Selden S30 User manual

1

Manual for 2-speed self-tailing winches

S30, S40, S48

&

S54

597-225-E

2016-06-01

2

Contents

Page

1 Introduction 3

1.1 The manual 3

1.2 Warranty 3

1.3 General warning & instructions 4

1.4 Product information 4

1.4.1 Seldén winch range 4

1.4.2 S-winch feature 4

1.4.3 Winch handle 5

1.4.4 Technical data 5

1.4.5 Parts and descriptions 6

2 Operation instructions 7

2.1 Winch handle 7

2.2 Winching 7

3 Installation 8

3.1 Installation preparations 8

3.1.1 Winching orientation 8

3.1.2 Line routing 8

3.2 Installation instructions 9

3.2.1 Installation with hexagon headed bolts

(Sliding bolts) 9

3.2.2 Adjustment of the self-tailing arm 10

3.2.3 Installation with hexagon socket head cap

screws (Allen screws) 11

4 Dismantling and maintenance 15

4.1 Dismantling for normal service 15

4.2 Dismantling for extended service 18

4.3 Service instructions 21

5 Notes 22

3

1 Introduction

1.1 The manual

1.2 Warranty

To achive the maximum benet and enjoyment from your Seldén winch, we recommend that you study this

manual carefully.

All safety-related information is indicated by the following symbol:

The manual covers 4 different winch sizes; S30, S40, S48 and S54. The model designation can be found on the

top of the winch.

Identication-/serial number is located inside the winch, but also on the delivery box.

The Seldén winch installation system is based on metric screws/bolts.

This manual will be updated subsequently. For the latest update check www.seldenmast.com

Seldén Mast AB guarantees the winch for 2 years. The guarantee covers faults arising from defective design,

materials or workmanship.

The guarantee is only valid if the winch is installed, operated and maintained in accordance with this manual

and is not subjected to loads in excess of those indicated in the brochure and instructions.

If the winch is repaired by anyone else other than Seldén Mast AB or one of our authorized dealers, the guaran-

tee ceases to be valid.

The Seldén winch is designed for line handling on sailboats only.

Complete shipment and warranty conditions are to be found on Seldén’s website www.seldenmast.com.

See Technical information/ General conditions of sale (595-546-E).

Seldén Mast AB reserves the right to alter the content and design without prior warning.

This information must be followed to avoid damage to the winch and risk of personal

injury. The 2-year warranty on the Seldén winch is only valid if the winch is installed

and operated correctly according to the manual.

4

1.3 General warning & instructions

1.4 Product information

Make sure the winch is dimensioned according to Seldén’s design standards and not subjected to loads greater

than those stated in the brochure and instruction materials and is used solely for its intended use, i.e. normal

sailboat applications for running rigging.

Exceeding the stated maximum working load (MWL) may lead to winch failure or that the winch detaches from

the boat which may lead to serious injuries.

Keep hands, ngers, hair and clothing away from moving parts. It is recommended to let only one person, work

with the winch at any one time.

If a Seldén winch, despite the above, is used for going aloft in the mast, double halyards must be used, to be

hauled in and eased off at the same time. (Seldén rigging manual “Hints & Advice”, 595-540-E, “Working

aloft”).

For your own personal safety, make sure the winch is installed, regularly inspected and maintained according to

this manual.

This manual is available in English only. If you do not understand the manual content we advise you to obtain

expert assistance for the installation and operation!

Seldén have two ranges of winch, S-winches and the R-winches, which are manually operated and of self-

tailing type with two forward gears.

The difference between these two models are that the R-winches are revisable, which means it is possible to let

the line out by reversing the winch drum using the winch handle. The S-winches do not have this feature.

With modern manufacturing technology and by optimizing the choice of materials Seldén have succeeded to

reduce the weight and the need of maintenance to a minimum.

The drum has a unique design consist of several concave surfaces which provide an extraordinary grip for the

line. It means fewer turns on the drum which reduces the risk of an override and allows the line to be released

quickly.

The self-tailing jaws has a design which makes it possible to pull the slack out of the sheet with the line sitting

in the self-tailer and with the winch handle mounted. This means safer and quicker operation.

The Seldén winch is designed for line handling on sailboats only!

Exceeding maximum working load may lead to winch failure or serious injuries.

