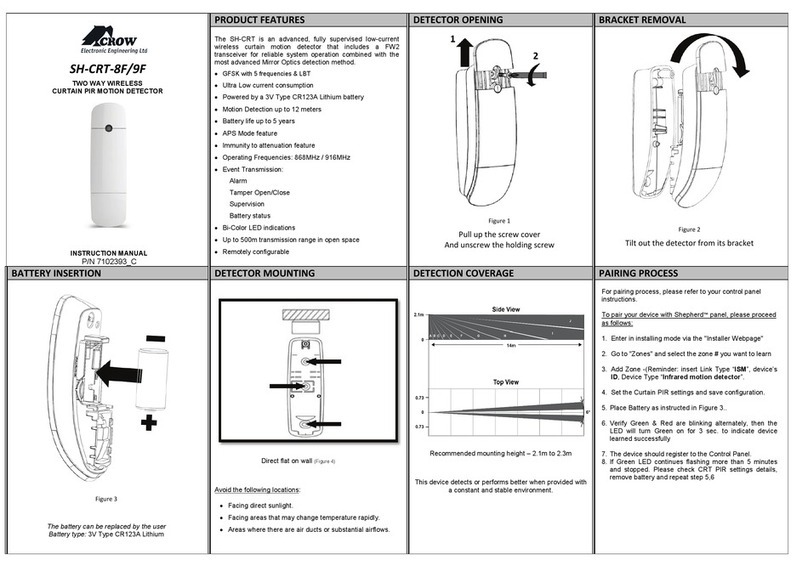

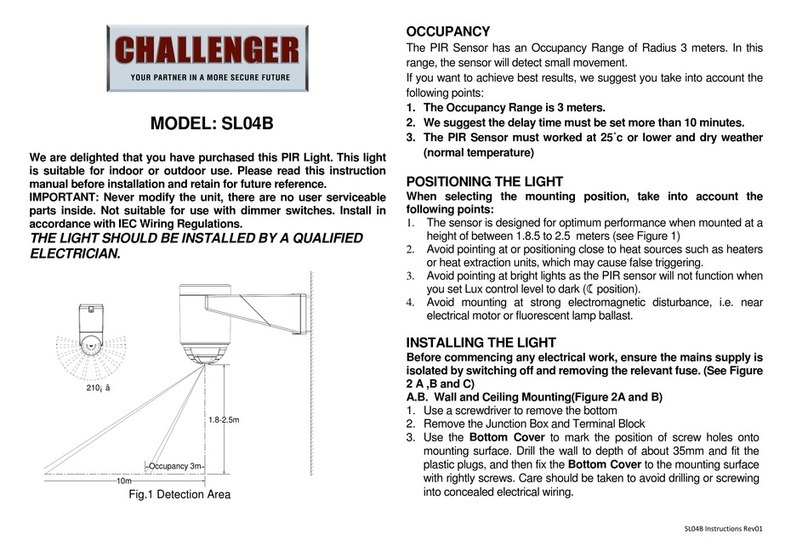

SETTING UP THE DETECTOR

PET IMMUNITYJUMPER SETTING

The PET jumper on the left side is used for setting the

PET Immune function - up to 12kg or 25kg, depending

on the pet size.

LED ENABLE JUMPER SETTING

The LED jumper on the right side is used for setting -

LED Enable / Disable.

OFF - The LED is disabled.

ON - LED ENABLE. The LED will activate when the

detector is in alarm condition.

** Factory Setting

PULSE WIDTH JUMPER SETTING

The PULSE jumper is used for setting the PULSE

count function in order to provide PIR sensitivitycontrol

according to the environment.

