Seametrics FT520 User manual

LT-10606A

Page 1 of 4

General Information Specifications

FT520 Batch Flow Processor

Instructions rev. b

Power 115 VAC (220 VAC optional),

50/60 Hz;12 VDC

Temperature 32°- 130°F (0°- 55°C)

Enclosure Precision cast aluminum,

NEMA 4X

Batch Outputs Two Form C SPDT relay,

115 VAC 5A max

Max Pulse Output 100 mA at 60 VDC

Memory Type Non-volatile EEPROM

auto-backup

Sensor Power 12 VDC, 10 mA

Totalizer 8 digit

Rate Display 5 digit

Volume Units Gallons, cubic feet, cubic

meters, liters, million gallons

Time Units Seconds, minutes, hours, days

Analog Output 4-20 mA, 0-10 VDC, 0-5 VDC

opto-isolated

Sensor Input Open collector current sink,

ESD protected

Max Input Frequency 1,000 Hz

Shipping Weight 7 lbs

Features

Easy-read

backlit display

Remote control terminals

(inside housing)

Rugged cast aluminum

housing

(wall or panel mount)

Accessible batch

control buttons

Relay output

indicator LED

Wide choice of

rate/volume units

The FT520 is a batching flow processor with additional

output features. It is designed for use with SeaMetrics

flowmetersandflowsensors,aswellasotherunitswhich

havefrequency output proportionaltoflow. Inadditionto

batch function, the FT520 indicates flow rate and

accumulatedtotalin large digitsonaneasily-readbacklit

display. Units are user selectable, and range from

milliliters per second to millions of gallons per day.

Batch output is controlled by two relays. The main relay

starts and stops the batch as a set. The auxiliary

“prewarn” relay can be used to operate a second valve,

inorder tohavea stagedshutoffat theendof thebatch,

for maximum accuracy.

Analogoutput(4-20mA, 0-10 VDC,0-5VDC)isincluded

for applications requiring it, such as flow rate logging.

Twoprogrammable pulse outputs arealsostandard,and

can be used, for example, to provide proportional

chemical feed with a pulse-responsive metering pump.

