Seikom Electronic NLSW 45-3 User manual

UserManual

NLSW®45-3

24 V AC/DC, 230 V AC

Version 1

Page 2

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

User Manual

NLSW®45-3

Page 3

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

CONTENTS

CONTENTS............................................................................................................................. 3

1. SAFETY INSTRUCTIONS .................................................................................................... 4

2. GENERAL INFORMATION .................................................................................................. 4

2.1 Proper Use.............................................................................................................................. 4

2.2 Function Principle ................................................................................................................... 4

3. TECHNICAL DATA............................................................................................................. 5

4. INSTALLATION AND COMMISSIONING .............................................................................. 6

4.1 Installation Conditions ............................................................................................................ 6

4.2 Electrical Connections ............................................................................................................ 7

4.3 Setting the Switching Point ...................................................................................................... 7

4.4 Commissioning Instructions.................................................................................................... 8

5. MAINTENANCE INSTRUCTIONS......................................................................................... 8

6. ERROR MESSAGES ........................................................................................................... 9

7. EU DECLARATION OF CONFORMITY................................................................................ 10

User Manual

NLSW®45-3

Page 4

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

1. SAFETY INSTRUCTIONS

Read the product description before commissioning the device. Make sure that the product

is suitable for your application without any restrictions.

Improper use or use not in accordance with the intended use can lead to malfunctions of the device

or to undesirable effects your application.

For this reason, the installation, electrical connection, startup, operation and maintenance of the

device may only be carried out by trained personnel.

2. GENERAL INFORMATION

The calorimetric flow monitors of the NLSW®45-3-series are an economical alternative to common

pressure transmitters. The installation of the separately available sensor is simple and quick by means

of a flange mount (for channel installation) or by means of a PG7 threaded connector. The switching

point can be selected via the integrated potentiometer. In case a flow is present, the switching output

is conductive (yellow LED on the unit is on).

2.1 Proper Use

The flow monitors of the NLSW®45-3 series are intended for monitoring gaseous media within the

specified technical data. Areas of application are the monitoring of chillers (water shortage), boiler

and sprinkler systems, pumps, cooling- and lubricant circuits.

2.2 Function Principle

Flow monitors of the NLSW®45-3 series function according to the calorimetric principle. A unit’s relay

switches when flow speed reaches a pre-selected threshold value. The calorimetric measuring

principle is based on a heated temperature-sensitive resistor. Flow in the medium dissipates heat

from the precision resistor, the temperature of the resistor changes and thus its resistance value. This

change is evaluated by the unit. However, not only the flow speed of the medium has an influence on

the dissipated amount of heat, but also its temperature, therefore a relation between flow and

temperature must be established. This is achieved by a second, temperature-dependent precision

resistor next to the first one. The second precision resistor (temperature compensation) is not heated

and serves to measure the temperature only.

