Seago Premium Stainless Steel Liftraft Cradle User manual

SEAGO PREMIUM STAINLESS STEEL LIFTRAFT CRADLE

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE ATTEMPTING TO ASSEMBLE AND FIT YOUR CRADLE

The cradle can be mounted on a 25mm diameter push pit rail or alternatively can be

mounted to the deck through the holes on the frame using suitable fixings (not supplied).

Firstly, you should decide on a suitable location for fitting the cradle to allow for quick and

easy development of the liferaft in an emergency.

You must refer to your liferaft operating handbook / fitting instructions to make sure it

is fitted in a compatible way to your liferaft cradle.

In particular you should follow the operating handbook instructions for the correct

launching/deployment of your liferaft. Warning…prior to sailing the painter line on the

liferaft should be attached to a strong point on your vessel in accordance with your

liferaft operating instructions.

WARNING...The secure assembly and fitting of this cradle is the responsibility of the

owner. Regular checks should be made to ensure that all the bolts and fittings are

tight and secure. No responsibility can be accepted for incorrect fitting or failure to

maintain the cradle and its fittings. These instructions are offered only as a guide and

should not be relied upon as being exhaustive or complete in any way.

IF YOU ARE IN ANY DOUBT AS TO THE CORRECT FITTING OF THIS CRADLE

YOU SHOULD SEEK QUALIFIED PROFESSIONAL ADVICE.

Before you start please ensure you have

all the correct fixings (see above).

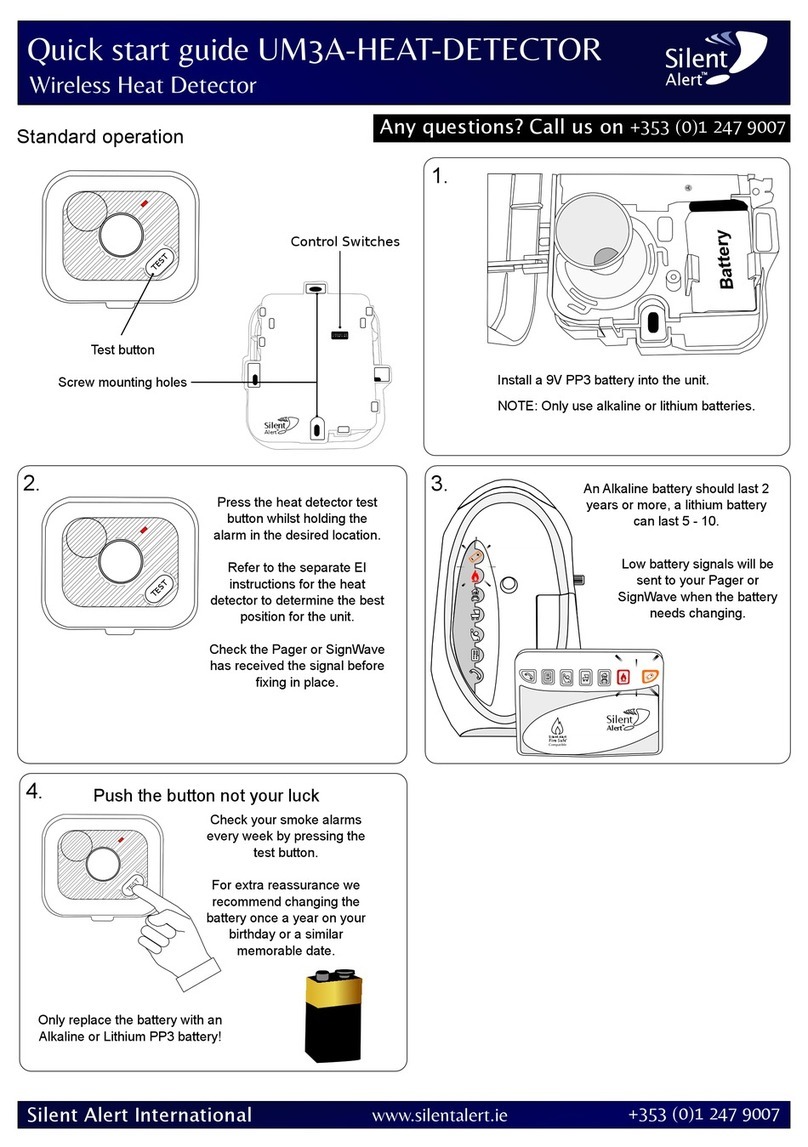

1. Before attempting to fit the cradle to your vessel you should assemble and

adjust the cradle to the correct size of Seago liferaft canister you have, this

will be easier to achieve on land.