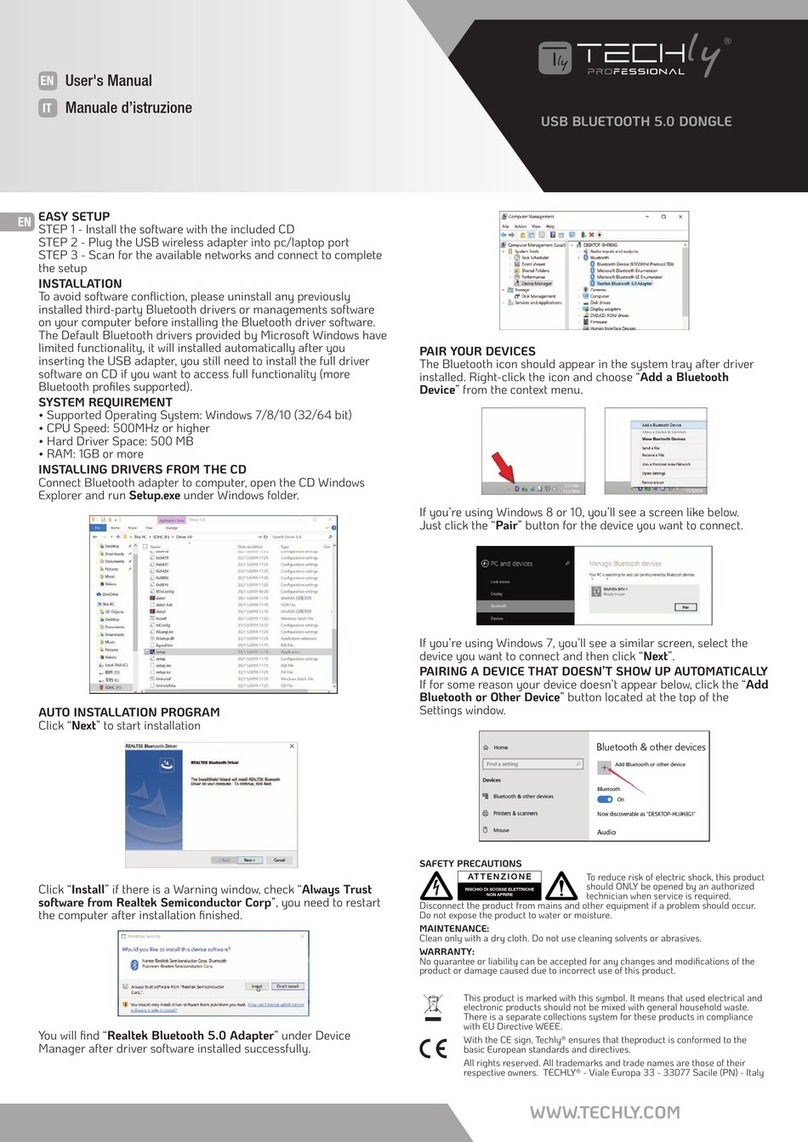

Installation

Wall Mounting. Usingthe four screwsprovided,attach

the two foot brackets to the sides of the enclosure. Then

attachthe unit toanysecure surface byinsertingscrews

through the mounting holes in the foot brackets.

Panel Mounting. Follow the dimensions given for

“PanelCutout”. Besure to includethe four cornerscrew

holes. After cutting and drilling, place the front plate on

the front side of the panel with its gasket against the

panel, and the remainder of the square housing on the

backside. Slide thescrewsthroughthe four holesdrilled

in the panel, and into the threaded holes in the housing.

Tighten until the gasket is firmly compressed against

the panel.

Expose Terminals. Removethefour screws which hold

the front plate to its flange. Remove the front plate. The

display board is attached to this front plate. It is also

connected to the power board by a ribbon cable. For

convenience this cable can be disconnected, while

making connections. Connections can be made inside

the enclosure, or the terminals can be unplugged by

gentle tugging for easier access.

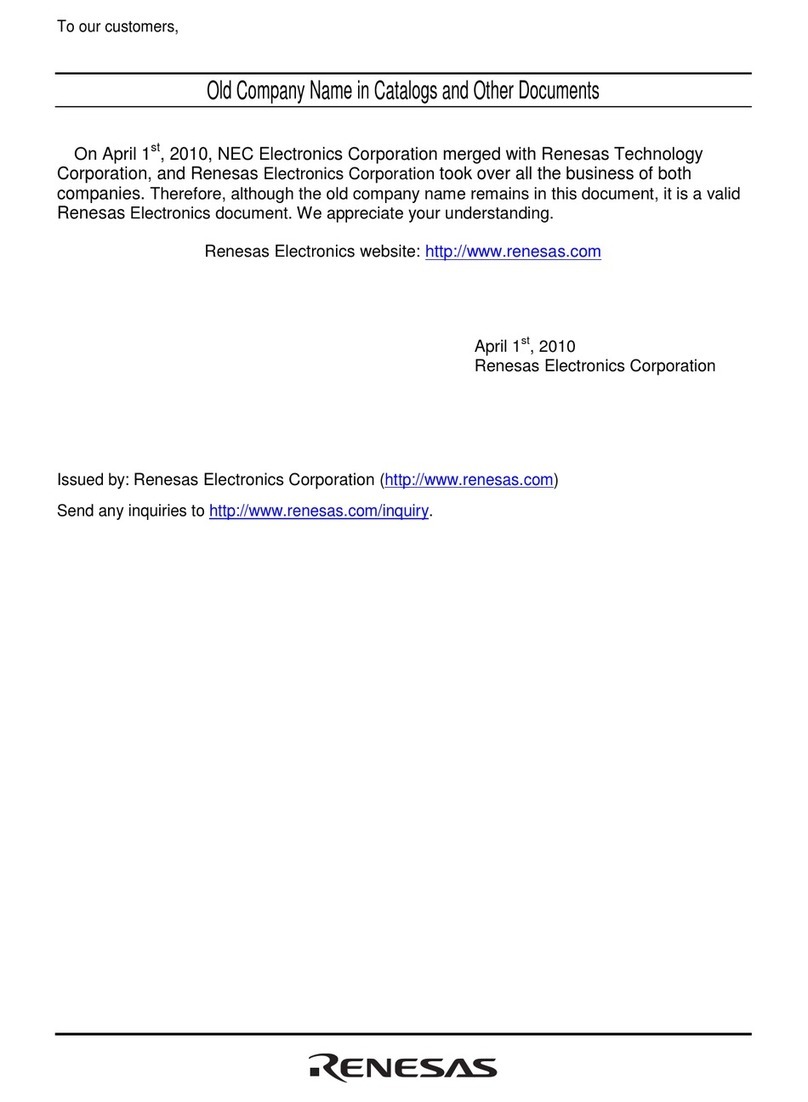

Sensor Connection. Follow the“Connections”diagram

to connect either two or three wires from the flow meter

or flow sensor.

