SED 024.16.720 User manual

Montageanleitung / Operating Instructions

Type 024.16.720

Elektropneumatischer Stellungsregler

Electropneumatic position controller

www.sed-owcontrol.com

2

We reserve the right to make technical changes without notice.

Technische Änderungen vorbehalten.

© 2011 SED Flow Control GmbH

Operating Instructions / BA11 0001 Rev. a

Type 024.16.720

www.sed-owcontrol.com

3

Type 024.16.720

Ta b l e o f Co n T e n T s

1. EC DECLARATION OF CONFORMITY....................................................................................................8

2. OPERATING INSTRUCTIONS .................................................................................................................9

2.1. Symbols ........................................................................................................................................9

3. AUTHORIZED USE................................................................................................................................10

3.1. Restrictions .................................................................................................................................10

3.2. Predictable Misuse .....................................................................................................................10

4. BASIC SAFETY INSTRUCTIONS ..........................................................................................................11

5. GENERAL INFORMATION.....................................................................................................................12

5.1. Scope of Supply .........................................................................................................................12

5.2. Contact Addresses .....................................................................................................................12

5.3. Warranty......................................................................................................................................12

5.4. Trademarks .................................................................................................................................13

5.5. Information on the Internet .........................................................................................................13

6. SYSTEM DESCRIPTION .......................................................................................................................14

6.1. Intended Application Area...........................................................................................................14

6.2. Function of the positioner and combination with valve types ....................................................14

6.3. Features of the valve types.........................................................................................................15

6.4. Structure of the positioner ..........................................................................................................16

6.4.1. Representation................................................................................................................16

6.4.2. Features..........................................................................................................................17

6.4.3. Function diagram of the positioner with single-acting actuator .....................................18

6.5. Type 024.16.720 Positioner with position controller ...................................................................19

6.5.1. Schematic representation of the position control Type 024.16.720 ...............................19

6.5.2. Properties of the position controller software.................................................................20

6.6. Interfaces of the positioner ........................................................................................................22

www.sed-owcontrol.com

4

Type 024.16.720

7. TECHNICAL DATA.................................................................................................................................23

7.1. Operating Conditions..................................................................................................................23

7.2. Conformity ..................................................................................................................................23

7.3. Mechanical data..........................................................................................................................23

7.4. Pneumatic data...........................................................................................................................24

7.5. Adhesive labels ...........................................................................................................................24

7.5.1. Label (example)...............................................................................................................24

7.5.2. Identicationlabeloftheignitionprotectionclasses ....................................................24

7.6. Electrical Data.............................................................................................................................25

7.6.1. Electrical data without bus control 24 V DC...................................................................25

7.6.2. Electrical data with AS interface bus control..................................................................25

7.7. Factory settings of the positioner ...............................................................................................26

8. CONTROL AND DISPLAY ELEMENTS .................................................................................................27

8.1. Operating status............................................................................................................................ 27

8.2. Control and display elements of the positioner ..........................................................................27

8.3. Congurationofthekeys .............................................................................................................. 28

8.4. Function of the DIP switches ........................................................................................................ 29

8.5. Display of the LEDs.......................................................................................................................30

8.6. Error Messages ............................................................................................................................. 31

8.6.1. Error messages in MANUAL and AUTOMATIC operating statuses .................................31

8.6.2. Error messages while the X.TUNE function is running ...................................................31

9. INSTALLATION ......................................................................................................................................32

9.1. Safety instructions ......................................................................................................................32

9.2. Installing the positioner Type 024.16.720........................................................................................ 33

9.3. Rotating the positioner for process valves .................................................................................37

10. FLUID INSTALLATION...........................................................................................................................38

10.1. Safety instructions ......................................................................................................................38

10.2. Installing the Process Valve ........................................................................................................38

10.3. Pneumatic connection of the positioner .....................................................................................39

www.sed-owcontrol.com

5

Type 024.16.720

11. ELECTRICAL INSTALLATION 24 V DC .................................................................................................40

11.1. Safety instructions ......................................................................................................................40

11.2. Electrical installation with circular plug-in connector .................................................................41

11.2.1. Designation of the contacts Type 024.16.720 ................................................................41

11.2.2. Connection of the positioner Type 024.16.720...............................................................41

11.3. Electrical installation with cable gland........................................................................................43

11.3.1. Designation of the screw-type terminals........................................................................43

11.3.2. Connection of the positioner Type 024.16.720...............................................................43

12. AS INTERFACE INSTALLATION ............................................................................................................45

