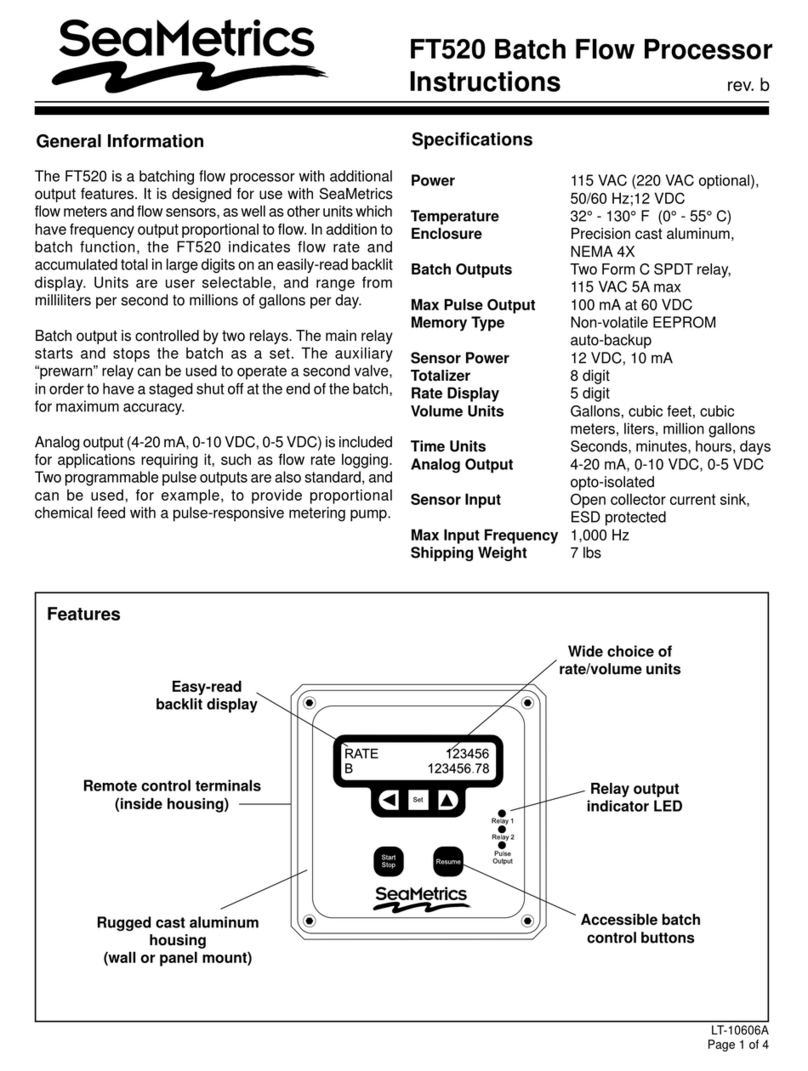

FT500 INSTRUCTIONS

Seametrics • 253.872.0284 Page 7 seametrics.com

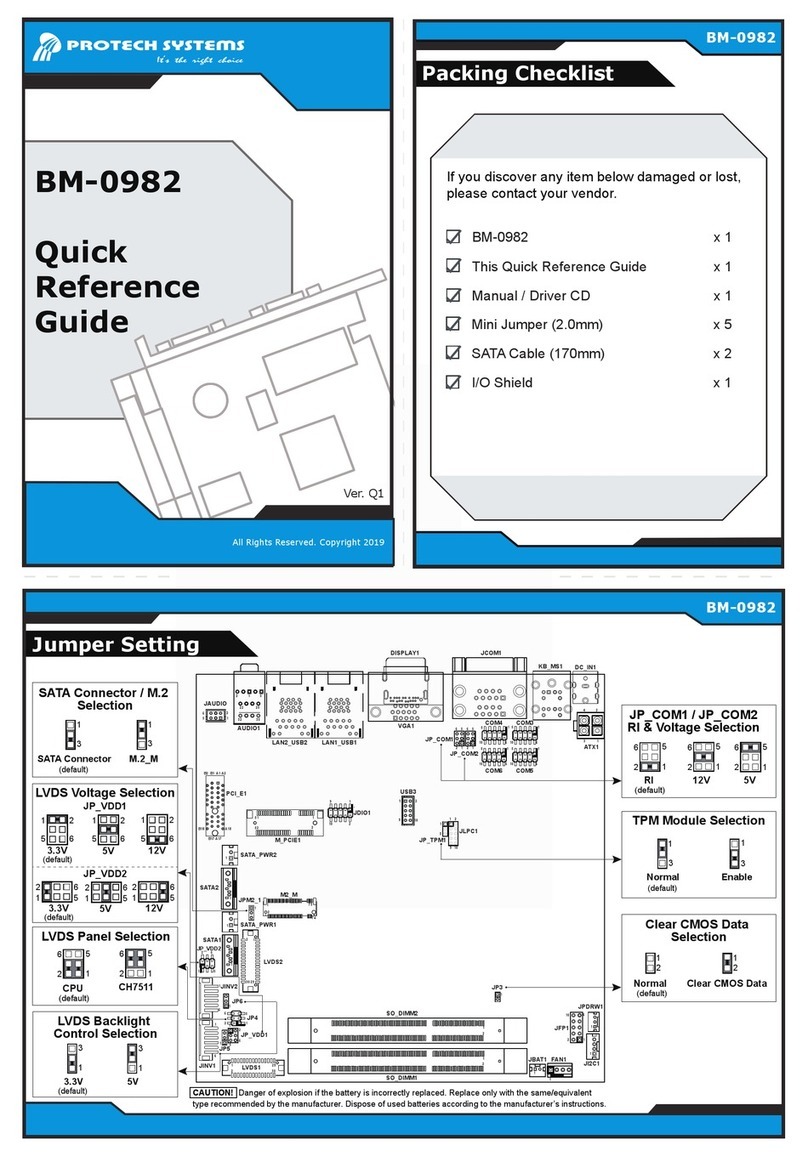

Relay 1

Relay 2

NC

COM

NO

NC

NO

COM

Tank 1

Tank 2

FT520-84 Filter Regeneration

In Filter Regeneration Mode, the display indicates a ow

rate on the top line, and one of two congurations on the

bottom line: an accumulated total ow (resettable), or batch

process remainder. The regeneration process is initiated by

setting a target volume, a value for regeneration time as

well. A single relay or alternate relay setting allows control

of either single tank or alternating dual tank systems.

On the input side, this model can be used with Seametrics

ow sensors and meters, as well as with water meters

from other manufacturers. The output can be used to

initiate regeneration in a variety of one-tank and two-tank

water treatment systems. In addition to the regeneration

functions, this unit features displays of ow rate and

accumulated ow, as well as programmable pulse output

and a 4-20 mA analog output, for use with remote recorders.

There are two regeneration relays, which can be used for

alternating regeneration of two tanks. The outputs remain

on for a duration programmed by the user, depending on

the requirements of the regeneration valve being used.

A programmable pulse output can be used as needed to

control a chemical metering pump, for controlled chemical

addition to the water stream.

Settings

Use Left Arrow and UP Arrow keys to change settings. Press

SET to advance to next menu.

- SET Flow/Rate

Select the particular volume unit desired (gallons, liters, etc.).

Then switch to time units and select the time unit desired

(minutes, hours, etc.).

- SET Decimal

Select none, one, or two decimal places on the ow units.

- SET K-Factor

The unit will not function properly until this number is entered.

The K-factor is simply the number of pulses which the ow

meter or ow sensor puts out per gallon of liquid. It is marked

on the Model/Serial tag of Seametrics ow meters and ow

sensor ttings. On adjustable depth ow sensors, the K-factor

must be taken from the chart in the ow sensor instructions,

based on pipe size.

- SET Pulse (scaled) Output 1

An output pulse is activated at the selected volume intervals if

this feature is in use. If a pulse output is not needed, pulse out

