SEAR KITCHEN ET-BQL-808 User manual

1

ICE CREAM MACHINE MANUAL

Please read this Manual carefully before trying to operate the machine.

一、Technical Data

Soft Ice Cream Machine Series

Par

Model

Main

Power

Rate

Power

(kW)

Refrigerant/fil

l

output

/L/H

Dimensions

(mm)

N.W.

(kg)

ET-BQL-

808

220V/50Hz

/60Hz

1.7kW

R22/R404A

/0.9kg

11-16kg

18-25L

518×740×780

108

ET-BQL-

838

220V/50Hz

/60Hz

1.7kW

R22/R404A

/1kg

11-16kg

18-25L

518×740×1310

135

ET-BQL-

S22

220V/50Hz

/60Hz

1.7kW

R22/R404A

/1kg

11-16kg

18-25L

540×770×1480

145

Note:

1. The output is measured under the 25℃ environmental tem.and 7℃. feed

stock tem.

2. Output of cups per hour is based on 60-70 grams .

3. Either R134A or R404A refrigerant can be used for all machines.

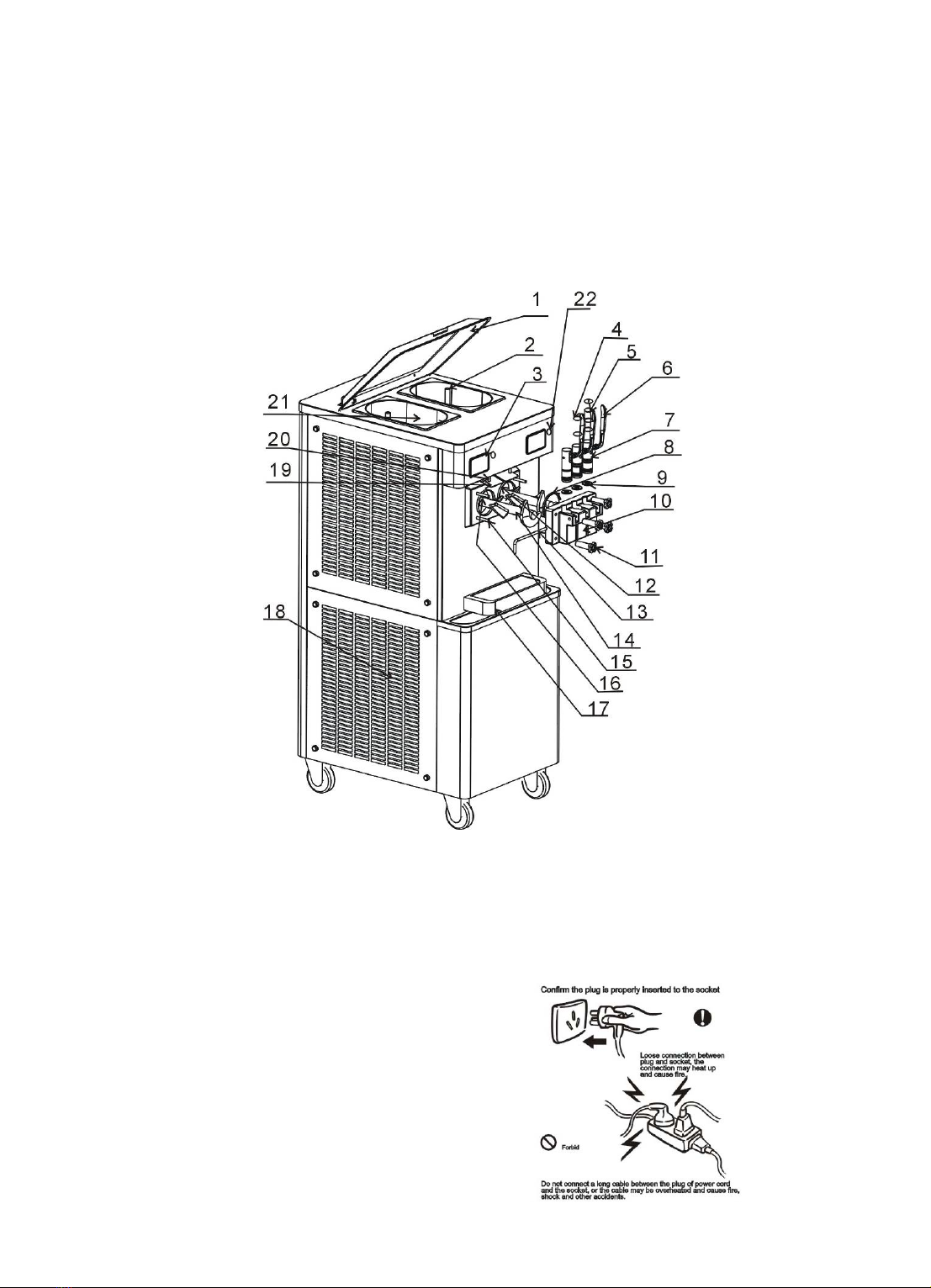

2. constructure

1. Top Cover 2.Expansion Tube 3.Control Panel

4. Piston Ring 5.Anti-cross-talk Piston Ring 6.SS Handle

7. Piston 8.Discharge Block-Drum Ring 9.Star Ring

10. Discharge Block Body 11. Plastic Nut 12.Plastic Deco-plate

2

13. Cross Bar 14.Stirer Shaft 15.Discharge Block Bolt

16.Stirer Drum 17.Receive Plate 18. Hot Air Exhaust

19. Proximity Switch Plate 20.Proximity Switch Pusher 21. Feed Basin

22. Electronic Lock Switch

Structure:

3. Precautions

Electricity

·Install the earthing device

According to the National Security

Standard for electrical equipment.

·Only use the feed line, method of

wiring and equipment in conformity

3

with the National Security Standard

for electrical equipment.

· Be sure installing a short and leakage

protective device on the feed line.

Hygiene

·To use the machine without strict

disinfection may pollute the food

which will be dangerous to your

health.

·Always keep the machine in clean

conditions. Remove the deteriorated

material immediately away from the

machine.

·washing and disinfecting procedure must strictly follow this Manual.

