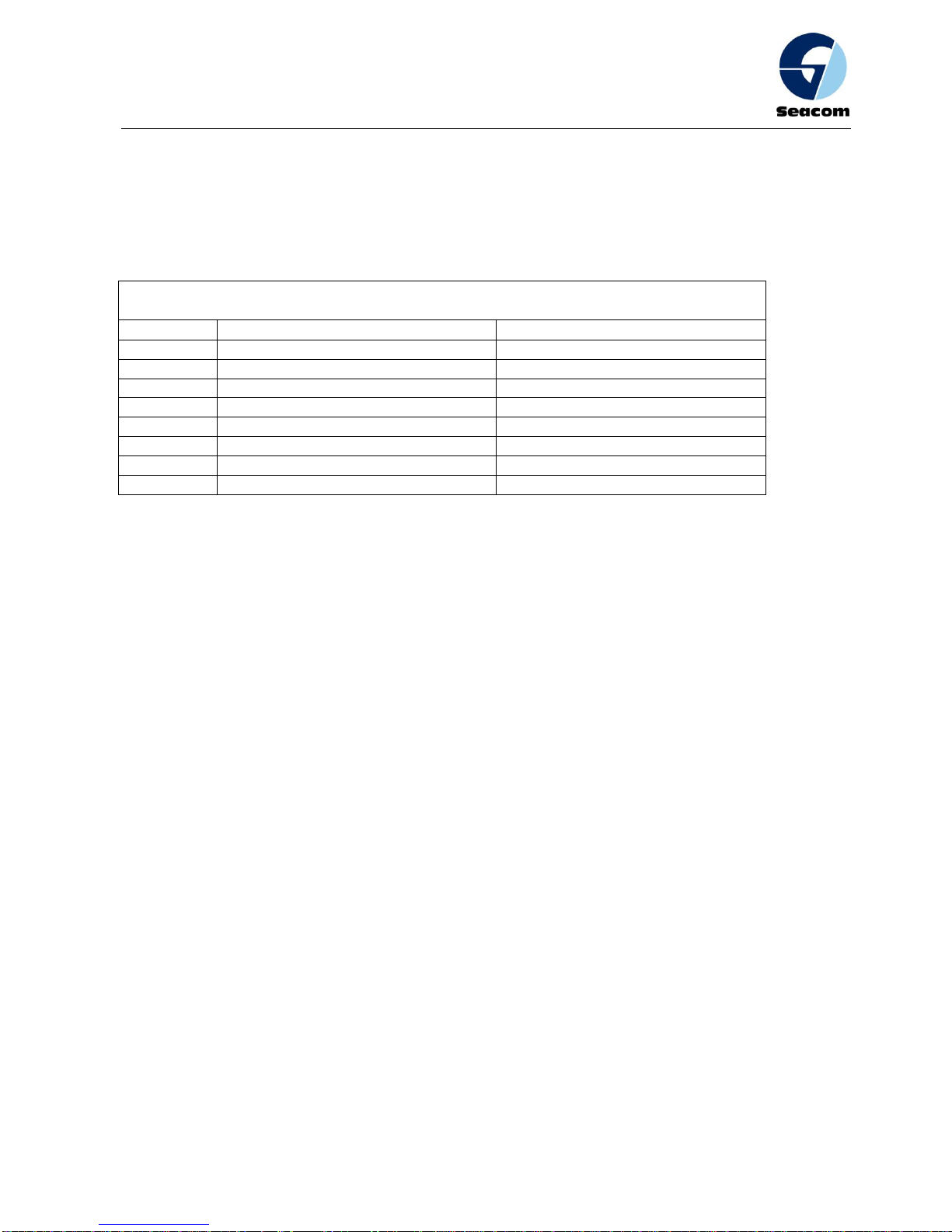

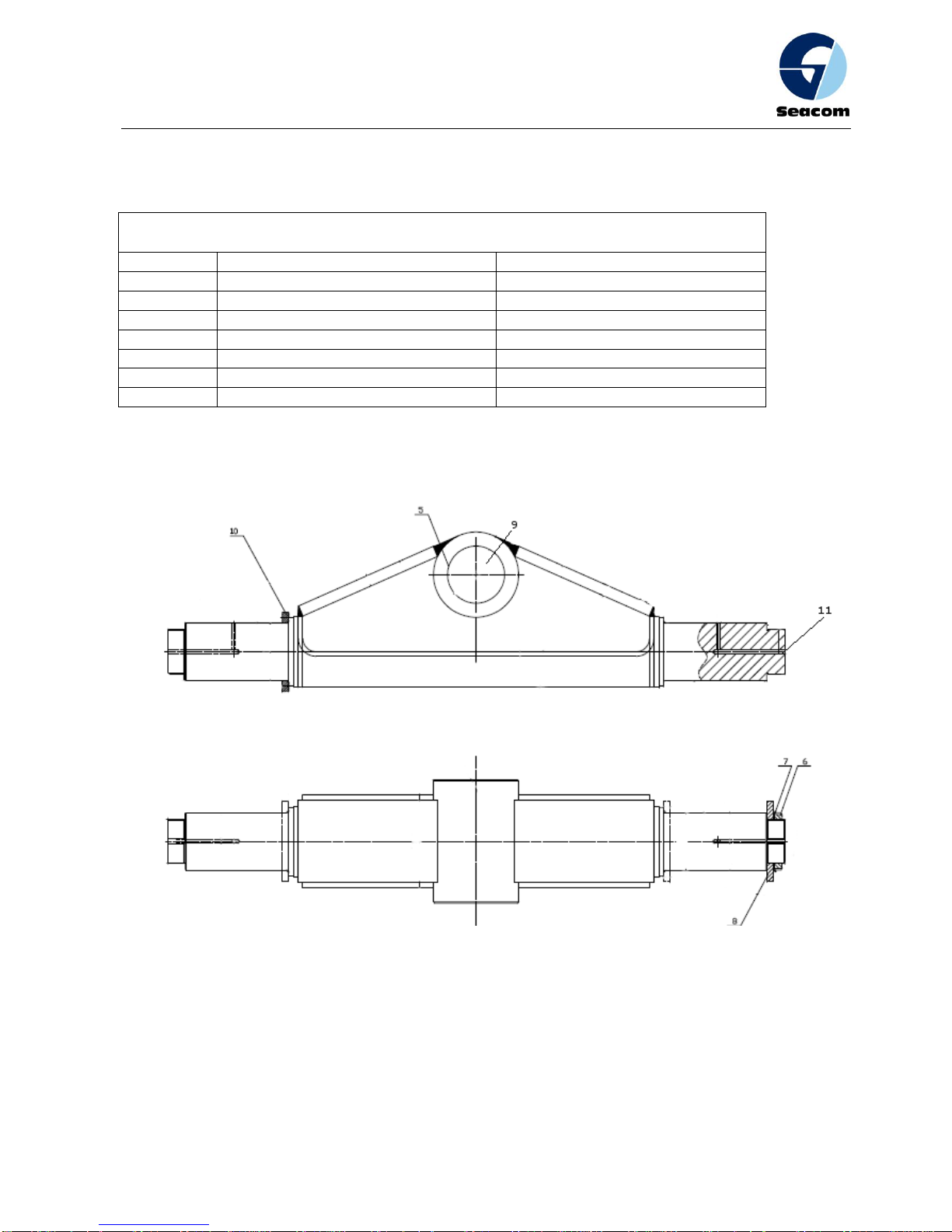

7.4 ROCKER BEAM

Dwg. No. 06.01.8082.39

Item

Description

Part. No

5

Plain bearing bush 150x130x100

06.01.8082.39.5

6

Nut M100x2 KM20 DIN981

06.01.8082.39.6

7

Washer MB20 DIN5406

06.01.8082.39.7

8

Washer

06.01.8082.39.8

9

Pin for rocker beam

06.01.8082.39.9

10

Washer

06.01.8082.39.10

11

Lubrication nipple AM10x1 DIN71412

