Selden S30 User manual

597-285-E

2019-01-23

Manual

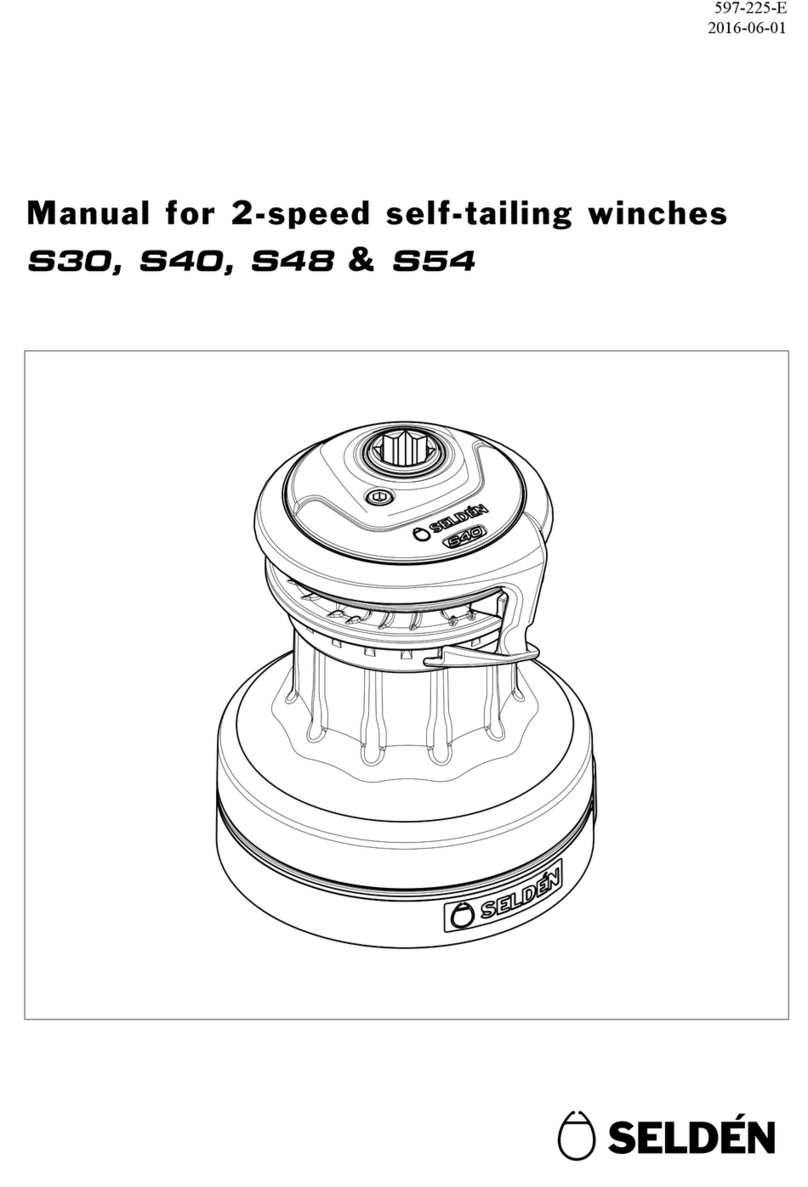

2-speed self-tailing winches

S30, S40, S48, S54

2

Contents

1 Introduction………………………………………………………………………….................. 3

2 Self-tailing winch……………………………………………………………............................ 5

2.1 Included parts………………………………………………………………………....... 6

2.2 Optional parts …………………………………………………………………….......... 6

2.3 Technicalspecication……………………………………………………………....... 7

3 Installation…………………………………………………………………………………......... 9

3.1 Installation preparation…………………………………………………………….......10

3.2 Deck installation……………………………………………………………………....... 12

3.3 Final adjustments………………………………………………………………….........15

4 Operation……………………………………………………………………………….…......... 16

5 Service and maintenance……………………………………………………………….........19

5.1 Frequent maintenance……………………………………………………………....... 19

5.2 Normal maintenance…………………………………………………………….......... 19

5.3 Extended Maintenance……………………………………………………………...... 21

6 Spare parts…………………………………………………………………………………...... 25

7 Warranty……………………………………………………………………………………....... 26

3

1. Introduction

Congratulations on the purchase of your new Seldén S-Winch.

This manual covers installation and operating instructions for S-winch model S30, S40, S48, S54.