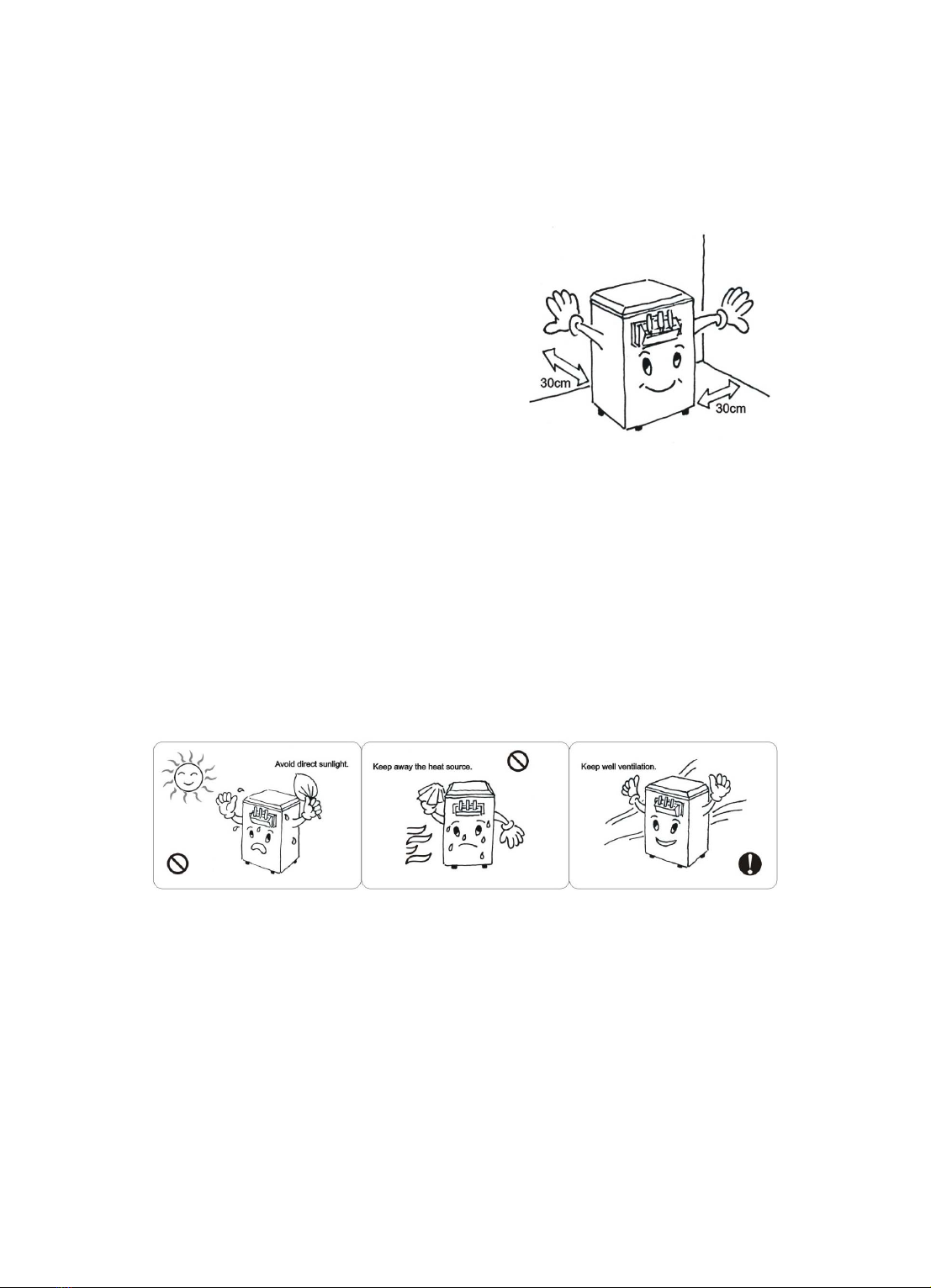

Installation

·The machine should be installed on a dry and firm floor. Do not install the

machine tilted. Any heat source over 70℃ must be kept at least 50cm away

from the machine. Keep the machine away from rain and direct sunlight.

· Leave a space no less than 30cm on both sides of the machine for proper

ventilation. To ensure heat dissipation, leave a space at least 1.5m from

the hot air exhaust outlet. Do not leave any object which may be sucked

by air flow, such as a plastic bag, near the hot air exhaust outlet.

Connect to Main Power

·The power socket must have an earth line or just connect the machine metal

case to the earth.

·Power Specifications:

Single Phase: 240V/50Hz, Voltage Fluctuation: 198V-240V

· connection area of the power conductor must be not less than 2.5 ㎡or the

line may be overloaded, the voltage dropped down which may impair or

even damage the machine.

4

Cautions:

·To avoid any adverse effect from vibration which is unavoidable during

transportation, on arrival of the machine, leave it for 24 hours before

trying to run it for the first time.

· The temperature of the feed stock must be between 7 ℃~40 ℃. If the

temperature is out of the range, it will damage the machine.

· To avoid the refrigerant being impaired, you should wipe off dust from the

hot air exhaust outlet regularly.

· it is prohibited to use only one drum or add one drum with ice cream pulp

for the machine of double drum models and the other drum with other

material pulp (except for machines with double-compressor set).

4. Operation

Production

1. Insert two expansion tubes into each feed

basin respectively.

2. Pour the prepared ice cream pulp into the

feed basin. The pulp flows to the stirrer

drum via the lower hole of the expansion

tube.

3. Wait for about 2 minutes until the ice cream

pulp has flowed into the drum. Push on

PRODUCE key to start the machine.

The stirrer motor starts first and then the

fans of compressor and condenser will be

started in 30 seconds. At this moment the

hot air flows from the outlet of the condenser

and the temperature in the drum drops down

quickly. The ice cream is ready to discharge

in 15 to 20 minutes. At this moment if you want to stop production, just push

the STOP key.

4. Any time when you pull one of the handle of the discharge block, the related

stirrer stops and the ice cream flows out of the discharge hole. The discharge

