SEC Sentry 822 PS User manual

1

Model 822 PS Pump Sentry

Owner's Manual

SEC America Corp.

SEC

Model 1622 PS Pump Sentry

November 5, 2019

2

Index

Page

Quick Installation & Battery Essentials………………….. 3

Precautions and Sequencing During Initial Hookup…. 4

How Pump Sentry Works……………………………..…….. 5

Important Safety Instructions…………………………….... 6

Safety Warnings……………………………………………… 7

Battery Precautions………………………………………….. 8

Battery Box……………………………………………………. 10

Installation Location…………………………………………. 10

Making Connections…………………………………………. 11

Installation Test………………………………………………. 11

Changing the Battery………………………………………… 12

Charger Functions.…………………………………………… 13

Uninterruptible Power Indicator …………………………… 13

Fan Operation ………………………………………………… 13

How to Discern when Pump Sentry

is Operational in Back Up Mode …………………………… 15

How to Discern when Pump Sentry

is Operational in Standby Mode …………………………... 15

Fuses …………………………………………………………… 15

Audible Alarm …………………………………………………. 15

Warranty……………………………………………………….. 16

3

Pump Sentry™

Models 822 PS & 1622 PS

INSTALLATION INSTRUCTIONS

QUICK INSTALLATION & BATTERY ESSENTIALS

Pump Sentry™ is designed to operate with an external battery or battery bank

whose nominal operating voltage is 12V, and whose single or combined A-

Hr. rating does not exceed 250 A-hr. A full recharge will take 13 hours or 30

hours for batteries of 100 A-hr. and 250 A-hr. respectively. Pump Sentry™

will maintain batteries at full charge while electricity is available. See page 13

of this manual to learn more about the charger function indicators.

BATTERY TYPE

Only batteries conforming to Battery Council International (BCI) group size

27 or larger are recommended (up to size 31). Only deep cycle batteries are

designed for the type of service which Pump Sentry™ requires. INSTALL

ONLY deep cycle batteries. (wet cell or AGM type) The marine-variety is

acceptable. DO NOT use car batteries. (See page 8 for some suggested

sources.)

BATTERY BOX

Your selected battery(ies) should be installed in a high quality plastic or metal

battery box that comes with a lid that is designed for said box. It is available

at the point of battery purchase.

BATTERY CABLES

Use only the cables furnished with Pump Sentry™ that are packaged in its

carton. They are equipped with the terminations necessary for reliable and

solid connection.

The ends with the blade terminals mate with the RED and BLACK battery

cable connectors on the Pump Sentry, while the other ends are furnished with

Ring terminals designed to fit over the wing nut posts of most batteries.

4

PRECAUTIONS & SEQUENCING DURING INITIAL HOOKUP

a) Secure Pump Sentry™ in its designated spot. It is recommended that

the unit be placed on a shelf or mounted to a wall.

b) Make sure the ON/OFF switch is in the OFF position and that the Pump

Sentry™ power cord is not plugged into an AC outlet.

c) Connect the blade end of the red battery cable supplied with the unit

into the red terminal block located adjacent to the fan air intake port.

Tighten the set screw of the block till the cable is well secured.

d) Perform the sequence in see with the black cable into the black terminal

block located adjacent to the red one.

e) Slide the battery into its protective box and place into its designated

spot sufficiently close to the Pump Sentry™ to allow the battery cables

to reach. DO NOT USE LONGER CABLES THAN THOSE

SUPPLIED WITH PUMP SENTRY™ as this may adversely affect the

time available for backup operation.

f) Connect the ring terminal end of the BLACK battery cable to the

battery NEGATIVE terminal.

g) Connect the ring terminal end of the RED battery battery cable to the

battery POSITIVE terminal. WARNING: WHEN DOING THIS STEP

THERE WILL BE A PERCEPTIVE SPARK AT THE TERMINAL

AS SOME COMPONENTS IN THE PUMP SENTRY™ CHARGE

UP. THIS IS NORMAL.

h) Once (g) is completed cover your battery box and secure the lid.

i) Plug the sump pump into the Pump Sentry™.

j) Plug the Pump Sentry™ into a wall outlet which has a minimum

capacity of 20A.

k) Turn ON the ON/OFF switch located to the left of the fan air intake

port.

l) Installation is complete.