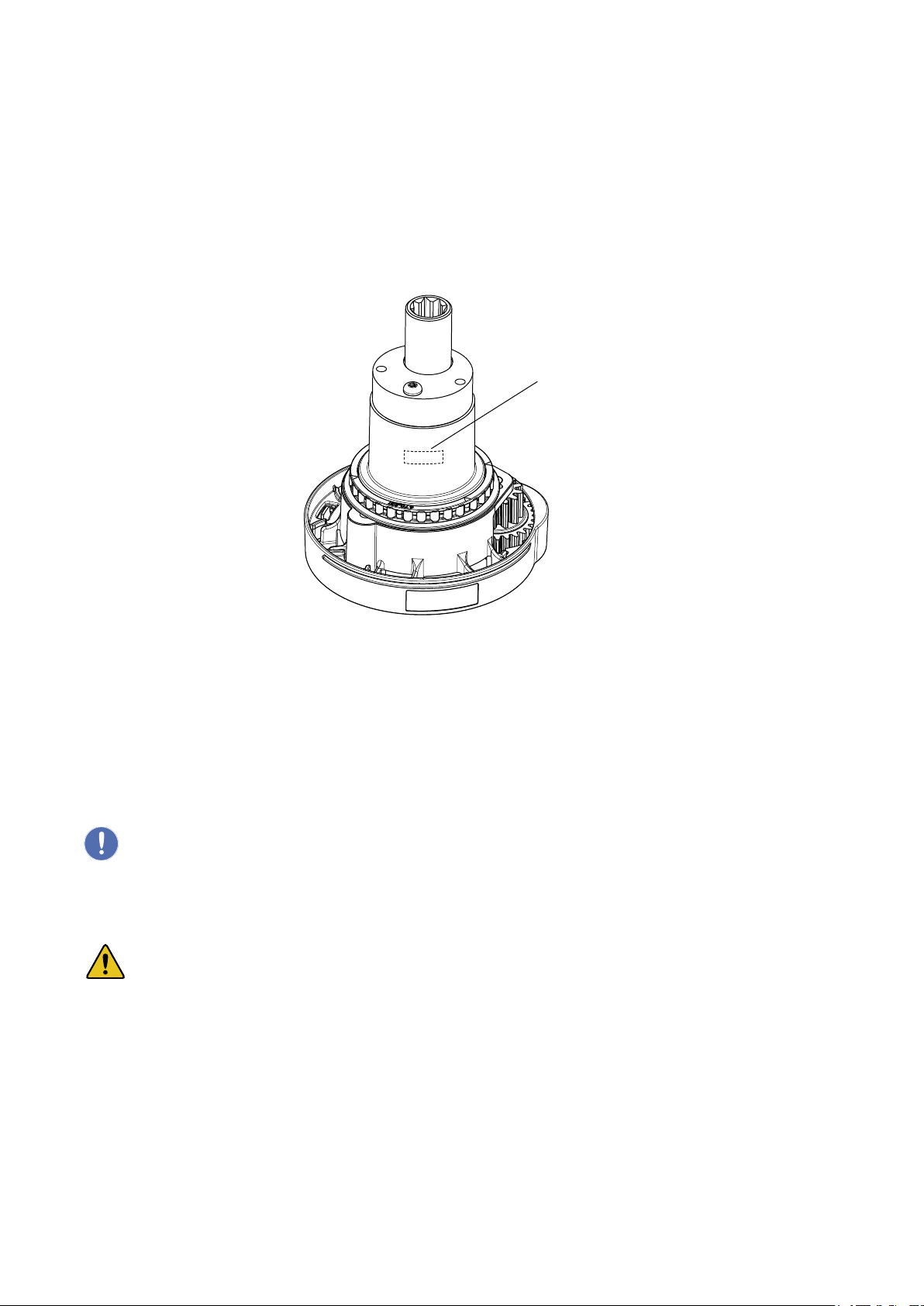

The model designation is found on the top of the winch. The serial number is found on the winch base,

as shown below, and on the delivery box.

Please read the entire manual before installation and use of the product. The manual shall be kept for

future reference.

Safety Precautions

Follow and pay careful attention to instructions with the following symbols:

ATTENTION

This symbol indicates a critical moment in the assembly or technical advice.

WARNING

This symbol indicates a potentially hazardous situation. If not avoided, this could result in serious personal

injury or damage to property.

Serial number

placed here.

4

Choosing the correct version of S-winch for your boat:

The key to a safe and properly working installation is correct dimensioning in relation to the boat size the

productsshallbeusedon.Seldénprovidesdimensioningguidelinesincatalogues,leaetsandonthe

website. If there are any questions about selecting the right product, please consult an authorized Seldén

dealer. All dealers are listed at www.seldenmast.com and divided in categories describing their competence.

The Seldén winch is designed for line handling on sailboats only!

Exceeding the stated maximum working load may lead to winch failure and serious injuries.

Keephands,ngers,hairandclothingawayfrommovingpartswhilewinchisinuse.Itis

recommended to let only one person work with the winch at any one time.

5

2 Self-tailing winch

The Seldén winches are manually operated and of self-tailing type with two available speeds. The ribs of the

drum provide an extraordinary grip. As a result, fewer coils of the line are required, reducing the risk of an

override and allowing the line to be released quickly. An optimized choice of materials makes for low weight

and high performance. The unique design of the self-tailer enables the trimmer to pull the slack out of the

sheet with the line sitting in the self-tailer and with the winch handle mounted.