06.01.8082.39.11

Table of contents

Popular Utility Vehicle manuals by other brands

abi

abi Workman Owner's manual & assembly instructions

Edscha Trailer Systems

Edscha Trailer Systems TipperRoof Repairing instructions

Truxta

Truxta BENDI 300G Operator's manual

Club Car

Club Car URBAN N1 user manual

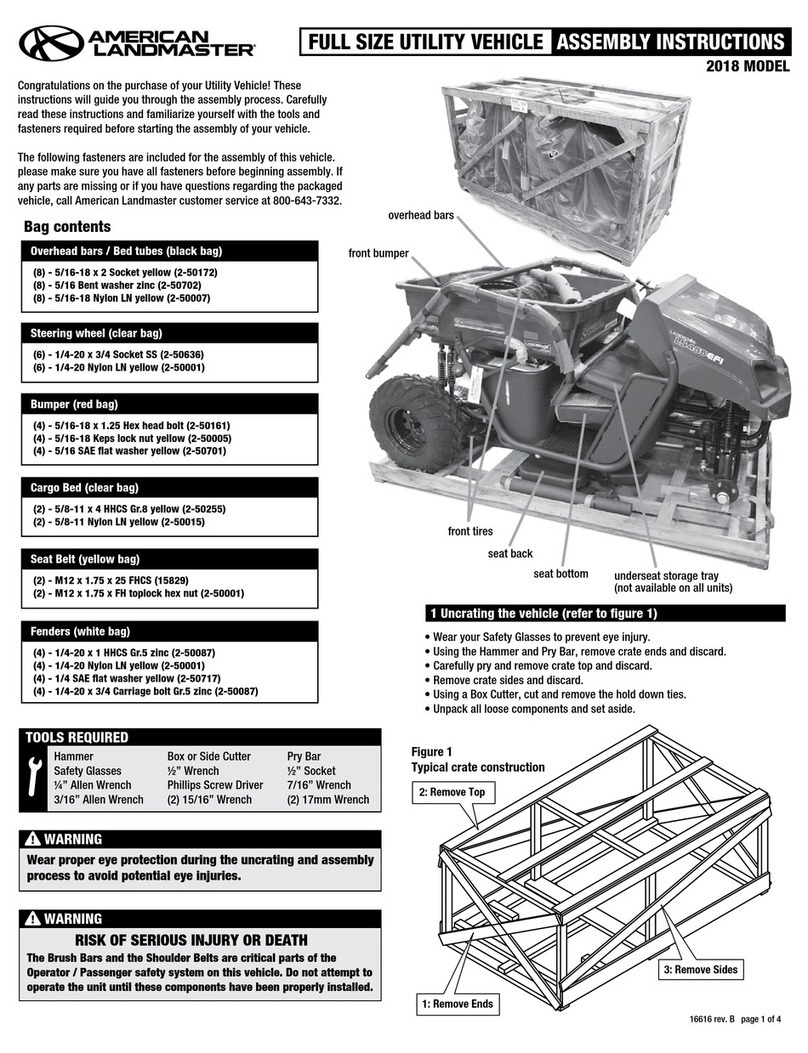

American Landmaster

American Landmaster LS455EFI 2018 Assembly instructions

