Semiconductor Components Industries NE592 User manual

©Semiconductor Components Industries, LLC, 2006

October, 2006 −Rev. 4

1Publication Order Number:

NE592/D

NE592

Video Amplifier

The NE592 is a monolithic, two-stage, differential output,

wideband video amplifier. It offers fixed gains of 100 and 400

without external components and adjustable gains from 400 to 0 with

one external resistor. The input stage has been designed so that with

the addition of a few external reactive elements between the gain

select terminals, the circuit can function as a high-pass, low-pass, or

band-pass filter. This feature makes the circuit ideal for use as a

video or pulse amplifier in communications, magnetic memories,

display, video recorder systems, and floppy disk head amplifiers.

Now available in an 8-pin version with fixed gain of 400 without

external components and adjustable gain from 400 to 0 with one

external resistor.

Features

•120 MHz Unity Gain Bandwidth

•Adjustable Gains from 0 to 400

•Adjustable Pass Band

•No Frequency Compensation Required

•Wave Shaping with Minimal External Components

•MIL-STD Processing Available

•Pb−Free Packages are Available

Applications

•Floppy Disk Head Amplifier

•Video Amplifier

•Pulse Amplifier in Communications

•Magnetic Memory

•Video Recorder Systems

http://onsemi.com

See detailed ordering and shipping information in the package

dimensions section on page 8 of this data sheet.