Flow ≥threshold value

Relay output energized

Yellow LED “Airflow” turns on

Flow < threshold value

Relay output not energized

Yellow LED “Airflow” shuts off

User Manual

NLSW®45-3

Page 5

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

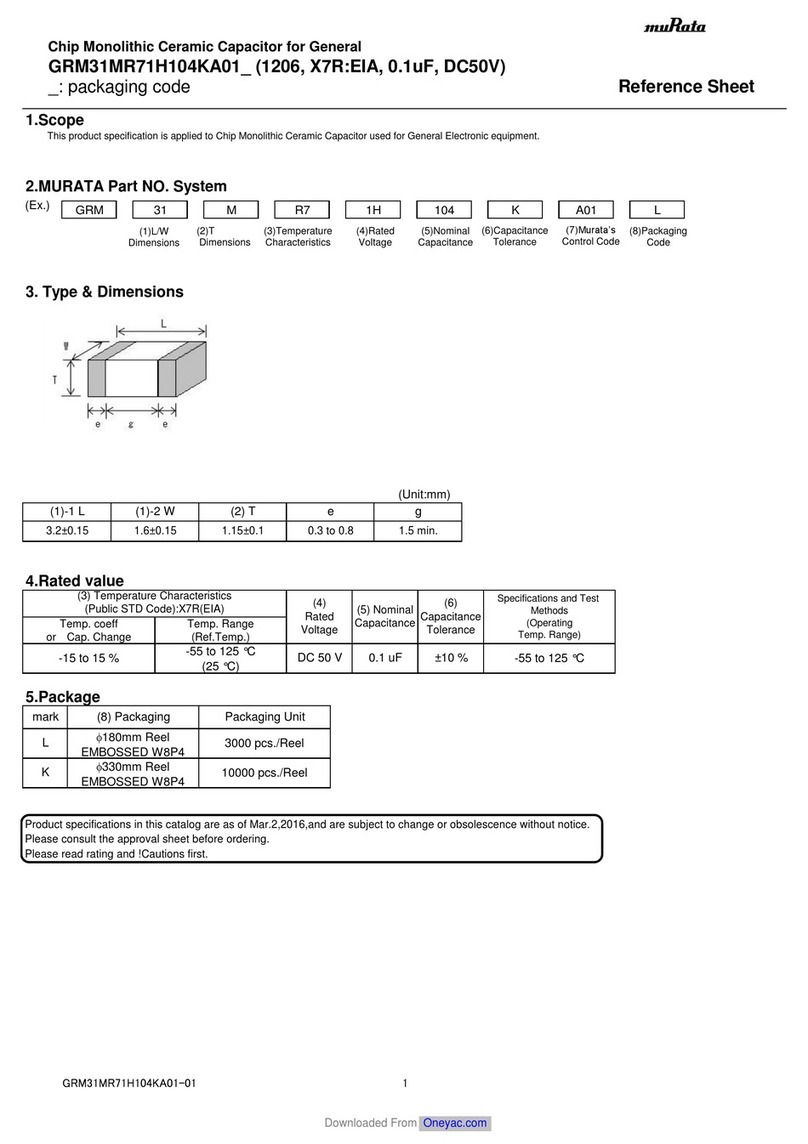

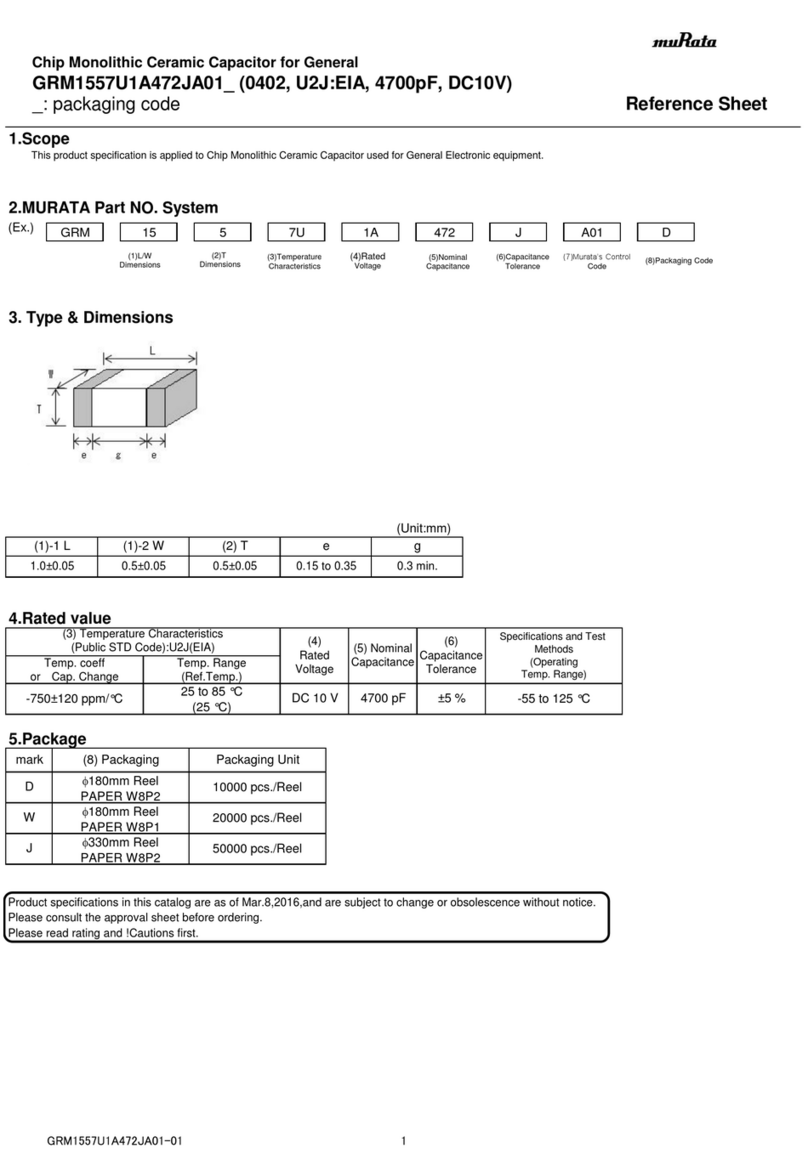

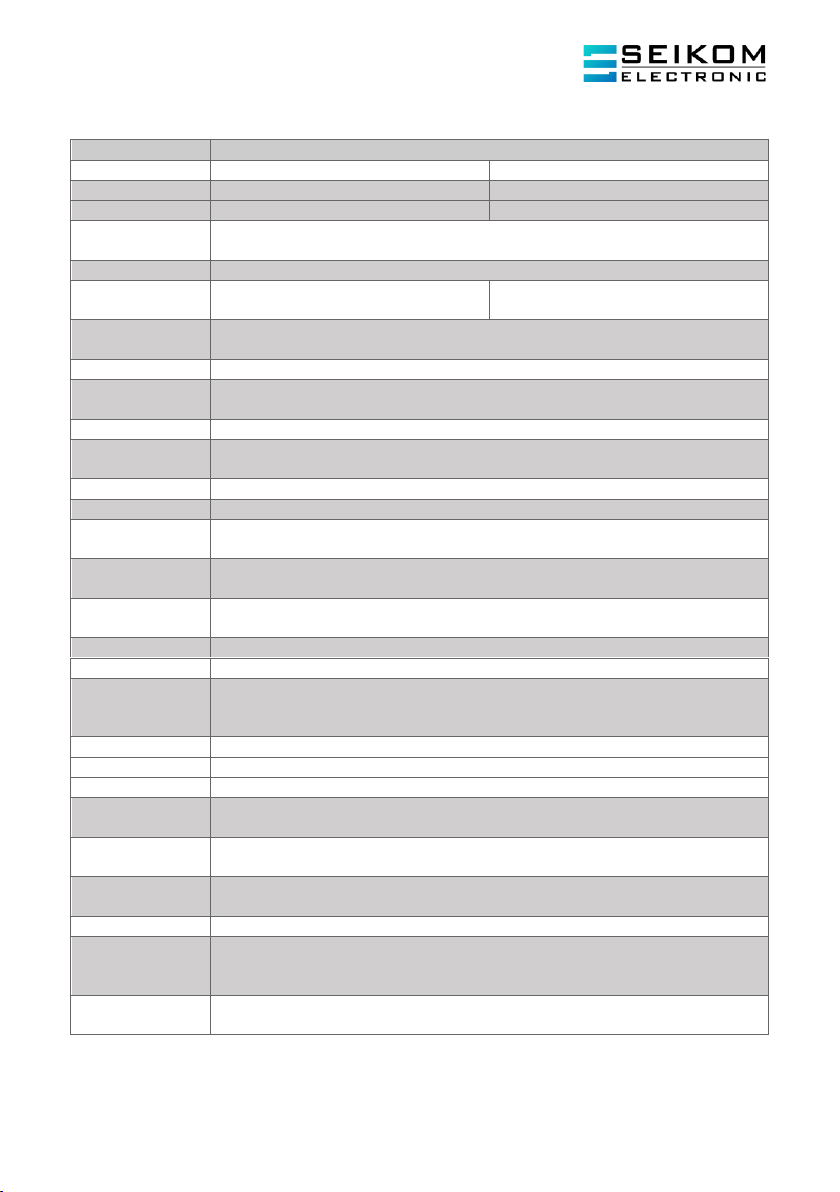

3. TECHNICAL DATA

Type

NLSW®45-3

Article-No.

77029

63377

Operating voltage

24 V AC/DC

230 V AC 50/60 Hz

Voltage tolerance

± 5%

± 6%

Overvoltage

category

II

Signal lamp voltage

Green LED

Power

consumption

3 VA

4,5 VA

Ambient

temperature

-20 … 50°C

Switching output

Relay, 1 change-over contact

Switching function

at flow

Relay engages

Relay output

250 V AC, 8 A, 2 kVA

Minimum switching

load

10 mA / 5 V DC

Signal lamp airflow

Yellow LED

Start-up delay

Adjustable approx. 5...60 s

Signal lamp start-

up delay

-

Media temperature

range

-25 … 120°C

Switching point

adjustment

With potentiometer

Airflow range

0,1 … 30,0 m/s

Sensor

Available separately, F2.x, F3.x (recommended), F4.x (made of PTFE)

Immersion depth

(depending on

sensor, approx.)

