General description 5

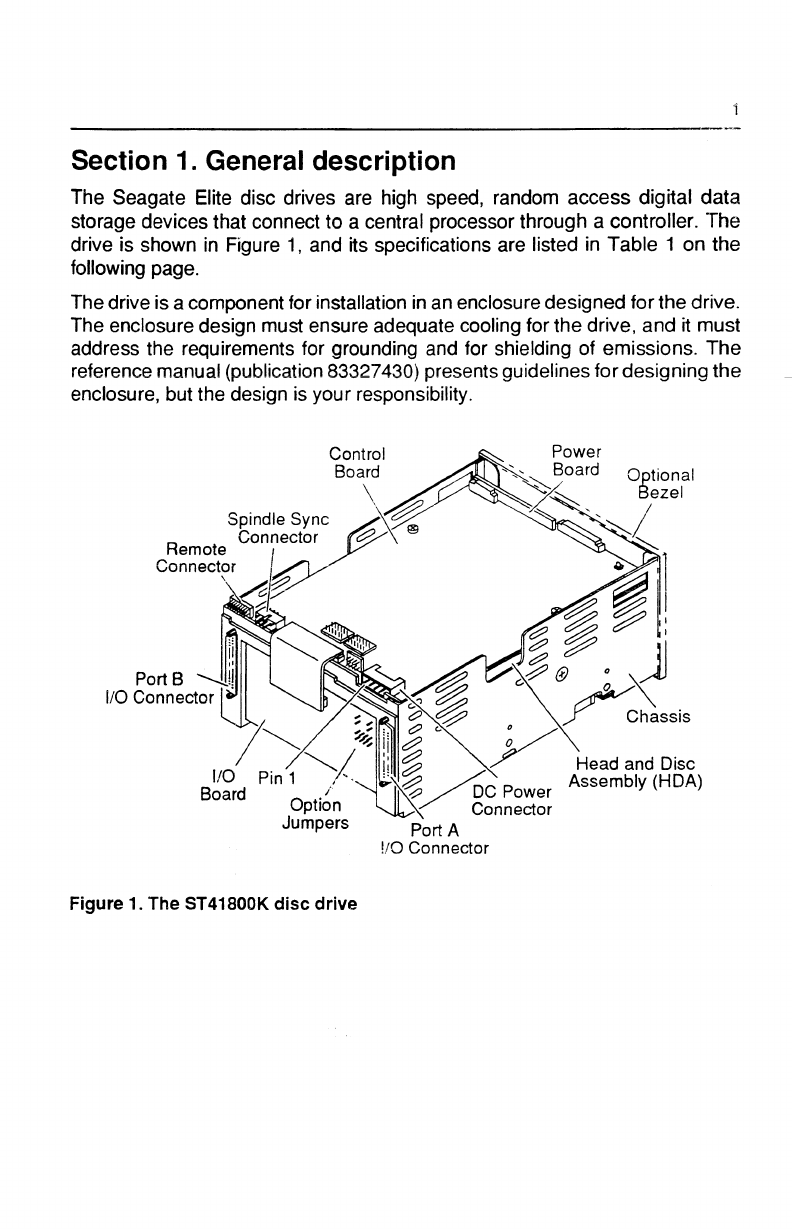

All operations performed by the drive are related to data recovery and storage

(normally referred

to

as reading and writing). The actual reading and writing is

performed by heads that are positioned over the recording surfaces

of

the

rotating discs. There is one head for each data surface. The heads are

positioned

in

such awaythatdata iswritten

in

concentrictracks aroundthe disc

surfaces (see Figure 2).

Before any read or write operation can be performed, the controller must

instruct the drive to position the heads over the desired cylinder (called

seeking) andusethe head located overthe surface (head selection) wherethe

operation is to be performed.

Theheadsare mounted onthe actuator, andtheactuatormovesthe headsover

the rotating discs. There are 19

heads-a

servo head

to

sense actuator

positioning and 18 physical data heads used for data transfers to and from the

discs. Asatwo-headparalleldrive, eachdatatransferemploystwophysicaldata

heads simultaneously. Each pair of physical (read/write) heads is known as a

logical head. The actuatorhas avoice coilthat moves

in

apermanent magnetic

field in response to signals from the servo positioning circuitry. The voice coil

moves the heads

in

an

arc across the rotating discs.

When the drive is not powered

on,

the heads rest on the disc surface in the

preassignedlanding zone (beyondthedatazone). The actuatorisautomatically

latched in thisposition

at

shutdown formoving orshipping protection. Whenthe

drive is activated to bring thediscs upto speed, the heads fly on a cushion

of

air

close to the disc surface.

After arriving at the data track and selecting a logical head, the controller must

locate that portion of the track where the data is to be read

or

written. The

controller usestrack orientation information it receives on

the

interface.

Whenthe head isabovethedesiredtrack location,the controllercommandsthe

drive to actually read

or

write the data. During a read operation, the drive

retrieves data from the discs, processes it, and transmits it

to

the controller.

During a write operation, the drive receives data from the controller, processes

it,

and stores it on the discs.

Thedrive is also capable of recognizing certain errors that may occurduring its

operation. When anerrorisdetected, status informationis availablethroughthe

controller.