Seamax M-22 User manual

AMM

Aircraft Maintenance Manual

Seamax M-22

Serial Number:

Copy N

0

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 2

Revisions Registration

The revisions pages are updated b SEAMAX AIRCRAF L DA, each time revision is issued.

The list below contains all the revisions made on the maintenance manual.

Revision

number

Date issued Affected

chapters

Affected pages Approved by

First Edition 06/15/2007 Miguel Rosario

01 03/20/2010 2, 2.2, 2.4 9,11, 12, 14, 15 Miguel Rosario

02 11/06/2013 Miguel Rosario

03 01/10/2017 2, 4, 7 2,10,11,18,21,

23,44, 58, 74

Miguel Rosario

04 02/28/2018 2 11, 12, 17, 25 Miguel Rosario

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 3

Table of Content

Seamax M-22 Aircraft Maintenance Manual front sheet ............................................................... 01

REVISIONS .........................................................................................................

02

able of Content .................................................................................................

04

2 General ...........................................................................................................

10

2.1

Instructions for Reporting Possible Safet of Flight Concerns ................... 12

2.2 Views and dimensions ............................................................................... 13

2.3 List of Materials ......................................................................................... 14

2.4 List of equipment’s ..................................................................................... 15

2.5 Sources to purchase parts ......................................................................... 17

2.6

List of disposable replacement parts .......................................................... 17

2.7 Engine specifications ................................................................................. 18

2.8

Weight and balance information ................................................................ 20

2.9 Tire inflation pressure ................................................................................ 23

2.10 Approved oils and capacities ..................................................................... 23

2.11 Recommended fasteners torque values .................................................... 24

2.12 General safet information ......................................................................... 24

2.13 Instructions for reporting possible safet of flight concerns found during

inspection / maintenance ...................................................................................... 25

3 Inspections ................................................................................................... 27

3.1

Aircraft records

.................................................................................... 27

3.2

Start-up ...................................................................................................... 28

3.3 Post run-up ................................................................................................ 29

3.4 Power plant ................................................................................................ 30

3.5 Wings ........................................................................................................ 31

3.6 Fuselage .................................................................................................... 31

3.7 Tail ............................................................................................................ 32

3.8 Landing gear .............................................................................................. 33

3.9 Cabin ......................................................................................................... 33

3.10 Inspection completion ................................................................................ 35

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 4

4 Structures

........................................................................................................... 36

