sebaKMT T 26/1 A User manual

Instruction Manual

- Date of release: 2003/ 29-

HV TEST SET

T 26/1 A

T 26/1 B

Mess- und Ortungstechnik

Measuring and Locating Technologies

Leitungsortung

Line Locating

Rohrleitungsnetze

Water Networks

Kommunikationsnetze

Communication Networks

Elektrizitätsnetze

Power Networks

2

3

CONSULTATION WITH SEBAKMT

The present system manual has been designed as an operating guide and

for reference. It is meant to answer your questions and solve your

problems in as fast and easy a way as possible. Please start with referring

to this manual should any trouble occur.

In doing so, make use of the table of contents and read the relevant

paragraph with great attention. Furthermore, check all terminals and

connections of the instruments involved.

Should any question remain unanswered, please contact:

Seba Dynatronic

Mess- und Ortungstechnik GmbH

Hagenuk KMT

Kabelmesstechnik GmbH

Dr.-Herbert-Iann-Str. 6

D - 96148 Baunach

Phone: +49 / 9544 / 68 – 0

Fax: +49 / 9544 / 22 73

Röderaue 41

D - 01471 Radeburg / Dresden

Phone: +49 / 35208 / 84 – 0

Fax: +49 / 35208 / 84 249

E-Mail: sales@sebakmt.com

http://www.sebakmt.com

SebaKMT

All rights reserved. No part of this handbook may be copied by photographic or other means

unless SebaKMT have before-hand declared their consent in writing. The content of this

handbook is subject to change without notice. SebaKMT cannot be made liable for technical or

4

printing errors or shortcomings of this handbook. SebaKMT also disclaims all responsibility for

damage resulting directly or indirectly from the delivery, supply, or use of this matter.

5

TERMS AND CONDITIONS OF WARRANTY

SebaKMT accept responsibility for a claim under warranty brought forward

by a customer for a product sold by SebaKMT under the terms stated

below.

SebaKMT warrant that at the time of delivery SebaKMT products are free

from manufacturing or material defects which might considerably reduce

their value or usability. This warranty does not apply to faults in the

software supplied. During the period of warranty, SebaKMT agree to repair

faulty parts or replace them with new parts or parts as new (with the same

usability and life as new parts) according to their choice.

This warranty does not cover wear parts, lamps, fuses, batteries and

accumulators.

SebaKMT reject all further claims under warranty, in particular those from

consequential damage. Each component and product replaced in

accordance with this warranty becomes the property of SebaKMT.

All warranty claims versus SebaKMT are hereby limited to a period of 12

months from the date of delivery. Each component supplied by SebaKMT

within the context of warranty will also be covered by this warranty for the

remaining period of time but for 90 days at least.

Each measure to remedy a claim under warranty shall exclusively be

carried out by SebaKMT or an authorized service station.

This warranty does not apply to any fault or damage caused by exposing a

product to conditions not in accordance with this specification, by storing,

transporting, or using it improperly, or having it serviced or installed by a

workshop not authorized by SebaKMT. All responsibility is disclaimed for

damage due to wear, will of God, or connection to foreign components.

For damage resulting from a violation of their duty to repair or re-supply

items, SebaKMT can be made liable only in case of severe negligence or

intention. Any liability for slight negligence is disclaimed.

Since some states do not allow the exclusion or limitation of an implied

warranty or of consequential damage, the limitations of liability described

above perhaps may not apply to you.

6

TABLE OF CONTENTS

1.GENERAL ...........................................................................................12

1.1.Safety instructions ........................................................................12

1.1.1.General safety regulations ....................................................14

1.1.2.General rules for working with high voltages ........................16

1.1.2.1.Supplementary instructions ...........................................17

1.1.2.2.Danger of recurring voltage from space charges ..........17

1.1.3.Indications used in the description........................................18

1.2.Connection regulations.................................................................19

2.TECHNICAL DESCRIPTION ..............................................................22

2.1.Application ....................................................................................22

2.2.Specifications ...............................................................................23

2.2.1.T 26/1 A HV test set ..............................................................23

2.2.2.T 26/1 B HV test set ..............................................................24

2.2.3.Specifications of equipment parts .........................................25