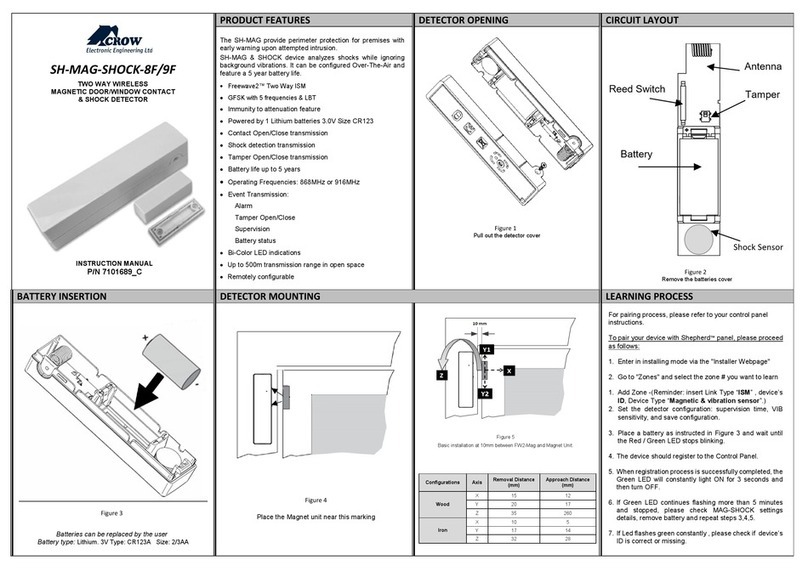

TESTING THE DETECTOR

Upon installation, the unit should be thoroughly tested to

verify proper operation. The end user should be

instructed on how to perform a walk test weekly.

Walk test (in local mode LED jumper = ON)

1. Remove front cover.

2. Set LED Jumper to ON position.

3. Reassemble the front cover.

4. Start walking slowly across the detection zone.

5. Observe that the LED lights whenever motion is

detected.

6. Allow 5 sec. between each test for the detector to

stabilize.

7. After the walk test is completed, you can set the

LED jumper to AUTO position.

Note:

To assure proper operation, the range and coverage

area should be checked at least twice a year.

For UL installations the detector shall be tested

annually.

Note:

The LED Switch does not affect the operation of the relay.

When an intrusion is detected, the LED will activate

according to LED jumper position and the ALARM relay will

switch into alarm condition for 2 sec.

Quad (Four element)

PIR & microwave pulse Doppler

Active: 18mA (± 5%)

Standby: 21mA (± 5%)

Form C - NC&NO

28Vdc 0.1 A with 10 Ohm

series protection resistors

N.C 28Vdc 0.1 A with 10 Ohm

series protection resistors

open when cover is removed

-10ºC ~ +50 ºC (14 ºF~122 ºF)

STANDARDS

European Council Directive 2004/108/EC

EN50130-4+A1+A2

EN61000-6-3

EN55022

EN50371

EN50130-5

EN50131-1

EN50131-2-2

SAFETY LVD 2006/95/EC

EN60950-1 (93/68/EEC)

Security Grade 2, Environmental Class II

For more detailed instruction please refer the manuals

which you could download from the internet at:

www.thecrowgroup.com

Certified by: ANPI INCERT NUMBER

XXXXXX

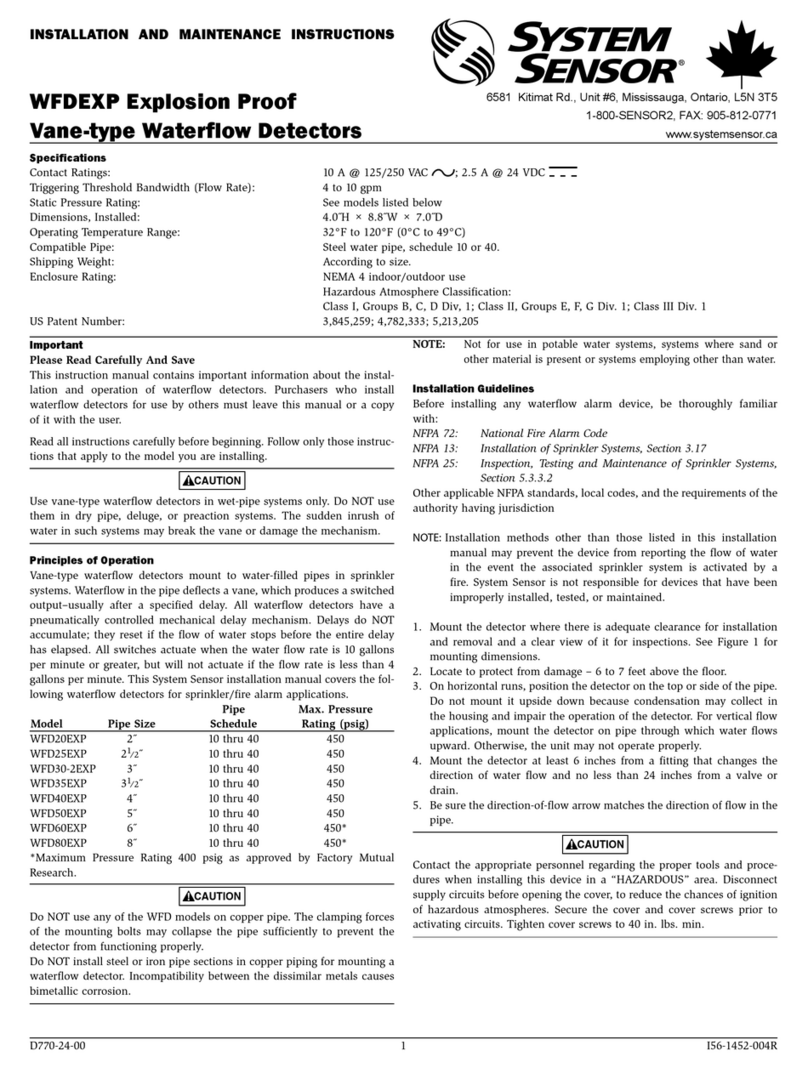

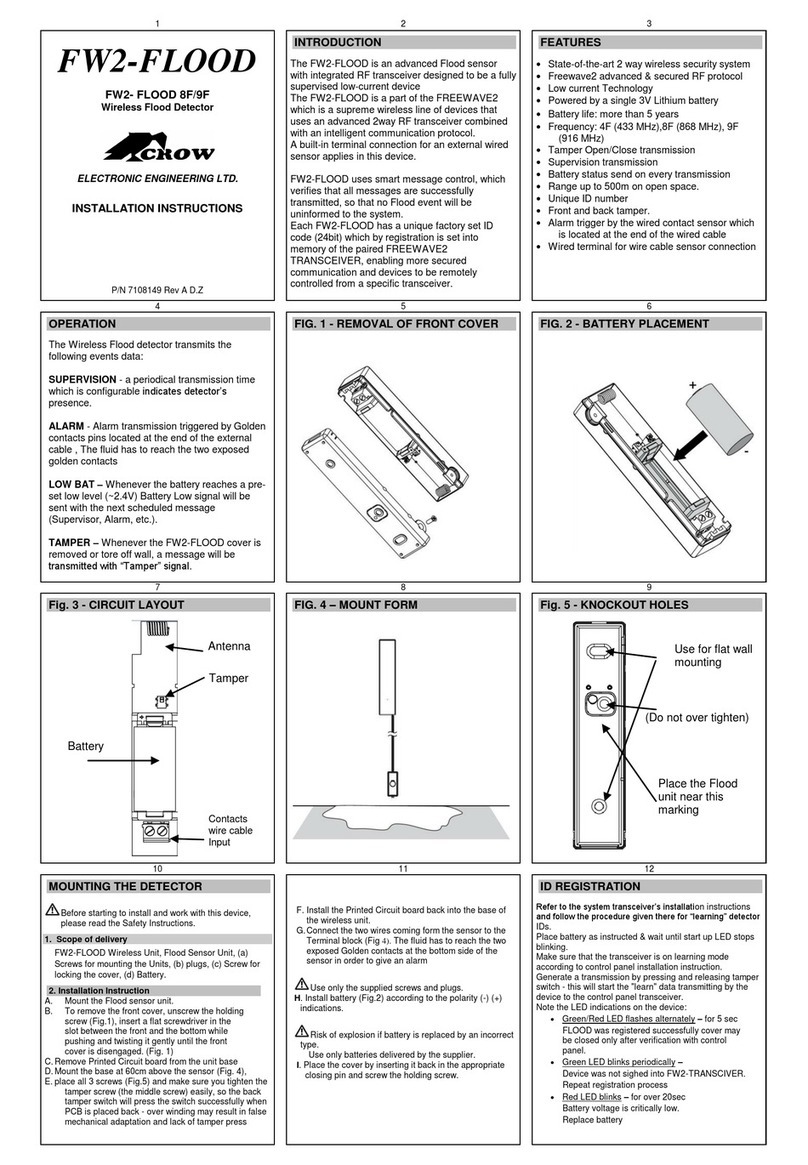

Option B - Connecting single detector with 2 wire and EOL resistors

EOL Connection Options

The End-Of-Line connection options are described in the

following drawings.