ORDERING INFORMATION

SOIC−8

D SUFFIX

CASE 751

PDIP−8

N SUFFIX

CASE 626

1

8

1

8

MARKING

DIAGRAMS

NE592N8

AWL

YYWWG

A = Assembly Location

L, WL = Wafer Lot

Y, YY = Year

W, WW = Work Week

Gor G = Pb−Free Package

http://onsemi.com

NE592

ALYW

G

1

1

SOIC−14

D SUFFIX

CASE 751A

1

PDIP−14

N SUFFIX

CASE 646

1

NE592D14G

AWLYWW

1

NE592N14

AWLYYWWG

1

14

14

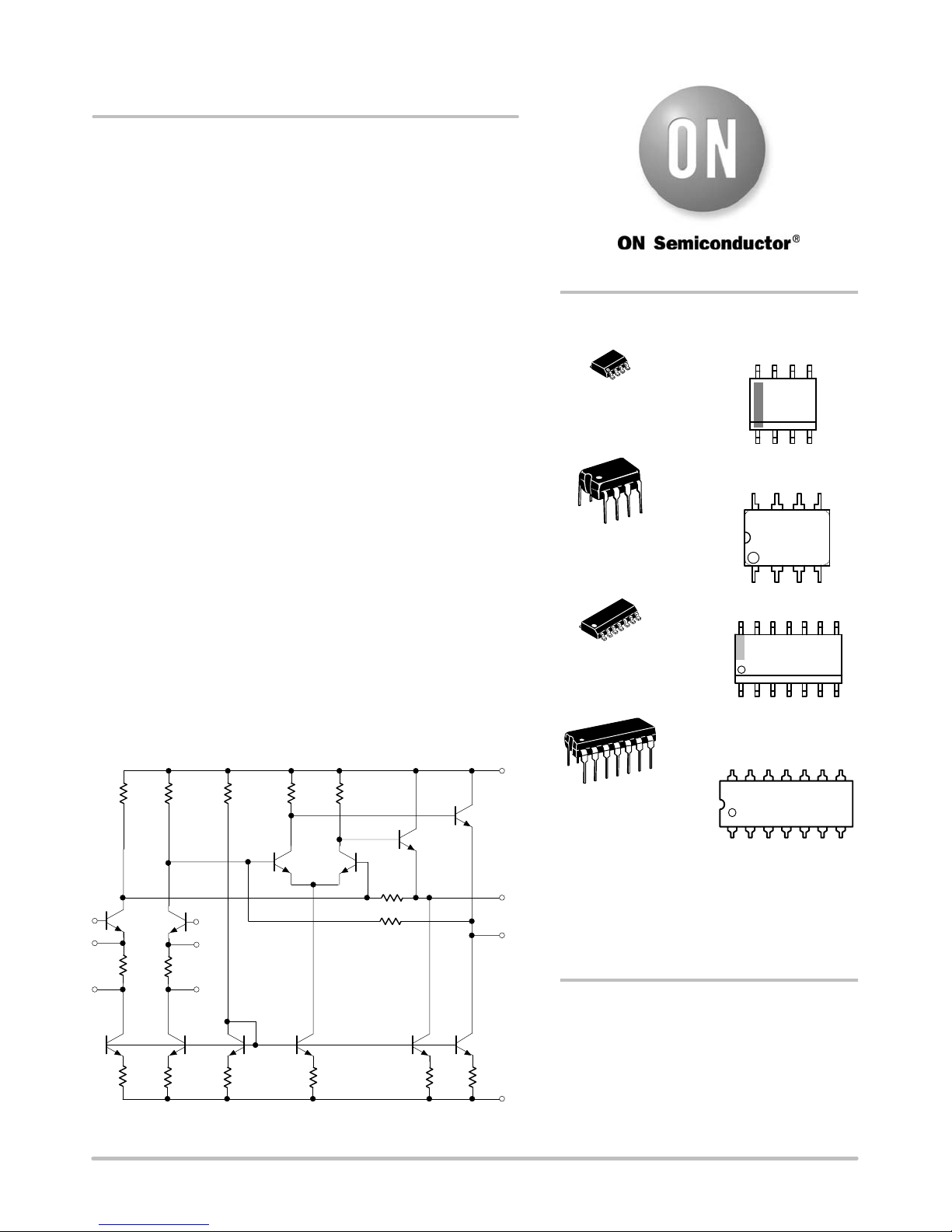

+V

Q6

OUTPUT 1

OUTPUT 2

R1 R2 R8 R10 R9

Q5

Q4 Q3

R11

R12

Q11

Q10

R13 R14R16R15R7BR7A

Q7B Q8 Q9

Q7A

G2A

G1A

INPUT 1 INPUT 2

R3 R5

G1B

G2B

Q1 Q2

-V

Figure 1. Block Diagram

NE592

http://onsemi.com

2

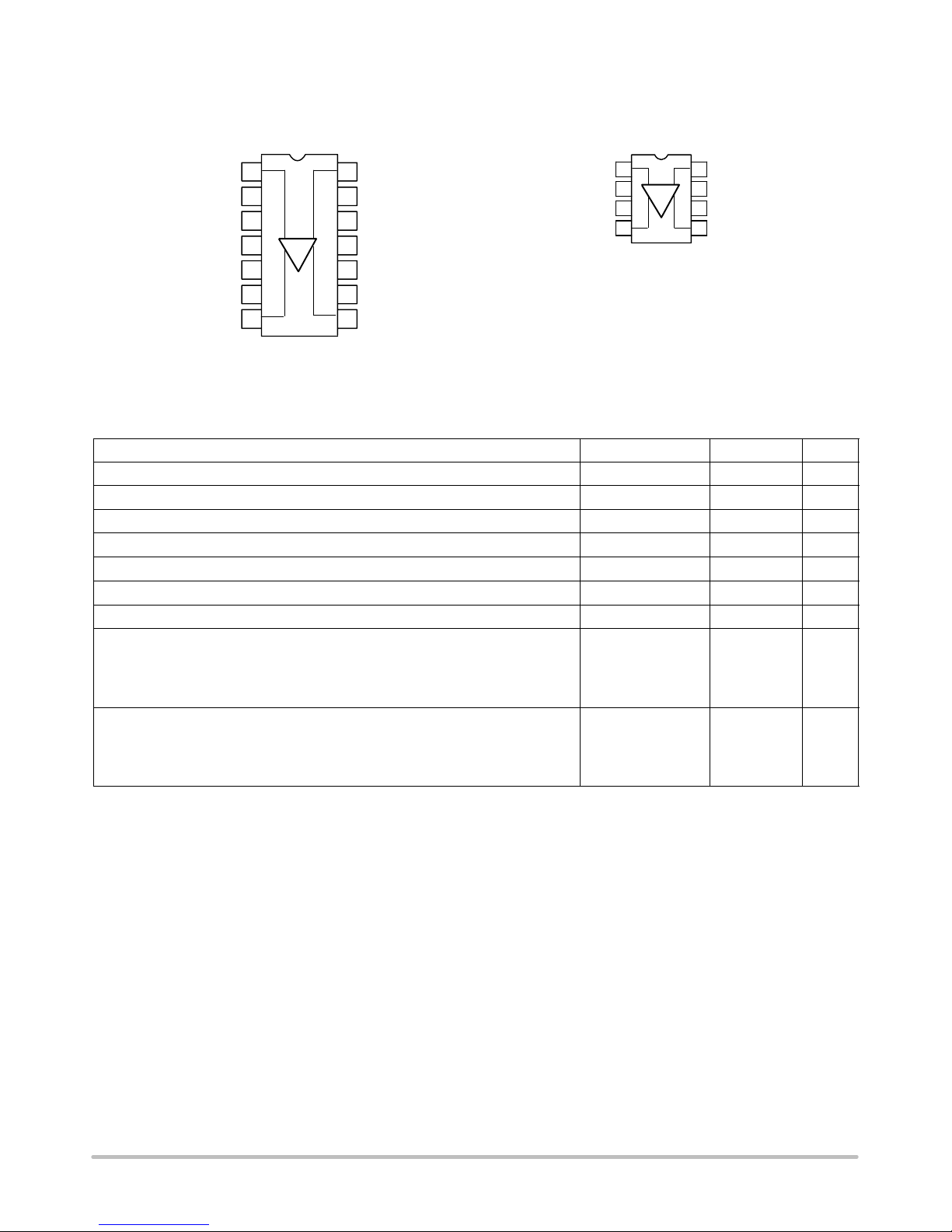

PIN CONNECTIONS

1

2

3

45

6

7

8

1

2

3

4

5

6

78

14

13

12

11

10

9

INPUT 1

NC

G2A GAIN SELECT

G1A GAIN SELECT

V+

NC

OUTPUT 1

INPUT 2

NC

G2B GAIN SELECT

G1B GAIN SELECT

V-

NC

OUTPUT 2

INPUT 2

V-

OUTPUT 2

INPUT 1

V+

OUTPUT 1

G1A GAIN SELECT

G1B GAIN SELECT

D, N Packages D, N Packages

(Top View)

(Top View)

MAXIMUM RATINGS (TA= +25°C, unless otherwise noted.)

Rating Symbol Value Unit

Supply Voltage VCC "8.0 V

Differential Input Voltage VIN "5.0 V

Common-Mode Input Voltage VCM "6.0 V

Output Current IOUT 10 mA

Operating Ambient Temperature Range TA0 to +70 °C

Operating Junction Temperature TJ150 °C

Storage Temperature Range TSTG 65 to +150 °C

Maximum Power Dissipation, TA= 25°C (Still Air) (Note 1)

D-14 Package

D-8 Package

N-14 Package

N-8 Package

PDMAX

0.98

0.79

1.44J1.17

W

Thermal Resistance, Junction−to−Ambient

D-14 Package

D-8 Package

N-14 Package

N-8 Package

RqJA 145

182

100

130

°C/W

Stresses exceeding Maximum Ratings may damage the device. Maximum Ratings are stress ratings only. Functional operation above the

Recommended Operating Conditions is not implied. Extended exposure to stresses above the Recommended Operating Conditions may affect