INSTALLATION TEST

To make sure the installation is good, it should be tested per the following:

a) Raise the water level float switch controlling the pump causing the

pump to go ON.

b) Disconnect the Pump Sentry’s plug, mentioned in (j), from the wall

outlet. After a slight pause your sump pump should continue to operate.

If it does not, review steps (a) though (l) above.

5

The Pump Sentry™ is an innovative power station designed to operate your

pump during a power outage. When properly installed, it will provide many

years of reliable service.

To ensure that the Pump Sentry™ is optimally used and properly connected,

we recommend its installation be made by a licensed electrician or fully

qualified professional. Read these instructions completely and follow

directions carefully.

AC Utility Power

12 Volt

Battery

Figure 1

1622PS/822 PS

Pump +-

How The Pump Sentry Works

When electricity is present, the Pump Sentry™ charges a 12-volt battery and

surveys the power line. At the instant that a power failure occurs, the Pump

Sentry converts the energy stored in the battery to AC power to operate your

pump. When AC utility power is restored, the Pump Sentry automatically

switches your pump back to AC utility power, recharges the battery, and

monitors the power line.

While the Pump Sentry is a sophisticated electronic device, it should not be

expected to perform beyond its limitations, and extreme care should be taken

to insure safe operation within specifications.

6

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS – THIS MANUAL

CONTAINS IMPORTANT INSTRUCTIONS

FAILURE TO FOLLOW SAFETY INSTRUCTIONS AND

WARNINGS COULD RESULT IN INJURY OR DEATH

Read all the instructions

before installing or

operating the Pump Sentry.

ALWAYS disconnect

batteries and AC power

source from the Pump

Sentry before storing,

handling, or making any

adjustments to the unit.

Use Pump Sentry only as

described in this manual.

Any other use not

recommended by the

manufacturer may cause

fire, electric shock, or

injury.

Do Not sit or stand on the

Pump Sentry unit. Keep

children away!

Do Not place objects on the

Pump Sentry unit or allow

vents to become blocked.

Do Not smoke, use sparking

electrical devices, or allow

open flame near the unit

while working with it.

Do Not install Pump Sentry

in locations classified as

harzardous per N.E.C.

ANSI/NFPA 70 – 1984.

WARNING:

ELECTRICAL SHOCK

HAZARD

This unit has not been

evaluated for use outdoors.

Never operate Pump

Sentry outdoors.

Never operate Pump Sentry

with battery enclosure open.

Never operate Pump Sentry

in a wet location.

Never operate Pump Sentry

in a location where liquid or

moisture will come in

contact with, splash, or drip

into unit.

Do Not insert or allow

foreign objects to enter any

ventilation or exhaust

opening as this may cause

electrical shock and/or fire

hazard.

7

WARNING:

RISK OF ELECTRICAL

SHOCK

In the event of a short circuit,

grounding reduces the risk of

electrical shock by providing a

safe path to ground. The Pump

Sentry must be properly grounded.

The Pump Sentry is equipped with

a cord having a ground wire with

an appropriate three pronged plug.

The plug must be used with an

outlet that has been installed and

grounded in accordance with all

local electrical codes and

ordinances. Where a two pronged

wall outlet is encountered, it must

be replaced with a three pronged

outlet by a qualified Electrician to

reduce the risk of shock, the third

prong must not be cut off the plug.

DO NOT attempt to defeat this

safety feature.

Use Pump Sentry only with

adequate wiring that is up to

electrical code specifications.

Connect to properly grounded

outlets only.

WARNING:

RISK OF ELECTRICAL

SHOCK

The Pump Sentry is capable of,

and intended to generate electrical

voltage when unplugged from a

wall outlet or when AC power is

shut off.

Because Pump Sentry uses batteries to

generate 120 volts of AC power, both

the batteries and the power cord must be

disconnected to neutralize the Pump

Sentry. Failure to disconnect both the

batteries and the power cord could result

in electrical shock sufficient to cause

injury or death

FAILURE TO COMPLY WITH THE ABOVE WARNINGS COULD

RESULT IN INJURY OR DEATH

8

BATTERY PRECAUTIONS:

WARNING:

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS.

1. Servicing of batteries should

be performed or supervised

by a person knowledgeable

about batteries and the

required precautions. Keep

unauthorized personnel

away from batteries.