hole on left and right is related to the stirrer drum on left and right and the ice

cream discharged is of single color. The discharge hole in the middle is the

mixture from both left and right drums and is of rainbow color.

Caution: The pulp level in the stirrer drum is dropping while ice

cream is discharging. If only little remains in the drum, abnormal

5

noise can be heard and the stirrer shaft may be damaged. You

should check if the lower hole of the expansion tube is chocked

up.

5. The machine will stop automatically when the ice cream reaches the preset

hardness. The OVERLOAD indicator is on. The machine will restart

about 5 minutes automatically. If you want to continue production when

the OVERLOAD is on, just push OVERLOAD RESET key or pull any one

of the handle at the discharge block (The model A11 does not have auto

reset function).

Caution:1. If you do not discharge the ice cream when it

reaches the preset hardness, do not push the OVERLOAD

RESET and PRODUCE keys frequently, or the machine may be

damaged.

2.when the stirrer drum discharges a large quantity ice cream

from the soft ice cream machine, you must await a few minutes

after refrigerating.

6. Hardness Setting

The principle of adjustment of hardness of ice cream is based on the fact

that the load of stirrer motor increases with the current. The control circuit

reacts when the current reaches a certain point and stops the machine.

Hardness has been properly set in the factory before delivery. If you have

special recipe for ice cream, it may be readjusted according to your particular

needs.

Depending on the machine model, there are two methods for hardness

adjustment:

1) The models with step adjuster. For purpose of hardness adjustment, you

have to open the side panel of the machine to access the step adjuster located

at the electrical box.

a. If the machine does not stop when the ice cream reaches the required

hardness, push the adjuster to a softer step until machine stops.

b. if the machine stops because of overloading and the ice cream is not hard

enough, you should push the adjuster to a harder step, when the ice

cream reaches the required harness it will stop production.

c. the machine must be allowed to run in one minute before you try to push

the adjuster to the next step, or the effect of the adjustment will be

6

impaired.

d. The hardness adjuster has 9 steps and the hardness increases in numeric

order.