Cub Cadet

Cub Cadet M465 Operator's manual

Landoll

Landoll 317C Operator's manual

Craftsman

Craftsman ZTS 7500 Operator's manual

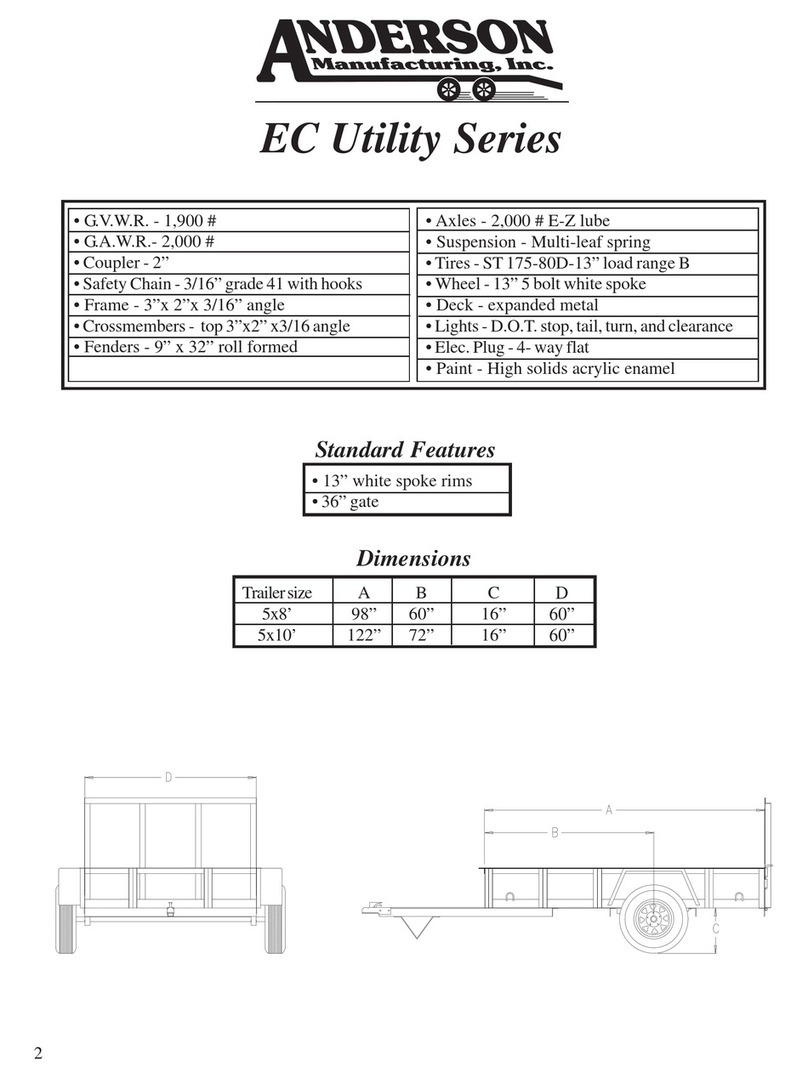

Anderson Manufacturing

Anderson Manufacturing EC Utility Series Specification sheet

forest river

forest river WIDE BODY Series operating manual

PRONAR

PRONAR T683P user manual

Primo Water

Primo Water ATV82x12-ATP Assembly instructions