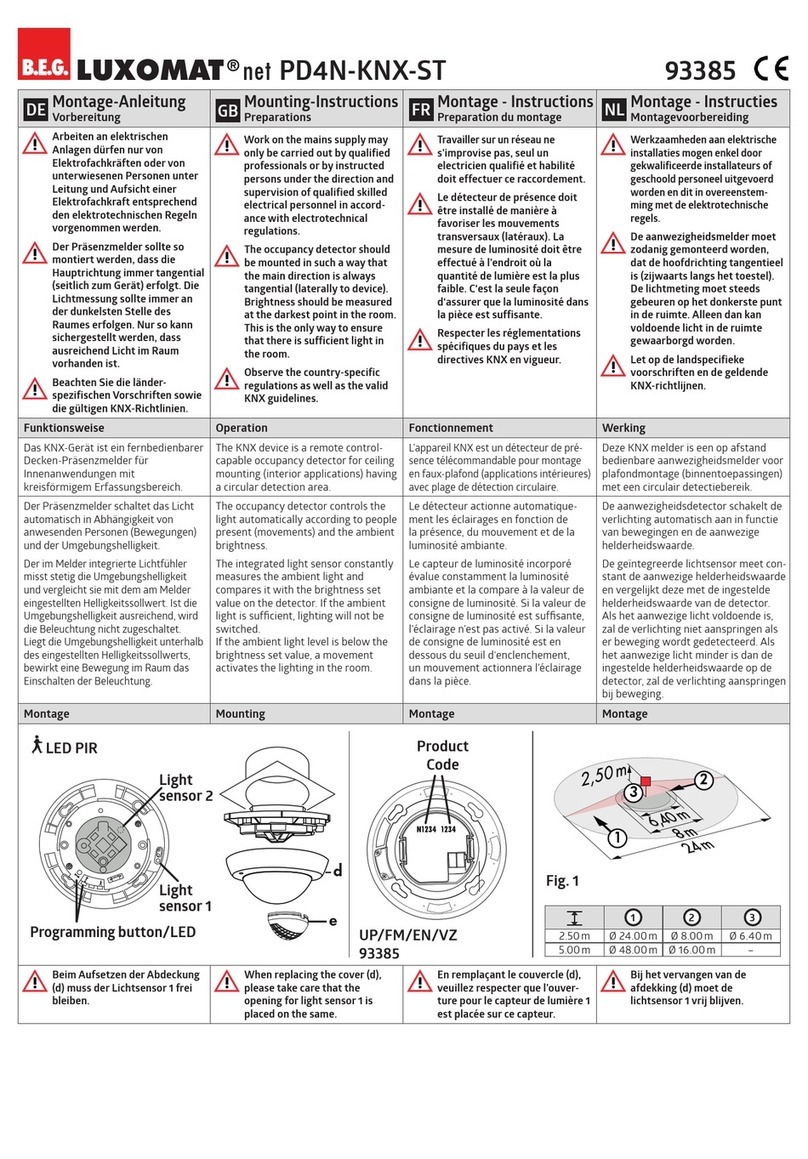

2. With the main frame laid flat on the floor so the drilled rails are closest to

the floor, you should begin by threading part E the logo on the end of the

long webbing strap over the left hand top rail of the main frame (see fig. 1)

3. Pre-measure the width of the life raft canister you are going to fit and adjust

the side rails of the cradle so the canister fits centrally. Position the securing

bolts to the nearest location hole in the main frame. Check the rails will not

foul the canister should it be deployed in an emergency (see fig.2)

4. Tighten the securing bolts on both the right and left hand rails, make sure

you use the correct security bolts provided.