2) The models with hardness adjustment on control panel. Press the set

key for more than 2 seconds, the number on the display flashes continually.

The system for hardness adjustment is now in set mode. Press +, the figure

increases; press —, the figure decreases; there are 1 to 15 steps available for

adjustment. The number 15 is the hardest and 1 is the softest. After the required

number has been selected, press PRODUCE or WASH key to save the

adjustment and withdraw from the set mode.

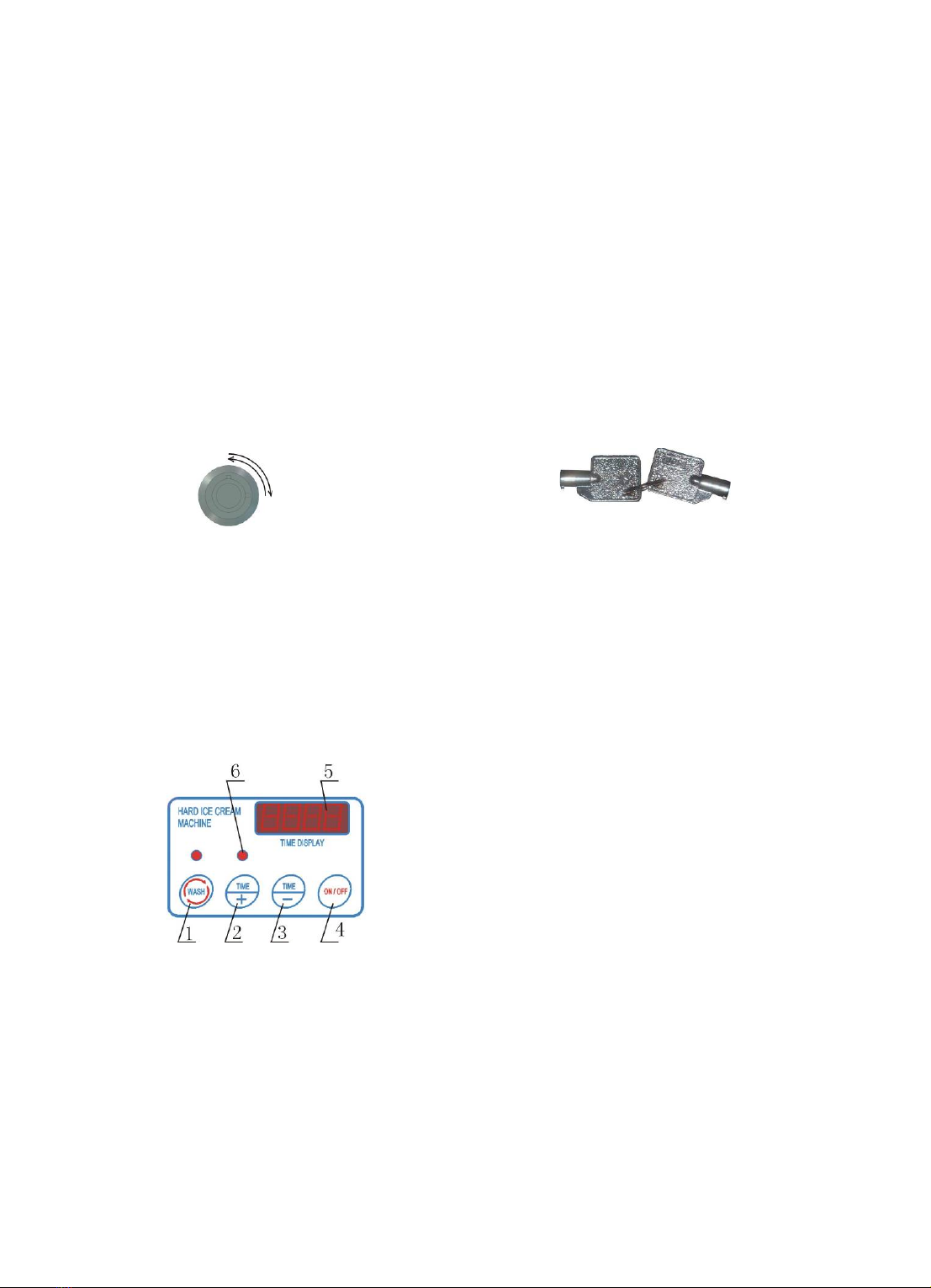

7. Operation of Different Type of Control Panel

Our ice cream machine series is accommodated with different type of control

Panel. Please identify which control Panel is used for your particular machine

model.