Pull the slack with

the sheet in the

self-tailing jaws

Two-speed operation

Ribbed Drum

Light weight

6

2.1 Included parts

2.2 Optional parts

S30 S40 S48 S54

472-630-02

S30 winch

472-640-02

S40 winch

472-648-02

S48 winch

472-654-02

S54 winch

164-088-01

Plastic

RBSwasher

(5pc)

Stainless

steel RBSwasher

(5pc)

164-088-01

Plastic

RBSwasher

(5pc)

Stainless

steel RBSwasher

(5pc)

164-089-01

Plastic

RBSwasher

(5pc)

Stainless

steel RBSwasher

(5pc)

164-089-01

Plastic

RBSwasher

(5pc)

Stainless

steel RBSwasher

(5pc)

597-226-E

Drilling

template

597-226-E

Drilling

template

597-227-E

Drilling

template

597-227-E

Drilling

template

597-285 -E

Manual

597-285 -E

Manual

597-285 -E

Manual

597-285 -E

Manual

597-28 5-E

2019-01-16

Manual

2-speed self-tailing winches

S30, S40, S48, S54

597-227-E

2016-03-14

Drilling template Winch S48/S54

For mounting with through bolt:

Drilling diameter = Ø9 mm

Rope entry position on Drum

for optimal performance

Ø189 mm

104 mm

Part

312-501

Seldén lubrication grease

533-927-20

Winch handle

7

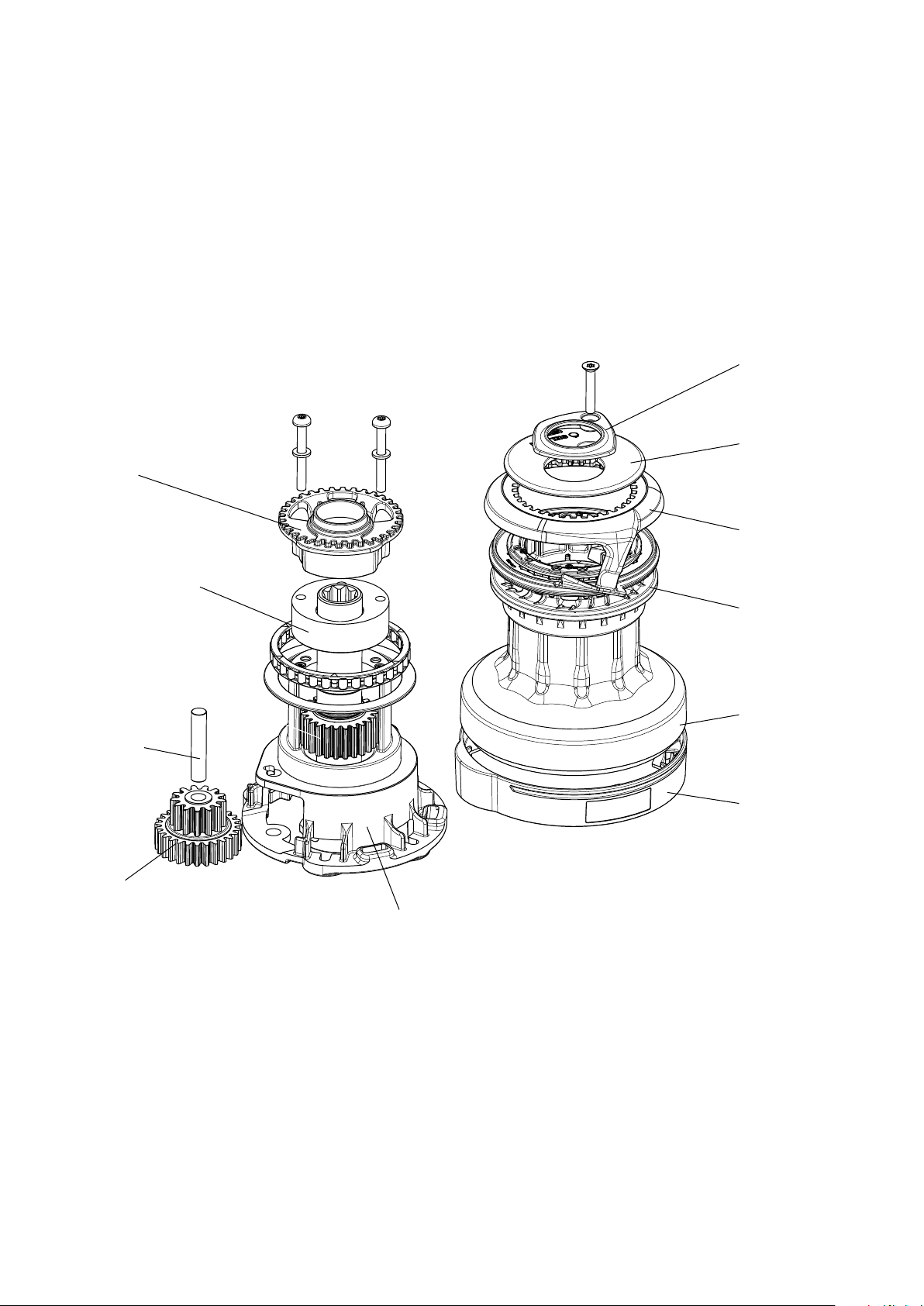

2.3 Technical specification

Parts and nomenclature

In the schematic below, the names of parts referred to in this manual can be viewed.