2. When replacing batteries,

use only models conforming

to Battery Council

International (BCI)

specifications for Group

size 27 or larger Deep

Cycle Marine batteries. At

the time of this publication,

the following model

batteries are typical of

minimum requirement. At

the time of purchase, verify

that the battery to be used

will be of BCI Group size

27 or larger .

Examples of Group 27

Deep Cycle Marine Battery

models:

Die Hard Model 27524

Exide Model NC-27

Interstate Model SRM-27

Metropolitan Model 27T-36

NAPA Model 8270

Larger BCI group sizes and

multiple-battery arrays may

also be used to increase

backup longevity.

3. CAUTION – Do Not

dispose of batteries in a fire.

The batteries might explode.

4. CAUTION – Do Not open

or mutilate the batteries.

Released electrolyte is

harmful to skin and eyes

CAUTION – A battery can

present a risk of electrical

shock and high short circuit

current. The following

precautions should be

observed when working on

batteries.

A. Remove Watches, Rings,

and other Jewelry and

metal objects.

B. Use tools with insulated

handles.

C. Do Not lay tools or metal

objects on top of

batteries.

D. Wear safety goggles and

a face shield.

5. CAUTION – The

electrolyte is a diluted

sulfuric acid mixture that is

Corrosive and harmful to

the skin and eyes. It is also

electrically conductive.

Observe the following rules

9

when working with the

electrolyte solution.

A. Wear full eye

protection and

clothing.

B. If electrolyte comes in

contact with the skin,

wash if off

immediately.

C. If electrolyte comes in

contact with the eyes,

flush thoroughly with

water and seek

medical attention

immediately.

6. CAUTION – Lead acid

batteries can present a risk

of fire and explosion

because they generate

hydrogen gases. The

following precautions must

be followed.

A. Do Not smoke when

near batteries.

B. Do Not cause sparks

or allow open flame

in the battery area.

C. Discharge static

electricity from your

body and clothing

before touching

batteries by first

touching a grounded

surface.

7. See Battery Manufacturers’ installation manual for additional

safety and maintenance instructions.

10

BATTERY BOX

Your selected battery should be

stored in a high quality plastic or

nylon battery box with a lid that is

designed for this purpose.

LOCATION

In a typical installation, the

Pump Sentry should be

mounted on the wall, above

the sump pit or crock, and in

accordance with all

applicable local electrical

codes.

It should be in close

proximity to a grounded AC

outlet and the battery box

(not closer than 2 feet).

VENTILATION

Do Not block either the fan

or the exit air ports of the

Pump Sentry. Allow at least

2 inches of air clearance on

all sides. Any room in which

the Pump Sentry is mounted

should have adequate

ventilation.

UNDER NO

CIRCUMSTANCES

Should the Pump Sentry be

mounted in a confined area or in

a sump pump pit or crock.

Pump Sentry is not only an

electrical appliance, but also

produces a potentially

dangerous and hazardous

electrical current even when

a power outage occurs. It is

safe when installed and used

properly. Keep children

away.

WARNING! The Pump Sentry has several components with

electrical contacts that switch electrical currents. Opening or

closing any of these electrical contacts can produce a spark that

could ignite an explosive air mixture. To prevent fire or

explosion, do not install the Pump Sentry in any area which

might contain flammable liquids or gases. Do not install Pump

Sentry in the same confined area as the battery box.

11

MAKING CONNECTIONS

After mounting Pump Sentry to the

wall, follow these steps.

Make sure the ON/OFF

switch is in the OFF

position.

Connect the red battery

cable to the Red (Positive) +

terminal of the Pump

Sentry.

Connect the black battery

cable to the Black

(Negative) – terminal of the

Pump Sentry.

WARNING! DO NOT

REVERSE THESE

CONNECTIONS. DAMAGE

TO THE PUMP SENTRY

WILL OCCUR AND YOU

WILL VOID THE

WARRANTEE.

WARNING! A spark may

occur when connecting the

second cable. This is normal.

An explosion hazard may

exist if flammable liquid or

gas is present. INSTALL

AND OPERATE PUMP

SENTRY IN A WELL

VENTILATED AREA

ONLY.

Plug your pump into the

Pump Sentry’s AC

outlet.

Plug the Pump Sentry

into a 120 volt AC

outlet.

