Seaflo 51 54 Series User manual

SEAFLO 51, 52, 52A & 54 Series are 5 chambers pump that can provide max pressure of 60 PSI and 3

to 5 GPM open flow rate. They are self-priming, and can run dry without damage. They can

automatically starts and stops the pump when the faucet is opened and closed. 52 series provide a

micro cut off pressure switch. 52A series provide a TTI cut off switch, IP54 and external fuse protection

and the bypass function can be optional choose. 54 Series provide a micro cut off and bypass switch.

The bypass switch in 52A and 54 series is able to reduce rapid cycling and allow water to flow back from

the outlet side to the inlet side of the pump, which ensure the performance reliable and low current.

SEAFLO also offers a variety of easy connect fittings and filters.

Diaphragm Pump Manual

The bypass comes preset for optimal operation of the pump. If your application calls for a different

setting for the bypass, you may change it yourself. Carefully tighten the screw to increase or loosen

the screw to decrease the minimum operational pressure of the bypass.

Please consult a professional technician in the case that the bypass needs adjustment. Improper

adjustment of the bypass may damage the pump.

ABOUT THE BYPASS (52A-BYPASS VERSION, 54 SERIES ONLY)

Please do follow the instruction manual to install the product. Any action outside what is

recommended in this manual may bring damage to the pump. Any inappropriate installation or

operation that causes the pump damage is not covered by warranty.

CAUTION

+

-

③

picture 2

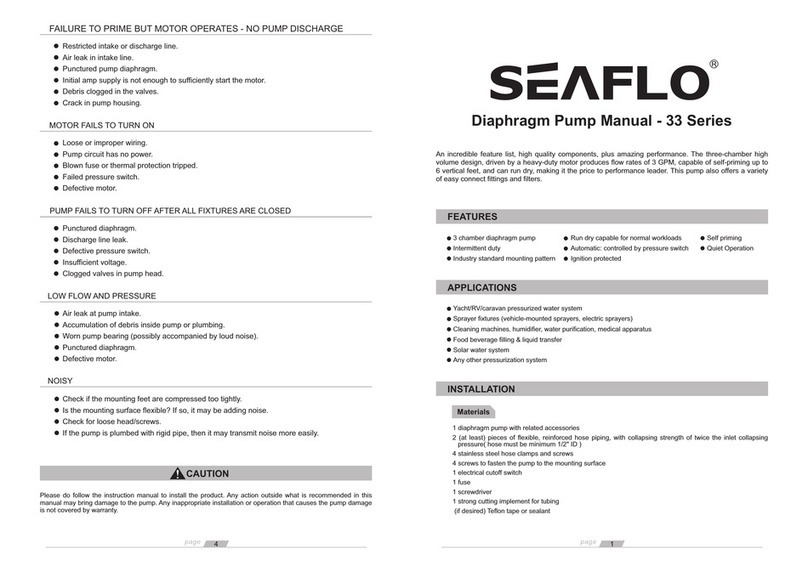

ADJUSTING THE BYPASS VALVE AND PRESSURE SWITCH (52A-bypass version, 54 SERIES ONLY)

About the Bypass Valve

The pump uses a spring-loaded bypass valve to maintain smooth performance as water

demands rise and fall. When a faucet is turned on the pump is providing full water flow, so

the bypass valve is closed. But when there is little to no water demand, the bypass valve

opens to allow water to flow back from the outlet side to the inlet side, keeping a steady flow

of water within the pump with almost no cycling.

TIP: Bypass adjustment should be performed by a professional technician using a

proper gauge and equipment. Without the proper equipment, you could mis-adjust the valve

or switch causing the pump to work improperly (see Caution below).

ADJUSTING THE PUMP’S SHUT-OFF PRESSURE: (1)

To lower the shut-off pressure, use a 2mm Allen

wrench to turn the pressure switch screw counter-

clockwise to the desired pressure.

To raise the shut-off pressure, use a 2mm Allen

wrench to turn the pressure switch screw clockwise

to the desired pressure.

ADJUSTING THE BYPASS: (2)

To lower the pressure at which the bypass starts

and lower the full bypass pressure, use a 2mm

Allen wrench to turn the bypass screw counter-

clockwise to the desired pressure.