device reliability.

1. Derate above 25°C at the following rates:

D-14 package at 6.9 mW/°C

D-8 package at 5.5 mW/°C

N-14 package at 10 mW/°C

N-8 package at 7.7 mW/°C.

NE592

http://onsemi.com

3

DC ELECTRICAL CHARACTERISTICS (VSS = "6.0 V, VCM = 0, typicals at TA= +25°C, min and max at 0°C vTAv70°C, unless

otherwise noted. Recommended operating supply voltages VS= "6.0 V.)

Characteristic Test Conditions Symbol Min Typ Max Unit

Differential Voltage Gain

Gain 1 (Note 2)

Gain 2 (Notes 3 and 4)

RL= 2.0 kW, VOUT = 3.0 VP-P

AVOL 250

80

400

100

600

120

V/V

Input Resistance

Gain 1 (Note 2)

Gain 2 (Notes 3 and 4)

−

TA= 25°C

0°C vTAv70°C

RIN

−

10

8.0

4.0

30

−

−

−

−

kW

Input Capacitance Gain 2 (Note 4) CIN −2.0 −pF

Input Offset Current TA= 25°C

0°C vTAv70°C

IOS −

−

0.4

−

5.0

6.0

mA

Input Bias Current TA= 25°C

0°C vTAv70°C

IBIAS −

−

9.0

−

30

40

mA

Input Noise Voltage BW 1.0 kHz to 10 MHz VNOISE −12 −mVRMS

Input Voltage Range −VIN "1.0 − − V

Common-Mode Rejection Ratio

Gain 2 (Note 4)

VCM "1.0 V, f < 100 kHz, TA= 25°C

VCM "1.0 V, f < 100 kHz,

0°C vTAv70°C

VCM "1.0 V, f < 5.0 MHz

CMRR 60

50

−

86

−

60

−

−

−

dB

Supply Voltage Rejection Ratio

Gain 2 (Note 4)

DVS= "0.5 V PSRR 50 70 −dB

Output Offset Voltage

Gain 1

Gain 2 (Note 4)

Gain 3 (Note 5)

Gain 3 (Note 5)

RL= R

RL= R

RL= R, TA= 25°C

RL= R, 0°C vTAv70°C

VOS

−

−

−

−

−

−

0.35

−

1.5

1.5

0.75

1.0

V

Output Common-Mode Voltage RL= R, TA= 25°C VCM 2.4 2.9 3.4 V

Output Voltage Swing Differential RL= 2.0 kW, TA= 25°C

RL= 2.0 kW, 0°C vTAv70°C

VOUT 3.0

2.8

4.0

−

−

−

V

Output Resistance −ROUT −20 −W

Power Supply Current RL= R, TA= 25°C

RL= R, 0°C vTAv70°C

ICC −

−

18

−

24

27

mA

AC ELECTRICAL CHARACTERISTICS (TA= +25°CVSS = "6.0 V, VCM = 0, unless otherwise noted. Recommended operating

supply voltages VS= "6.0 V.)