4.1 Wings ........................................................................................................ 36

4.1.1 Wing structure ................................................................................ 36

4.1.2 Wings installation and removal ....................................................... 37

4.1.2.1 Tools required ................................................................... 37

4.1.2.2 Parts and material required ............................................... 37

4.1.2.3 T pe of maintenance ........................................................ 37

4.1.2.4 Level of certification .......................................................... 37

4.1.2.5 Wing installation ............................................................... 47

4.1.2.6 Wing removal ................................................................... 40

4.1.2.7 Verification required .......................................................... 40

4.2 Tail ............................................................................................................ 41

4.2.1 Stabilator installation and removal .................................................. 41

4.2.1.1 Tools required ................................................................... 41

4.2.1.2 Parts and material required ............................................... 42

4.2.1.3 T pe of maintenance ........................................................ 42

4.2.1.4 Level of certification .......................................................... 42

4.2.1.5 Stabilator installation ......................................................... 42

4.2.1.6 Setting angles of deflection ............................................... 43

4.2.1.7 Verification of stabilator installation and adjustment .......... 44

4.3 Landing gear ............................................................................................. 44

4.3.1 Front landing gear .......................................................................... 44

4.3.1.1 Tools required ................................................................... 44

4.3.1.2 Material required ............................................................... 44

4.3.1.3 T pe of maintenance ........................................................ 45

4.3.1.4 Level of certification .......................................................... 45

4.3.1.5 General ............................................................................. 45

4.3.1.6 Inspections ....................................................................... 45

4.3.1.6.1 Arm/fork inspection ........................................... 45

4.3.1.6.2 Shock absorber inspection ................................ 46

4.3.1.6.3 Retract s stem inspection ................................. 46

4.3.1.7 Front landing gear removal / installation ........................... 47

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 5

4.3.1.7.1 Wheel and fork removal / installation ................ 47

4.3.1.7.2 Shock absorber removal / installation ................ 47

4.3.1.7.3 Arm removal / installation ................................... 48

4.3.2 Main landing gear .......................................................................... 49

4.3.2.1 Tools required ................................................................... 49

4.3.2.2 Material required ............................................................... 50

4.3.2.3 T pe of maintenance ........................................................ 50

4.3.2.4 Level of certification .......................................................... 50

4.3.2.5 General ............................................................................. 50

4.3.2.6 Inspections ............................................................................. 50

4.3.2.6.1 Arm inspection .................................................. 51

4.3.2.6.2 Shock absorber inspection ................................ 52

4.3.2.6.3 Retract s stem inspection ................................. 52

4.3.2.7 Main wheel and axle removal / installation ........................ 53

4.3.2.8 Triangle arm removal / installation .................................... 53

4.3.2.9 Shock absorber leg removal ............................................. 54

4.3.2.10 Retraction s stem tuning .................................................. 54

4.3.3 Brakes ............................................................................................ 55

4.3.3.1 Tools required ................................................................... 55

4.3.3.2 Materials required ............................................................. 56

4.3.3.3 T pe of maintenance ........................................................ 56

4.3.3.4 Level of certification .......................................................... 56

4.3.3.5 General ............................................................................. 56

4.3.3.6 Inspection ......................................................................... 57

4.3.3.7 Filling s stem with oil ........................................................ 58

4.3.3.8 Brake pads replacement ................................................... 58

4.4 Control surfaces ........................................................................................ 60

4.4.1 Ailerons .......................................................................................... 60

4.4.1.1 Tools required ................................................................... 60

4.4.1.2 Materials required ............................................................. 60

4.4.1.3 T pe of maintenance ........................................................ 60

4.4.1.4 Level of certification .......................................................... 60

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 6

4.4.1.5 General ............................................................................. 61

4.4.1.6 Inspection ......................................................................... 61

4.4.1.7 Aileron removal / installation ............................................. 61

4.4.1.8 Aileron setting ................................................................... 62

4.4.1.9 Aileron verification and adjustment ................................... 62

4.4.2 Flaps ............................................................................................. 63

4.4.2.1 Tools required ................................................................... 63

4.4.2.2 Material required ............................................................... 63

4.4.2.3 T pe of maintenance ........................................................ 63

4.4.2.4 Level of certification .......................................................... 63

4.4.2.5 General ............................................................................. 64

4.4.2.6 Inspection ......................................................................... 64

4.4.2.7 Flaps removal / installation ............................................... 65

4.4.2.8 Flaps settings ................................................................... 65

4.4.2.9 Flaps verification and adjustment ...................................... 66

4.4.3 Rudder .......................................................................................... 66

4.4.3.1 Tools required ................................................................... 66

4.4.3.2 Materials required ............................................................. 66

4.4.3.3 T pe of maintenance ........................................................ 66

4.4.3.4 Level of certification .......................................................... 67

4.4.3.5 General ............................................................................. 67

4.4.3.6 Water rudder removal / installation ................................... 67