Batch Control Connection. Connectthevalveor other

device(s) to be controlled for starting and stopping the

batch to the appropriate relay terminals. Note: if the

staged shutoff (“prewarn”) will not be used, connect to

relay one only. Relay 1 remains energized for the entire

batch cycle. If a staged shutoff is desired, connect the

main valve to Relay 2 (early shutoff) and the low-flow

valve to Relay 1.

Analog Connection. This output can be configured 4-

20mA, 0-10 Vor0-5 V byplacingajumper inthecorrect

position on the analog header. The swith next to the

headerselectsactive (powered) orpassive(unpowered)

output. Whenusing the 12VDCpowered inputyoumay

only select passive output.

Power Connection. Connect AC or DC power as

2 of 4

desired to the appropriate terminals. For safety, if using

AC power, be sure to connect the ground terminal

provided to a good earth ground. If using 12 VDC, use

a PC1 (part # 05040) or equivalent 12 VDC 500 mA

power supply.

Replace the front panel, taking care to reconnect the

ribbon cable if it has been disconnected. When power is

switchedon, the display shouldlightupimmediately with

meaningful letters or digits.

Caution: When the control is

powered up, relay or analog

outputs may be present. If this

could be a hazard, wait to make

external connections until pro-

gramming is complete.

!

0 GPM

0 GPM

O GAL

0 GPM

O GAL

B

T

SETTINGSOPERATION MODE

SET BATCH SIZE

123 GAL

SET

SET SET PREWARN SIZE

123 GAL

SET

SET

SET

SET

SET

SET

SET

SET DECIMAL

0.00 GPM

SET K-FACTOR

123.456

SET PULSE OUT

123 GAL

TO CLEAR TOTAL

PRESS UP & LEFT

SET 20mA RATE

0.00 GPM

GAL

MINUTE

FLOW

RATE

return to

operation mode

Bar

Graph

Batch

Running

Totalizer

Settings

Set Batch Size. Set the batch size for the desired

number of units, using and keys. If the staged

shut-off feature is not being used, this is the only setting

required for the batch.

Set Prewarn. This is only used for a staged shut-off.

The number set is the number of units early (before the

end of the batch) that Relay 2 will shut off.

Set Flow Units. Use to select volume units. Use

to select the particular unit desired (gallons, liters,

etc.). Then use to switch to time units.Again, select

theunitdesired. Press toadvanceto the next menu.

3 of 4

Connections

Set Decimal. Use toselectzero,one,ortwodecimal

places on the flow units. Press to advance to the

next menu.

Set K-Factor. The unit will not function properly until

thisnumberisentered.TheK-factorissimplythenumber

of pulses which the flow meter or flow sensor puts out

per gallon of liquid. It is marked on the Model/Serial tag

of SeaMetrics flow meters and flow sensor fittings. On

adjustableflow sensors, theK-factormustbe taken from

the chart in the flow sensor instructions, based on pipe

size. Set the number with keys. The digit which

is underlined is the one being set. The moves one

digit to the left. The increases the digit. When the

appropriate number has been set, press again to

move on to the next menu item.

Set Pulse Out. An output pulse is activated at the

selected volume intervals if this feature is in use. If a

pulse output is not needed, pulse out does not need to

be set. Press to move on to the next menu item.

Set 20 mA Out. The “SET 20mA RATE”programs the

flow rate at which the output is 20 mA, 5 V or 10 V. Use

and to set the maximum flow rate for full scale

output. Press for next menu item.

Clear Total. This function resets the running total back

to zero. It is unrelated to the regeneration function, and

can be ignored unless it is needed. To reset to zero,

press and simultaneously. Press to return

to batch mode.

Operation

Start Batch. Pressingthe Start/Stop key starts thebatch

byenergizingRelay 1.Theindicator for Relay1willlight,

indicating normal operation. The indicator for Relay 2

may also light, depending on the prewarn setting. If

staged shut-off is being used, the Relay 2 indicator light

shouldgoout before the endofthebatch,at the prewarn

set point.