To raise the pressure at which the bypass starts

and raise the full bypass pressure, use a 2mm Allen

wrench to turn the bypass screw clockwise to the

desired pressure. CAUTION: The pressure setting for full bypass

must be at least 8psi higher than the shut-off

pressure of the pump. If the switch and bypass

is adjusted too closely, the bypass and switch

shut-off can overlap and the pump will not shut

off.

pressure switch 1

by-pass switch 2

①

②

1

page

8

page

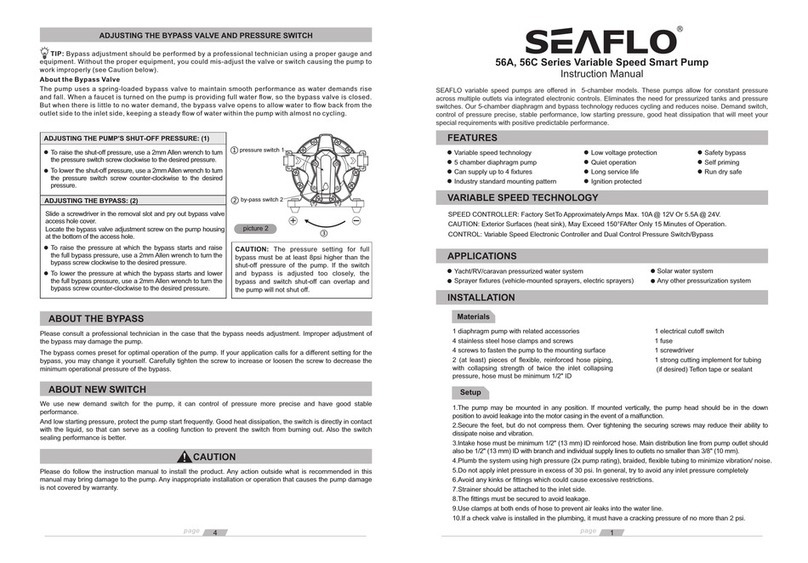

FEATURES

Bypass: reduces cycling (only for

52A-bypass version and 54 series)

5 chamber diaphragm pump

Continuous duty

APPLICATIONS

Automatic: controlled by pressure switch

Industry standard mounting pattern

Run dry capable for normal workloads

Quiet Operation

Self priming

Ignition protected

Cleaning machines, humidifier, water purification, medical apparatus

Yacht/RV/caravan pressurized water system

Solar water system

Sprayer fixtures (vehicle-mounted sprayers, electric sprayers)

Food beverage filling & liquid transfer

Any other pressurization system

INSTALLATION

Materials

(if desired) Teflon tape or sealant

2 (at least) pieces of flexible, reinforced hose piping, with collapsing strength of twice the inlet collapsing

pressure, hose must be minimum 1/2" ID (54 series) or 3/4" ID (52 series)

1 diaphragm pump with related accessories

1 electrical cutoff switch

1 fuse

1 strong cutting implement for tubing

4 screws to fasten the pump to the mounting surface

4 stainless steel hose clamps and screws

1 screwdriver

51, 52, 52A, 54 Series

3

page

2

page

Setup

13. In an easily accessible location, install a switch to control electricity to the pump. Turn the pump off when

not used for extended periods or when the tank is empty.

14. The electrical circuit should be protected with an over-current protection device (fuse) in the positive

lead. This pump requires a 40 amp fuse.

15. The pump circuit should not include any other electrical loads.

17. After installation, check the voltage at the pump motor. Voltage should be checked when pump is

operating. Full voltage must be available at the pump motor at all times.

12. This pump should be wired on its own dedicated circuit. Connect the positive lead (red) to the positive

terminal of your battery and the negative wire (black) to the negative terminal of your battery.

16. As the water supply pump is non-essential, reference the wire chart under the electrical information. Be

sure to have the correct wire sizing for the length of wire you are using.

3. Intake hose must be minimum 1/2" (13 mm) ID (54 series) or 3/4" (19 mm) ID (52 series) reinforced hose.

Main distribution line from pump outlet should also be 1/2" (13 mm) ID (54 series) or 3/4" (19 mm) ID (52

series) with branch and individual supply lines to outlets no smaller than 3/8" (10 mm).

5. Do not apply inlet pressure in excess of 30 psi. In general, try to avoid any inlet pressure completely.

11. If applying a sealer or plumbing tape, be careful to not overtighten, as they may be sucked into pump.

7. Strainer should be attached to the inlet side.

2. Secure the feet, but do not compress them. Overtightening the securing screws may reduce their ability to

dissipate noise and vibration.

6. Avoid any kinks or fittings which could cause excessive restrictions.

4. Plumb the system using high pressure (2x pump rating), braided, flexible tubing to minimize vibration/

noise.

9. Use clamps at both ends of hose to prevent air leaks into the water line.

1. The pump may be mounted in any position. If mounted vertically, the pump head should be in the down

position to avoid leakage into the motor casing in the event of a malfunction.

8. The fittings must be secured to avoid leakage.

10. If a check valve is installed in the plumbing, it must have a cracking pressure of no more than 2 psi.

ELECTRICAL INFORMATION

Notes

2. SEAFLO does not recommend the use of metal fittings. When possible, use the provided plastic fittings.

3. Do not adjust the bypass personally without the help of technician.

1. Flexible potable water hose or PEX tubing is recommended instead of rigid piping at pump. If you choose to

use rigid piping, provide a short length of hose between pipe and the pump to avoid noise and vibration.