2.3.Equipment parts / scope of supply ...............................................27

2.4.T 26/100 operation unit ................................................................30

2.4.1.Structure of T 26/110 operation unit .....................................30

2.4.2.Working method of T 26/110 operation unit..........................30

2.5.T 26/100 high-voltage basic unit ..................................................33

2.5.1.Structure................................................................................33

2.5.2.Working method of high-voltage unit ....................................34

2.6.Safety and warning device ...........................................................35

2.7.Configuration and test set-up .......................................................36

3.OPERATION .......................................................................................44

3.1.Start-Up ........................................................................................44

3.1.1.Test preparations ..................................................................44

3.1.2.Minimum distances when setting up equipment ...................46

3.1.3.Fitting the cascades ..............................................................48

3.1.4.Connecting the liquid resistor................................................48

3.1.5.Installing the discharge switch ..............................................49

3.2.Controls ........................................................................................50

3.3.Performing measurements with the T 26/1 A...............................54

3.3.1.Cable testing .........................................................................54

3.3.1.1.Directions in brief ...........................................................54

7

3.3.1.2.Directions....................................................................... 55

3.3.2.Surging.................................................................................. 57

3.3.3.Burning.................................................................................. 58

3.4.Performing measurements with the T 26/1 B .............................. 59

3.4.1.Cable testing ......................................................................... 59

3.4.1.1.Directions in brief ........................................................... 59

3.4.1.2.Directions....................................................................... 60

3.4.2.Measurement up to 650 kV................................................... 62

4.CARE, MAINTENANCE AND REPAIR .............................................. 66

4.1.Care and maintenance................................................................. 66

4.2.Repair........................................................................................... 66

8

LIST OF ABBREVIATIONS

DIN Deutsches Institut für Normung

German Standards Institute

HV High Voltage

IEC International Electrotechnical Commission

UVV Unfallverhütungsvorschrift

Accident prevention regulations applicable in Germany

VDE Verband Deutscher Elektrotechniker

Association of German Electrotechnical Engineers

9

ELECTROMAGNETIC COMPATIBILITY

OF THE HIGH VOLTAGE TEST SETS T 26/1 A, T 26/1 B

The high voltage test sets T 26/1 A and T 26/1 B comply with the

requirements of EN 55011 concerning conducted emission voltages on the

mains supply.

The requirements concerning radiated electromagnetic fields in accordance

with EN 55011 are fulfilled up to a voltage of 110 kV.

Voltages above 110 kV result in exceedings of the limits in the frequency

range 30 ... 120 MHz. These disturbances are caused by principle of

operation and cannot be prevented by any technical procedure.

During operation of the equipment an appropriate distance to any

susceptible instrument or installation has to be kept.

10

CHAPTER 1

GENERAL

11

12

1. GENERAL

1.1. Safety instructions

All persons involved in the installation, operation, maintenance

and repair of this system must have read this user manual

carefully.

The instrument and all additional equipment are in accordance

with the current state of safety technology at the time of

delivery. Owing to the work processes involved, however,

there may be parts of the instrument and its peripherals which

cannot be given optimum protection without an unreasonable

reduction in function and usability. Good personal safety

practice is therefore indispensable in terms of the protection of

staff and the instrument.

The following safety instructions must be complied with.

General instructions

Work on this instrument and its peripherals must only be

performed by qualified and/or trained staff. Other persons

must be kept away.

This user manual must be available for the supervisory,

operating and maintenance staff to refer to.

Improper use may endanger life and limb, the system and

connected equipment, as well as the efficient functioning of

the system (accident prevention regulations). The instrument

may only be used for the purpose for which it is intended by

the manufacturer.

Always use correct tools in perfect condition for all work.

13

Regular checks must be made to ensure that the relevant

safety regulations are being complied with during operation

and maintenance.

The instrument may only be operated by authorised persons

with the appropriate skills.

Only operate the system if it is in technically perfect condition.

No non-original parts may be used for the instrument and its

peripherals, as the necessary safety will not otherwise be

guaranteed. No mode of working which detracts from the

safety of the instrument must be used.

The user is under an obligation to report any changes in the

system to the supervisor responsible without delay.