1.4.1 Seldén winch range

1.4.2 S-winch features

5

Seldén have two different models of winch handles designed for S-winches and R winches respectively. The

winch handle for the R-winches differs from the S-winch handle by it having a button for a reverse function on

the grip. Both winch handles t in each winch model and works for forward winching, while the reverse

function on R-winch only can be operated by the R-winch handle.

The S-winch has two different fastening methods:

1. By hexagon headed bolts which slide into a groove in the winch base and where the hexagon heads are

locked against rotation due to the winch base structure. This method allows installation without dismantling

the winch. The bolts are tted through deck and fastened using washers and nuts. (See g.3.2.1.c).

2. By hexagon socket head cap screws (Allen screws) mounted from above. The winch needs to be dismant-

led. E.g. for cases where the boat is prepared with metal inserts in the deck construction. (See g. 3.2.3.j).

See chapter “Installation” for requested screw type and dimension.

S-winch handle R-winch handle

Art. No. 533-927-20 Art. No. 533-927-10

Fig. 1.4.a Fig. 1.4.b

Fig. 1.4.c

1.4.3 Winch handle

1.4.4 Technical data

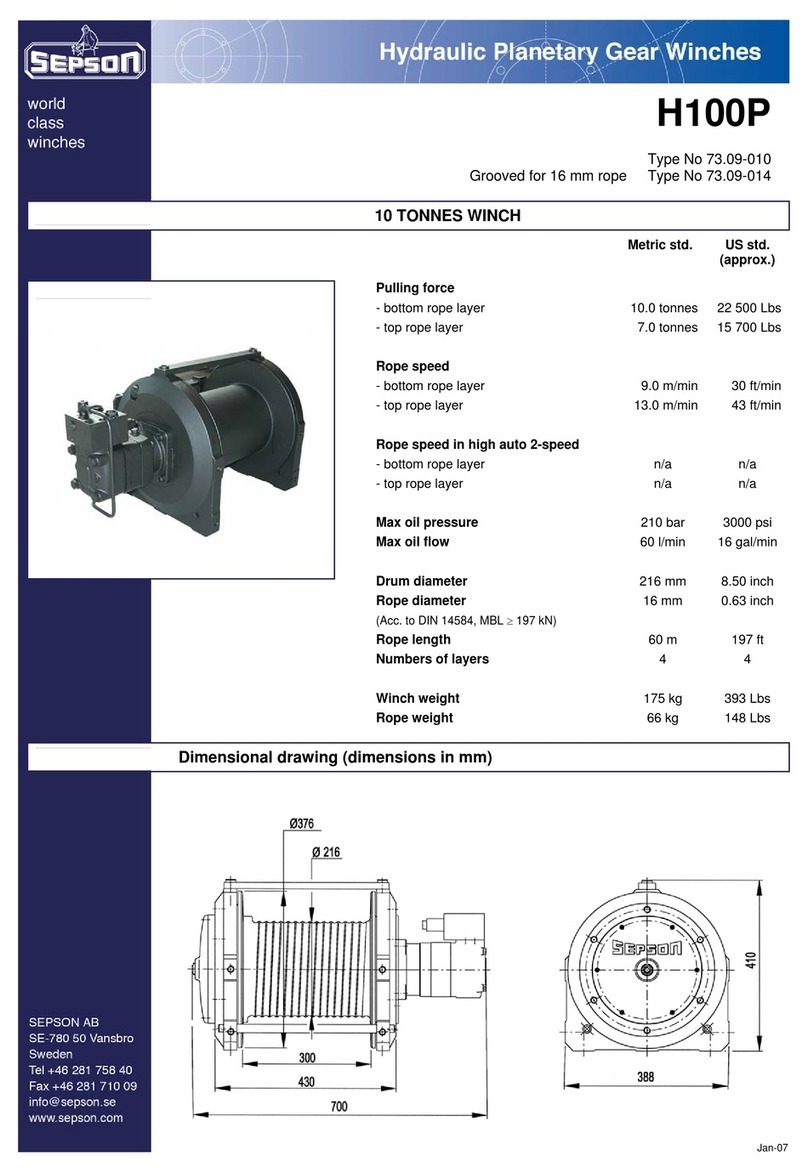

Winch

size

Art. No. Base dia

(Ø D mm)