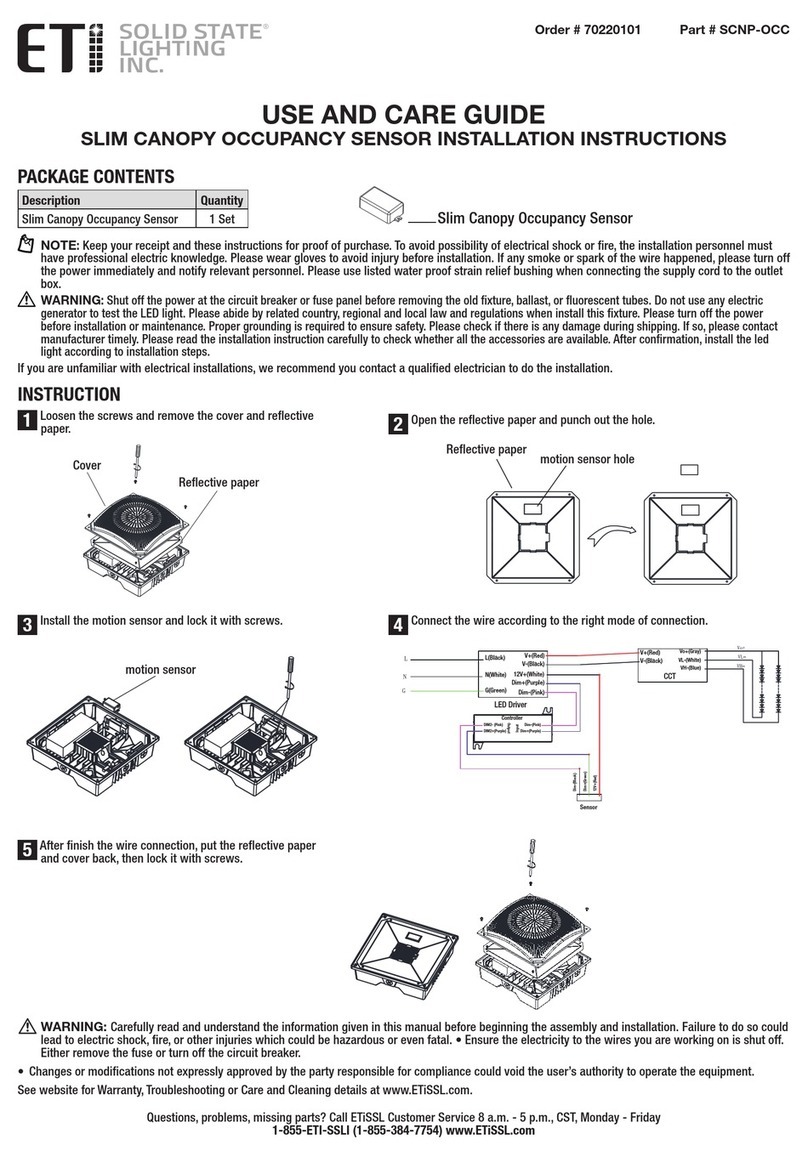

5. After you have secured both left and right hand side rails you can now fit

the lower support rail. Before adjusting and fixing the bolts and the nuts to

the lower rail you need to position the short webbing strap over the rail

making sure the stainless-steel D ring is facing out (see fig.3)

6. There are 3 adjustments positions for the lower rail to suit the size of the

raft you are fitting. You should choose the position that allows the top of

the canister to be level with the top of the rails as possible, make sure the

bolts are tightened and you use the bolts and security nuts supplied

(fig.4).

Follow the steps below for the fitting to a 25mm diameter push-pit or rail. The cradle is designed to

accept Seago life raft canisters for the sizes 4, 6,8 and 10.