The user is under an obligation to shut down the instrument

immediately in the event of an instrument malfunction which

detracts from the safety of staff. The instrument may only be

put back into operation once the malfunction has been

rectified.

Electrotechnical instructions

The instrument and all additional equipment must be

connected properly. The relevant DIN and VDE regulations

must be complied with.

Repair and maintenance work must only be carried out when

the system is switched off (dead) and then only by a skilled

electrician in accordance with current accident prevention

regulations (APR). A skilled electrician in the sense of the

accident prevention regulations is a person who can assess

the work assigned to him/her and recognise possible dangers

on the basis of his/her technical training, knowledge and

experience, and of his/her knowledge of the relevant

regulations.

14

1.1.1. General safety regulations

Fuses

The patching or bridging of fuses is forbidden, as is the use of

patched fuses.

When replacing fuses, only use replacements with the same

or a smaller rated current strength and action (slow, quick,

super-quick). Fitted bolts must not be replaced with ones for

fuses with a higher rated current strength.

Fuses must not be detached or pulled under load. Fuses must

not be used for switching electric circuits.

Handling regulations for fixed and movable cables and

lines

Mains cables and their mountings must not be used for

securing, attaching or suspending equipment, items of

clothing, etc.

When cables are disconnected, they must be protected

against kinking. The penetration of cable ends by moisture

must be prevented. Suitable moisture protection must be used

were necessary.

Moveable supply leads must not be subjected to unacceptable

stress while equipment is being operated or transported. In

particular, care must be taken that instruments are not

suspended by their leads and plugs are not pulled out of

sockets by the lead.

15

Handling regulations for connectors

Movable electrical plant must only be connected using the

connectors (plugs, sockets) provided.

The use of adapters and plugs which fit sockets of a different

voltage is not permissible.

When replacing connectors, care must be taken that the

terminals are connected in proper phase.

Handling regulations for cable accessories

Cable terminals must be secured against working loose by

means of retainer washers and spring washers.

When reconnecting cables to equipment and plant, care must

be taken that the cable shielding is earthed (earth cone) and

the cable lead-in is tight (in accordance with the protection

class of the equipment in question).

16

1.1.2. General rules for working with high voltages

Working with high-voltage devices and systems demands

special care.

This is particularly true of mobile operation, i.e. if the

accommodation in question and its equipment do not ensure

safety with permanent safety devices from the outset.

VDE Regulation 0104 "Installation and operation of electrical

test systems" and/or the equivalent IEC standard must be

complied with to the letter.

This clearly instructs:

- that high-voltage installations must only be operated in

properly secured rooms or behind corresponding barriers,

and safety devices must not be circumvented or put out of

operation.

- that at least two persons must be present during operation,

with one person being able to activate the emergency-off

circuit in the event of an emergency.

17

1.1.2.1. Supplementary instructions

The following supplementary instructions are not taken directly

from the regulations.

- To avoid dangerous charges, all metal parts in the vicinity

of a high-voltage system must be grounded. Special care is

required in the case of mobile operation in this respect.

- Do not disconnect while live (risk of arcs).

- High-voltage test and burn equipment is short-circuit proof.

This means that there is a danger that the voltage will run

up when a short circuit is removed.

- Connect a discharger parallel to the measuring equipment

in the case of short-circuit current measurements

(e.g. 90 V corona discharger).

- Only ever touch component parts which have been live and

read measuring/test devices if they are visibly grounded

and short-circuited, even if they have been switched off

and discharged properly.

1.1.2.2. Danger of recurring voltage from space charges

- Only remove grounding and short-circuit when the test

object is to be put into operation again.

- Cables which are not in operation are capacitors.

Ground and short-circuit as a matter of principle.

18

1.1.3. Indications used in the description

Important instructions concerning personal protection, work

safety and technical safety are indicated as follows:

WARNING: Warning indicates work and operating

procedures which must be complied with in

full to exclude the possibility of persons

being put at risk. This includes instructions

concerning particular dangers when

handling the instrument.

ATTENTION: Attention indicates work and operating

procedures which must be complied with in

full to prevent the instrument/peripherals

from being damaged or destroyed.