12.1. AS Interface Connection.............................................................................................................45

12.2. Technical Data for AS Interface PCBs ........................................................................................45

12.3. Programming Data......................................................................................................................45

12.4. LED Status Display .....................................................................................................................46

12.5. Electrical installation AS interface...............................................................................................47

12.5.1. Safety instructions ..........................................................................................................47

12.5.2. Connection with circular plug-in connector M12 x 1, 4-pole, male................................47

12.5.3. Connection with multi-pole cable and ribbon cable terminal.........................................48

13. START-UP..............................................................................................................................................49

13.1. Safety instructions ......................................................................................................................49

13.2. Specifying the standard settings ................................................................................................49

13.2.1. Running the automatic adjustment X.TUNE: .................................................................50

14. OPERATION AND FUNCTION...............................................................................................................51

14.1. Basic functions..............................................................................................................................51

14.1.1. DIR.CMD - Effective Direction of the Position Controller Set-Point Value.....................52

14.1.2. CUTOFF - Sealing Function for the Position Controller.................................................53

14.1.3. CHARACT - Select the transfer characteristic between input signal (position set-point

value) and stroke.............................................................................................................54

14.2. Auxiliary Functions ........................................................................................................................ 55

15. SAFETY POSITIONS .............................................................................................................................56

15.1. Safety positions after failure of the electrical or pneumatic auxiliary power...............................56

www.sed-owcontrol.com

6

Type 024.16.720

16. MAINTENANCE.....................................................................................................................................57

16.1. Serviceattheairintakelter.......................................................................................................57

17. ACCESSORIES .....................................................................................................................................58

17.1. Communications software (PC SOFTWARE based on FDT/DTM technology):..........................58

17.1.1. PACTware 3.6..................................................................................................................58

17.1.2. Serial interface RS 232 ...................................................................................................58

17.1.3. Download........................................................................................................................58

18. PACKAGING AND TRANSPORT...........................................................................................................59

19. STORAGE .............................................................................................................................................59

20. DISPOSAL.............................................................................................................................................59

www.sed-owcontrol.com

7

Type 024.16.720

www.sed-owcontrol.com

8

EC Declaration of Conformity

Type 024.16.720

1. EC DECLARATION OF CONFORMITY

As manufacturer we hereby declare that the products with the designation:

Type 024.16.720

satisfyrequirementswhicharespeciedinthefollowingDirectivesoftheEuropeanCouncil:

2006/95/ EC Low Voltage Directive

2004/108/EC Electromagnetic Compatibility Directive

97/23/EC Pressure Equipment Directive

94/9/EC ATEX-Directive

The products have been subjected to the following conformity assessment procedure:

Module A Internal production control

The Pressure Equipment Directive for products with a nominal voltage < 50V is applied to the CE mark only

for equipment which has a nominal width > 25 mm and controls gases belonging to Group 1 or vapour or

equipment which has a nominal width > 32 mm and controls gases belonging to Group 2 and the product is

within the range > 1,000 and < 3,500 for the calculation nominal pressure x nominal width.

The products with a nominal voltage >= 50V with respect to Pressure Equipment Directive (97/23/EC) are

assessed in Article 1 Paragraph 3.6 of this directive, according to which the equipment is measured by the

Low Voltage Directive and therefore does not drop below the scope of the Pressure Equipment Directive.

The units are designed and built in a way that

•therewillnotbeanignitionsourceinnormaluseand

•themaximalsurfacetemperatureislessthanthelimitofthegiventemperaturecodeontheunit.

Depending on the marking the units may be used as a Category 3 unit in zone 2 or 22.

SED Flow Control GmbH

Am Schafbaum 2

D - 74906 Bad Rappenau

Bad Rappenau, 01. March 2011

(This document was issued electronically and is therefore valid without signature)

www.sed-owcontrol.com

9

Operating Instructions

Type 024.16.720

2. OPERATING INSTRUCTIONS

The operating instructions describe the entire life cycle of the device. Keep these instructions in a location which

is easily accessible to every user, and make these instructions available to every new owner of the device.

WARNING!

The operating instructions contain important safety information!

Failure to observe these instructions may result in hazardous situations.

The operating instructions must be read and understood.•

2.1. Symbols

DANGER!

Warns of an immediate danger!

Failure to observe the warning will result in a fatal or serious injury.•

WARNING!

Warns of a potentially dangerous situation!