4.4.3.7 Rudder removal / installation ............................................ 68

4.4.3.8 Rudder adjustment ........................................................... 69

4.4.3.9 Rudder verification and adjustment ................................... 69

5 Engine ....................................................................................................... 70

6 Fuel system ................................................................................................. 71

6.1 General ...................................................................................................... 71

6.2 Tools required ............................................................................................ 72

6.3 Material required ........................................................................................ 72

6.4 T pe of maintenance ................................................................................. 72

6.5 Level of certification ................................................................................... 72

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 7

6.6 Fuel s stem inspection check list ............................................................... 72

6.7 Fuel filter .................................................................................................... 73

6.8 Fuel vents .................................................................................................. 73

6.9 Removal / installation of wing fuel tanks .................................................... 73

6.10 Header tank ............................................................................................... 74

7 Propeller ...................................................................................................... 75

7.1 T pe of maintenance ........................................................................ 75

7.2 Level of certification .......................................................................... 75

8 Instruments and avionics ............................................................................ 76

8.1 Tools required ................................................................................... 76

8.2 Parts required .................................................................................... 76

8.3 T pe of maintenance ........................................................................ 76

8.4 Level of certification .......................................................................... 76

8.5 Maintenance ..................................................................................... 76

8.5.1 Airspeed ................................................................................. 77

8.5.2 Altimeter ................................................................................. 77

8.5.3 Vertical speed ......................................................................... 77

8.5.4 Compass ................................................................................ 78

8.5.5 Bank indicator ......................................................................... 78

8.5.6 RPM ........................................................................................ 78

8.5.7 Oil pressure ............................................................................ 78

8.5.8 Oil temperature ....................................................................... 78

8.5.9 Water temperature ................................................................. 79

8.5.10 Flap position indication lights .................................................. 79

8.6 Pitot line and static port ..................................................................... 79

8.7 Special instruments and avionics ...................................................... 79

9 Electrical system .......................................................................................... 80

9.1 Tolls required .................................................................................... 81

9.2 Materials required ............................................................................. 81

9.3 T pe of maintenance ........................................................................ 81

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 8

9.4 Level of certification .......................................................................... 81

9.5 General ............................................................................................. 81

9.6 Inspection .......................................................................................... 81

9.7 Batter replacement .......................................................................... 82

9.8 Wiring diagram .................................................................................. 83

10 Structural repairs ........................................................................................ 84

10.1 T pe of maintenance ........................................................................ 84

10.2 Level of certification .......................................................................... 84

11 Painting and coating .................................................................................. 85

11.1 Tools required ................................................................................... 85

11.2 Materials required ............................................................................. 85

11.3 T pe of maintenance ........................................................................ 85

11.4 Level of certification .......................................................................... 85

11.5 Putting ............................................................................................... 86

11.6 Priming ............................................................................................... 86

11.7 Painting ............................................................................................. 86

11.8 Polishing ........................................................................................... 86

11.9 Final verification ................................................................................. 86

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 9

2. General

This is the four revision of the Seamax AMM manual, for the airplane version 2018. Minor

modifications, as optional, are available to this version or earlier. Those modifications as new high

performance wing tips and fins for elevator are described in this manual.

Seamax M-22 is a monohull seaplane, with a S-LSA certification, with composite fuselage /

hull, elevator and wing tip floats, and an aluminum fabric covered wing, ailerons and flaps. Landing

gear is a retractable tric cle configuration with differential breaking steering. One piece canop ,

pusher engine and stabilator with anti servo tab are the main characteristics of this airplane.

NOTE: to accomplish the tasks described on this manual needed responsible person with

following level of certification:

OWNER - responsible owner of the Light Sport Aircraft, which holds a sport pilot certificate,

or higher rating.

REPAIRMAN – To make repairs on this aircraft, one must be a Light Sport Repairman

Maintenance Aircraft (LSRMA) - which holds a FAA repairman certificate (LSA), with maintenance

rating or equivalent (FAA A&P).

SEAMAX compliance with all standards ASTM for LSA: F2245-16c, F2483-12, F2295-10,

F2746-14, F2972-15, F3035-13, F2745-11

WARNING

To assure the receiving supplemental notification bulletins, and manuals

revisions, is owner/operator responsibilit , providing SEAMAX with current

contact information, where the will be sent

BRAZIL HEADQUAR ERS:

SEAMAX AICRAF L DA.

Aeroporto de São João da Boa Vista – SP - BRA

Hangar 01

Rod. SP 344, km 19, ZIP: 13.870-970

Phone: (55) 19 99850-6810

Site: www.seamaxaircraft.com

UNI ED S A ES HEADQUAR ERS:

SEAMAX, LLC.