50 mm, 130 mm, 165 mm, 300 mm, 400 mm, 500 mm

Process connection

PG7, flange

Sensor material

MS58, nickel-plated, optional stainless steel

Pressure resistance

10 bar

Electrical

connection

10 terminals, 2.5 mm²

Protection

category, housing

IP40

Protection

category, terminals

IP20

Pollution class

2

Housing

dimensions

(L x W x H)

120 mm x 45 mm x 73 mm

Type certification

Type examination TÜV Nord according to

DIN EN 61010-1:2011-07

User Manual

NLSW®45-3

Page 6

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

4. INSTALLATION AND COMMISSIONING

Installation and commissioning must be performed by authorized and qualified

personnel.

Connections to main supply (L, N) must be made by means of a protected isolating switch with usual

fuses. As a matter of principle, the General VDE regulations must be complied with (VDE 0100, VDE

0113, VDE 0160). If the potential-free contact is connected to an extra-low safety voltage, sufficient

insulation must be provided for the connecting cables up to the terminal, since otherwise the double

insulation to the mains voltage side may be impaired. The current load capacity of the potential-free

contact is limited to 10 A.

The NLSW®45-3 is designed for mounting on a profile rail (DIN EN 50022-35). If the device should be

exposed to greater vibrations, mount it on vibration metal as appropriate. The built-in device according

to IP20 (corresponds to VBG4) must be mounted in a housing or in the control cabinet.

4.1 Installation Conditions

To avoid malfunctions, please refer to the following points:

▪The tip of the sensor should be as close as possible to the center of the pipe. The traverse

hole in the shaft of the sensor must be within the full of the gaseous medium.

▪There is a small notch in the metal at the end of the sensor. This mark is intended as a

mounting aid and should be placed in the direction from which the current is coming.

▪In case of vertical pipes, the direction of flow should be upwards, especially for small air

flows (up to 1 m/s), in order to avoid influences from thermally rising air.

▪The sensor needs at least 5 x D (inside pipe diameter) of free inlet and 3xD (inside pipe

diameter) of outlet path to avoid false measurement due to turbulence.

▪Screw in the associated sensor (available separately) only via the hexagon of the sensor

housing.

▪The device operates independently of the installation position.

▪Connect the sensor to the device according to the connection diagram. Reversing the

connections will result in malfunctions and possible damage.

▪If the sensor line is laid in a duct together with other current-carrying lines (e.g., motors or

solenoid valves), we recommend shielding the sensor line (apply shield).

▪To avoid malfunctions, the sensor cable must be extended with a cross-section of at least

1.5 mm². The maximum cable length should not exceed 50 m.