Characteristic Test Conditions Symbol Min Typ Max Unit

Bandwidth

Gain 1 (Note 2)

Gain 2 (Notes 3 and 4)

−BW

−

−

40

90

−

−

MHz

Rise Time

Gain 1 (Note 2)

Gain 2 (Notes 3 and 4)

VOUT = 1.0 VP−P

tR

−

−

10.5

4.5

12

−

ns

Propagation Delay

Gain 1 (Note 2)

Gain 2 (Notes 3 and 4)

VOUT = 1.0 VP−P

tPD

−

−

7.5

6.0

10

−

ns

2. Gain select Pins G1A and G1B connected together.

3. Gain select Pins G2A and G2B connected together.

4. Applies to 14-pin version only.

5. All gain select pins open.

NE592

http://onsemi.com

4

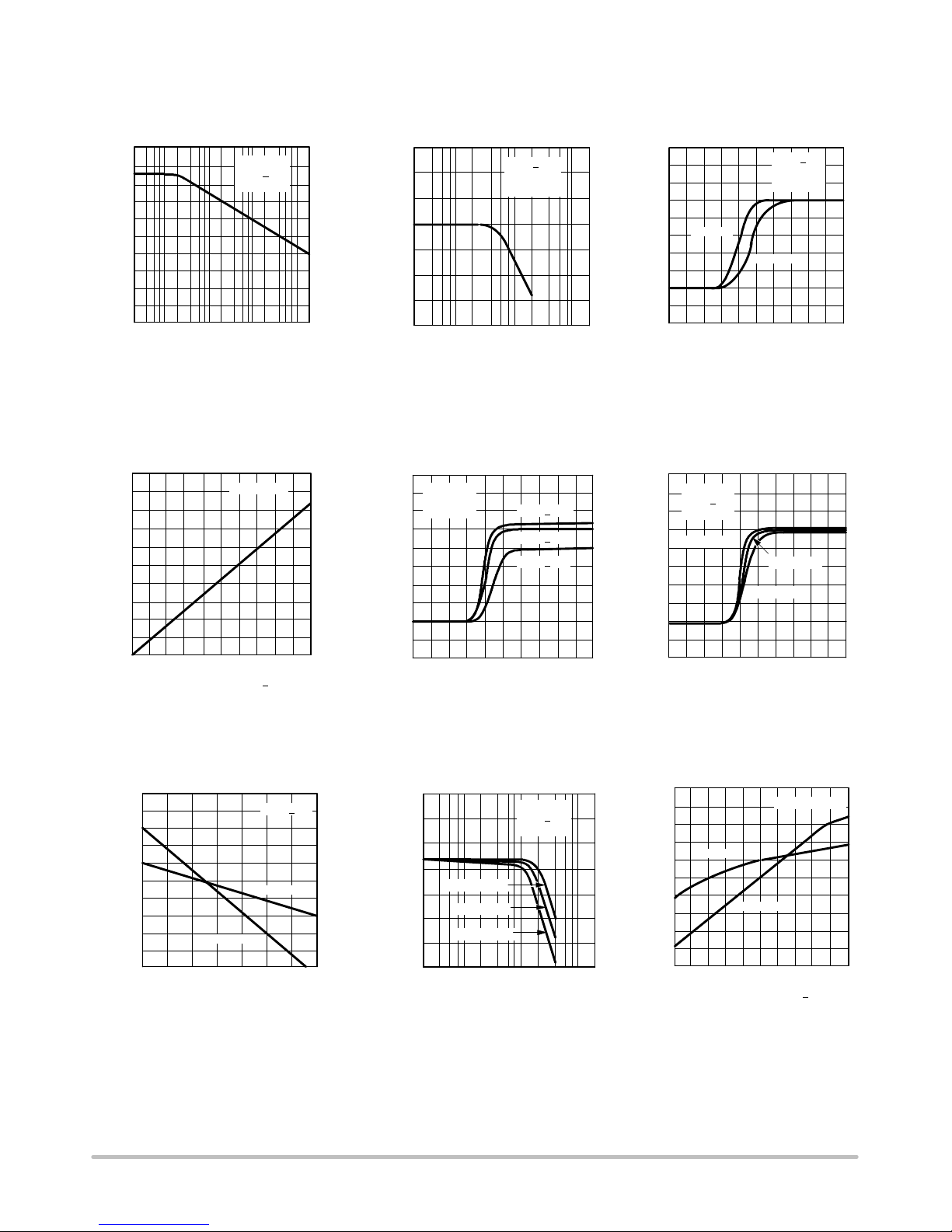

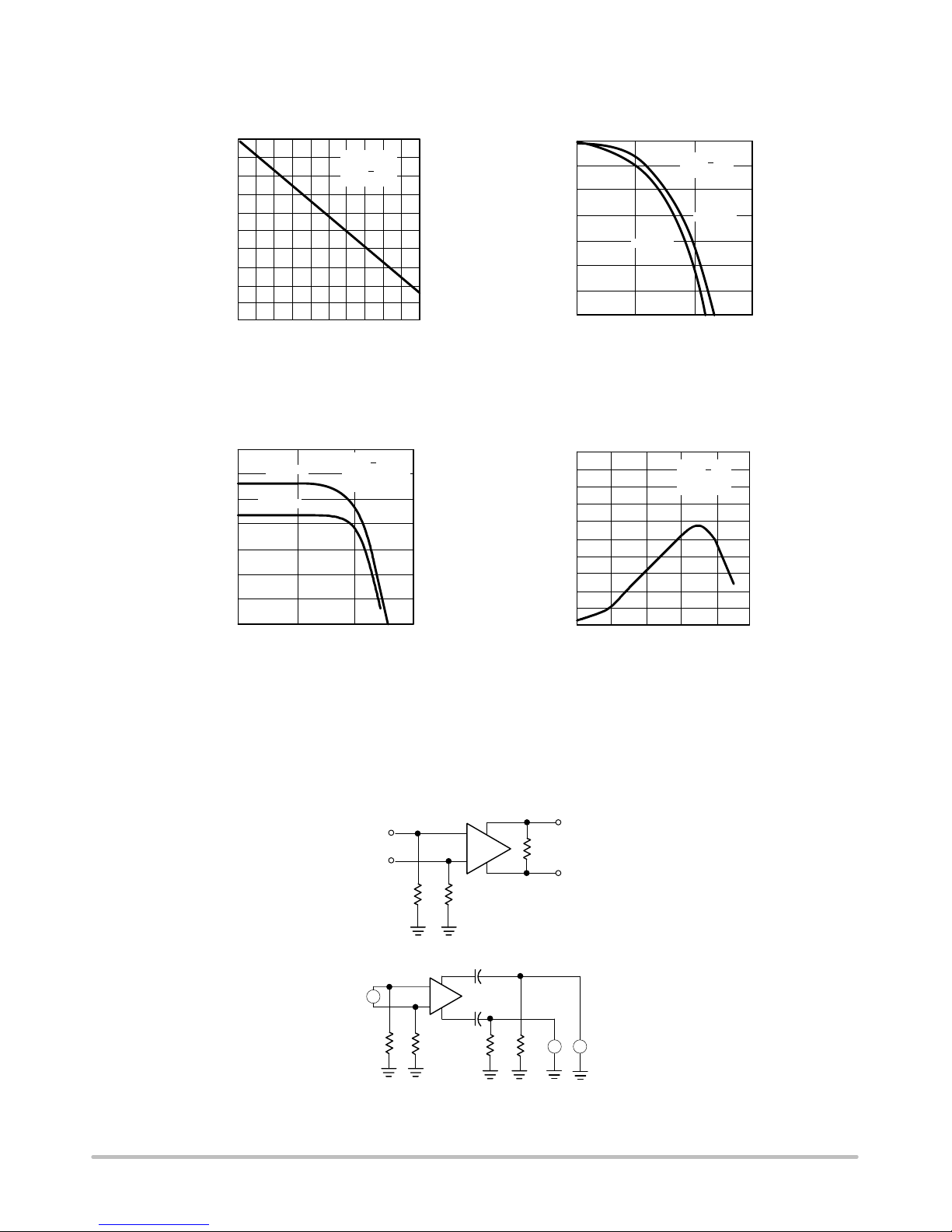

TYPICAL PERFORMANCE CHARACTERISTICS

COMMON-MODE REJECTION RATIO −dB

100

90

80

70

60

50

40

30

20

10

0

10k 100k 1M 10M 100M

FREQUENCY −Hz

GAIN 2

VS= +6V

TA= 25oC

OUTPUT VOLTAGE SWING −Vpp

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

1 5 10 50 100 500 1000

FREQUENCY −MHz

VS= +6V

TA= 25oC

RL= 1kW

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-15 -10 -5 0 5 10 15 20 25 30 35

TIME −ns

VS= +6V

TA= 25oC

RL= 1k

GAIN 2

GAIN 1

Figure 2. Common−Mode

Rejection Ratio as a Function

of Frequency

Figure 3. Output Voltage Swing

as a Function of Frequency

Figure 4. Pulse Response

SUPPLY CURRENT −mA

28

24

20

16

12

8

34 5678

SUPPLY VOLTAGE −+V

TA= 25oC

OUTPUT VOLTAGE −V

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-15 -10 -5 0 5 10 15 20 25 30 35