4. Lack of sanitizing and maintenance is one of the main reasons of under performance of the pump. Please do

maintenance and winterize the pump at appropriate times, especially before and after a period of storage.

30-50 (9-15)

Ft. (M)

0-20 (0-6)

20-30 (6-9)

50-65 (15-19)

14 AWG

8 AWG

10 AWG

AWG (MM²)

12 AWG

REPAIR KITS

A

B

C

D

12

3

4

5

6

51 Series

Quantity

1

1

1

1

1

1

1

1

1

1

Description

Pump Head Assembly

Valve Assembly

Diaphragm Assembly

Motor Assembly

Pressure switch

Diaphragm of Pressure Switch

Pump Head

Diaphragm

Rubber Feet

Motor

A

B

C

D

Key

1

2

3

4

5

6

5

page

4

page

52 Series

A

B

C

D

1

2

3

4

5

6

7

52A Series

Quantity

1

1

1

1

1

1

2

1

1

1

1

Description

Pump Head Assembly

Valve Assembly

Diaphragm Assembly

Motor Assembly

Pressure switch

Diaphragm of Pressure Switch

Quick Attach Clip

Pump Head

Diaphragm

Rubber Feet

Motor

A

B

C

D

Key

1

2

3

4

5

6

7

Quantity

1

1

1

1

1

1

1

1

1

1

1

1

Description

Pump Head Assembly

Valve Assembly

Diaphragm Assembly

Motor Assembly

Pressure Switch

Pump Head

Seat

Motor

Swing Bracket

Pump Base

Diaphragm

Fuse

A

B

C

D

Key

1

2

3

4

5

6

7

8

B

A

1

2

3

D

C

76

5

4

8

7

page

6

page

LOW FLOW AND PRESSURE

Accumulation of debris inside pump or plumbing.

Air leak at pump intake.

Worn pump bearing (possibly accompanied by loud noise).

Punctured diaphragm.

Defective motor.

Punctured diaphragm.

Clogged valves in pump head.

Discharge line leak.

Defective pressure switch.

Insufficient voltage.

PUMP FAILS TO TURN OFF AFTER ALL FIXTURES ARE CLOSED

NOISY

If the pump is plumbed with rigid pipe, then it may transmit noise more easily.

Check if the mounting feet are compressed too tightly.

Check for loose head/screws.

Is the mounting surface flexible? If so, it may be adding noise.

pump

water tank

pressure guage valve

outlet

1.Install the pump as the picture 1.

picture 1

USE THE FOLLOWING PROCESS TO ADJUST SHUT-OFF AND BY-PASS PRESSURES

MOTOR FAILS TO TURN ON

Loose or improper wiring.

Blown fuse.

Failed pressure switch.

Defective motor.

Pump circuit has no power.

FAILURE TO PRIME BUT MOTOR OPERATES - NO PUMP DISCHARGE

Air leak in intake line.

Initial amp supply is not enough to sufficiently start the motor.

Restricted intake or discharge line.

Punctured pump diaphragm.

Debris clogged in the valves.

Crack in pump housing.

TROUBLESHOOTING

PULSATING FLOW– PUMP CYCLES ON AND OFF

Plumbing lines or fittings may be too small.

Clean faucets and filters.

Check lines for kinks.

Check fitting tightness for air leaks.

A

B

D

124

5

6

7

3

C

Quantity

1

1

1

1

1

1

1

1

1

1

1

Description

Pump Head Assembly

Valve Assembly

Diaphragm Assembly

Motor Assembly

Pressure switch

Diaphragm of Pressure Switch

Bypass

Pump Head

Diaphragm

Rubber Feet

Motor

A

B

C

D

Key

1

2

3

4

5

6

7

54 Series

52A(bypass version) or 54 Series

This manual suits for next models

3

Other Seaflo Water Pump manuals

Seaflo

Seaflo 51 Series User manual

Seaflo

Seaflo SFDP1-022-070-34 Instruction Manual

Seaflo

Seaflo 42 Series User manual

Seaflo

Seaflo 33 Series User manual

Seaflo

Seaflo TWIST N’ LOCK’ User manual

Seaflo

Seaflo SFMTP1-01 User manual

Seaflo

Seaflo 34 Series User manual

Seaflo

Seaflo 56A Series User manual

Seaflo

Seaflo 13A User manual

Seaflo

Seaflo SFBP1-G600-07 User manual

Popular Water Pump manuals by other brands

REM POWER

REM POWER SPG 18502 CDR Operating instruction

Denso

Denso first time fit instructions

FLOWTECH

FLOWTECH flowboost F.V Operation and maintenance manual

Grizzly

Grizzly TRP 350 K Translation of the original instructions for use

Pentax

Pentax HPV operating instructions

Speck

Speck BADUJET Perla operating instructions