User Manual

NLSW®45-3

Page 7

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

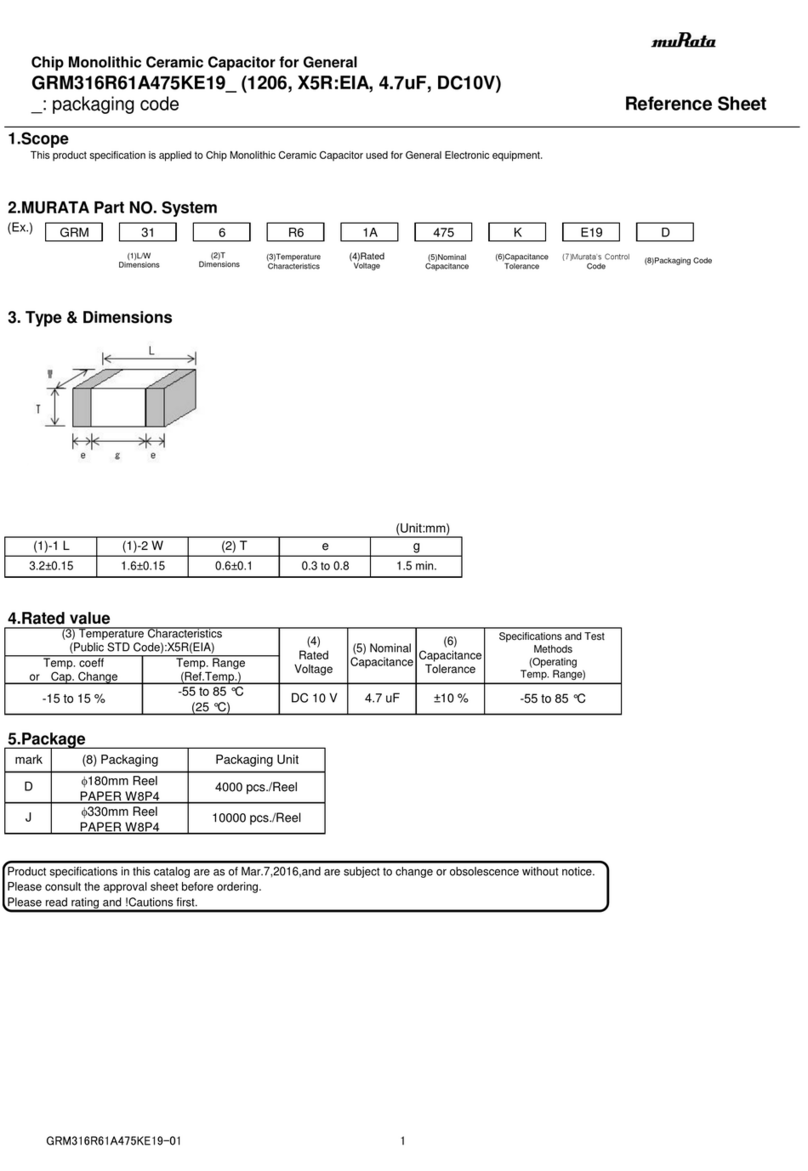

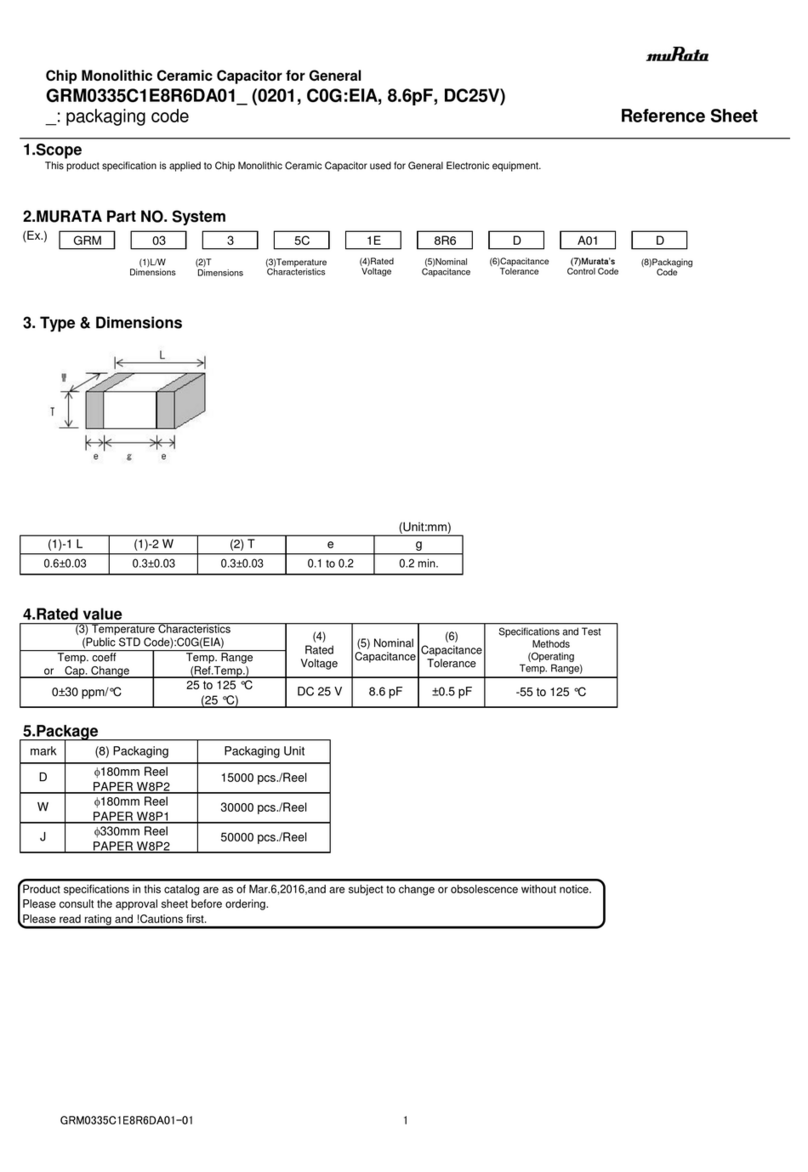

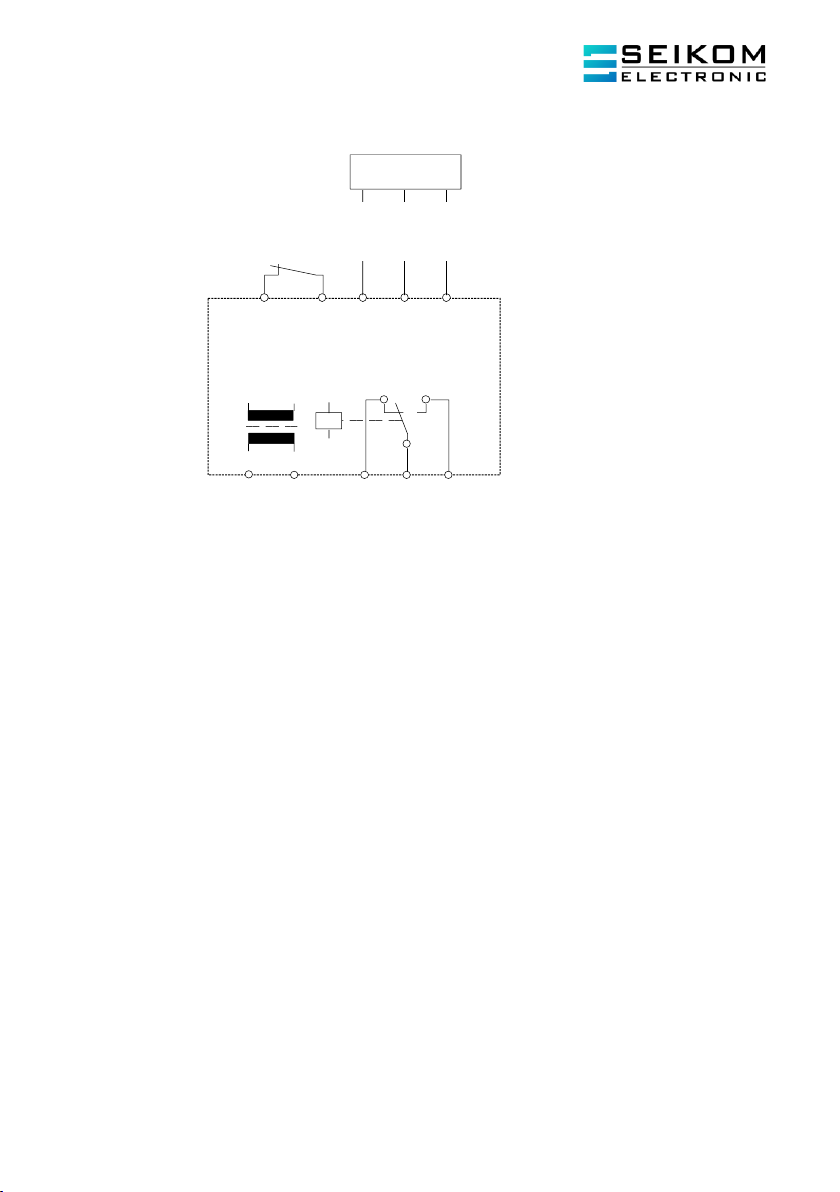

4.2 Electrical Connections

Colors: BN = brown WH = white GN = green YE = yellow

4.3 Setting the Switching Point

The interrelation between air speed and resistance change of the precision resistors is not linear. In

the lower range (low rates of flow) the relative change of resistance is large. In the upper range, the

change of resistance at identical deviations in flow speed becomes increasingly smaller. When setting

the switching point, it must first be determined what change is to be monitored, since some settings

result in certain disadvantages. The following requirements must be taken into consideration:

Low change in the rate of flow in the high flow speed range: the switching point must be chosen

very close to the measuring value of the normal flow, since the change of measuring values is very

small when the rate of flow changes. Since the temperature compensation exhibits a certain amount

of delay in comparison to the actual change of temperature, such a setting of the switching point is

possible only with slow changes of temperature.

Low change in the rate of flow in the low flow speed range: the switching point may be selected at

a greater distance from the measuring value of the normal rate of flow, since the changes of the

measuring values are larger when the rate of flow changes. A change in temperature has no effect on

the switching behaviour.

