forest river WIDE BODY Series User manual

OPERATING

MANUAL

Mobile Restroom Trailer

Forest River Cargo 3731 California Road Elkhart, IN 46514

Welcome to Forest River

Forest River is one of the World’s largest manufacturers

of Cargo, Auto transport, Specialty trailers, and

Recreational Vehicles.

At Forest River, we have attempted to design and

manufacture a very functional and serviceable portable

Restroom facility. Using the best materials we have been

able to obtain, we feel that this product will offer durability

and performance for a long period of time.

Thank You

Table of Contents

•Introduction

•Table of Contents

•Knowing your trailer: Pictures and Descriptions

•Wiring Diagram

•Pre-Trip check list and Hooking Up

•Set Up – Leveling & Assembly –

Steps, Porches, & Railings

-- Electrical & Water Hook-Up

•Operation – Climate Control – LED Waste Tank Sensor -

Doors - Mirrors, Soap, & Towel Dispensers

•Tear Down / Dismantling

•Winterizing - City Fill & On-Board Tanks

•Routine Trailer Maintenance

•General Trailer Maintenance

•Reporting Safety Defects

•Warranties

•Replacement Parts

Knowing Your Trailer

View of theTrailer with Steps and Porches Retracted. Side View showing Steps, Railings,

Railings are Stored in the Front Carrier & Porches Assembled

Rubber Draw Latch - Holds the Bracket - Holds Porch

Porch Steps in Retracted Position in Retracted Position

View of Rail Locking Pin at Bottom Leveling Foot for Steps

with the various components of your trailer

Please review these pictures and descriptions so you can familiarize yourself

Railing Installed at Top Leveling Jack

Exterior RV Style Electrical Cord Hook-Up City Water Fill

Front of Trailer Showing Porch Light

Pump Out Valve and Wash Out Port

Fresh Water Pump (exposed) Fresh Water Pump with Cover

Urinal Pump View of Vent Pipe and Fresh Water Tank

with Level Indicator Tube

On-Board Fresh Water Tank Showing Electrical Panel

Fill Cap on Top of Tank

Roof A/C and Ducts A/C Climate Control

View of Women's Restroom Example of Toilet Paper Dispenser

and Sanitary Napkin Recepticle

Sink and Soap Dispenser Paper Towel Dispenser and

Trash Disposal Access

View of Trash Collection Recepticle View of Men's Restroom

In Locking Base Cabinet

View of Sink Drain Set-Up Inside Century Series Vacant / Occupied Lights

Lockable Base Cabinet

Slide Bolt that Operates Vacant / Occupied Vacant / Occupied Slide Bolt

Indicators

Pre-Trip Checklist

This is the most important thing you should look at before using your new trailer. Please take

your time, and make sure you go over this list completely! A description of how these parts work and

how they should be properly checked is included in the Trailer Owner’s Manual.

•Hitch and coupler w/safety pin

•Safety chains crossed and secured properly

•All Jacks are up

•All running lights, brake lights, and turn signals functioning

•Brakes, brake controller, and breakaway system

•Proper tire pressure and tire condition on trailer and tow vehicle

•Wheel lug nuts tightened

•Doors, windows, and roof vents closed and secured

•Tie-down Steps, Porches, & Railings

•Proper load distribution

•Both Fresh & Waste Water tanks must be empty prior to transporting the trailer.

Always remember that some common causes of accidents are (1) driver error, (2) failure to

match your road speed with road conditions, and (3) improper loading.

Safety chains: Be sure to always connect the safety chains by crossing them beneath the coupler

when hooking up your trailer. Crossing your safety chains will create a cradle to catch the tongue in

case of disconnect from the hitch. Allow enough chain for turning, if too long, then they should be

shortened (just simply twist them). If they look like they have been over-stressed, they should be

replaced. In some states it is required by law, that you cross your safety chains.

Brakes: Forest River trailers come with many different types of brake options. Repair and service

information for each available type of brake can be found in the Axle Manufacturer’s Service Manual.

Please follow all of the Axle Manufacturer’s instructions concerning brakes. Remember that failure to

follow instructions could result in loss of warranty. Brakes on new trailers usually tend to “pull” or

pulsate, but don’t worry, this is normal. Remember that not all Forest River trailers are equipped with

brakes.