TIME −ns

GAIN 2

TA= 25oC

RL= 1kWVS= +8V

VS= +3V

VS= +6V

TA= 70oC

Tamb = 0oC

OUTPUT VOLTAGE −V

1.6

1.4

1.2

1.0

0.8

0.6

0.4

0.2

0

-0.2

-0.4

-15 -10 -5 0 5 10 15 20 25 30 35

TIME −ns

GAIN 2

VS= +6V

RL= 1kW

TA= 25oC

Figure 5. Supply Current as

a Function of Temperature

Figure 6. Pulse Response as

a Function of Supply Voltage

Figure 7. Pulse Response as

a Function of Temperature

RELATIVE VOLTAGE GAIN

1.10

1.08

1.06

1.04

1.02

1.00

0.98

0.96

0.94

0.92

0.90

0 102030 405060 70

TEMPERATURE −oC

VS= +6V

GAIN 2

GAIN 1

SINGLE ENDED VOLTAGE GAIN −dB

60

50

40

30

20

10

0

-10

1 5 10 50 100 500 1000

FREQUENCY −MHz

GAIN 2

VS= +6V

RL= 1kW

TA= 125oC

TA= −55oC

TA= 25oC

RELATIVE VOLTAGE GAIN

1.4

1.3

1.2

1.1

1.0

0.9

0.8

0.7

0.6

0.5

0.4

34567 8

SUPPLY VOLTAGE −+V

Tamb = 25oC

GAIN 2

GAIN 1

Figure 8. Voltage Gain as a

Function of Temperature

Figure 9. Gain vs. Frequency

as a Function of Temperature

Figure 10. Voltage Gain as a

Function of Supply Voltage

NE592

http://onsemi.com

5

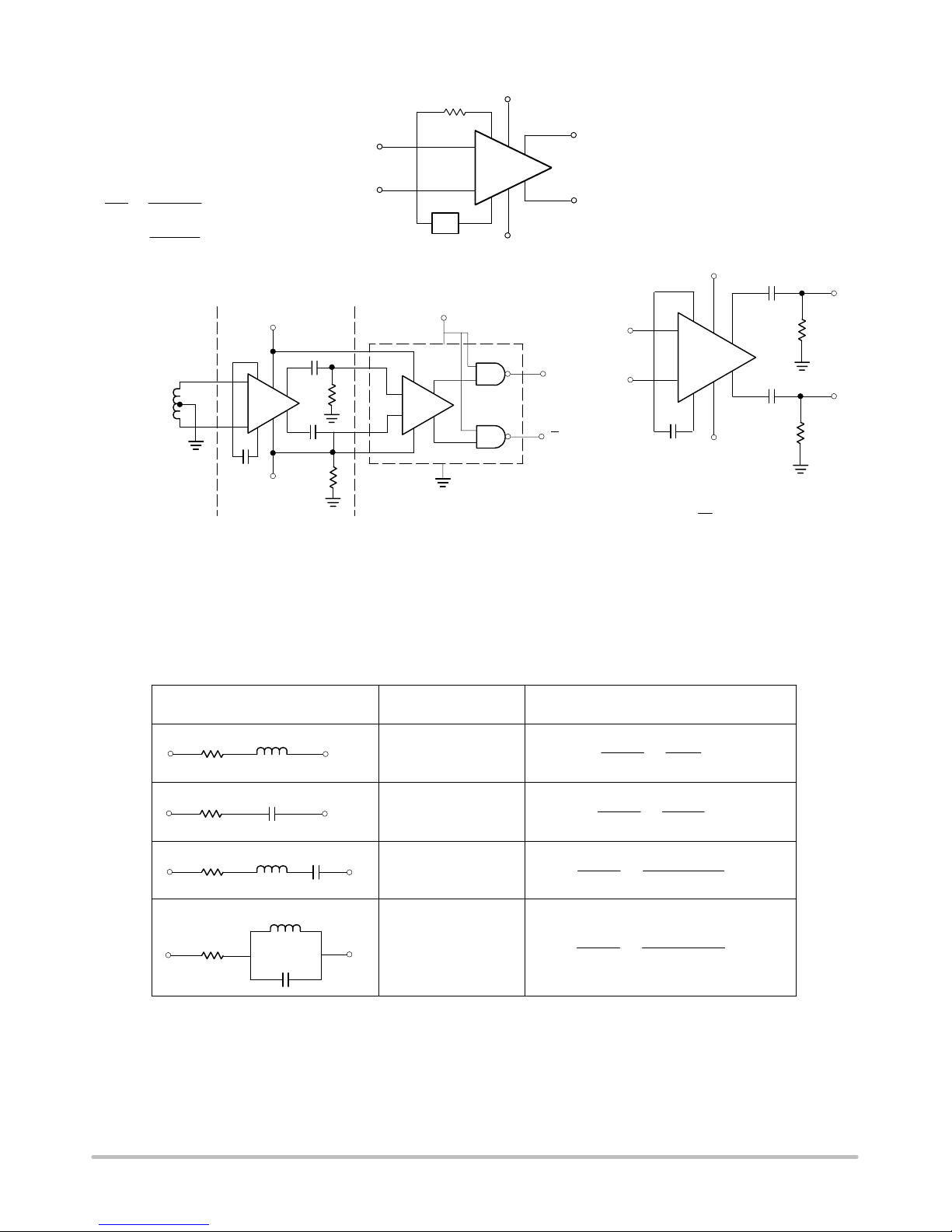

TYPICAL PERFORMANCE CHARACTERISTICS

SINGLE ENDED VOLTAGE GAIN −dB

60

50

40

30

20

10

0

-10

1 5 10 50 100 500 1000

FREQUENCY −MHz

VS= +8V

VS= +3V

VS= +6V

GAIN 2

TA= 25oC

RL= 1kW14

1

1211 8

7

4

3

0.2mF

0.2mF

592

51WRADJ 1kW1kW

TA= 25oCVS= +6V

DIFFERENTIAL VOLTAGE GAIN −V/V

1000

100

10

1

.1

.01

1 10 100 1K 10K 100K 1M

RADJ −W

VS= +6V

f = 100kHz

TA= 25oC

FIGURE 2

Figure 11. Gain vs. Frequency

as a Function of Supply Voltage

Figure 12. Voltage Gain Adjust

Circuit

Figure 13. Voltage Gain as a

Function of RADJ (Figure 2)

SUPPLY CURRENT −mA

21

20

19

18

17

16

15

14

-60 -20 20 60 100 140

TEMPERATURE −oC

VS= +6V

OVERDRIVE RECOVERY TIME −ns

70

60

50

40

30

20

10

0

0 20 40 60 80 100 120 140 160 180 200

DIFFERENTIAL INPUT VOLTAGE −mV

VS= +6V

TA= 25oC

GAIN 2

OUTPUT VOLTAGE SWING −V OR

OUTPUT SINK CURRENT −mA

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

3.0 4.0 5.0 6.0 7.0 8.0

SUPPLY VOLTAGE −+V

TA= 25oC

VOLTAGE

CURRENT

OUTPUT VOLTAGE SWING −Vpp

7.0

6.0

5.0

4.0

3.0

2.0

1.0

0

10 50 100 500 1K 5K 10K

LOAD RESISTANCE −W

VS= +6V

TA= 25oC

Figure 14. Supply Current as a

Function of Temperature

Figure 15. Differential Overdrive

Recovery Time

Figure 16. Output Voltage and

Current Swing as a Function of

Supply Voltage

INPUT RESISTANCE −K

70

60

50

40

30

20

10

0

-60 -20 0 20 60 100 140

TEMPERATURE −oC

GAIN 2

VS= +6V

Ω

INPUT NOISE VOLTAGE −Vrms

100

90

80

70

60

50

40

30

20

10

0

1 10 100 1K 10K

SOURCE RESISTANCE −W

GAIN 2

VS= +6V

TA= 25oC

BW = 10MHz

μ

Figure 17. Output Voltage

Swing as a Function of Load

Resistance

Figure 18. Input Resistance as a

Function of Temperature

Figure 19. Input Noise Voltage

as a Function of Source

Resistance

51W

NE592

http://onsemi.com

6

TYPICAL PERFORMANCE CHARACTERISTICS

PHASE SHIFT −DEGREES

0

-5

-10

-15

-20

-25

012345678910

FREQUENCY −MHz

GAIN 2

VS= +6V

TA= 25oC

VOLTAGE GAIN −dB

60

50

40

30

20

10

0

1 10 100 1000

FREQUENCY −MHz

VS= +6V

Tamb = 25oC

RL= 1KW

GAIN 1

GAIN 2

Figure 20. Phase Shift as a

Function of Frequency

Figure 21. Phase Shift as a

Function of Frequency

Figure 22. Voltage Gain as a

Function of Frequency

PHASE SHIFT −DEGREES

0

-50

-100

-150

-200

-250

-300

-350

1 10 100 1000

FREQUENCY −MHz

VS= +6V

TA= 25oC

GAIN 1

GAIN 2

VOLTAGE GAIN −dB

.01 .1 1 10 100 1000

40

30

20

10

0

-10

-20

-30

-40

-50

FREQUENCY −MHz

VS= +6V

TA= 25oC

GAIN 3

Figure 23. Voltage Gain as a

Function of Frequency

VIN VOUT

RL

592

51W51W

51W51W

ein

eout eout

1kW1kW

0.2mF

0.2mF

592

TEST CIRCUITS (TA= 25°C, unless otherwise noted.)

Figure 24. Test Circuits

NE592

http://onsemi.com

7

NOTE:

Basic Configuration

Disc/Tape Phase-Modulated Readback Systems

Differentiation with High

Common-Mode Noise Rejection

NOTE:

For frequency F1<< 1/2 π(32) C

VO]1.4 x 104CdVi

dT

Z

V1

2re

+6

V0

7

5

4

1

14 11

10

-6

592

READ HEAD DIFFERENTIATOR/AMPLIFIER ZERO CROSSING DETECTOR

+5

948

529 7

5

Q

Q

6

3

2

1

10

+6

14 11

10 8

7

5

4

1

-6

AMPLITUDE: 1-10 mV p-p

FREQUENCY: 1-4 MHz

592

0.2mF

+6

0.2mF

2KW

2KW

V0

V1

C

14

1

11

4

10

5

7

8

-6

592

V0(s)

v1(s) [1.4 @104

Z(S) )2re

[1.4 @104

Z(S) )32

Figure 25. Typical Applications

NOTES:

In the networks above, the R value used is assumed to include 2re, or approximately 32W.