Embr Riddle Aeronautical Universit Research Park

1511, Aviation Center Parkwa

Da tona Beach, FL, 32114 - USA

Phone: +1 (260) 460-7587

E-mail: [email protected]m

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 10

DEFINI IONS

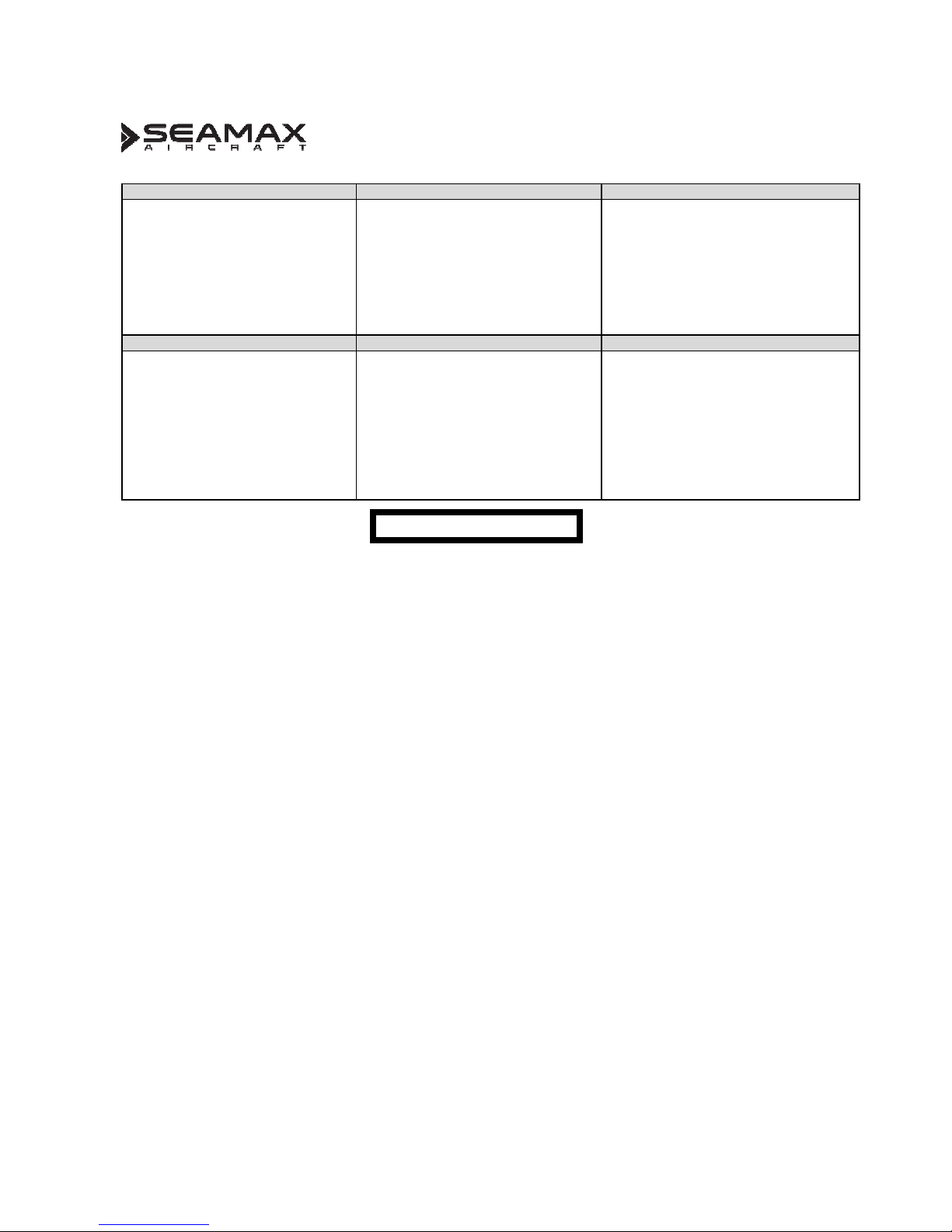

Heavy Maintenance Line Maintenance Overhaul

any maintenance, inspection, repair, or

alteration a manufacturer has designated that

requires specialized training, equipment, or

facilities.