A. The model with 3 displays but without precooling

1. PRODUCE/STOP key

2. WASH/STOP key

3. OVERLOAD RESET/HARDNESS SET/+ key

4. - key

5. STEP/TIME display

6. COUNTER display

7. Ice Cream Tem. display

8. LED indicator

B. The model with 3 displays

1. PRODUCE/STOP key

2. WASH/STOP key

3. OVERLOAD RESET / HARDNESS SET /+

7

key

4. STEP、TEMPETURE—/ Keep Fresh 、

PRECOOLING ON-Off / HARDNESS SET/

TEMPETURE、SET key

5. STEP/PROCESS display

6. COUNTER display

7. FEED BASIN PRECOOLING TEM. display

8. LED indicator

D. Electronic Lock-switch for Batch Number Reset Key for Lock Switch

Counter: it will show you the figure when each ice cream is made out.The

maximum figure is “999”. An electronic lock switch is located on front or below the

control panel, which is used for reset the figure to zero. Insert the key to the slot

of lock-switch, turn the key round, the figure reset to “000”.

E. The models for hard ice cream machine

1. WASH key

2. Time+ key

3. Time — key

4. PRODUCE ON-OFF/WASH STOP key

5. Washing Of The Machine

6.LED indicator

5. Washing Of The Machine

8

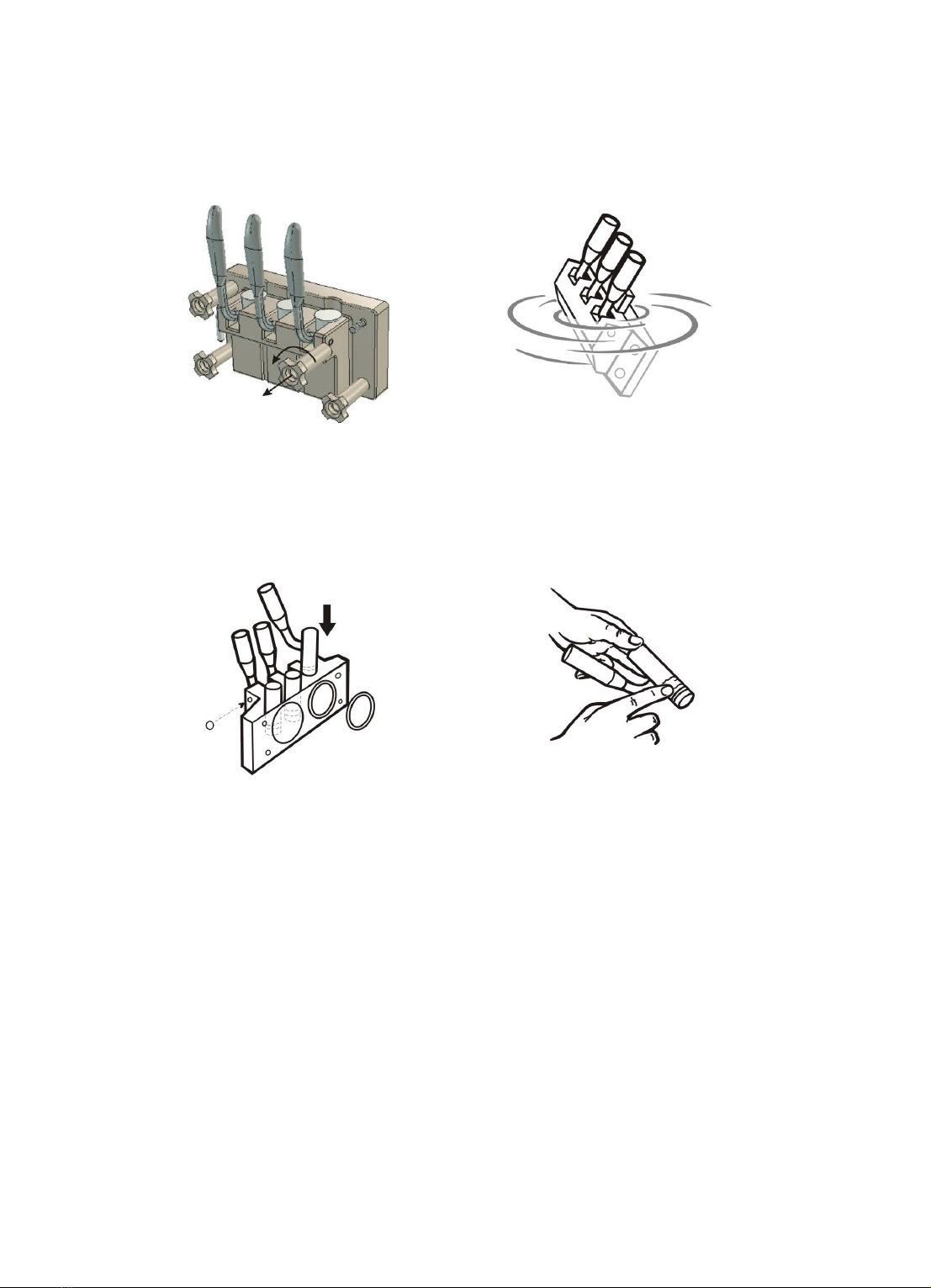

1. Washing Before Production

a. Turn the plastic set nuts for the discharge block, totally 4 nuts, in counter

clockwise direction, dismount the discharge block.