does not need to be set.

- SET Pulse (scaled) Output 2

An output pulse is activated at the selected volume intervals if

this feature is in use. If a pulse output is not needed, pulse out

does not need to be set.

- SET 20 mA Rate

The “SET 20 mA RATE” programs the maximum ow rate at

which the output is 20 mA full scale, at 5 V or 10 V.

- SET Regeneration Volume

This is the volume (in the units you have selected; typically

gallons) at which the relay energizes to initiate a regeneration

cycle.

TX Flow Sensor

FT520-84

Tank 1 Tank 2

Alternating Tanks

Application

Connections for

Alternating Tanks

SETTINGS AND OPERATION

- SET Regeneration Time in seconds (3 digits)

This is the length of time in seconds, the relay remains energized

to initiate regeneration. Enter a value slightly over the minimum

time required by the regeneration valve to begin a cycle.

- SET Relay Mode to one or alternate relays

Choose between single relay (Relay No. 1) and dual relay

(Alternate Relays) operation. In alternate relay mode, the rst

regeneration will use Relay 1, the next will use Relay 2, and

successive regenerations will switch between the two.

- Clear Total

This function resets the accumulated total back to zero. It is

unrelated to the regeneration function, and can be ignored

unless it is needed.

Operation

Choice of Displays. When all of the settings have been

entered, the next press of the SET Key puts the unit in

operation. If a T appears at the left side of the display, the

values shown are ow rate and running total. If there is

no T, the values shown are ow rate and units remaining

until regeneration. The total increases with ow, and the

regeneration quantity counts down. Use the UP Arrow to

choose the preferred display, usually regeneration quantity.

Regeneration Initiation. When the regeneration quantity

number rst reaches 0, Relay No. 1 energizes for the length

of time which has been set. The regeneration quantity

immediately resets and begins counting down again.

If alternating mode has been selected, the next time it

reaches 0, Relay No. 2 will energize, and the cycle after

that, will return to Relay No. 1. An output can be manually

forced at any time by pressing the Start/Stop key. The relay

will energize for the set time, and regeneration volume will

return to its original setting to begin counting down again.