SEAFLO variable speed pumps are offered in 5-chamber models. These pumps allow for constant pressure

across multiple outlets via integrated electronic controls. Eliminates the need for pressurized tanks and pressure

switches. Our 5-chamber diaphragm and bypass technology reduces cycling and reduces noise. Demand switch,

control of pressure precise, stable performance, low starting pressure, good heat dissipation that will meet your

special requirements with positive predictable performance.

56A, 56C Series Variable Speed Smart Pump

Instruction Manual

INSTALLATION

Materials

4 screws to fasten the pump to the mounting surface

1 diaphragm pump with related accessories

4 stainless steel hose clamps and screws

2 (at least) pieces of flexible, reinforced hose piping,

with collapsing strength of twice the inlet collapsing

pressure, hose must be minimum 1/2" ID

APPLICATIONS

Sprayer fixtures (vehicle-mounted sprayers, electric sprayers)

Yacht/RV/caravan pressurized water system

FEATURES

Please do follow the instruction manual to install the product. Any action outside what is recommended in this

manual may bring damage to the pump. Any inappropriate installation or operation that causes the pump damage

is not covered by warranty.

CAUTION

We use new demand switch for the pump, it can control of pressure more precise and have good stable

performance.

And low starting pressure, protect the pump start frequently. Good heat dissipation, the switch is directly in contact

with the liquid, so that can serve as a cooling function to prevent the switch from burning out. Also the switch

sealing performance is better.

ABOUT NEW SWITCH Setup

1.The pump may be mounted in any position. If mounted vertically, the pump head should be in the down

position to avoid leakage into the motor casing in the event of a malfunction.

2.Secure the feet, but do not compress them. Over tightening the securing screws may reduce their ability to

dissipate noise and vibration.

3.Intake hose must be minimum 1/2" (13 mm) ID reinforced hose. Main distribution line from pump outlet should

also be 1/2" (13 mm) ID with branch and individual supply lines to outlets no smaller than 3/8" (10 mm).

4.Plumb the system using high pressure (2x pump rating), braided, flexible tubing to minimize vibration/ noise.

8.The fittings must be secured to avoid leakage.

5.Do not apply inlet pressure in excess of 30 psi. In general, try to avoid any inlet pressure completely.

7.Strainer should be attached to the inlet side.

10.If a check valve is installed in the plumbing, it must have a cracking pressure of no more than 2 psi.

6.Avoid any kinks or fittings which could cause excessive restrictions.

9.Use clamps at both ends of hose to prevent air leaks into the water line.

1 fuse

1 screwdriver

1 electrical cutoff switch

1 strong cutting implement for tubing

(if desired) Teflon tape or sealant

Any other pressurization system

Solar water system

The bypass comes preset for optimal operation of the pump. If your application calls for a different setting for the

bypass, you may change it yourself. Carefully tighten the screw to increase or loosen the screw to decrease the

minimum operational pressure of the bypass.

Please consult a professional technician in the case that the bypass needs adjustment. Improper adjustment of

the bypass may damage the pump.

ABOUT THE BYPASS

+

-

③

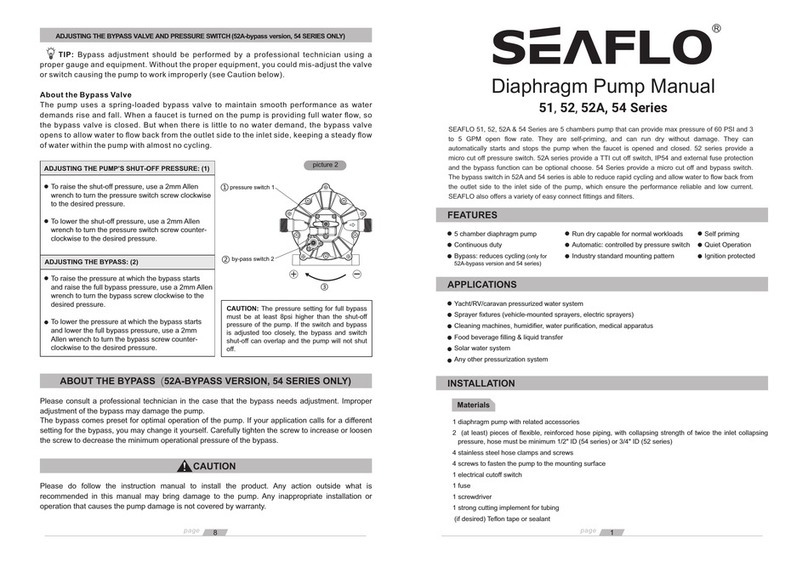

picture 2

To raise the shut-off pressure, use a 2mm Allen wrench to turn

the pressure switch screw clockwise to the desired pressure.

To lower the shut-off pressure, use a 2mm Allen wrench to turn

the pressure switch screw counter-clockwise to the desired

pressure.

ADJUSTING THE BYPASS: (2)

To lower the pressure at which the bypass starts and lower

the full bypass pressure, use a 2mm Allen wrench to turn the

bypass screw counter-clockwise to the desired pressure.

To raise the pressure at which the bypass starts and raise

the full bypass pressure, use a 2mm Allen wrench to turn the

bypass screw clockwise to the desired pressure.

CAUTION: The pressure setting for full

bypass must be at least 8psi higher than the

shut-off pressure of the pump. If the switch

and bypass is adjusted too closely, the

bypass and switch shut-off can overlap and

the pump will not shut off.

pressure switch 1

by-pass switch 2

①

②

Slide a screwdriver in the removal slot and pry out bypass valve

access hole cover.

Locate the bypass valve adjustment screw on the pump housing

at the bottom of the access hole.

ADJUSTING THE BYPASS VALVE AND PRESSURE SWITCH

TIP: Bypass adjustment should be performed by a professional technician using a proper gauge and

equipment. Without the proper equipment, you could mis-adjust the valve or switch causing the pump to

work improperly (see Caution below).

About the Bypass Valve

The pump uses a spring-loaded bypass valve to maintain smooth performance as water demands rise

and fall. When a faucet is turned on the pump is providing full water flow, so the bypass valve is closed.

But when there is little to no water demand, the bypass valve opens to allow water to flow back from the

outlet side to the inlet side, keeping a steady flow of water within the pump with almost no cycling.

ADJUSTING THE PUMP’S SHUT-OFF PRESSURE: (1)

1

page

4

page

Can supply up to 4 fixtures

Variable speed technology

5 chamber diaphragm pump

Industry standard mounting pattern

Low voltage protection

Quiet operation

Ignition protected

Long service life

Self priming

Run dry safe

Safety bypass

VARIABLE SPEED TECHNOLOGY

CONTROL: Variable Speed Electronic Controller and Dual Control Pressure Switch/Bypass.

SPEED CONTROLLER: Factory Set To Approximately Amps Max. 10A @ 12VOr 5.5A @ 24V.

CAUTION: Exterior Surfaces (heat sink), May Exceed 150°F After Only 15 Minutes of Operation.