Set J3 JUMPER “2/4” according to connection option

Set J4 “REOL” and J2 “RAL” Jumpers according to

EOL resistors value (see fig. 3)

Option A - 4 Wire Connection with EOL

Option C - Connecting multiple detectors with 2 wire and EOL resistors

CROW ELECTRONIC ENGINEERING LTD. ("Crow") - WARRANTY POLICY CERTIFICATE

This Warranty Certificate is given in favor of the purchaser (hereunder the "Purchaser") purchasing the products directly fromCrow or from its authorized distributor.

Crow warrants these products to be free from defects in materials and workmanship under normal use and service for a period of 24 months from the lastday of theweek and

year whose numbers are printed on the printed circuit board inside these products (hereunder the "Warranty Period").

Subject to the provisions of this Warranty Certificate, during the Warranty Period, Crow undertakes, at its sole discretion and subject to Crow's procedures, as such procedures

are form time to time, to repair or replace, free of charge for materials and/or labor, products proved to be defective in materials or workmanship under normaluse and service.

Repaired products shallbe warranted for the remainder of the original Warranty Period.

All transportation costs and in-transit risk of loss or damage related, directly or indirectly, to products returned to Crow for repair or replacement shall be borne solely by the

Purchaser.

Crow's warranty under this Warranty Certificate does not cover products that is defective (or shall become defective) due to: (a) alteration of the products (or any part thereof) by

anyone other than Crow; (b) accident, abuse, negligence, or improper maintenance; (c) failure caused by a product which Crow did not provide; (d) failure caused by software or

hardware which Crow did notprovide; (e) use or storage other than in accordance with Crow’s specified operating and storage instructions.

There are no warranties, expressed or implied, of merchantability or fitness of the products for a particular purpose or otherwise,which extend beyond the description on the face

hereof.

This limited Warranty Certificate is the Purchaser's sole and exclusive remedy againstCrow and Crow's sole and exclusive liability toward the Purchaser in connection with the

products, including without limitation - for defects or malfunctions of the products. This Warranty Certificate replaces all other warranties and liabilities, whether oral,written,(non-

mandatory) statutory, contractual, in tort or otherwise.

In no case shall Crowbe liable to anyone for any consequential or incidental damages (inclusive of loss of profit, and whether occasioned by negligence ofthe Crow or any third

party on its behalf) for breach of this or any other warranty, expressed or implied, or upon any other basis ofliability whatsoever. Crow does not represent that these products

can not be compromised or circumvented; that these products will prevent any person injury or property loss or damage by burglary, robbery, fire or otherwise; or that these

products will in all cases provide adequate warning or protection.

Purchaser understands that a properly installed and maintained product may in some cases reduce the risk of burglary, fire, robbery or other events occurring without providing

an alarm, but it is not insurance or a guarantee that such willnot occur or that there will be no personalinjury or property loss or damage as a result.

Consequently,Crow shall have no liability for any personal injury; property damage or any other loss based on claimthat these products failed to give any warning.

If Crow is held liable, whether directly or indirectly, for any loss or damage with regards to these products, regardless of cause or origin, Crow’s maximumliability shall notin any

case exceed the purchase price of these products, which shall be the complete and exclusive remedy againstCrow.

These instructions supersede all previous issues in circulation prior to October 2010.

CROW ELECTRONIC ENGINEERING LTD.

ISRAEL: Crow Electronic Engineering Ltd.

12 Kineret St. Airport City

P.O. Box 293

Ben Gurion Airport , 70100

Tel: 972-3-9726000

Fax: 972-3-9726001

www.thecrowgroup.com

sales@crow.co.il

support@crow.co.il

P/N 7101055 REV. A Y.S - 2 -

NO: Pet Immune non-active -

Suppresses alarm for pets up

to a weight of 12 kg.

** Factory Setting

YES: Pet Immune active - Suppresses

alarm for pets up to a weight of 25 kg

Very stable environment

Jumper #1 = ON

Without PET

Moderate nuisance

situation,

Harsh environment