S = jW

W= 2πf

1.4 104

Lƪ1

s)RńLƫ

1.4 104

Rƪs

s)1ńRCƫ

1.4 104

Lƪs

s2)RńLs )1ńLCƫ

1.4 104

Rƪs2)1ńLC

s2)1ńLC )sńRCƫ

Z NETWORK FILTER

TYPE

V0(s) TRANSFER

V1(s) FUNCTION

LOW PASS

HIGH PASS

BAND PASS

BAND REJECT

RL

RC

RLC

R

L

C

Figure 26. Filter Networks

NE592

http://onsemi.com

8

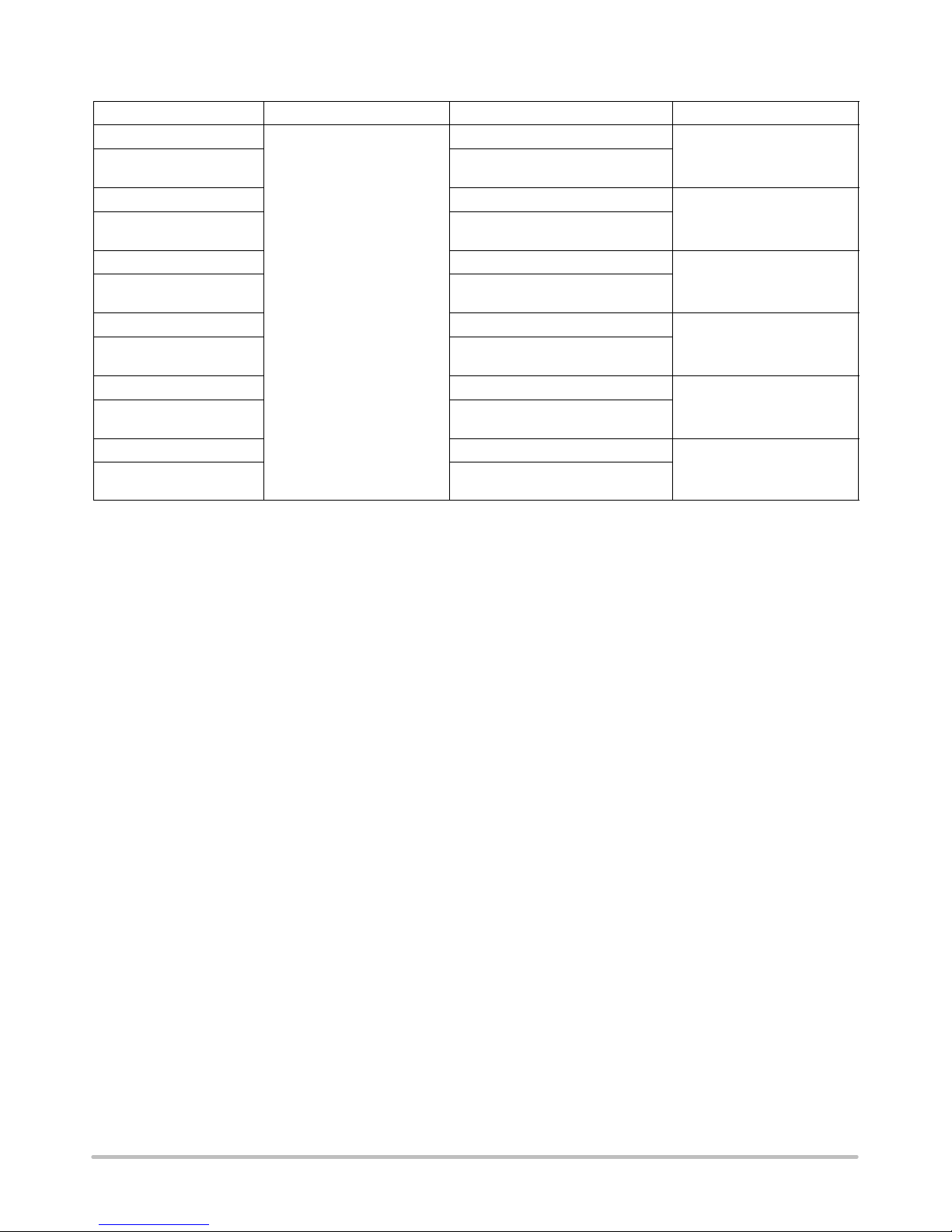

ORDERING INFORMATION

Device Temperature Range Package Shipping†

NE592D8

0 to +70°C

SOIC−8

98 Units/Rail

NE592D8G SOIC−8

(Pb−Free)

NE592D8R2 SOIC−8

2500 / Tape & Reel

NE592D8R2G SOIC−8

(Pb−Free)

NE592N8 PDIP−8

50 Units/Rail

NE592N8G PDIP−8

(Pb−Free)

NE592D14 SOIC−14

55 Units/Rail

NE592D14G SOIC−14

(Pb−Free)

NE592D14R2 SOIC−14

2500 / Tape & Reel

NE592D14R2G SOIC−14

(Pb−Free)

NE592N14 PDIP−14

25 Units/Rail

NE592N14G PDIP−14

(Pb−Free)

†For information on tape and reel specifications, including part orientation and tape sizes, please refer to our Tape and Reel Packaging Specification

Brochure, BRD8011/D.