Top cover wear

protection

Top Cover

Self-tailing

arm

Self-tailing

jaws

Drum

Base cover

Locator

bracket

Bearing cylinder

Drive shaft

Twin gear

axle

Twin gear

ratchet

Winch

base

8

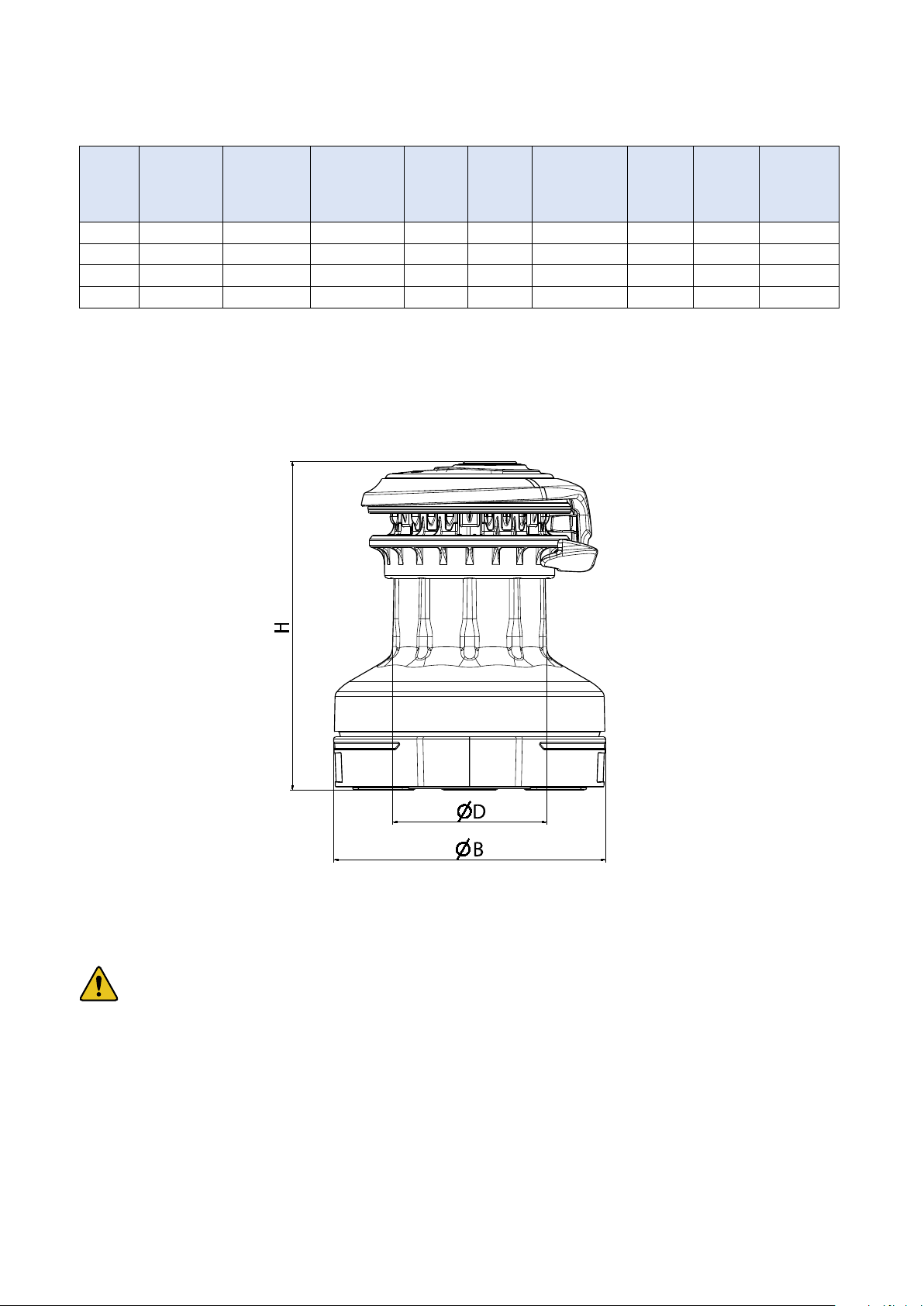

Model Item. No. Base

diameter

(ØB)

[mm]

Drum

diameter

(ØD)

[mm]

Height

(H)

[mm]

Weight

[kg]

Suitable

Line

dimensions

[mm]

Gear

ratio

HIGH

GEAR

Gear

ratio

LOW

GEAR

Safe

Working

Load

(SWL) [kN]

S30 472- 630-10 150 85 183,5 3,5 8-12 10:1 30:1 8,4

S40 472- 640-10 150 85 183,5 3,5 8-12 10:1 40:1 11,2

S48 472- 648-10 188 108 218 5,6 10-14 10:1 48:1 13,4

S54 472-654-10 188 108 218 5,6 10-14 10:1 54:1 15,1

Dimensions and technical data

Exceeding the stated safe working load may lead to winch failure and/or fatal injuries.

9

3 Installation

Installation of a Seldén Winch must be carried out by a competent installer who has read and

understood this installation manual, the purpose and function of the winch and has checked the

loads, winch sizing and mounting requirements prior to installation.