Failure to observe the warning may result in serious injuries or death.•

CAUTION!

Warns of a possible danger!

Failure to observe this warning may result in a moderate or minor injury.•

NOTE!

Warns of damage to property!

Failure to observe the warning may result in damage to the device or the equipment.•

Indicates important additional information, tips and recommendations.

refers to information in these operating instructions or in other documentation.

→Designates a procedure which you must carry out.

www.sed-owcontrol.com

10

Authorized use

Type 024.16.720

3. AUTHORIZED USE

Non-authorized use of the positioner Type 024.16.720 may be a hazard to people, nearby equipment

and the environment.

The device is designed to be mounted on pneumatic actuators of process valves for the control of•

media.

Do not expose the device to direct sunlight.•

Useaccordingtotheauthorizeddata,operatingconditionsandconditionsofusespeciedinthecon-•

tract documents and operating instructions. These are described in the chapter entitled “7. Technical

Data”.

The device may be used only in conjunction with third-party devices and components recommended•

and authorized by SED Flow Control.

In view of the large number of options for use, before installation, it is essential to study and if necessary•

to test whether the positioner is suitable for the actual use planned.

Correct transportation, correct storage and installation and careful use and maintenance are essential•

for reliable and faultless operation.

Use the positioner Type 024.16.720 only as intended.•

3.1. Restrictions

Devices which are designed for use in Zone 2/22:

The user is responsible for protection class IP54 in accordance with EN 60529 of this device.

If exporting the system/device, observe any existing restrictions.

3.2. Predictable Misuse

•The positioner Type024.16.720 maybe used inhazardousexplosive areasonly inaccordancewiththe

ignitionprotectionclassindicatedontheidenticationplateoftheignitionprotectionclasses.

•Donotfeedanyaggressiveorammablemediaintothepressuresupplyconnection.

•Donotfeedanyliquidsintothepressuresupplyconnection.

•Donotputanyloadsonthebody(e.g.byplacingobjectsonitorstandingonit).

•Donotmakeanyexternalmodicationstothedevicebodies.Donotpaintthebodypartsorscrews.

www.sed-owcontrol.com

11

Basic Safety Instructions

Type 024.16.720

4. BASIC SAFETY INSTRUCTIONS

These safety instructions do not make allowance for any

•contingencies and events which may arise during the installation, operation and maintenance of the

devices.

•localsafetyregulations–theoperatorisresponsibleforobservingtheseregulations,alsowithreferenceto

the installation personnel.

DANGER!

Danger – high pressure!

Before dismounting pneumatic lines and valves, turn off the pressure and vent the lines.•

Risk of electric shock!

Before reaching into the device or the equipment,• switch off the power supply and secure to prevent

reactivation!

Observe applicable accident prevention and safety regulations for electrical equipment!•

General hazardous situations.

To prevent injury, ensure:

that the system cannot be activated unintentionally.•

Installation and repair work may be carried out by authorized technicians only and with the appropriate•

tools.

After an interruption in the power supply or pneumatic supply, ensure that the process is restarted in a•

denedorcontrolledmanner.

The device may be operated only when in perfect condition and in consideration of the operating•

instructions.

The general rules of technology apply to application planning and operation of the device.•

NOTE!

Electrostatic sensitive components / modules!

The device contains electronic components, which react sensitively to electrostatic discharge (ESD).•

Contact with electrostatically charged persons or objects is hazardous to these components. In the worst

case scenario, they will be destroyed immediately or will fail after start-up.

Observe the requirements in accordance with EN 100 015 - 1 and 5 - 2 to minimize or avoid the possibility•

of damage caused by sudden electrostatic discharge!

Also ensure that you do not touch electronic components when the power supply is on!•

The positioner Type 024.16.720 was developed with due consideration given to the accepted safety

rules and is state-of-the-art. Nevertheless, dangerous situations may occur.

Failure to observe this operating manual and its operating instructions as well as unauthorized tampering

with the device release us from any liability and also invalidate the warranty covering the devices and

accessories!

www.sed-owcontrol.com

12

General Information

Type 024.16.720

5. GENERAL INFORMATION

5.1. Scope of Supply

Check immediately upon receipt of the delivery that the contents are not damaged and that the type and scope

agree with the delivery note and packing list.

Generally this consists of:

Pneumatically actuated valve with attached positioner, the operating instructions for the positioner and for

the valve with pneumatic actuator.

For the multipole version of the positioner we will provide you with cable connectors as suitable

accessories.