NE592

http://onsemi.com

9

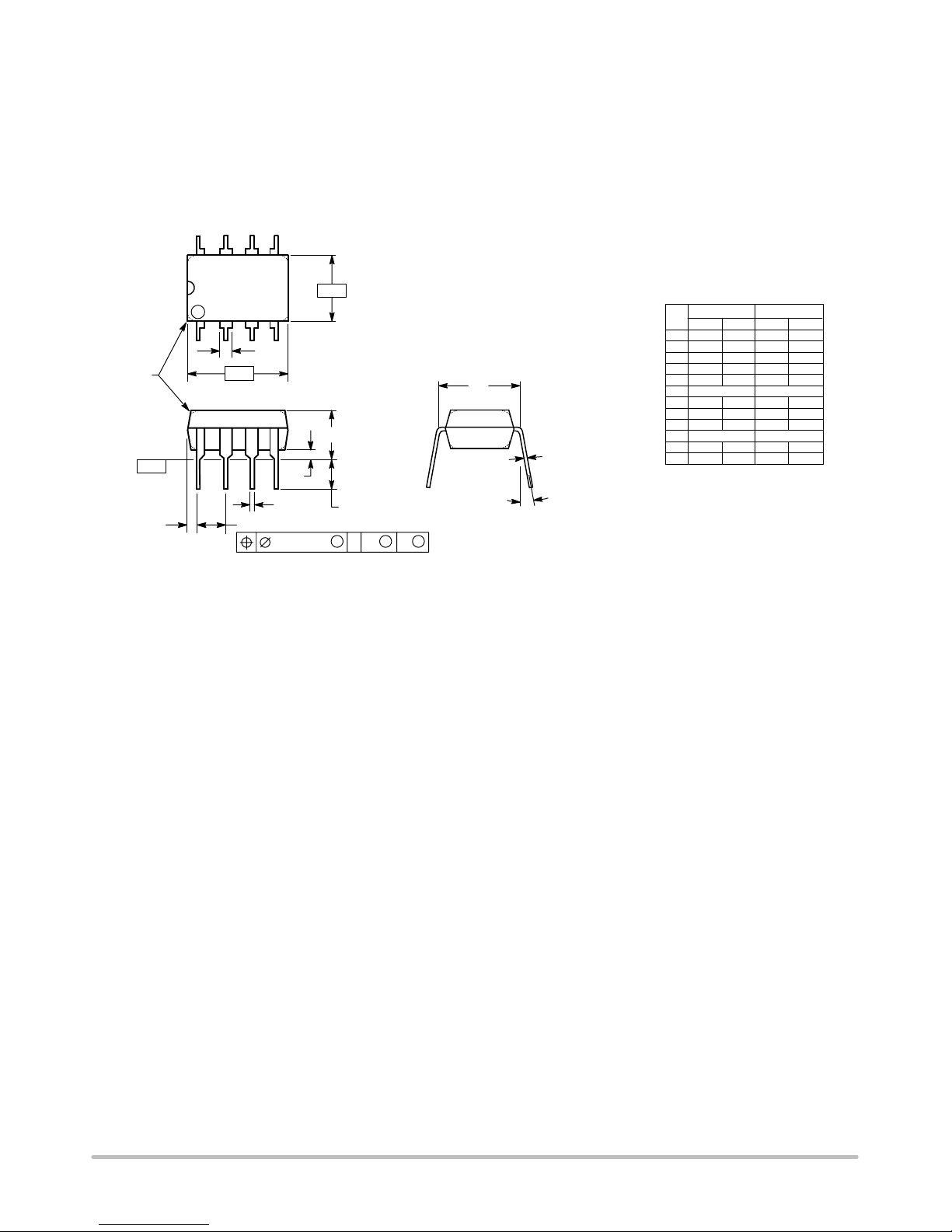

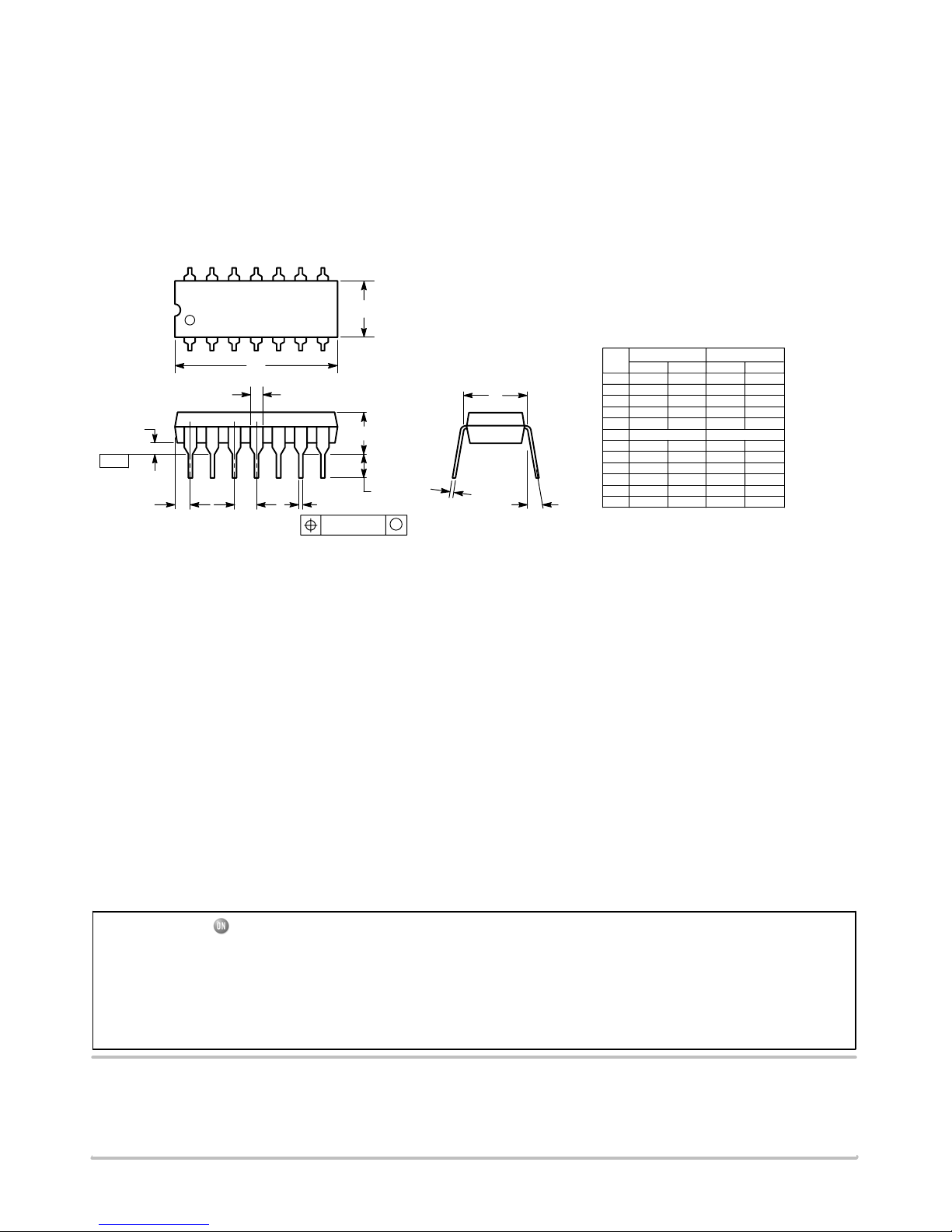

PACKAGE DIMENSIONS

SOIC−8 NB

CASE 751−07

ISSUE AH

SEATING

PLANE

1

4

58

N

J

X 45_

K

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSION A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE DAMBAR

PROTRUSION. ALLOWABLE DAMBAR

PROTRUSION SHALL BE 0.127 (0.005) TOTAL

IN EXCESS OF THE D DIMENSION AT

MAXIMUM MATERIAL CONDITION.

6. 751−01 THRU 751−06 ARE OBSOLETE. NEW

STANDARD IS 751−07.