Winch orientation, position relative to associated components and location regarding deck reinforcement

and suitability must be checked and any reinforcement work carried out prior to installation. The installer

takes full responsibility to ensure these checks have been undertaken. This may require the assistance of

aboatyardorcertiedmarineengineers.

Seldén Mast does not provide fasteners. The installer is responsible for the sourcing and specifying load

capacity of the fasteners, ensuring they are rated for the expected loads from the winch. Any fastener

should be made from marine grade stainless steel.

SeldénMastABdoesnottakeresponsibilityfortheincorrectinstallationofawinch,theinsucientrein-

forcementofthedeckatthelocationofthewinch,wateringressduetoinsucientsealingoranydamage

to interior as a result of water ingress.

10

3.1 Installation preparation

Priortoinstallation,ndasuitablemountingpointforthewinch.Whenchoosingamountingpoint,

consider previous and following requirements.

Orienting the winch

For optimum performance during use, the winch must be oriented correctly for the intended application.

If the winch is to be used for handling of multiple lines, e.g. placed on the coach roof for use as a halyard

winch in combination with running spinnaker or gennaker sheets, the winch shall be oriented and optimized

for the highest load.

The line shall enter the drum tangential to the base cover protrusion. This is shown in the

gurebelow.

Failingtoalignthewinchinaccordancewiththegureabovemayleadtowinchfailure

which may lead to fatal injuries or damages to the boat or equipment.

Cover

protrusion

Cover

protrusion

To sail clew

To sail clew

11

Preventing override

To prevent override, the line must be guided onto the winch at an angle of approximately 5-10° to the

horizontalplane,asshowninthegurebelow:

To achieve the correct angle, installing a block or sheet lead to divert the sheet or halyard to the winch may

be necessary. Please visit www.seldenmast.com to browse our selection of suitable deck hardware.

Failingtoleadtheropeontothewinchatrecommendedangleasseeningureabovemay

lead to winch failure which may lead to fatal injuries or damages to the boat or equipment.

5-10°

12

3.2 Deck installation

Thewinchescaneitherbeinstalledwithscrewssecuredwithnutsbelowdeckorwithscrewstteddirectly

in the deck, provided that the hull is prepared with appropriate reinforcement plates.

Follow procedure A or B depending on your installation method:

A: Installation with screws and nuts below deck

B: Installation directly in the deck

Equipment

Material and equipment needed for installation:

1.

A/B:

Dismantle the winch according to chapter 5.2,

steps 1 and 2.

Installing winches directly into the deck is only possible on yachts equipped with aluminium- or

stainless-steel deck-inserts intended for mounting winches. If at any point there is uncertainty if

the yacht is equipped in this way, please abort the installation and seek assistance at the yard or

builder.

Material and equipment S30/40 S48/54 Quantity

Stainless steel and plastic

RBS-washers

164-088-01 164-089-01 1 pc

Installation and drilling template 597-226-E 597-227-E 1 pc

Fasteners of suitable length

and size

M6 M8 5pc

(not included)

Drill and drill bit Ø4mm

A: Ø7mm

B: Ø5mm

Ø4mm

A: Ø9mm

B: Ø6,8mm

(not included)

Thread tapping tool B: M6x1 B: M8x1,25 (not included)

Masking tape (not included)

Awl or center punch (not included)

Countersink (not included)

Marine sealing compound (not included)

Methylated spirits, cloth (not included)

B: Locking adhesive (not included)