Tire pressure: The proper air pressure for your tires is printed on the sidewall of the tire. Air

pressure should always be checked when tires are cold for the most accurate reading. You must not

raise or lower your air pressure to meet your load. Serious injury may result in under and over

inflation. Excessive wear and tear will also result if recommended pressure is not met. You must

avoid, if possible, any chuckholes, curbs, or other hazards in the road.

Hitch and coupler: You must correctly match your tow vehicle to your trailer. It is essential that

your tow vehicle can handle the total trailer weight (GVWR). You should also check to see that the

hitch weight carrying capacity of your tow vehicle matches the loaded tongue weight of your trailer.

If you have a brake controller, then you want it to match with the number of braking wheels on your

trailer. The electrical wiring of your tow vehicle needs to match the wiring on your trailer. It is very

important that the ball on your hitch matches the coupler size on the trailer.

Proper load distribution: All Forest River trailers are carefully designed to maintain a proper hitch

weight when the trailer is evenly loaded. If improperly loaded, your trailer can become very unstable

and difficult to control on the road. Uneven loading and improper hitch weight can make steering

difficult and result in unsafe stopping and braking of the trailer and the tow vehicle.

For bumper-hitch trailers, always load 60 percent of the cargo weight evenly in front of the

axles. For Goosenecks, load 70% of the weight in front of the axles. This will result in an

approximate 10 percent of the loaded trailer weight on the hitch. Hitch weight should never be

less than 10 percent of the gross vehicle weight (trailer plus payload).

Distribute load as shown below:

Tips for the beginner – Turning & Backing up

Always remember when turning, that the trailer makes tighter and quicker turns than your tow

vehicle. To help compensate for this, please allow as much space as possible when turning so that the

trailer will not jump the curb or hit any obstacles. When backing up place your hand on the bottom of

the steering wheel while watching in your outside mirror. If you want the rear of the trailer to turn

right move your hand right, and if you want the rear of the trailer to turn left then move your hand left.

Please always remember to check the area behind the trailer to see that there are no obstacles in the

way before you begin to back up.

Hitching Up

To ensure safe towing, make sure you have a suitable vehicle, hitch, and trailer. It is the

trailer owner’s responsibility to correctly match the combination of tow vehicle and trailer.

Contact a hitch specialist, who can help you match your tow vehicle and hitch, and equip you

with a properly installed brake controller.

Make sure the ball on your hitch matches the coupler size on the trailer.

•Use the jack to raise the coupler high enough for the hitch ball to slip beneath.

•Release the coupler-locking device (raise the lever).

•Back your tow vehicle into mounting position.

•When properly aligned lower the coupler onto the ball.

•Continue raising the jack until it is fully raised.

•Latch the coupler-locking device (It is very important to lower the lever and insert a pin in the lock hole).

•Connect the safety chains by crossing the chains beneath the coupler and attach them to the tow vehicle.

Allow enough slack for turning, but no dragging (Tip: if chains are too long, simply twist them).

•Connect the electrical plug on the trailer to the plug on the tow vehicle. Check to make sure that all

running, directional, and brake lights are functioning.

•Load properly approx. 60% in front of the axles (you want 10-15% of the trailer and load weight on the

hitch), balance the load side to side, and secure it (you don’t want it getting loose). Don’t overload, go by

acceptable payload ratings or you may void the warranty.

•Take a trial run and familiarize yourself with the handling characteristics of our tow vehicle and trailer.