b. Wash the feed basin, stirrer shaft and expansion tube with detergent liquid or

disinfectant liquid.

c. Put the discharge block in one of above liquids. Push and pull the handle 2 to

3 times. Dismount the cross bar, pull the piston out from the block, clean the

cross bar and piston.

2. Wash After Production

a. Pour water into the feed basin. Push on WASH key to run the stirrer for 3 to 5

minutes until remains of ice cream in the stirrer drum completely melted.

Discharge the water from the drum by pulling the handle. Repeat the above

procedure several times.

b. Wash the discharge block:

Repeat above “Wash Before Production” item a. and b.

6. Service and Maintenance

Notice for Service and Maintenance

1. The machine must be kept clean and neat conditions after using and it will be

managed by a professional person.

2. when you complete the operation for each time, you should clean the

9

machine parts in contact with the ice cream, such as discharge block, stirrer

drum, stirrer shaft, expansion tube, feed basin etc. immediately after the

machine is stopped. Air dry the parts for the next operation.

3. Check the tightness of the belts regularly. If the belt is loos, adjust the center

distance between the pulley and the stirrer motor.

4. If the machine is not in use for a long time, put the main switch to OFF

position. The machine will be in standby mode.

2). Time Setting Operation

a. While the machine is in Stop mode, press the time + or — key, the display

indicates the time value set at the last time and the figure flashes. At this

moment press + key to increase the time value in minutes and — key to

decrease the time value in minutes.

b. The time value can be set from 1 minute to 20 minutes, changing at 1 minute

increments each time you press the key.

c. While the display is flashing, if you do not press + key or — key in 5 seconds,

the system will withdraw from the time setting mode, the time value set at the

last time is saved and the display returns to “00”.

Caution: If the time is set to a too long time and the ice cream in the chilling

drum is too hard. The machine will stop immediately and enter into the

protective mode. At the same time, the machine will sound alarm and the

display shows “L:L”. In this case, switch the power off and on again in no less

than 1 minute. Adjust the production time again.

3). Washing

Press WASH key, the machine is in WASH mode. Press On/Off key, the

stirrer will be stopped.