any repair, maintenance, scheduled checks,

servicing, inspections, or alterations not

considered heavy maintenance that is approved

by the manufacturer and is specified in the

manufacturer's maintenance manual

maintenance, inspection, repair, or alterations that

are only to be accomplished by the original

manufacturer or a facility approved by the original

manufacturer of the product

100 hours Annual Inspection Major Repair/Alteration

This is the required inspection in RBH 91

section 91.409 (b) with the scope detailed in

ppendix D of RB C 43. This type of

inspection is required in the aircraft

manufacturer's maintenance manual

Inspection which is intended to attest to the

airworthiness conditions of an aircraft, including

its components and equipment, as defined by

RB C 91.403 (e) and ppendix D of RB C 43.

means a modification not listed in the approved

technical specification of the aircraft, engine or

propeller and which: (1) may substantially affect

weight, balance, structural strength, flight and

maneuverability characteristics or any other

airworthiness related feature; or (2) is not

performed in accordance with acceptable practices

or can not be performed using elementary

operations.

NO E

MAJOR REPAIRS A D/OR ALTERATIO S

All major repairs and/or alterations require an approved MRA (Major Repair and/or Alteration) form from

SEAMAX. Requests for an MRA can be made to Customer Support at SEAMAX, or through a form on the

compan website, link: http://www.seamaxaircraft.com/ownership.html

The latest revisions of all applicable service documents released b SEAMAX, require an MRA form. These

documents, which include service alerts, service bulletins, and echnical Information ( I), are considered

appendices to this maintenance manual.

AUTHORIZATIO TO PERFORM HEAVY MAI TE A CE

No heav maintenance, as outlined in ASTM F2483, RBAC/FAR 43, or in this manual are authorized at this

time.

To obtain engineering approvals for an major repairs or alterations, please contact SEAMAX AIRCRAFT

LTDA.

HEAVY MAINTENANCE TASKS:

1- Removal and Replacement of Components

2- Repair of Components or Aircraft Structure

3- Alterations of Components or Aircraft Structure

OVERHAUL

No overhauls as outlined in ASTM F2483, RBAC/FAR 43, or in this manual are authorized at this time.

Overhauls can onl be performed b SEAMAX.

To obtain engineering approvals for an major repairs or alterations, please contact SEAMAX.

COMPONENTS PLANNED FOR OVERHAUL: 1- Structure, 2- Engine, 3- Propeller

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 11

2.1 Instructions for Reporting Possible Safety of Flight Concerns Found

During Operation

Possible safet of flight concerns should be reported to the factor , b e-mail, letter or fax. Bellow

adresses for report:

SEAMAX BRAZIL HEADQUARTERS:

SEAMAX AICRAF L DA.

Aeroporto de São João da Boa Vista - SP

Hangar 01

Rod. SP 344, km 19, ZIP: 13.870-970

Phone: (55) 19 99850-6810

Site: www.seamaxaircraft.com

SEAMAX UNITED STATES HEADQUARTERS:

SEAMAX, LLC.

Embr Riddle Aeronautical Universit Research Park

1511, Aviation Center Parkwa

Da tona Beach, FL, 32114 - USA

Phone: +1 (260) 460-7587

E-mail: [email protected]m

AUTHORIZED MAINTENANCE CENTER:

LOCKWOOD AVIA ION SUPLY

1, Lockwood Lane

Sebring, FL 33870, USA

Phone: + 1 (863) 655-4242

Website: https://lockwood.aero/

AUTHORIZED MAINTENANCE CENTER:

OMI AIRCRAF , INC.