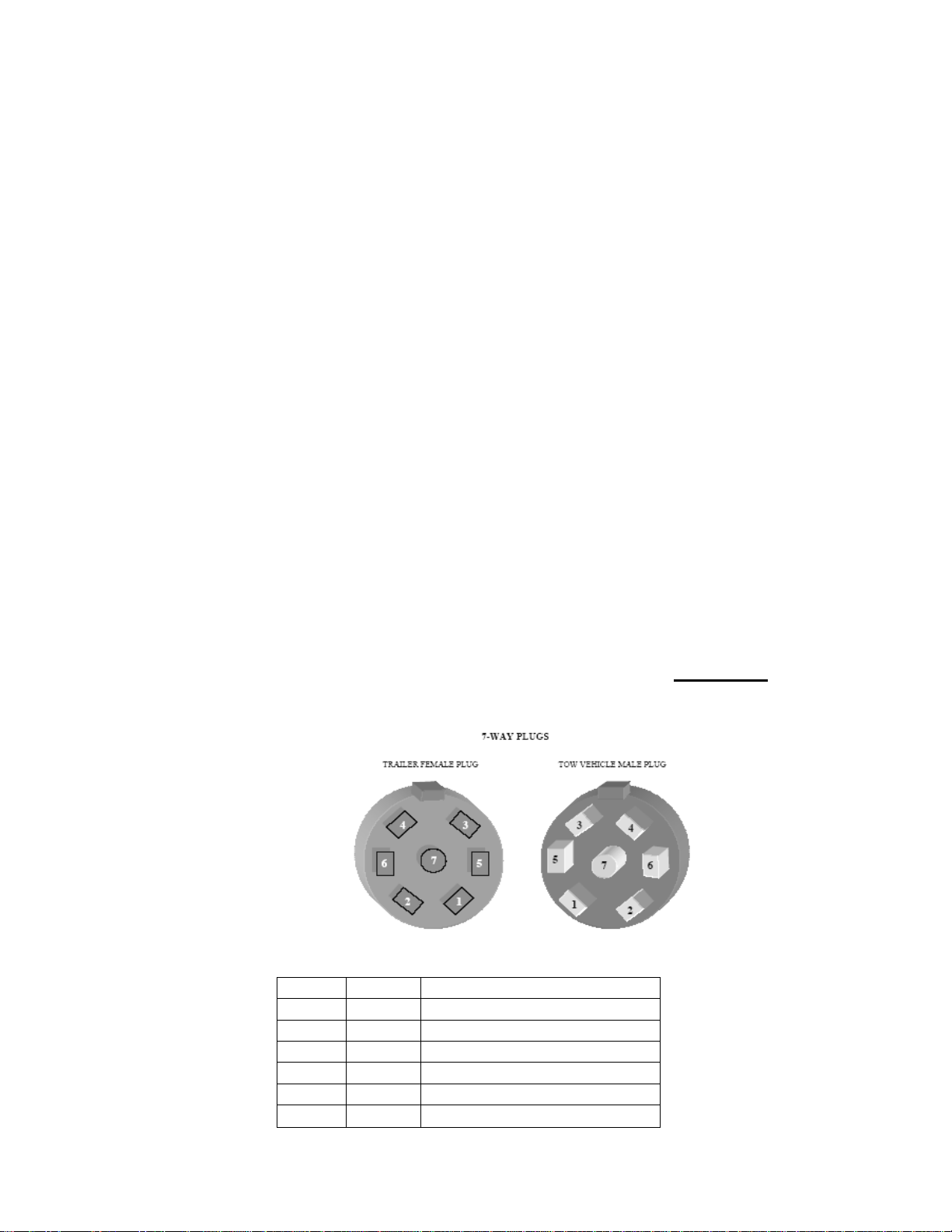

Electrical Wiring

You must have the correct vehicle wiring when using your trailer. Trailers are equipped

with brakes and a 7-way plug. Don’t forget that a ground wire running from the plug back to the

frame of the tow vehicle must be incorporated into proper tow vehicle wiring. WARNING:

Safety chains, hitches, and couplers DO NOT provide adequate grounding by themselves

and can cause electrical failures.

Number Wire Color Function

1

White

Common Ground

2

Blue

Electric Brakes

3

Green

Tail, License, & Running Lights

4

Black

Battery Charge, Hot, & Dome

5

Red

Stop & Left Turn Signal

6

Brown

Stop & Right Turn Signal

7

Yellow

Extra Auxiliary

SET-UP

Please follow these step-by-step procedures. Set-up time will be about ½ hour.

Leveling your unit

Thoroughly inspect the site location. The site should be level and have proper access to

water and electricity. Consider proper facing of the unit for convenient access and adequate

drainage.

After positioning the unit, block the wheels prior to disconnecting from the tow vehicle.