Drum dia

(Ø d mm)

Height

(H mm)

Weight

(kg)

Line size

(mm)

Power ratio

High gear

Power ratio

Low gear

Maximum

working load

(MWL)

S30 472-630-10 Ø 150 Ø 85 185 3.2 8-12 10:1 30:1 900 kg

(1984 lb)

S40 472-640-10 Ø 150 Ø 85 185 3.2 8-12 10:1 40:1 900 kg

(1984 lb)

S48 472-648-10 Ø 188 Ø 108 222 5.1 10-14 10:1 48:1 1000 kg

(2204 lb)

S54 472-654-10 Ø 188 Ø 108 222 5.1 10-14 10:1 54:1 1300 kg

(2866 lb)

D

d

H

6

Winch handle

(Not included)

Lock-in switch

Top plate

Top cover

Self tailing arm

Base collar

Self tailing jaws

Winch handle socket

Locator bracket

Cog wheel

Lower roller bearing

Drum

Bushings Hub

Shaft

Washer

Twin Cog wheel

Base

1.4.5 Parts and descriptions

Fig. 1.4.d

7

2 Operation instructions

2.1 Winch handle

2.2 Winching

Seldén S-winches are manually operated and are a self-tailing type with two forward gears.

The purpose of the winch handle is to operate the winch. The S-winch handle (Art. No. 533-927-20) has no

reverse button and does not work with the reversible R-series. R-winch handle (Art. No. 533-927-10) with

release button does work with the S-winch series. See g. 1.4.a and 1.4.b.

Fast gear: Turn the winch handle clockwise.

Low gear: Turn the winch handle anticlockwise.

2. Lead the line over the self-tailing arm, into the self-tailing jaws for ¾ of a lap. The line remains in the self-

tailing jaws all the time during the winching operation.

3. Put the winch handle into the socket.

1. With the line, take 2-3 turns clockwise around the winch. The number of turns determines the grip and is

related to the line construction.

Fig. 2.a

Consider the risk of injury which is associated with winching! See chapter 1.3.

Due to the design of the self-tailing jaws it is also possible to pull the slack out of the sheet with the line sitting

in the self-tailing jaws and with the winch handle mounted. This means safer and quicker operation.

8

3 Installation

3.1 Installation preparations

1. The winch should be mounted on a at surface. If not, any uneven surface must be compensated with shims.

2. Make sure the installation area is strong enough for the chosen size of winch.

3. The winch should not be mounted on any part of deck that is laminated using sandwich construction, such

as foam, etc.

4. If the winch is to be mounted on a surface of steel, bronze or brass, the base must be insulated against

galvanic corrosion. This is best done using a plastic insulator (0.5-1 mm) or sealant which covers the entire

contact area between the base and the mounting surface.

Decide the orientation of the winch according to operation direction, with reference to the mostly used line and

the bulb on the winch base. See g. 3.1.1.a or the drilling template, enclosed in the winch package.

The line should enter the winch according to g. 3.1.2.a to prevent from override.

3.1.1 Winching orientation

3.1.2 Line routing

Fig. 3.1.1.a

Fig. 3.1.2.a

Line entry position on Drum

for optimal performance

5-10º

9

3.2 Installation instructions

The winch has two systems for installation:

1. Hexagon headed bolts which slides into a groove

in the winch base and where the hexagon heads

are locked against rotation due to the winch base

structure. No need to dismantle the winch. To

be used with washers and nuts below deck.See

chapter 3.2.1.

2. Hexagon socket head cap screw (Allen screws),

mounted from above. The winch needs to be

partly dismantled. E.g for cases where boats are

prepared with metal inserts in the deck con-

struction. See chapter 3.2.2.

1. Cut the enclosed drill template to match the winches outline.

2. Place the template on deck at the desired position according to chapter 3.1.1 ”Winching orientation”

3. Drill the holes through deck using a drill according to the table below. We recommend predrilling with a

smaller drill for better accuracy.

3.2.1 Installation with hexagon headed bolts (sliding bolt system)

Winch Screw/Thread Drill for through

deck fastening

Drilling

template

S30 M6 Ø 7 mm 597-226-E

S40

S48 M8 Ø 9 mm 597-227-E

S54

Winch Hexagon headed

bolts

Hexagon socket

head cap screws

Cheese headed

screws

W Dmax

S30 10 mm 10 mm Cheese headed

screws are

generally to large

in diameter to t.