1310, Filghtline, Blvd

Deland, FL 32724

Phone: + 1 (863) 446-3001

Website: http://www.tomiaircraft.com/

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 12

2.2 Views and Dimensions

Wing span 33, 07 ft 10, 08 m

Stabilator span 10, 09 ft 3, 07 m

Vertical fin 6, 4 ft 1905 m

Length 19, 8 ft 6,05 m

Wing area 129, 6 sqft 12, 04 sqm

Height 6, 2 ft 1, 9 m

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 13

2.3 List of Materials

1 Epox resin GY 260 (Huntsman)

2 Hardener HY 951 (Huntsman)

3 Fiberglass bidirectional fabric 4 Oz

4 Fiberglass bidirectional fabric 10Oz

5 Fiberglass bidirectional fabric 16 oz

6 Carbon fiber bidirectional fabric 8 oz

7 Carbon fiber unidirectional tape

8 Kevlar bidirectional fabric 10 oz

9 Aluminum 6061T6 tubing

10 Aluminum 5051H34 sheets

11 Stainless steel sheet and tubing AISI 304

12 Covering fabric

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 14

2.4 List of Equipments

Seamax M-22 S-LSA “read to fl ” seaplane

Standard Equipment

Outside paint, UV resistant, PU base white;

Outside decorative stripes in vin l;

One piece canop , tinted green with two snap vents;

Inside leather finishing;

Three point seat belts;

Adjustable seats, in leather cushions;

Carpets for both sides;

Front pockets in leather;

Central jo stick mount;

Dual power levels;

Dual h draulic brakes, differential for steering;

Electric pitch trim with level on dashboard;

Electric actuated flaps, with position lights on dashboard;

Two fuel valves, one for each tank;

Two wing tanks and a central heater tank;

Retractable, electric activated tric cle landing gear with position lights on dashboard;

Ignition switch with ke ;

Circuit brakes for all electric s stem;

Retractable water rudder;

Landing lights;

Strobe lights;

Navigation lights;

Electric fuel pump;

Electric bilge pump.

Engine

Rotax 912 ULS 100hp, equipped with clutch and stainless steel exhaust s stem.

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 15

Standard Flight Instruments

3 1/8 UMA altimeter

UMA Vertical speed indicator

UMA airspeed indicator

Magnetic compass

Optional Flight Instruments

Glass instruments D non D-100, or D-180

Engine Instruments

Mitchell 2 ¼ analogical instruments

Fuel pressure

Voltmeter

Oil pressure

Oil temperature

C linder head temperature

UMA 2 ¼ RPM

Propeller

Warp drive, three blades constant speed shape, with nickel protection leading edge, HPL-R

hub

Fiberglass spinner is optional.

Communication & Navigation (optional)

VHF Radio X-com

Transponder Becker with “C” mode

ELT

Ameri-king corporation model AK-450 per TSO-C91a and DO-160c Requirements.

Options

VHF radio, Xponder, GPS, EFIS, EMS, Auto pilot, Intercom, PCAS, GPS.

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 16

General Options

Canop protection cover;

Jack for landing gear test;

Hardware for water operation;

Fins for elevator;

Wing tips model 2010.

2.5 Sources to Purchase Parts

All the spare parts can be purchased from the factor , SEAMAX AIRCRAF L DA.

(www.seamaxaircraft.com.br) E-mail [email protected].

Usual aircraft parts as bolts, nuts, rivets, turnbuckles, etc, can be purchase on an aviation suppl

compan .

All parts can be checked and ordered, using the information’s and drawings along this maintenance

manual.

2.6 List of Disposable Replacement Parts

Air filter KN

Fuel filter fuel filter

Oil filter oil filter

Main wheel tire 500X5

Main wheel tube 500X5 bent valve

Front wheel tire 350X4

Front wheel tube 350X4 bent valve

Brake pads brake pads

Engine Spark plugs spark plugs

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 17

2.7 Engine Specifications

NO E: for complete information about engine specifications and limitation, read the

Maintenance Manual for Rotax 912 series, supplied with the aircraft

Manufacturer Rotax

T pe 912

Model ULS/S

General Specifications:

4 stroke, 4 c linders opposed, one central camshaft, push rods OHV

Liquid cooled heads

Ram air cooled c linders

Dr sump forced lubrication

2 constant depression carburetors

Mechanical fuel pump

Propeller drive via reduction gear with shock absorber and clutch, ratio 2,43:1

Electric starter

Integrated AC generator with external rectifier/regulator

Operating Limits

Speed

Take off speed 5800 rpm/min (5 minutes)