N.B.: N.B. indicates special technical

requirements to which the user must pay

particular attention when using the

instrument.

19

1.2. Connection regulations

WARNING: Establish protective earth connection in

accordance with regulations before

inserting mains plug!

WARNING: System earth connection to shielding of

test object!

The system earth of the measuring van/mobile pallet should

be connected to the earthed cable shielding of the test object,

or if that is not directly possible, to the connecting line to the

earth connection as a matter of principle. The unused leads of

the test object should if possible, and must in the case of

unshielded cables, be earthed directly to the system earth

connection.

WARNING: Establish potential equalization

If the test object and supply network are connected to

different, unconnected earth systems, the potential

equalization should be established by means of a connecting

line with a cross-section of at least 16 mm² Cu during

operation of the

measuring van/mobile pallet.

20

CHAPTER 2

TECHNICAL DESCRIPTION

This manual suits for next models

1

Table of contents

Popular Test Equipment manuals by other brands

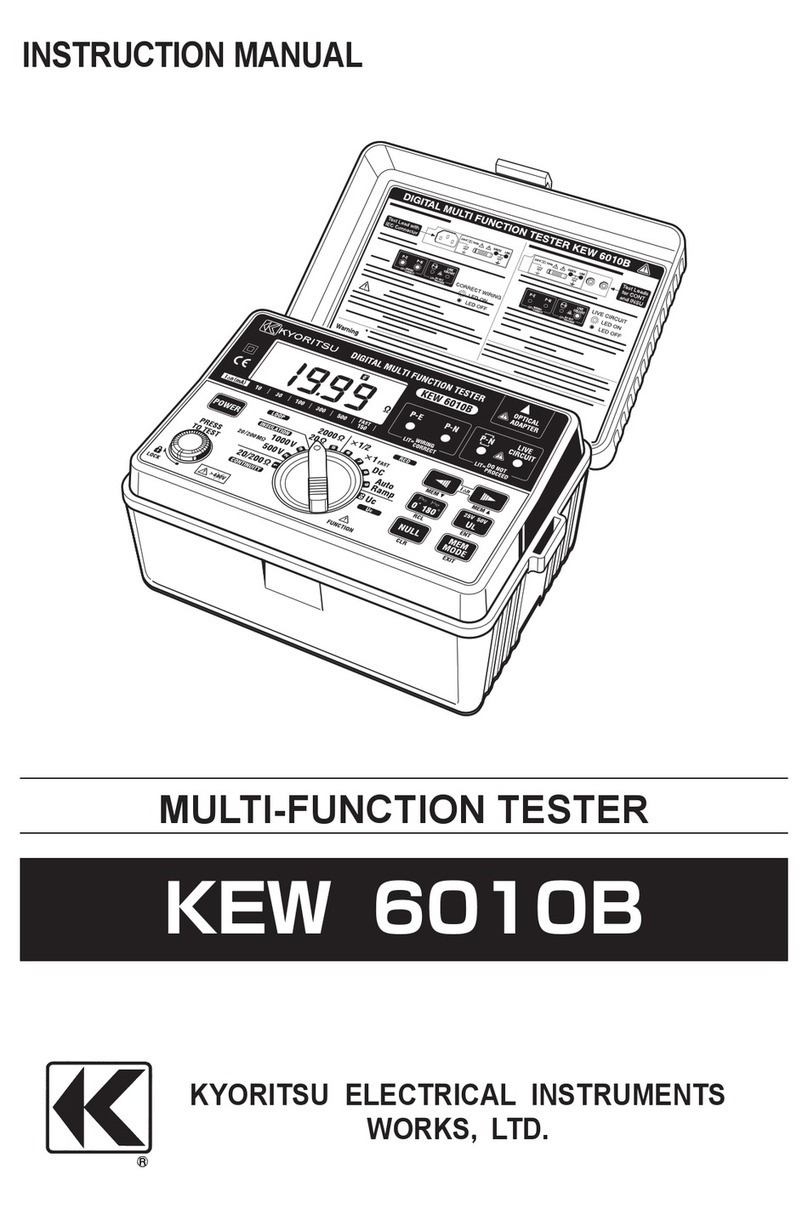

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. KEW 6010B instruction manual