S40

S48 13 mm 13 mm

S54

Fig. 3.2.1.a

Fig. 3.2.1.b

Countersunk recess

4. Cut the enclosed drill template to match the winches outline.

5. Place the template on deck at the desired position according to chapter 3.1.1 ”Winching orientation.

6. Drill the holes through deck using a drill according to table the table below. We recommend predrilling with

a smaller drill for better accuracy.

D

W

10

3.2.2 Adjustment of the self-tailing arm

Fig. 3.2.1.c

Fig. 3.2.2.a

The direction of the Self-tailing arm may be adjusted. Preferably it should be mounted so that the line feeds into

the cockpit when using the winch.

Tools needed: Hexagon key 5 (M6).

1. Remove the cap screw (1), the top plate and the top cover.

7. Slide on an L-shaped washer onto each bolt according to g 3.2.1.b.

8. Mount the screw by sliding the hexagon head and the L-shaped washer into the base and apply sealant into

the U-recess and around the screw. Apply enough sealant to ll the entire cavity under the L-washer and the

countersunk recess at the holes in the deck.

9. Install the winch with the bolts into the deck simultaneously. Mount the washers and nuts below deck and

tighten opposite nuts from below, according to g. 3.2.1.c (bottom, right).

Crosswise tightening

1

11

2. Push the Self tailing arm upwards while the opposite side of

the ring is lifted out of its position.

3. Turn it to the desired position.

4. Reassemble the parts in reverse order.

Fig. 3.2.2.b

Fig. 3.2.3.a

3.2.3 Installation with Hexagon socket head cap screw (Allen screws) with

cylindric head (None sliding bolt installation)

If the winch should be tted with Hexagon socket head cap screw (Allen screws), the winch must be partly

disassembled. This method of installation has to be used for threading into the deck, e.g. if the boat has purpose

made metal plates laminated into the deck structure or if non-hexagon headed through deck screws are used

with washer and nuts.

Tools needed for winch dismantling:

S30 & S40: Hexagon key 5 (M6), Hexagon key 6 (M8)

S48 & S54: Hexagon key 6 (M8), Hexagon key 8 (M10)

1. Remove the cap screw (1) on the top of the winch and remove the top plate and the top cover.

1

12

Fig. 3.2.3.b

Fig. 3.2.3.c

2. Push the Self tailing arm upwards while the opposite side of the ring is lifted. Remove it.

3. Loosen the three screws which have now become visible. Remove the locator bracket (2).

2

13

4. Lift the drum/self tailing jaws (3) together straight up. Make sure the composite hub remains on the base.

5. Loosen the clip (5) (x3) carefully from the base while lifting the base collar (4) and remove it.

Fig. 3.2.3.d

Fig. 3.2.3.e

4

5

3

14

6. Mark the fastening holes using the winch base as a template or use the enclosed paper drilling template.

If the winch base is used as a template, use a smaller drill bit to mark the location of the hole.

If the paper drilling template is used, pre-drilling with a smaller drill (Ø 3-4 mm) is recommended for better

accuracy.

7. Drill either for through deck fastening or for threading in metal inserts.

8. Make a countersunk recess at the top of the holes. Along with the sealant, this recess will create aid sealing

around the bolt.

10. Reassemble the winch in reverse order of dismantling. Mount the self tailing arm so it guides the line into

the cockpit or preferred direction.

9.

Through deck fastening:

Slide an L-shaped washer onto each screw according to

g. 3.2.3.i. Mount the screws into the base and apply sealant

into the U-recess and around the screw. Apply enough sealant

to ll the countersunk recess at the hole in the deck.

Install the base and screws, in the deck simultaneously.

Mount the washer and nuts below deck. Hold the head of the

screw without turning it while the nuts are tightened opposite

nuts from below, according to g. 3.2.3.k.

Fastening by threading:

Apply sealant into the countersunk recess at the top of the

holes in deck. Make sure to get a full measure of sealant.

Position the winch over the holes. Slide on an L-shaped

washer on each screw according to g. 3.2.3.i. and t.

Tighten opposite screws is recommended, according to

g. 3.2.3.k.