If there are any discrepancies, please contact us immediately.

5.2. Contact Addresses

SED Flow Control GmbH

Am Schafbaum 2

D - 74906 Bad Rappenau

P.O. Box 1306

D - 74900 Bad Rappenau

Phone: +49(0)7264/921-0

Fax: +49(0)7264/921-21

E-Mail:info@sed-owcontrol.com

Web:www.sed-owcontrol.com

5.3. Warranty

This document contains no promise of guarantee. Please refer to our general terms of sales and delivery. The

warrantyisonlyvalidifthepositionerType024.16.720isusedasintendedinaccordancewiththespecied

application conditions.

The warranty extends only to defects in the positioner Type 024.16.720 and its components. We accept

no liability for any kind of collateral damage which could occur due to failure or malfunction of the

device.

www.sed-owcontrol.com

13

General Information

Type 024.16.720

5.4. Trademarks

Brands and trademarks listed below are trademarks of the corresponding companies / associations /

organizations

Loctite Henkel Loctite Deutschland GmbH

5.5. Information on the Internet

The operating instructions and data sheets for Type 024.16.720 can be found on the Internet at:

www.sed-owcontrol.com

www.sed-owcontrol.com

14

System Description

Type 024.16.720

6. SYSTEM DESCRIPTION

6.1. Intended Application Area

The positioner Type 024.16.720 is designed to be mounted on pneumatic actuators of process valves for

the control of media.

6.2. Function of the positioner and combination with valve types

Positioner Type 024.16.720 is an electropneumatic position controller for pneumatically actuated control valves

with single-acting actuators.

Together with the pneumatic actuator, the positioner forms a functional unit.

Thecontrolvalvesystemscanbeusedforawiderangeofcontroltasksinuidtechnologyand,dependingon

the application conditions, different process valves from the SED range can be combined with the positioner.

Angle-seatvalves,diaphragmvalvesorballvalvesttedwithacontrolconearesuitable.

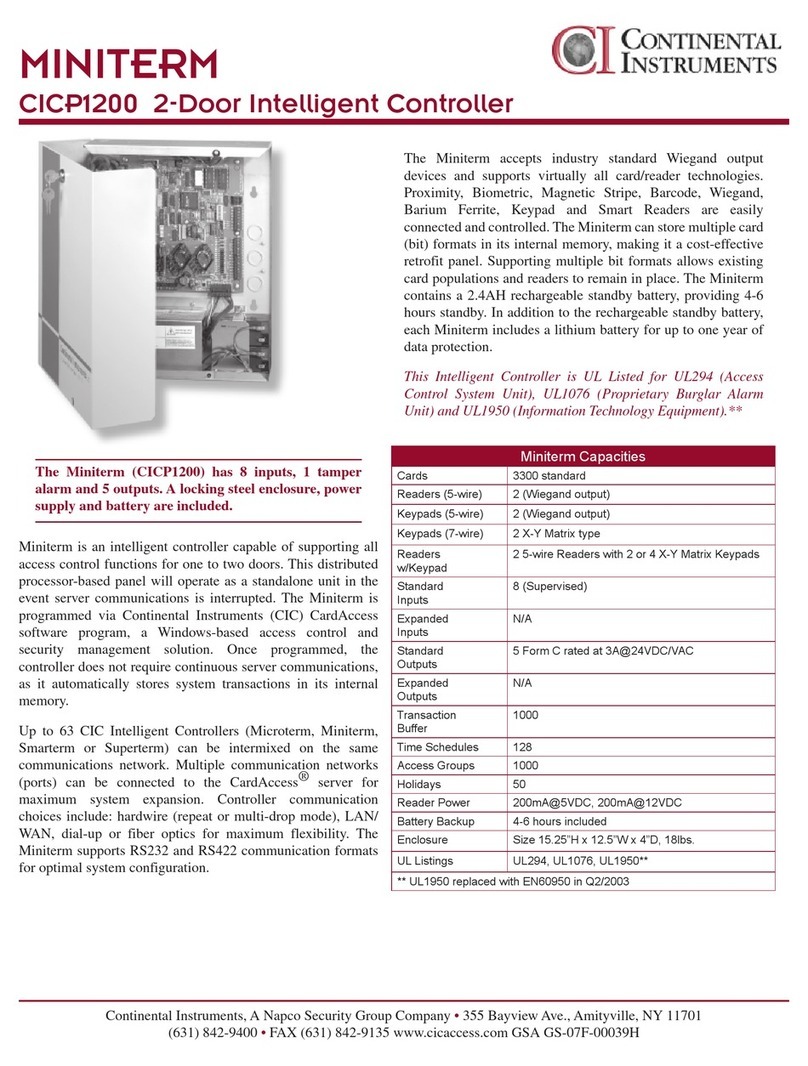

“Fig. 1: ” shows an overview of the possible combinations of positioner and different pneumatically actuated

valves. Different actuator sizes and valve nominal widths, not illustrated here, are available for each type. More

precisespecicationscanbefoundontherespectivedatasheets.Theproductrangeisbeingcontinuously

expanded.