Fig.1

Fig.4

Fig.3

Fig.2

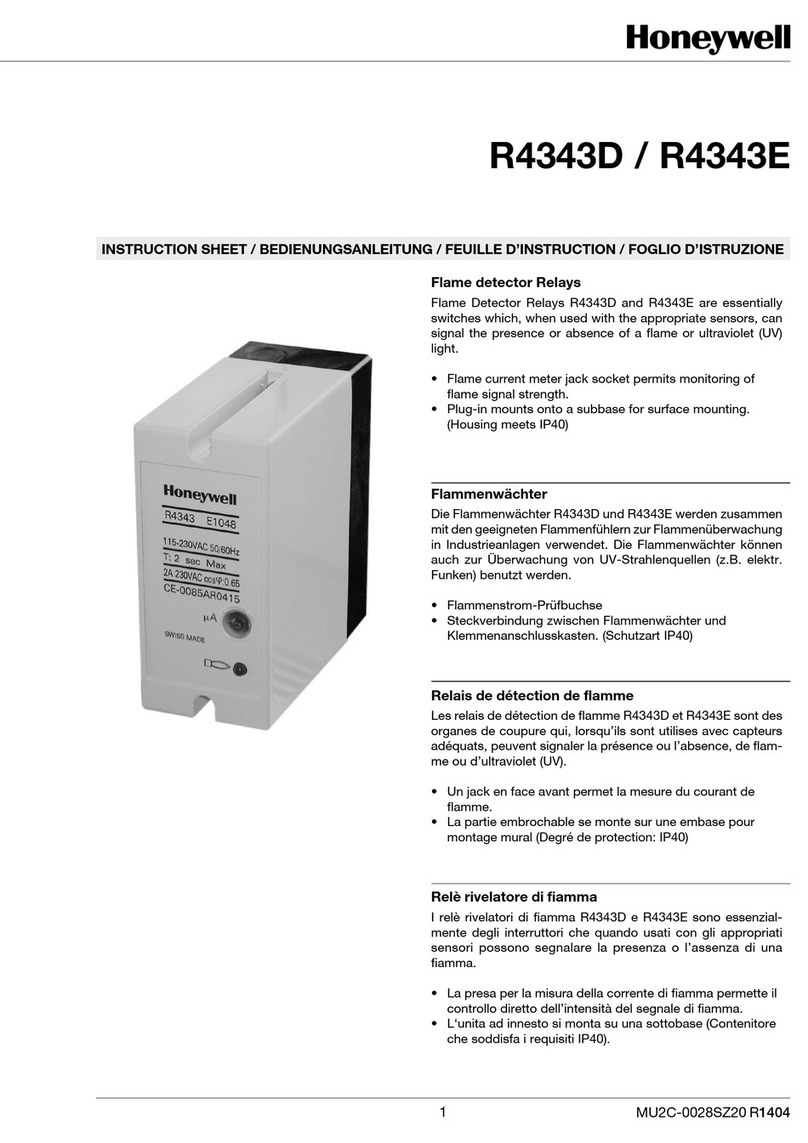

7. Before fixing the cradle to either the deck or push-pit you should fix and adjust the webbing retaining

strap that secures the canister within the cradle (see fig.5)

8. To adjust the webbing retaining strap to the correct tension you should place the cradle flat on the

floor and lay the life raft canister in position. Follow the diagram for the correct threading of the white

webbing retaining strap. The quick release mechanism acts a tensioner for the webbing so you should

adjust the webbing gradually until the point the release mechanism is in the closed position and

causes the webbing to be in a taught and tensioned state (see fig. 6), To make sure there is no

slippage of the webbing you should thread the free end of the webbing back under and through the 3

bar stainless steel adjuster buckle (see fig.6a) make sure the canister is held firmly and there is no

sign of movement in any direction. You must regularly check that the retaining strap is tight and the

raft canister is secure. the tension

9. When you are satisfied with the fitting of the cradle parts and the 4 adjustment of the webbing

retaining strap you can proceed to mounting the cradle to either the push-pit or the deck.

10. For deck mounting you should use suitable fixings (not supplied) to bolt or screw the cradle frame to the

deck. You can use the fixing saddles to further secure the frame of the cradle to the deck (fig. 7).

11. For push-pit mounting you should first offer up the assembled cradle but without the canister fitted.

Ascertain where you need to fix the cradle to the push-pit and secure with the saddles and rail brackets

making sure you use the correct bolts and security nuts (see fig.8).

12. No responsibility will be accepted for the loss of the liferaft if it is not securely fitted and maintained.

13. If you have any warranty issues with this product it must be returned directly to where you purchased it

from to be inspected.

14. You should familiarise yourself and other crew members on the correct method of opening the quick

release buckle / tensioner so as to deploy.

Fig.5

Fig.8

Fig.7

Fig.6

Fig.6a

When stainless-steel is produced, the chromium forms as an outer oxide

layer. As long as that remains intact, the stainless-steel remains passive.

To prevent corrosion, the passivated stainless steel is immersed in a

heated bath of phosphates or salts. This solution forms an oxide film that

seals off the iron. Once the oxide layer begins to break down, the stainless

-steel becomes active and its corrosion resistance is reduced. Rust is

obvious, visible evidence of corrosive activity, ways in which the oxide layer

is compromised; pitting and crevice corrosions caused by microscopic

water-retaining cracks or scratches, microscopic impurities and stress

fatigue cracking.

For preventive maintenance, polish the surface of the stainless steel polish.

Polishing creates a smooth metal surface and helps minimize the number

of pits, valleys and microscopic cracks where moisture can reside and

create the environment corrosion loves.

Table of contents

Other Seago Security Sensor manuals