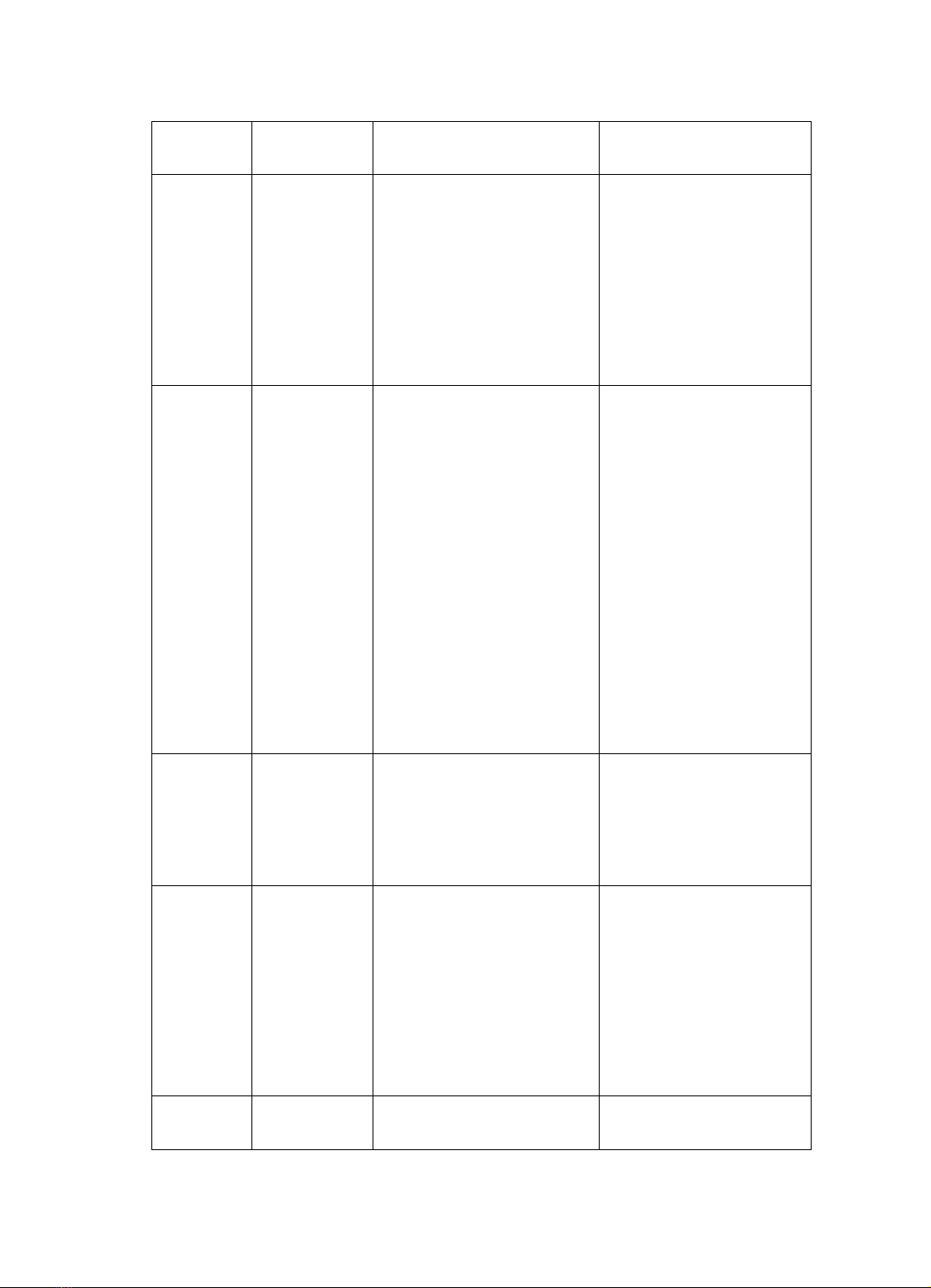

8.analytical sheet for obstacle

10

PHENOME

NON

REASONS

ANALYSIS

REMEDY

THE

MACHINE

DOSE

NOT

RUN.

1.Power Supply Failure.

2.Power switch is

damaged.

3.No power supply to

control circuit.

4.No.DC12V supply.

5.Overload protection

tripped.

1.No power supply or

disconnection

2.change.

3.Transformer for the conrtol

circuit burnt out

4. Rectification circuit

damaged.

5. Check the circuit.

REFRIGE-

RATION

SYSTEM

DOESN'T

WORK

Compressor

doesn't

work.Pipe

Leakage.

1.Temperature reaches the

preset value.

2.Supply voltage is too low.

3.Section area of power cable

is too small.

4.Start capacitor of the

compressor damaged.

5.Compressor is damged.

6.Overload protection tripped.

7.Maltfunction of logic citcuit.

8.Leakage of Refrigerant pipe.

1.Wait until temperature

rises to certain degress and

start again.

2. Discuss with commercial

power supply company.

3.Change the cable to a

larger size.

4.Change the damaged

parts.

5.Same as item4.

6.Check the overload circuit.

7.Same as item4.

8.Solder the pipe cracks and

refill the refrigerant.

MIXER

DOESN'T

WORK.

Mixer motor

doesn't work

1.The capacitor for the motor

is damaged.

2. The motor is damaged.

3.Overload protection circuit

tripped.

1.Change the damaged

parts.

2.Change the damaged

parts.

3.Check the overload circuit.

OVERLOA

D

INDICATO

R

ON OR

SWITCHED

ON FREQ-

UENTLY

The system

overloard.

1.Too much water and less

sugar in ice cream formula.

2.Ice cream is made too

harder.

3.Gearbox is damaged.

4.Overloard protection

circuit tripped.

1.Change the formula to

proper amunt of water and

sugar.

2.Adjust the hardness of ice

cream.

3.Repair the gearbox.

4.Check the overload circuit.

LOW

OUTPUT

It takes too

much time to

1.The airflow inlet and outlet is

too close to the wall.

1.The airflow inlet or outlet

must keep away from the

11

make ice

cream.

2.Lack of refrigerant.

3.Evaporting temperature is

not high enugh.

The piping of refrigeration

system is

Clogged or frozen.

wall or any object for good

ventilation.

2.Refill the refrigerant.

3.Adjust the expansion tem.

Or change the valve.

4.Drain the refrigerant from

system.Dry, clean and

vacuumize the system.Refill

the refrigerant.

MATERIAL

LEAKING

Material or

water leakage

1.Material or water leaking

from the discharge block.

2.Material or water leaking

from the reducer.

3.Condensate from

copper pipe of

refrigeration system.

1.Change the related rubber

sealing.

2.Tighten the fixing bolts of

the discharge block.

3.It is normal.

NO ICE

CREAM

DISCHARG

E

Wrong

operation

1.The mixer cylinder empty.