Turn ON/OFF switch to

the ON position.

INSTALLATION TEST

After making the

connections as instructed

above, cycle the pump to

ensure its operation under

normal conditions.

Remove power cord from

the AC wall outlet to

simulate a power failure.

The fan will not necessarily

be activated. It is thermostat

controlled and will turn only

when the temperature of the

wall of the stove sentry

exceeds 45C (113F).

Cycle the pump to ensure

operation in “battery back

up” mode.

Plug the Pump Sentry AC

power cord back into the

wall outlet. Cycle the pump.

Note that after 2 seconds at

least one of the Battery

Monitor LEDs has lit. This

is normal and is an

indication that the Pump

Sentry has recognized the

return of normal AC power.

The Pump Sentry is no

12

longer in “battery back up”

mode and has returned to its

normal state of charging the

battery and providing line

power.

CHANGING

THE

BATTERY

If for any reason the battery needs

changing, it is important to follow

the steps below, in the order shown

to avoid damage to the Pump

Sentry unit.

1. Turn the ON/OFF switch

on the Pump Sentry to the

OFF position.

2. Unplug the input power cord

of the Pump Sentry from the

AC outlet.

3. Unplug the input power cord

of the pump from the AC

outlet on the Pump Sentry

4. Disconnect the battery

cables from the battery.

CAUTION: MAKE SURE

THAT THE PUMP

SENTRY IS

DISCONNECTED FROM

AC POWER BEFORE

DISCONNECTING

BATTERY CABLES.

5. Replace the battery.

6. Reconnect the Pump Sentry

following the steps under

the heading MAKING

CONNECTIONS.

MAINTENANCE

Once properly connected, the

Pump Sentry requires no

maintenance. When AC power

fails, it will automatically convert

battery power to AC power for

operation of the pump. It will

automatically recharge the battery

when AC power returns. During

all of these times and power

transitions, the Pump Sentry

requires no manual adjustments.

SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE.

13

Charger Function s

The smart charging system in Pump Sentry is microprocessor controlled to yield optimum charging rates

and long battery life.

When the electrical source is restored allowing the resumption of the charging process, there is a 2

second delay during which the charge state of the battery is assessed. After this delay, the bottom of the

two LED indicators comprising the battery monitor will illuminate. These LEDs inform the user

regarding the state of the battery:

LED State of Battery

Bottom LED “Flashing” - The battery is in the process of recharging.

Bottom LED “On” - The battery is fully charged.

Replace Battery LED - When batteries age to the point where they can maintain their fully

charged state only for short periods of time, it is an indication that their capacity

has decreased. They no longer have the ability to sustain their loads as they did

when they were new. The Pump Sentry detects this degradation causing the

Replace Battery LED to illuminate. When the battery reaches below 50% of its

new battery state, this condition is detected by the monitor. Other LED’s may be

lit at the same time.

Figure #1 on page 14 shows the Battery Monitor LED array.

Uninterruptible Power Indicator

The “Power Output” indicator shown in Figure #1 informs the user that AC power is present at the

output receptacle providing power to the load. This LED is applicable to both the standby (AC line

power present) and Back Up (Battery Power) states.

This LED will be extinguished in the following situations:

a) The main fuse is blown (in the Standby or Back Up states). See Section on Fuses (Page 15)

b) The battery is exhausted (in the Standby state)

Figure #1 on page 14 shows the location of this Uninterruptible Power Indicator.

Fan Operation

The air-intake fan, located adjacent to the red DC cable terminal, is thermostat controlled. It operates

only when the internal surface of the Pump Sentry exceeds 100F. This eliminates unnecessary fan

operation thereby minimizing battery loading.

14

Figure #2

Charger Fuse

Main Fuse

F1

F2

SIDE VIEW

Figure #1

ON/OFF

Inverter

TOP VIEW

POWER OUTPUT

Active When Lit

Charged = ON

Replace Battery

Charging = Flashing

BATTERY MONITOR

ALL Battery Indicators Are OFF

When Utility AC is Down

15

How to Discern When Pump Sentry is Operational in the Backup Mode

When all LED’s of the battery monitor are OFF, and the pump sentry is plugged into an AC outlet, the

unit is in the back up mode. In this mode when there is sufficient energy in the battery to operate the

system, the uninterruptible power LED is illuminated. Once the battery is depleted the uninterruptible

power light will extinguish, indicating an absence of AC power at the Pump Sentry’s output.