Level the unit from front to back using the front tongue jack. Level the unit side to side by

using the scissor jacks located on each corner.

When setting up the trailer for use, it is important that the stabilizer jack on each corner be

lowered and the trailer leveled. Levels are located on each side of the trailer near the wheel

fenders and on the front and back of the trailer. The levels have been applied to indicate

level when the trailer is actually tilted slightly to the rear, roadside corner. This is to allow

air conditioner condensation to run off that corner rather than over the doorways and for

waste drainage to the Waste Water Tank.

Step Assembly – Century Series

(Tools required: 9/16” Box wrench & Ratchet with 9/16” Socket)

**Do not unlock doors until porches are down and railings are installed**

Release rubber latch under step

Unbolt step latch from trailer

Carefully extend and lower step. Watch for pinch points

Place sand pad under step legs

Remove Thumbscrew from rail tube

Insert railing tube & secure with Thumbscrew

Fasten railing to trailer at bracket

Repeat for other railing

Secure by tightening thumb screws

Step Assembly – Denali/Rainier Series

(Tools required: 9/16” Box wrench & Ratchet with 9/16” Socket)

**Only unlock the one door at a time to access porches and steps**

**Care should be taken to insure the rear door is not damaged during set-up**

Remove porch and step unit from the men’s room

Set porch in the channel under the door

**Immediately install railings on this porch**

Remove Thumbscrew from rail tube

Insert railing tube & secure with Thumbscrew

Fasten railing to trailer at bracket

Repeat for other railing

Secure by tightening thumb screws

Repeat the same process for the female room (and exit sides on a Denali)

Steps, Porches, and Railings

It is also important when lowering each porch and step arrangement, to be certain that the

porch is properly leveled using the screw jacks on each step. Levels are also provided on

each porch for this purpose. Proper leveling of the porches facilitates easier placement of

the step to sidewall railing. The railing is attached by removing the two black thumbscrews,

inserting the railing into the pockets then reapplying the thumbscrews. The sidewall railing

is first inserted into the pocket after removing the thumb screw, then carefully swing the

bracketed end of the railing to meet the sidewall bracket, insert a 3/8” x 1” bolt and secure it

with a self-locking nut. Next re-install the thumbscrew.

Instructions for Lowering and Raising an ADA Unit

1. Position unit on a level and flat area.

2. Located in the mechanical room, there are three (3) switches that control the electrical

jacks that raise and lower the unit.

To lower the unit:

1. Use all three switches to raise the unit so that the axle and tires are off the ground.

2. Remove the pins from both sides of the independent axle system.

3. Use all three switches to lower unit so that it rests completely on the ground.

4. Remove the step(s) from the cube(s) and pin them in place. Adjust leveling feet as

needed.

5. Unbolt and lower the ADA platform. Adjust leveling feet as needed.

6. Remove the ramp sections from the ADA cube. Install ramp sections to the ADA

platform.

7. Install rails for ramp and platform.

To raise the unit:

1. Remove rails, ramps, steps and stow them in their appropriate cube.

2. Raise and bolt the ADA platform in place.

3. Use all three switches to raise the unit completely.

4. Re-insert pins in both sides of the independent axle system.

5. Lower the unit back onto the axle and tires and continue to retract the roadside and

curbside jacks into the full upright and stored position.

Electrical Hook-Up

The power connector is located on the (roadside) wall, to the left of the utility door.

Connect to a 120 Volt, minimum 15 Amp, GFI, (Ground Fault Interrupter) outlet. Use up to

a 100ft long 12 Ga. (minimum) Lifeline. Units with a Water Heater will require two

Lifelines.

Check for tripped breakers on the breaker panel located inside the mechanical room.

Electrical

The breaker panel has two 15 Amp single pole breakers, one breaker for the lights and one

for the Air Conditioner. If the trailer comes equipped with a water heater, the lights and Air

Conditioner are on one breaker. The water heater is on the other breaker. Both breakers are

activated by pushing each breaker into the up position. NOTE: If your unit is supplied with

a water heater, it is important to remember that the water heater must be filled before

turning on the power to the heater. Failure to do so could result in overheating and damage

to the element.