EL-CELL

EL-CELL PAT-Press user manual

HQ Power

HQ Power VDL20ST2 user manual

Power Fist

Power Fist 8597668 manual

HQ Power

HQ Power DERBY HQLE10027 user manual

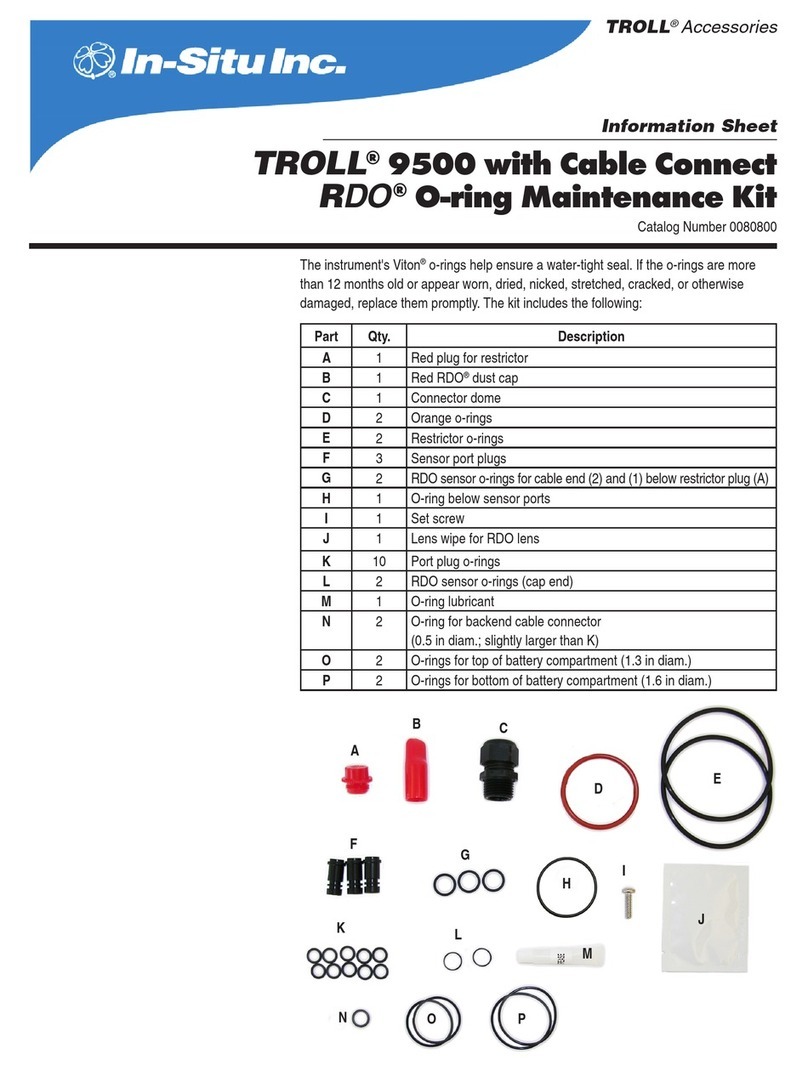

In-situ

In-situ SMARTROLL Operator's manual

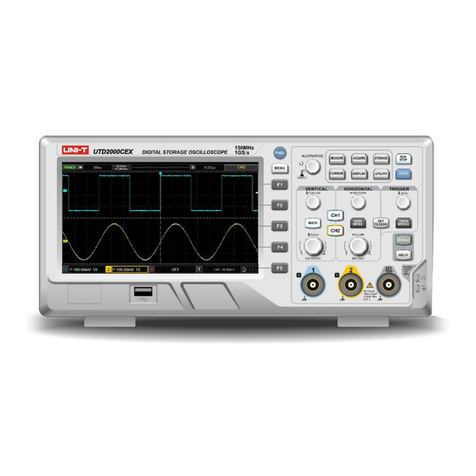

Unit

Unit UTD2052CL+ user manual

Isotech

Isotech ICM A7 instruction manual

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. 6050 instruction manual

In-situ

In-situ TROLL RDO 9500 Information sheet

Provision

Provision TM-43AHDBL manual

Metrix

Metrix HandScope OX5022B quick start guide