13

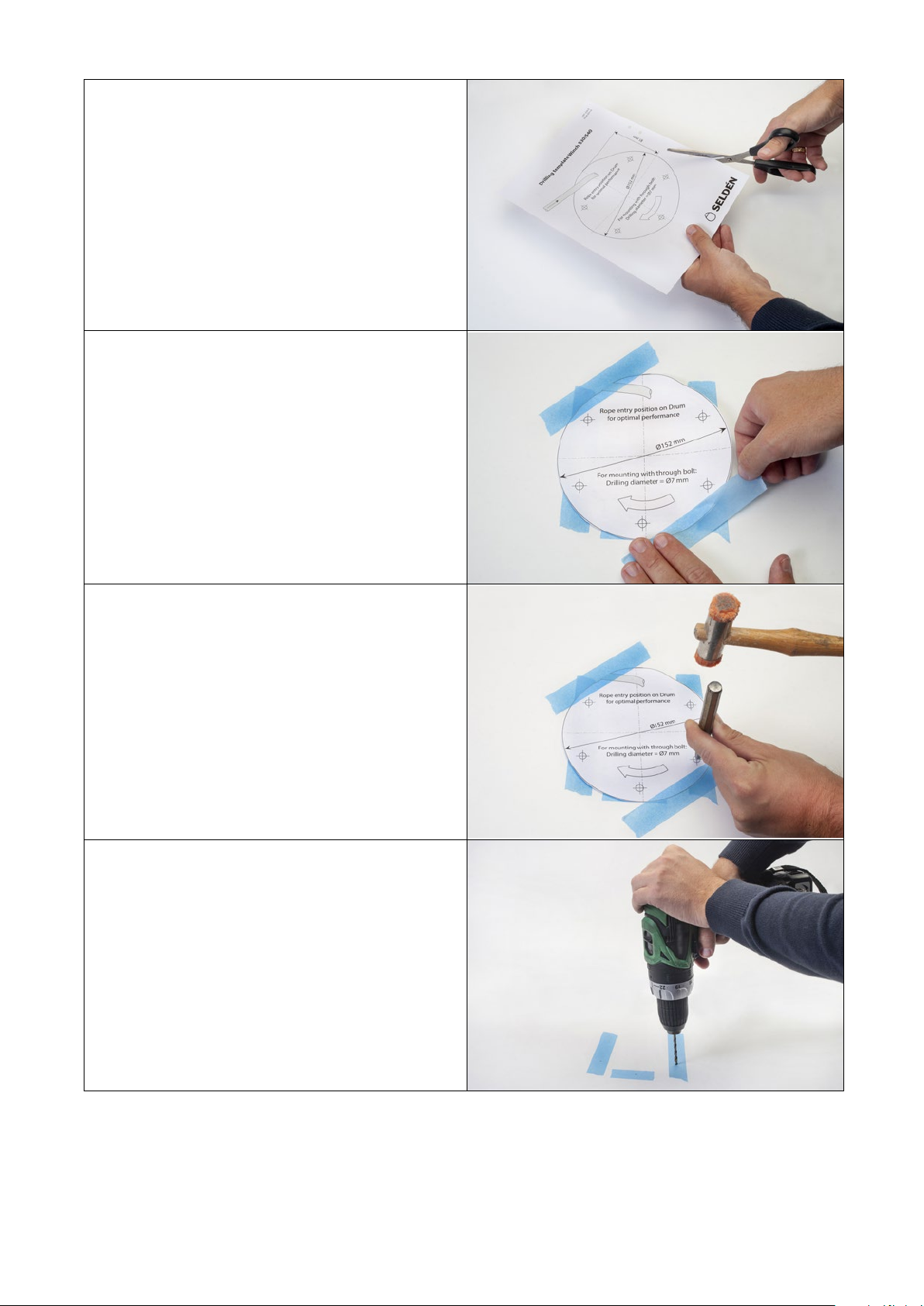

2.

A/B:

Cut out the drilling template provided in the

delivery box.

3.

A/B:

Test-tandalignthedrillingtemplatein

accordance with chapter 3.1 Orienting the

winch and attach it to the deck using

masking tape.

4.

A/B:

Mark all hole positions using an awl or

center-punch.

5.

A/B:

Remove the template and pre-drill a pilot

hole at each position using the 4mm drill bit.

14

6.

A:

Continuedrillingtheholestonalsize,

using the larger drill-bit.

Drill sizes:

S30/40: Ø7mm

S48/54: Ø9 mm

B:

Continue to drill the holes for the

recommended internal thread diameter.

Clean the hole followed by tapping to correct

thread size.

Drill and tap sizes:

S30/40: Ø5mm drill, M6X1 tap

S48/54: Ø6,8mm drill, M8X1,25 tap

7.

A/B:

Countersink each hole approximately 3 mm

to allow enough marine sealing compound

to be applied to stop water ingress.

8.

A/B:

Remove any masking tape and debris and

proceed to wipe the area down using

acetone or methylated spirits to remove

any grease.

9.

A/B:

Fill the countersunk hole with marine

sealing compound and mount the winch,

ensuring the winch is correctly aligned.

15

10.

A:

Fit screws, placing the included steel and

plastic RBS-washers between the winch

base and the screw head, with the plastic

washers closest to the winch base.

Tighten the winch down to the deck in a

crosswise pattern.

Recommended tightening torques

for screws are as follows:

M6 =7 Nm

M8=12 Nm

B:

Apply thread locking adhesive to screws

intended for mounting the winch.

Fit the screws, placing the included steel

and plastic washer between the winch base

and the screw head, with the plastic

washer closest to the winch base.

Tighten the winch down to the deck in a

crosswise pattern.

Recommended tightening torques

for screws are as follows:

M6=7 Nm

M8=12 Nm

Avoid mixing locking adhesive and

marine sealant as this may cause

either to fail.

3.3 Final adjustments

Whennishedwiththeinstallation,theself-tailing-arm(ST-arm)needstobeadjustedtoguidetheropeinthe

preferred direction. To adjust the position of the ST-arm, dismantle the winch according to step 1 in chapter

5 Maintenance and Service.TheST-armcanthenbettedfollowedby

reassembly of the winch.

It is recommended to guide the line into the cockpit.

16

1.

Apply 2-3 turns clockwise around the

winch. The number of turns suitable for

optimal performance is determined by

the wind conditions and the line type.

2.

Lead the line over the self-tailing arm and

into the self-tailing jaws for ¾ of a turn.

The line can remain in the self-tailing jaws

during the winching operation.

3.

Pull the slack of the line until tensioned.

4 Operation

Seldén S-winches are manually operated and are of self-tailing type with two available speeds.

Winching

17

4.

Insert the winch-handle into the socket by

twisting the lever on the handle to enable

insertion into the handle-socket.