A

BS

D

H

C

0.10 (0.004)

DIM

A

MIN MAX MIN MAX

INCHES

4.80 5.00 0.189 0.197

MILLIMETERS

B3.80 4.00 0.150 0.157

C1.35 1.75 0.053 0.069

D0.33 0.51 0.013 0.020

G1.27 BSC 0.050 BSC

H0.10 0.25 0.004 0.010

J0.19 0.25 0.007 0.010

K0.40 1.27 0.016 0.050

M0 8 0 8

N0.25 0.50 0.010 0.020

S5.80 6.20 0.228 0.244

−X−

−Y−

G

M

Y

M

0.25 (0.010)

−Z−

Y

M

0.25 (0.010) ZSXS

M

____

1.52

0.060

7.0

0.275

0.6

0.024

1.270

0.050

4.0

0.155

ǒmm

inchesǓ

SCALE 6:1

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

SOLDERING FOOTPRINT*

NE592

http://onsemi.com

10

PACKAGE DIMENSIONS

PDIP−8

N SUFFIX

CASE 626−05

ISSUE L

NOTES:

1. DIMENSION L TO CENTER OF LEAD WHEN

FORMED PARALLEL.

2. PACKAGE CONTOUR OPTIONAL (ROUND OR

SQUARE CORNERS).

3. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

14

58

F

NOTE 2 −A−

−B−

−T−

SEATING

PLANE

H

J

G

DK

N

C

L

M

M

A

M

0.13 (0.005) B M

T

DIM MIN MAX MIN MAX

INCHESMILLIMETERS

A9.40 10.16 0.370 0.400

B6.10 6.60 0.240 0.260

C3.94 4.45 0.155 0.175

D0.38 0.51 0.015 0.020

F1.02 1.78 0.040 0.070

G2.54 BSC 0.100 BSC

H0.76 1.27 0.030 0.050

J0.20 0.30 0.008 0.012

K2.92 3.43 0.115 0.135

L7.62 BSC 0.300 BSC

M−−− 10 −−− 10

N0.76 1.01 0.030 0.040

__

NE592

http://onsemi.com

11

PACKAGE DIMENSIONS

SOIC−14

CASE 751A−03

ISSUE H

NOTES:

1. DIMENSIONING AND TOLERANCING PER

ANSI Y14.5M, 1982.

2. CONTROLLING DIMENSION: MILLIMETER.

3. DIMENSIONS A AND B DO NOT INCLUDE

MOLD PROTRUSION.

4. MAXIMUM MOLD PROTRUSION 0.15 (0.006)

PER SIDE.

5. DIMENSION D DOES NOT INCLUDE

DAMBAR PROTRUSION. ALLOWABLE

DAMBAR PROTRUSION SHALL BE 0.127

(0.005) TOTAL IN EXCESS OF THE D

DIMENSION AT MAXIMUM MATERIAL

CONDITION.

−A−

−B−

G

P7 PL

14 8

7

1

M

0.25 (0.010) B M

S

B

M

0.25 (0.010) A S

T

−T−

F

RX 45

SEATING

PLANE D14 PL K

C

J

M

_DIM MIN MAX MIN MAX

INCHESMILLIMETERS

A8.55 8.75 0.337 0.344

B3.80 4.00 0.150 0.157

C1.35 1.75 0.054 0.068

D0.35 0.49 0.014 0.019

F0.40 1.25 0.016 0.049

G1.27 BSC 0.050 BSC

J0.19 0.25 0.008 0.009

K0.10 0.25 0.004 0.009

M0 7 0 7

P5.80 6.20 0.228 0.244

R0.25 0.50 0.010 0.019

__ __

7.04

14X

0.58

14X

1.52

1.27

DIMENSIONS: MILLIMETERS

1

PITCH

SOLDERING FOOTPRINT*

7X

*For additional information on our Pb−Free strategy and soldering

details, please download the ON Semiconductor Soldering and

Mounting Techniques Reference Manual, SOLDERRM/D.

NE592

http://onsemi.com

12

PACKAGE DIMENSIONS

PDIP−14

CASE 646−06

ISSUE P

17

14 8

B

ADIM MIN MAX MIN MAX

MILLIMETERSINCHES

A0.715 0.770 18.16 19.56

B0.240 0.260 6.10 6.60

C0.145 0.185 3.69 4.69

D0.015 0.021 0.38 0.53

F0.040 0.070 1.02 1.78

G0.100 BSC 2.54 BSC

H0.052 0.095 1.32 2.41

J0.008 0.015 0.20 0.38

K0.115 0.135 2.92 3.43

L

M−−− 10 −−− 10

N0.015 0.039 0.38 1.01

__

NOTES:

1. DIMENSIONING AND TOLERANCING PER ANSI

Y14.5M, 1982.

2. CONTROLLING DIMENSION: INCH.

3. DIMENSION L TO CENTER OF LEADS WHEN

FORMED PARALLEL.

4. DIMENSION B DOES NOT INCLUDE MOLD FLASH.

5. ROUNDED CORNERS OPTIONAL.

F

HG D

K

C

SEATING

PLANE

N

−T−

14 PL

M

0.13 (0.005)

L

M

J0.290 0.310 7.37 7.87

ON Semiconductor and are registered trademarks of Semiconductor Components Industries, LLC (SCILLC). SCILLC reserves the right to make changes without further notice

to any products herein. SCILLC makes no warranty, representation or guarantee regarding the suitability of its products for any particular purpose, nor does SCILLC assume any

liability arising out of the application or use of any product or circuit, and specifically disclaims any and all liability, including without limitation special, consequential or incidental

damages. “Typical” parameters which may be provided in SCILLC data sheets and/or specifications can and do vary in different applications and actual performance may vary over

time. All operating parameters, including “Typicals” must be validated for each customer application by customer’s technical experts. SCILLC does not convey any license under

its patent rights nor the rights of others. SCILLC products are not designed, intended, or authorized for use as components in systems intended for surgical implant into the body,

or other applications intended to support or sustain life, or for any other application in which the failure of the SCILLC product could create a situation where personal injury or death

may occur. Should Buyer purchase or use SCILLC products for any such unintended or unauthorized application, Buyer shall indemnify and hold SCILLC and its officers, employees,

subsidiaries, affiliates, and distributors harmless against all claims, costs, damages, and expenses, and reasonable attorney fees arising out of, directly or indirectly, any claim of

personal injury or death associated with such unintended or unauthorized use, even if such claim alleges that SCILLC was negligent regarding the design or manufacture of the part.

SCILLC is an Equal Opportunity/Affirmative Action Employer. This literature is subject to all applicable copyright laws and is not for resale in any manner.

PUBLICATION ORDERING INFORMATION

N. American Technical Support: 800−282−9855 Toll Free

USA/Canada

Europe, Middle East and Africa Technical Support:

Phone: 421 33 790 2910

Japan Customer Focus Center

Phone: 81−3−5773−3850

NE592/D

LITERATURE FULFILLMENT:

Literature Distribution Center for ON Semiconductor

P.O. Box 5163, Denver, Colorado 80217 USA

Phone: 303−675−2175 or 800−344−3860 Toll Free USA/Canada

Fax: 303−675−2176 or 800−344−3867 Toll Free USA/Canada

Email: [email protected]

ON Semiconductor Website: www.onsemi.com

Order Literature: http://www.onsemi.com/orderlit

For additional information, please contact your local

Sales Representative

Table of contents