Positioner Type 024.16.720

with diaphragm valve

with angle seat valve

Fig. 1: Overview of possible combinations

www.sed-owcontrol.com

15

System Description

Type 024.16.720

The position of the actuator is regulated according to the position set-point value. The position set-point value

isspeciedbyanexternalstandardsignal.

Pneumatically actuated piston actuators and rotary actuators can be used as an actuator. Single-acting

actuators are offered in combination with the positioner.

For single-acting actuators, only one chamber is aerated and deaerated in the actuator. The generated pressure

works against a spring. The piston moves until there is an equilibrium of forces between compressive force

and spring force.

6.3. Features of the valve types

Angle seat control

valves / straight seat

control valves

Diaphragm valves Ball valves Flap valves

Features incomingowunder•

seat

no closing impact•

straightowpathof•

the medium

self-adjustingstufng•

box for high leak-

tightness

medium is hermeti-•

cally separated from

the actuator and

environment

cavity-free and self-•

draining body design

anyowdirection•

with low-turbulence

ow

steam-sterilizable•

CIP-compliant•

no closing impact•

actuator and dia-•

phragm can be

removed when the

body is installed

scrapable•

minimum dead•

space

unaffected by•

contamination

little pressure loss•

compared to other

valve types

seat and seal can•

be exchanged in

the three-piece ball

valve when installed

Note

can be used as

process controller

only

unaffected by•

contamination

little pressure•

loss compared

to other valve

types

inexpensive•

low construction•

volume

Typical

media

water, steam and•

gases

alcohols, oils, propel-•

lants,hydraulicuids

salt solutions, lyes•

(organic)

solvents•

neutral gases and•

liquids

contaminated,•

abrasive and

aggressive media

media of higher•

viscosity

neutral gases and•

liquids

clean water•

slightly aggressive•

media

neutral gases•

and liquids

slightly•

aggressive

media

Table 1: Features of the valve types

www.sed-owcontrol.com

16

System Description

Type 024.16.720

6.4. Structure of the positioner

The positioner Type 024.16.720 consists of the micro-processor controlled electronics, the position measuring

system and the control system. The device is designed using three-wire technology. The positioner is operated

via 2 keys and a 4-pole DIP switch. The pneumatic control system for single-acting actuators consists of 2

solenoid valves.

6.4.1. Representation

Pressure supply connection

(label: 1)

Exhaust air con-

nection (label: 3)

Electrical connection

(cable gland M16 x 1.5

or circular plug-in connector M12 x

1)

Body casing removed: Buttons

DIP Switches

LED

Transparent cap

Pressure limiting valve

(for protection against

too high internal

pressure in case of error)

Airintakelter

(exchangeable)

Body casing

Version 1

Circular plug-in connector

Version 2

AS interface

Cable gland

Communications

interface

Pressure supply connection

(label: 1)

Exhaust air con-

nection (label: 3)

LED

Communica-

tions interface

Airintakelter

(exchangeable)

Screw-

type

terminals

Fig. 2: Structure

www.sed-owcontrol.com

17

System Description

Type 024.16.720

6.4.2. Features

•Models

for single-acting valve actuators.

•Positionmeasuringsystem

Contactless and therefore wear-free position measuring system.

•Microprocessor-controlledelectronics

for signal processing, control and valve control.

•Controlmodule

The device is controlled via 2 buttons and a 4-pole DIP switch. 2x 2-colored LEDs indicate different sta-

tuses of the device.

•Controlsystem

The control system consists of 2 solenoid valves. One valve is used to aerate and another to deaerate the

pneumatic actuator. The solenoid valves operate according to the rocker principle and are controlled with

aPWMvoltageviathecontroller.Doingsoachievesahigherexibilitywithregardtoactuatorvolumeand

nalcontrolspeed.Thedirect-actionmodelhasanoriceofDN0.6.Inlargerpneumaticactuatorsthe

solenoidvalvesfeaturediaphragmamplierstoincreasethemaximumowandthereforetoimprovethe

dynamics (DN 2.5).