When inserted, release the lever to secure

the handle in the socket.

5.

Operate the winch by turning the winch

handle in either clockwise of anticlockwise

direction.

High gear: Turn the winch handle

clockwise.

Low gear: Turn the winch handle

anticlockwise.

1.

While keeping tension in the pulling end of

the line, undo the line from the self-tailing

jaws. If needed, reduce the number of turns

on the drum to 2-3 turns.

Reducing the number of turns under

high loads may cause the line to slip

in an un-controlled manner, with the

potential risk of personal injury.

Release the line

Clockwise:

High gear

Anticlockwise:

Low gear

18

2.

Gently ease the tension in the pulling end to

induce slipping over the winch drum,

releasing the tension in the sheet.

Do this until the desired tension is obtained.

Lock the line by putting it into the self-tailing

jaws.

Keep body parts and clothing away

from the winch when releasing the line.

The Seldén winch is designed for line handling on sailboats only!

Keep body parts and clothing away from moving parts while the winch is in use.

It is recommended to let only one person work with the winch at any one time.

If a Seldén winch is used for going aloft, double halyards must be used, to be hauled in and

easedoatthesametime.(Seldénriggingmanual“Hints&Advice”,595-540-E,“Workingaloft”).

19

5.1 Frequent maintenance

To aid longevity and performance of the winch it is recommended to rinse the winch with fresh water

after sailing. This removes any build-up of salt and will ensure that the winch runs smoothly between

services.

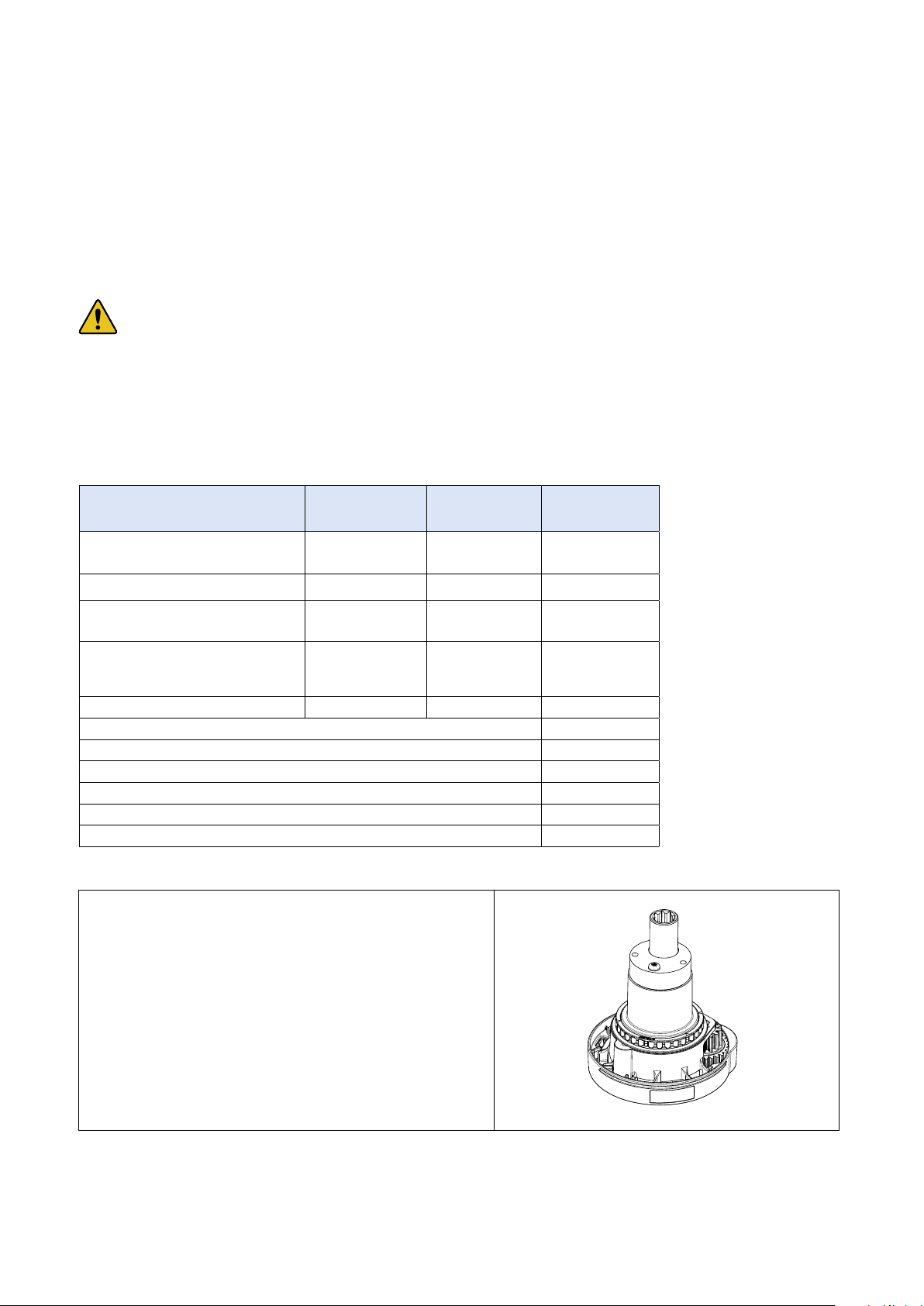

5.2 Normal maintenance

For heavy sailing or racing, a normal service is recommended before any major regatta or event. For the

regular sailor, a normal service can be performed once a year adding to the annual extended service.