How to Discern When Pump Sentry is Operational in the Standby (Line Power) Mode

When at least one of the Battery Monitor LED’s in ON, and the pump sentry is plugged into an AC

outlet, the unit is in standby mode. In this mode, the uninterruptible power LED remains illuminated.

Fuses

Figure #2 on page 14 shows the location of two protective fuses F1 and F2.

F1, the charger fuse, provides protection against charger or battery catastrophic failure. When this fuse is

blown the pump sentry will operate on standby power only until the battery is depleted.

F2, the main fuse, provides secondary protection against severe overload. When this fuse is blown, 120

VAC to the output receptacle of the pump sentry is cut off. In this state, the Uninterruptible Power LED

will be OFF. Replace fuses only with the types indicated on the fuse rating label of your unit which can

be found next to the fuse holders on the flat side of the unit to the left of the line cord.

Audible Alarm

While operating on Battery Backup Power, when the battery is depleted to the point where it dips below

10.8V, a high pitched audible alarm is emanated from the Pump Sentry. This is a sign, to the user, that

he will imminently loose battery power. If the maintenance of battery power is crucial, the user may

substitute the spent battery for a fully charged one, by carefully following the directions in the section

“Changing the Battery” on page 12.

If the audible alarm is found to be irritable, it may be turned off by simply turning off the ON/OFF

switch of the pump sentry. IT IS IMPORTANT TO TURN THIS SWITCH BACK “ON” WHEN THE

UNIT’S OPERATION IS REINSTATED. This should take place when utility power comes back on or

after the battery has been replaced. FAILURE TO DO THIS WILL LEAVE THE USER WITHOUT

BACK UP PROTECTION.

16

Pump Sentry 822 PS, 1622 PS

Manufactured by

SEC America Corp.

S. Burlington, VT, 05403

Manufacturers Limited Warranty

Pump Sentry is warranted to be free from defects in material and workmanship and

to perform within applicable specifications for a period of two years after original

shipment. Obligation under this guarantee is limited to repairing or replacing any

part thereof, except fuses and pilot lights, which shall within one year returned to

us with transportation charges prepaid, and prove after our examination to be thus

defective.

The above limited warranties take the place of all other warranties, expressed of

implied and correction of such defects by replacement or repair shall constitute a

fulfillment of all obligations under the terms of the warranties. The warranties do

not cover any unit, which has been damaged either in transit or by misuse, accident

or negligence. No warranty or representation by anyone other than this Company

shall be binding on us.

SEC America Corp.

78 Ethan Allen Drive,

S. Burlington, VT 05403

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Becker

Becker U 4.70 Series Repair and service manual

GORMAN-RUPP

GORMAN-RUPP AMT 4S13XZR manual

Graco

Graco Bulldog 245185 instructions

Oase

Oase Aquarius Universal Classic 600 operating instructions

Aspen Pumps

Aspen Pumps PERI PRO AIR Installation

PROCESSTEC

PROCESSTEC ViscoTwin 104 3-A Series Technical data

TATRA

TATRA PC-10 Installation and operation manual

Samoa

Samoa Larius 2 Operating and maintenance manual

Barnes

Barnes 3SEH-L Installation and operation manual

Jesco

Jesco MIDIDOS E Series Operation & maintenance instructions

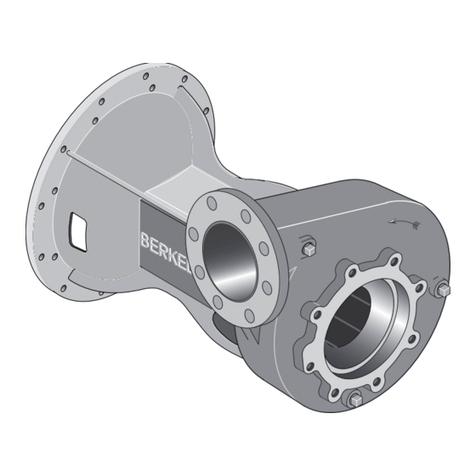

Berkeley

Berkeley S.A.E. Installation, Repair, and Operating Instructions

Calpeda

Calpeda NCES Series Original operating instructions