Large change in the rate of flow: in most cases like this a simple yes/no statement is desired (e. g.

ventilator is running or ventilator stopped). Therefore, a larger safety margin may be selected, so that

neither temperature changes nor turbulence have any influence on the switching behaviour.

The switching points are set on the evaluation unit of the Flow monitor.

16 15 18

BN BK BU

a2 b2 a3

L(+) N(-)

NLSW45-3

Sensor

Z Z a2 b2 a3

Start

t2-60s

BN BK GY

1 2 3

User Manual

NLSW®45-3

Page 8

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

4.4 Commissioning Instructions

When commissioning and adjusting the device, the following procedure is recommended:

▪Install and connect the flow controller in accordance with installation instructions and

conditions.

▪Align the mark on the end of the sensor with the air stream.

▪If necessary. Set jumper for start-up delay.

▪Set trimmer “Sensitivity” to minimum sensitivity (left limit stop).

▪Connect main voltage. The green LED lights up. When the jumper is set, the start-up delay

expires (approx. 5... 60 sec.).

▪The yellow LED lights up briefly and goes out again (with maximum set start-up delay, it

remains on until the delay time has elapsed. (If terminal Z/Z* is connected, the relay is

switched through, the yellow LED lights up and the set delay time only expires after the Z/Z

connection is opened).

▪Set nominal rate of flow.

▪Slowly turn trimmer “sensitivity” clockwise until the yellow LED lights up and the signal

output switches. To avoid faulty switching when the flow rate changes slightly, turn the

potentiometer slightly beyond the switching point. If the start-up delay is preset, do not make

this adjustment until the yellow LED has gone out.

▪To check the function of the flow controller, reduce or stop the flow.

▪The yellow LED will go off (output relay at NLSW®45-3 is released).

The device is now set to function.

*Function of terminals Z/Z: Time-delayed start of start-up delay: when terminals Z/Z are bridged, the

relay is switched through / selected start-up delay time expires after the Z/Z connection is opened.

5. MAINTENANCE INSTRUCTIONS

The flow sensor should be serviced at regular intervals, i.e., the flow sensor should be cleaned when

used in heavily contaminated media. The following procedure is expedient:

▪Dismantle flow monitor.

▪Carefully soak the flow monitor in lukewarm soapy water for approx. 10minutes (depending

on the degree of soiling).

▪Carefully rinse the flow monitor with lukewarm water.

▪Install the flow monitor.

▪Put the flow monitor into operation and, if necessary, carry out a new calibration with the

evaluation electronics.

Do not clean the sensor tip with a screwdriver, wire brush or similar. There is a high

risk of damage.

User Manual

NLSW®45-3

Page 9

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

6. ERROR MESSAGES

The following instructions are intended as first level support in case your flow monitor is not working

properly.

Problem

Potential Cause

Solution

Device does not work at all.

Missing or wrong supply

voltage.

Check supply voltage and

connection.

Device does not detect a flow.

Sensor is not installed

properly.

Flow is outside of the

measurement range.

Review if the sensor was

installed with its marking

positioned towards the airflow

source and close to the duct’s

center.

Adjust the tube’s diameter to

increase or decrease the flow.

Device detects flow when no

flow is present.

Flow is present even at

standstill e.g., due to

ventilation flaps through

which air enters from the

outside.

Adjust the sensor’s switching

point.

Device shows delayed

reaction behavior.

Sensor tip is polluted.

Carefully clean the sensor

with water.

Device switches in the event

of a rapid media temperature

increase.

Temperature gradient is

outside of technical

specifications.

Turn the "Sensitivity"

potentiometer a little further

clockwise.

Set switching point in hot

media environment.

User Manual

NLSW®45-3

Page 10

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

7. EU DECLARATION OF CONFORMITY

User Manual

NLSW®45-3

Page 11

+49 2058 916 900 0 •info@seikom-electronic.com •www.seikom-electronic.com

Growing network of local distributors available online

www.seikom-electronic.com

Our Product Portfolio

Flow

Temperature

Pressure

Air Quality and CO2

Zener Barriers

Universal Transmitters

+49 2058 916 900 0

info@seikom-electronic.com

www.seikom-electronic.com

SEIKOM-Electronic GmbH & Co. KG

Gold-Zack-Straße 7

40822 Mettmann

This manual suits for next models

2

Table of contents