•Positionfeedback(optional)

The position of the valve can be transmitted to the PLC via an analog 0/4-20 mA output.

•Binaryinput

If a voltage > 10 V is applied, SAFE POSITION is activated, i.e. the valve is moved to the safety position

(factory setting, can be changed with communications software).

Pneumatic interfaces•

1/4“ connections with different thread

forms (G, NPT)

hose plug-in connection

Electrical interfaces•

Circular plug-in connector or cable

gland

•Body

The body of the positioner is protected from excessively high internal pressure, e.g. due to leaks, by a

pressure limiting valve.

•Communicationsinterface

Forcongurationandparameterization.

www.sed-owcontrol.com

18

System Description

Type 024.16.720

6.4.3. Function diagram of the positioner with single-acting actuator

The illustrated function diagram describes the function of the positioner (Type 024.16.720).

Control system

1

2

Position

controller

Control system

1: Aeration valve

2: Bleed valve

Pressure

supply

Exhaust air

Position

measuring

system

Actual

position

external

position

set-point value

Positioner

Pneumatic

actuator

(single-acting)

Valve

(actuator)

Fig. 3: Function diagram

www.sed-owcontrol.com

19

System Description

Type 024.16.720

6.5. Type 024.16.720 Positioner with position controller

The position measuring system records the current position (POS) of the pneumatic actuator. The position con-

trollercomparesthisactualpositionvaluewiththeset-pointvalue(CMD)whichisdenableasstandardsignal.In

case of a control deviation (Xd1), a pulse-width modulated voltage signal is sent to the control system as a manip-

ulated variable. If there is a positive control difference in single-acting actuators, the air inlet valve is controlled via

output B1. If the control difference is negative, the bleed valve is controlled via output E1. In this way the

position of the actuator is changed until control difference is 0. Z1 represents a disturbance variable.

Valve

opening

Control valve

Control system

Solenoid valves

Position measuring system

Position

controller

Position

set-point

value

CMD Xd1 B1

E1 PK

Z1

POS

Position control

circuit

+-

Fig. 4: Signal ow plan of position controller

6.5.1. Schematic representation of the position control Type 024.16.720

4 ... 20 mA1)

0 ... 20 mA

CHARACT

SPLTRNG2)

DIR.CMD CUTOFF X.TIME2)

X.CONTROL

DBND

POS

CMD

INP

POS

CMD

DIR.ACT2) X.LIMIT2)

1) Default setting

2) can only be activated with communications software

Fig. 5: Schematic representation of position control

www.sed-owcontrol.com

20

System Description

Type 024.16.720

6.5.2. Properties of the position controller software

Functions I

•ActivationviaDIPswitches

•Parametersettingviacommunicationssoftware

Additional function Effect

Sealing function

CUTOFF

Valveclosestightoutsidethecontrolrange.Speci-

cation of the value (as %), from which the actuator is

completely deaerated (when 0 %) or aerated (when

100 %)

(see Chapter “8.4. Function of the DIP switches”).

Correction line to adjust the operating

characteristic

CHARACT

Linearization of the process characteristic can be

implemented (see Chapter “8.4. Function of the DIP

switches”).

Effective direction of the controller set-point

value

DIR.CMD

Reversal of the effective direction of the set-point

value

(see Chapter “8.4. Function of the DIP switches”).

Table 2: Functions I

This manual suits for next models

1

Table of contents

Popular Controllers manuals by other brands

Hatteland

Hatteland HD REM SX1-A1 manual

National Instruments

National Instruments NI cRIO-9024 User manual and specifications

PEITIAN ROBOTICS

PEITIAN ROBOTICS ARC4-50 manual

Franklin Fueling Systems

Franklin Fueling Systems TS-SCM installation guide

HighPoint

HighPoint SSD7000 Series installation guide

AuCom

AuCom CSX-007 Service manual

Spirax Sarco

Spirax Sarco LC2500 Installation and maintenance instructions

POSEIDON

POSEIDON Triton/Octopus instructions

Continental Instruments

Continental Instruments CICP1200 datasheet

KELCO

KELCO F60 Mk2 Installation & programming manual

Geco

Geco GH10NA user manual

rauland

rauland 2524 ChronoCom Programming manual