Max. Continuous speed 5500 rpm/min

Idle speed 1400 rpm/min

Performance

Take off performance 73,5 KW @ 5800 rpm

Max. Continuous performance 69 KW @ 5500 rpm

Acceleration

Max. 5 seconds at max -0,5 g´s

Oil pressure

Max. 7 bar (short period, cold start)

Min. 0,8 bar (12 psi) below 3500 rpm

Normal 2,0-5,0 bar (29-7 psi) above 3500 rpm

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 18

Oil temperature

Max 130 C (266 F)

Min 50 C - 130 (120 F – 266 F)

Normal 90-110 C (190-230 F)

Cylinder head temperature

Normal 130 (266)

Attention 130 (266)–135 (275)

Max 135 C (275 F)

Engine start, operating temperature

Max 50 C (120 F)

Min -25 C (-13 F)

Fuel pressure

Max 0, 4 bar (5, 8 psi)

Min 0, 15 bar (2, 2 psi)

More detailed engine information is available in the Maintenance Manual for Rotax, type 912,

supplied with the aircraft

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 19

2.8 Weight and Balance Information

Weights starting:

Minimum load with ballast on front seats, 122 lb 55 kg

Maximum load on front seats, w/o ballast 489 lb 220 kg

Maximum take off weight 1320 lb 600 kg

Baggage weight (limited b MTOW) 44 lb 20 kg

Empt weight (standard ULM) 715 lb 325 kg

Empt weight (Fixed Wing) 753 lb 342 kg

Empt weight (Foldable Wing) 818 lb 350 kg

Datum line is wing leading edge

Level line is wing lower surface, at root section, with 4,6 degrees positive.

Baggage is located ver close to CG position, so limit of baggage weight is onl limited b maximum

take off weight.

Leveling: The airplane should be leveled b the bottom of the wing with + 4, 6 degrees positive.

Main landing gear wheels should be positioned over level blocks. Depending on shock absorbers on

main landing gear, those blocks probabl will have different heights in different airplanes.

Measuring: Measurement should be taken with a bob weight, marked on ground and then

measured.

Weighting: Using one or three scales, the airplane should sta on same level for weighting.

Aircraft Maintenance Manual - Seamax M-22

SW / FW

Page 20

Empty Weight @ CG position

Tail Number Maker

Model S/N:

Datum

Weight Scale: Model:

S/N Date last certfication:

1. Pesagem

=

-

=

x

Pontos de reação Scale Value Tara Weight Arm Moment

units

lb

lb

lb

in

in.lb

1.1

Left MLG L2 LH (+) 380,0 380,0 32,05 12.179,0

1.2

Right MLG

L2 RH (

+

) 379,8 379,8 32,05 12.172,6

1.3

Third point L1(

-

) or L5(

0,0 0,0 -56,95 -

1.4

totals

759,8

24.351,6

Note: Arms L1, L2 or L5 shall be measured for each specific aicraft

Notes;

a) Empty fuel tanks, lines with fuel, engine with oil, radiator with water

b) NO Ballast

c) NO Ballistic Parachute

2. Items to add or to subtract

2.1

0

2.2

0

2.3

0

2.4

0

2.5

0

2.6

0

2.7

0

2.8

0

3. Empty Weight and C.G.

=

/

3.1

Basic Empt Weight (

BEW

) (lb)

equal 1.4 + (2.1 a 2.8)

759,8

24.351,6

3.2

CG for Basic Empt Weight (

CGBEW

); inchs from Datum

32,05

Date: Operator

4. Notation

Cell to INPUT data

CALCULATED usefull data

CALCULATED data

Acft Basic Itens not installed in the aircraft when aircarft was weighte (individual weight sha have p us signal)

Not Acft Basic Items installed in the aircraft when aircarft was weighte (individual weight sha have minus signal)

Table of contents