5 Service and maintenance

Material and equipment

(not included) S30/40 S48/54 Quantity

Torx-key T30 T30, T45 1 pc

Seldén pawl oil 312-709-01 312-709-01 1 pc

Seldén lubricating grease 512-501 512-501 1 pc

Brush - - 1 pc

Cloth - - 1 pc

20

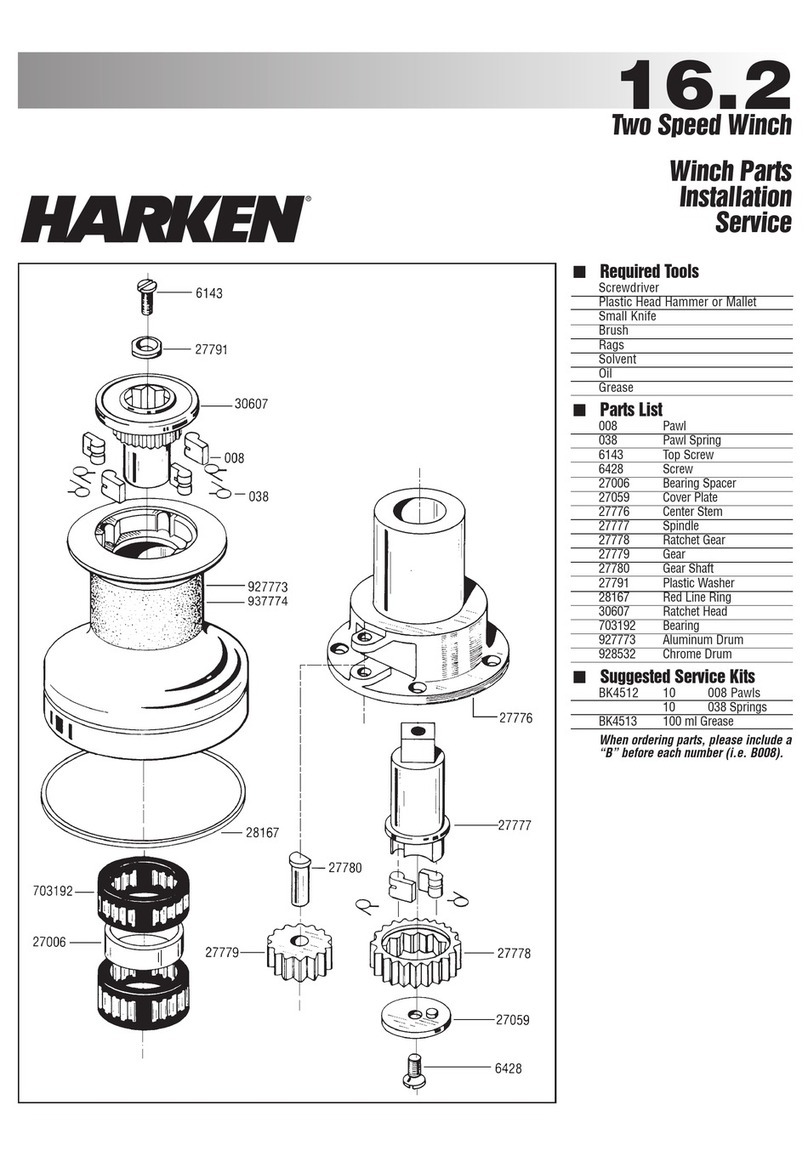

1.

Unscrewthetopscrew(1)usingtheTorx-key,

T30.Removethewearprotection(2),thetop

cover(3)andtheself-tailingarm(4).Besureto

keep track of any parts removed

2.

Continue to dismantle the winch by

unscrewing the two Torx-screws with the

Torx-key, T30 or T45.

Removethescrewsandwashers(5).

Follow this by removing the locator bracket

(6)andnallythedrumassembly(7).

3.

With the winch disassembled, apply Seldén

lubrication grease to all visible gears.

4.

Reassemble the winch in reverse order.

7

6

5

1

2

3

4

Dismantling

Recommended tightening torques for screws are as follows:

M6=7 Nm,

M8=12 Nm

Other manuals for S30

3

This manual suits for next models

7

Table of contents

Other Selden Winch manuals

Popular Winch manuals by other brands

Comeup

Comeup CWG-30075 quick start guide

Ingersoll-Rand

Ingersoll-Rand force5 GULF MAN-RIDER FA2A-GMR Parts, operation and maintenance manual

TRAVELLER

TRAVELLER 12000 user manual

Paccar Winch

Paccar Winch Braden BA2A Installation maintenance and service manual

Harken

Harken Powered Performa Installation and maintenance manual

Warrior Winches

Warrior Winches S9500HS Assembly & operating instructions