Winch Screw/Thread Suitable size

for marking

Drill for through

deck fastening

Drill for thread in

metal inserts

Drilling

template

S30 M6 Ø 6 mm Ø 7 mm Ø 4.9 mm 597-226-E

S40 Tap M6

S48 M8 Ø 8 mm Ø 9 mm Ø 6.5 mm 597-227-E

S54 Tap M8

Fig. 3.2.3.g

Fig. 3.2.3.i

Fig. 3.2.3.h

Fig. 3.2.3.j

Fig. 3.2.3.k

Countersunk recess

Countersunk recess

15

Fig. 4.1.a

4 Dismantling and maintenance

4.1 Dismantling for normal service

To obtain full function and performance of the winch it is important that these maintenance instructions are

followed carefully. Grease should be applied ONLY at these places where stated.

During dismantling, check wear and condition of all parts. Replace if necessary.

Tools needed:

S30 & S40: Hexagon key 5 (M6), Hexagon key 6 (M8)

S48 & S54: Hexagon key 6 (M8), Hexagon key 8 (M10)

1. Remove the cap screw (1) and remove the top plate and the top cover.

Fig. 4.1.b

2. Push the Self tailing arm upwards while the opposite side of the ring is lifted. Remove it.

1

16

Fig. 4.1.c

3. Loosen the three screws which now has become visible. Remove the locator bracket (2).

4. Lift the drum/self tailing jaws (3) together straight up. Make sure the composite hub remains on the base.

Fig. 4.1.d

2

3

17

5. Loosen the clip (5) (x3) carefully from the base while lifting the base collar (4) and remove it.

6. Remove the lower roller bearing (6) and the washer (7).

7. Perform service according to chapter 4.3 “Service Instructions”.

8. Reassemble the winch in reverse order of dismantling. Mount the self tailing arm so it guides the line into

the cockpit or preferred direction.

Fig. 4.1.e

Fig. 4.1.f

6

7

54

18

4.2 Dismantling for extended service

Continuation of the dismantling according to chapter 4.1 “Dismantling for normal service”, steps 1-6.

Keep careful track of the order in which the parts are dismantled.

Reassemble sub-assemblies directly after checking and cleaning if possible.

Handle all parts carefully. Place the disassembled parts on soft cloths or similar.

Tools needed:

Small-medium sized at screwdriver

Needle nose pliers

Hexagon key 5 (M6)

Fig. 4.2.a

Fig. 4.2.b Fig. 4.2.c

Fig. 4.2.eFig. 4.2.d

3. Pull off the ratchet wheel and check functionality of the pawls (12). Dismantle the pawls and pawl springs if

necessary. Worn pawls and springs should be replaced.

2. Remove the washer (10). Note how this washer and ratchet wheel (11) are mounted. The washer has an

asymmetrical rear and t only to the ratchet wheel if this is tted in the correct direction.

1. Remove the shaft (8) and the twin cog wheel (9).

8

9

11

10

12

19

Fig. 4.2.f

Fig. 4.2.g

Fig. 4.2.h

4. Lift out the winch handle socket (13) together with its bushings (14).

5. Remove the hub (16) from the base.

6. Remove the drive shaft (17) from the base by lifting it straight up.

13

14

17

16

20

7. Remove the circlip (18) and the washer (19) from the drive shaft.

8. To dismantle the pawls and pawl springs remove the gear wheel (20).

9. Check functionality of the pawls. Dismantle the pawls and pawl springs if necessary. Clean the parts to

ensure full function. Worn pawls and springs should be replaced.

10. Reassemble the winch in reverse order of dismantling. Adjust the self tailing arm so it guides the line into

the cockpit or preferred direction.

Fig. 4.2.i

Fig. 4.2.j

Fig. 4.2.k Fig. 4.2.l

18

19

20

Other manuals for S30

3

This manual suits for next models

3

Table of contents

Other Selden Winch manuals

Popular Winch manuals by other brands

Gude

Gude GGHW 540/8 Translation of the original instructions

Wahlberg

Wahlberg 239.701 user manual

Laubjerg vinsch

Laubjerg vinsch LV-O4500 Series Assembly & operating instructions

Runva

Runva T-2000 Assembly & operating instructions

Superwinch

Superwinch PRO Series owner's manual

TALBOT Industrie

TALBOT Industrie Goliath TS Series Use and maintenance