The batch will continue on to the set amount unless it is

haltedinthemiddlebypressingtheStart/Stopkeyagain.

Pulse 1

Alternate

12 VDC power

Pulse 2

Relay 2

Relay 1 NC

COM

NO

NC

NO

COM

Batch Outputs

Line

Neutral

Ground

Resume

0-5 V or

0-10 V or

4-20 mA

Sensor Input

Start/Stop

–

+

–+

s1

+

–

s2

RESUME

COM

BATCH

Remote

Controls

Pulse Outputs

(for metering pumps)

Main

power fuse

250mA

part # 26926

AC Power

Ribbon connector

from display board

Meter

Power signal

RED

BLACK

Dry contact

Customer Supplies

1A Fuse

Ground

A

B

An Output

A

P

Passive

Active

Jumpers

5V

10V

4-20mA

PC1 power supply

P/N 05040

WHITE

Analog Switch

Analog Header

20419 80th Ave. So., Kent, WA 98032 USA

Phone: 253-872-0284 Fax: 253-872-0285

www.seametrics.com 1-800-975-8153

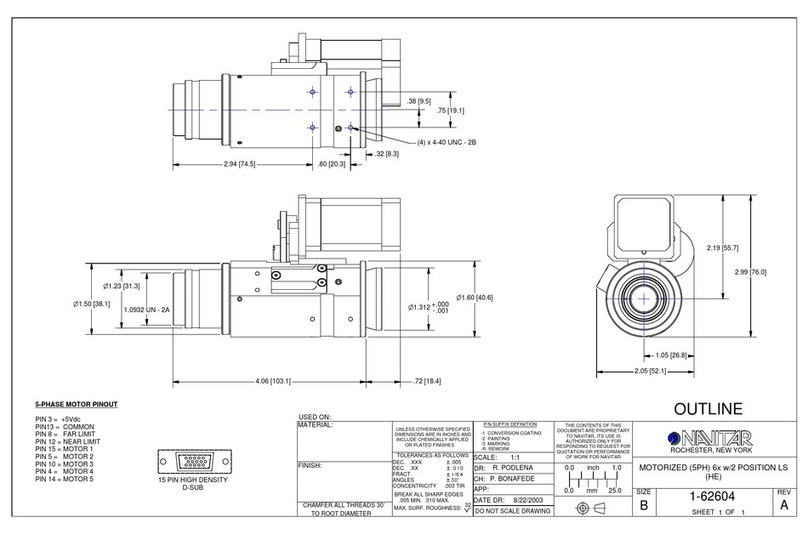

Staged Shut-off Application

4 of 4

TX Flow Sensor

High-Flow

Valve

Low-Flow

Valve

Tank

FT520

Caution: Always disconnect

power to the unit before opening

the terminal cover. Do not recon-

nect power until all connections

have been made and the terminal

cover has been replaced.

!

Stop Batch/Resume Batch. Pressing the Start/Stop

key anywhere in the batch will stop it. It will remain

stopped until the Resume key is pressed. Pressing the

Start/Stop key again allows the batch to restart from

zero.

Choice of Displays for Batching. When in Operation

Mode, press to change the type of display. Running

Totalizer (“T”) accumulates a Total Flow until it is reset.

Batch (“B”) accumulates the flow of the present batch

only, then resets. Bar Graph (“❚”) graphically indicates

from left to right, how much of the batch has already

accumulated.

Repair

Theonly field-repairable componentonthe FT520 isthe

fuse. Iffailure isdueto a causeother than ablownfuse,

itisnecessary to replacetheentireboardstack. Contact

your distributor for information.

High-Flow Valve

Low-Flow Valve

Relay 1

Relay 2

NC

COM

NO

NC

NO

COM

Power

Source

Conection for Staged Shut-off

5.50"

gasket

PANEL

CUTOUT

5.50"

6.03"

6.03"

1/4" holes (4 required)

Panel Cut-out

Other manuals for FT520

2

Other Seametrics Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Nuvoton

Nuvoton ISD91300 Series Technical reference manual

Cypress Semiconductor

Cypress Semiconductor CY7C1303BV25 Specification sheet

Sony

Sony MSAC-PR1 operating instructions

Advantech

Advantech PCM-26D1DB Startup manual

AMCC

AMCC PPC405 user manual

Cypress Semiconductor

Cypress Semiconductor Perform CY7C1511KV18 manual