All Water Pumps and Lights, (fluorescent stall lights, porch lights, vacancy lights, and

closet light), operate on 12volts. Power is supplied through the 120 volt /12 volt Converter

and Fuse panel which is located in the mechanical room.

Water Hook-Up - City Fill and On-Board

City Fill: Connect to the water source using a 3/4" water hose. Attach the hose to the City

Fill water connection located on the roadside wall to the right of the utility door.

All the plumbing originates at the City Fill connection located on the roadside of the trailer.

This is a standard 3/4" hose connection. Water is fed from this point, into the mechanical

room via 1/2" plastic tubing. From that point forward the unit is supplied using 3/8" plastic

tubing. Items supplied by this tubing include the toilets, sinks, and water heater.

If your unit is supplied with a optional water heater, it will be located under the cabinet in

the Men’s restroom. The temperature has been preset to approximately 104F, eliminating

the need for a mixing valve. The single push to operate faucets will supply warm water

only and are timed for approximately 5seconds. The supply line to the water heater also

contains a shut-off valve. This shut-off valve will normally remain open except when

performing water heater maintenance or when winterizing.

On-Board: If your unit is equipped with the On-Board Fresh Water System, you will find

all of the components located in the mechanical room. This will include a fresh water tank,

a fresh water pump and an expansion tank mounted above the fresh water tank. The fresh

water tank is filled, by removing the fill cap, at the top of the tank. The water level

indicator is the vertical clear plastic hose on the face of the water tank. The supply pump

will operate based on demand. The expansion tank acts as a reserve, so the pump does not

cycle continuously.

The fresh water pump, powered through the 12V fuse panel, has an On/Off switch located

directly below the fuse panel.

Do not transport water to your site. Fill the tank at the nearest water source to your set-up

site. When filling the fresh water tank, make sure the drain valve is in the closed position

(turned to the side).

Make sure the demand pump power switch is turned on during operation, so that the

expansion tank (located above the water tank) is filled intermittently.

Shower Model:

If your trailer is a shower model, most features will be the same as those on a standard

restroom trailer. However, the shower model has no designated men’s or women’s stalls

and therefore, none of the stalls will contain a urinal. By virtue of that, any and all

components associated with the auto-flush urinal are not included in the shower trailer.

Another difference is the use of a propane heated, continuous flow water heater, which is

used to supply hot water to the sinks and showers. Please read the owner’s manual, for

the water heater, to familiarize your self with its operation BEFORE using it.

The dual propane cylinders are connected to a single regulator which has a selection valve

attached to it. This valve allows you to use one bottle while holding the second bottle in

reserve. When the first bottle has been depleted, turn the knob left or right to begin using

the second bottle. It is then advised that you remove the empty bottle immediately for

refilling. DO NOT wait until the second bottle is depleted, as doing so will render the

trailer unusable, with regards to having hot water available for use.

The thermostat for the water heater is located in the mechanical room, on the electrical

panel board and is set to a temperature of 104F. The shower valves are of the pull and

release style and will only release water when the valve is turned.

Behind the small access door on the rear of the trailer, is a spigot and a large red handled

valve. When the large valve is in the vertical position, shower water will drain into the

waste tank. If the large valve handle is in the horizontal position, shower and sink water is

diverted to the spigot valve. By connecting a garden hose to this valve and extending it past

the side of the trailer, shower water can be drained onto the ground. Be certain that local

laws allow this action before attempting this diversion. Once the garden hose is

attached, open the spigot valve to its full open position.

All other components with the shower trailer are the same as on a standard restroom trailer

and should be viewed as such for general hook-up, plus operating and winterizing

procedures

OPERATION

Air Conditioning / Heating

Climate Control is provided via a roof air conditioner and a heat strip. The cooling and

heating controls are located inside the mechanical room and are mounted on the ceiling.

Refer to A.C. Manual for operation.

The air conditioner and optional heater are both located in the mechanical room and

operate on 120 volts. The controls for the unit are located on the underside of the air

conditioner. The unit has three fan speeds; Low, Medium, and High. Heat is introduced

into the unit by switching the control knob to the “Heat” position.

Monitoring the Waste Tank

The Waste Water tank has an LED tank level monitor. Located in the mechanical room, the

display panel is at the bottom of the electrical board below the closet light and water pump

switches. When the button is pressed, the last illuminated light will indicate how full the

waste tank is.

