2

Contents

PAGE

1.00 SAFETY INSTRUCTIONS ..............................................................................................................................3

1.10 ASSEMBLY/START-UP .....................................................................................................................................3

1.20 SAFETY INSTRUCTIONS...................................................................................................................................3

1.21 Safety risks...............................................................................................................................................3

1.22 Safety directives.......................................................................................................................................3

1.30 SPARE PARTS ................................................................................................................................................4

1.40 TRANSPORTATION/STORAGE...........................................................................................................................4

1.50 ELECTRICAL CONNECTION ..............................................................................................................................4

1.51 Beer connection .......................................................................................................................................4

1.52 Operation..................................................................................................................................................4

1.60 SERVICE........................................................................................................................................................4

2.00 PROPER USE.................................................................................................................................................4

3.00 COMMISSIONING...........................................................................................................................................5

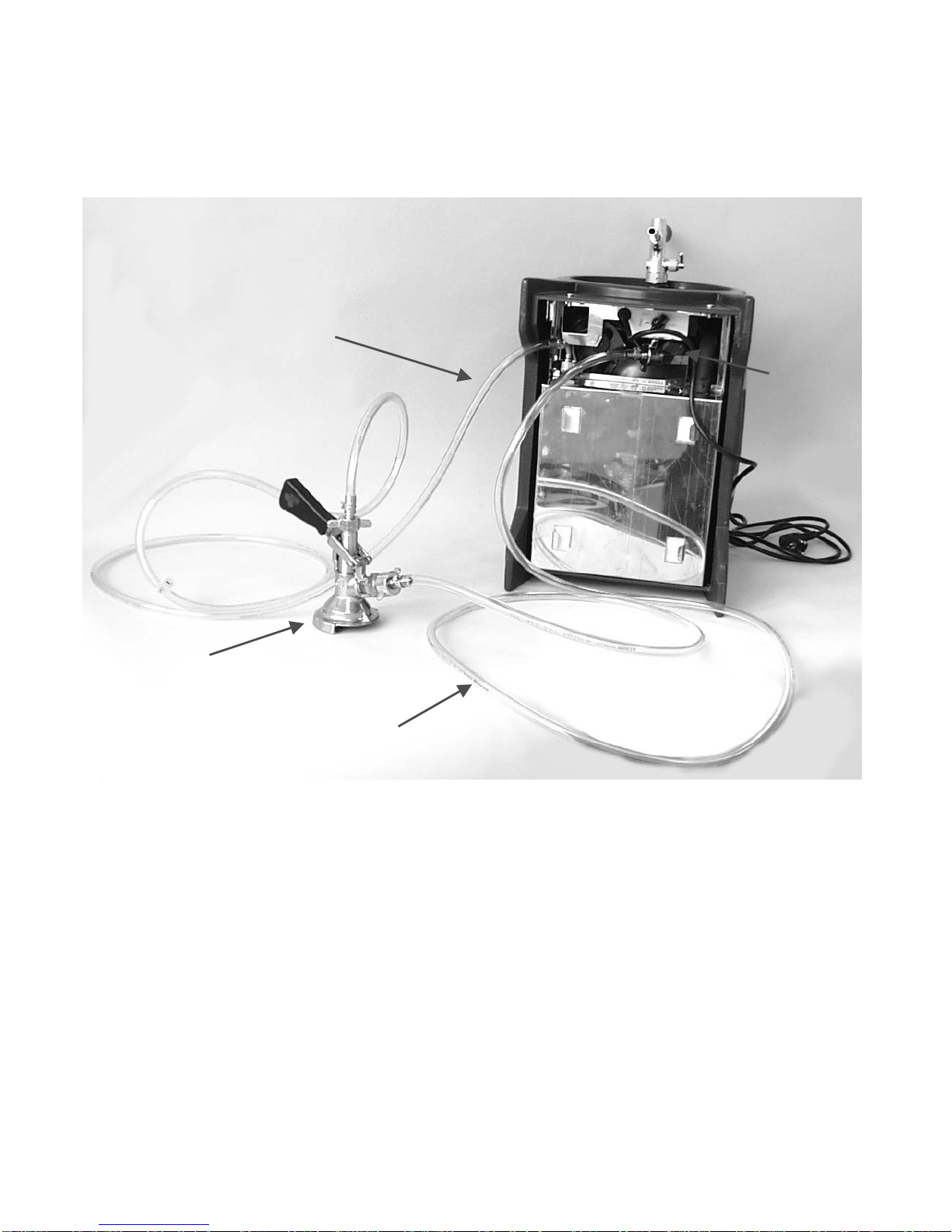

3.10 CONNECTING .................................................................................................................................................5

3.20 POURING DRAUGHT BEER ...............................................................................................................................6

3.30 COMMISSIONING MODEL WITH MEMBRANE PUMP....................................................................................6

3.40 TUBING DIAGRAM ...........................................................................................................................................7

3.41 Tubing diagram party keg with membrane pump.....................................................................................7

3.41 Tubing diagram party keg with membrane pump.....................................................................................8

4.00 SHUT-DOWN..................................................................................................................................................9

5.00 TEMPERATURE ADJUSTMENT ...................................................................................................................9

6.00 MAINTENANCE..............................................................................................................................................9

6.10 OPENING APPLIANCES ....................................................................................................................................9

6.20 CLEANING THE BEVERAGE PUMP .....................................................................................................................9

7.00 TROUBLESHOOTING..................................................................................................................................11

8.00 SPARE PARTS LIST....................................................................................................................................12

8.10 ACCESSORIES..............................................................................................................................................12

9.00 DATA ABOUT NOISE EMISSION................................................................................................................12

9.10 TECHNICAL DATA..........................................................................................................................................12