2.Ice cream is too harder.

3.The handle doesn’t open

enough.

4.Mixer motor doesn’t work.

5.Travel switch doesn’t work.

6.No mixer screw mounted.

1.Add material to the basin.

2.Adjust to proper hardness.

3.Full open the handle.

4.Check the related circuit

for the motor.

5.Check the auto travel

switch.

6.Mount the screw and start

again.

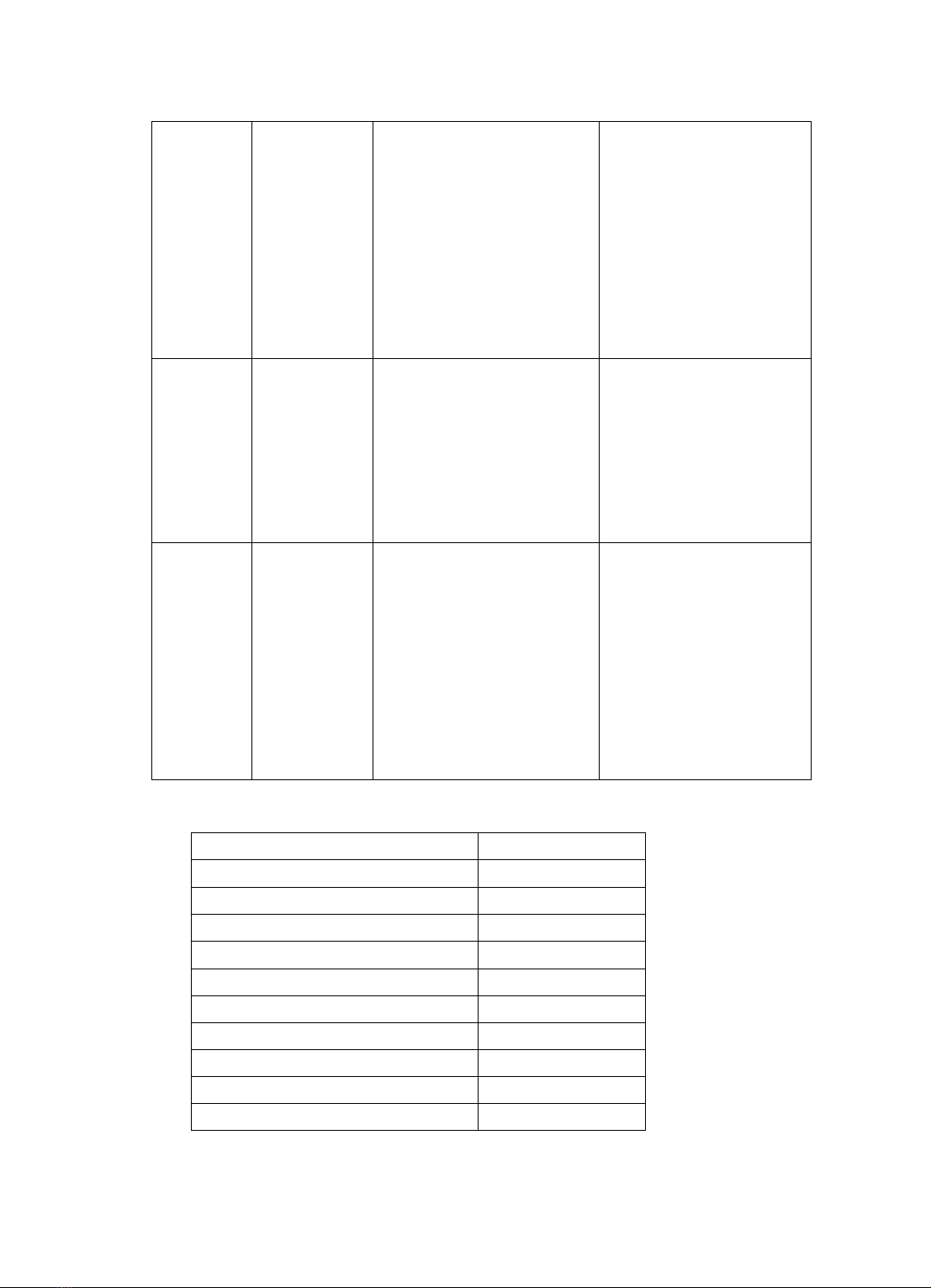

9. Packing List

1. Soft Ice Cream Machine

Name

Quantity

Machine Set

1

Discharge Block-Drum Ring

2

Piston Ring

6

Anti-cross-talk Ring

1

Expansion Tube

2

Ring for Expansion Tube

4

Star Washer

3

Operation Manual

1

Plastic Bag

1

Electron lock

2

10.Electrical Diagram

12

This manual suits for next models

2

Table of contents