The toilets drain directly into the waste tank. The sinks drain into a sump pump located just

inside the mechanical room. The sink water is used to flush the urinal in the men’s stall,

which is then drained to the waste tank through the waste tank vent pipe.

The toilets are foot operated. The shut off valves for the toilets are located in the

mechanical room. In addition, each sink or water heater also has a shut-off valve, which is

located under each vanity. Inside the cabinet, hanging from the locking mechanism, are the

keys for each cabinet and a strainer key for the faucet. The strainer key is used to remove

the faucet strainer for cleaning, when necessary.

Add the appropriate odor control and waste digesting chemicals to the waste holding tank

Prior to winter storage, the water heaters, fresh water tank, and expansion tank, should be

drained of any water, and charged with RV antifreeze.

TEAR DOWN/ Dismantling

After cleaning and washing down the entire interior, follow the step-by-step

procedures that follow.

Turn off the climate control by using the control in the mechanical room. You can also

accomplish this by turning off the breaker on the breaker panel.

Disconnect the Electrical power supply.

Disconnect the City Fill water supply.

If allowed, drain the On-Board Fresh Water Holding Tank. Remove the fill cap for venting.

Tear down steps and porches by following the set-up instructions in reverse making sure to

always lock the doors when the railings are removed.

Crank all four, scissor jacks completely to the up position

Pumping the Waste Holding Tank

Contact your waste removal source. When scheduling your on-sight waste removal, inquire

as to the size of their waste hose connection. A 3" connection is the most common,

however, 2" connections are widely used and an adapter will be required.

The waste holding tank is emptied, by connecting the 3" septic waste hose to the quick

connect drain valve. The valve is located at the front of the trailer, is opened by rotating the

yellow handle counter-clockwise. Lower the front of the unit with the tongue jack for

optimum drainage. Avoid interfering with the waste hose connection.

For the rinsing out of the waste tank, remove the 1" wash out plug. The plug is located at

the front of the trailer to the left of the waste tank access valve.

Waste and Fresh Water Tanks

Both the waste tank and freshwater tank are constructed of 3/8" co polymer, extrusion

welded polyethylene and is virtually indestructible. However, it should be noted that for

safety reasons, both tanks must be empty prior to transporting the trailer. It is also

suggested that a waste digesting chemical be added to the waste tank after every other

pumping.

Doors

The “in-use” lock is the slide bolt located inside the door above the door knob. A label on

each slide bolt indicates the locked and unlocked position of the bolt. When the slide bolt is

moved into the locked position, the bolt activates the occupied light changing it to red

(occupied). When the slide bolt is moved back to the unlocked position, the light will

change to green (vacant). The inside door lock of each door has been deactivated to prevent

accidental locking. Each door can be key locked from the outside for security and for

transporting.

Mirrors, Soap, and Towel Dispensers

All mirrors are made of shatter-proof glass. . For best results, clean mirror with warm

water, wipe and dry using a soft, lint free cloth. When using common household glass

cleaners, never spray directly on the mirror. Always apply cleaner directly to a lint free

cloth, wipe, and dry immediately. Proper care and handling should always be taken to

avoid allowing any liquid or substance to contact the edges of the mirror. Continuous use

of household cleaners can result in edge damage as many contain chemicals such as

chlorine, alkali or sulfuric acid, which can be harmful to mirrors.

Motion Activated Towel Dispensers use rolls of paper towels that are 10" wide. (Georgia –

Pacific #GP-89460)

Soap dispensers use any non-foaming liquid soap.

This manual suits for next models

12

Table of contents

Other forest river Utility Vehicle manuals

Popular Utility Vehicle manuals by other brands

GOKARTS USA

GOKARTS USA TrailMaster MINI instructions

Hisun

Hisun HS700UTV-4 Maintenance handbook

Cushman

Cushman Turf Truckster 84069 Parts & maintenance manual

Metal-Fach

Metal-Fach T930 operating instructions

Cub Cadet

Cub Cadet 37BK466D710 Operator's manual

Columbia ParCar

Columbia ParCar Gasoline ParCar Service manual