Senator SEN-557-0300K User manual

5

l

Reversible ratchet head.

l

”CLICK + SNAP” action indicates when the

pre-set torque level has been reached.

l

Engraved kgf.m and Nm scale

on barrel.

l

Micrometer type sleeve allows preset

torque values to be accurately set.

l

Manufactured to ISO 6789-2:2017

(BS EN 26789:2003).

OPERATING INSTRUCTIONS

1/4" SQUARE DRIVE

TORQUE WRENCH

CAPACITY: 5-25Nm

ORDER CODE

SEN-557-0300K

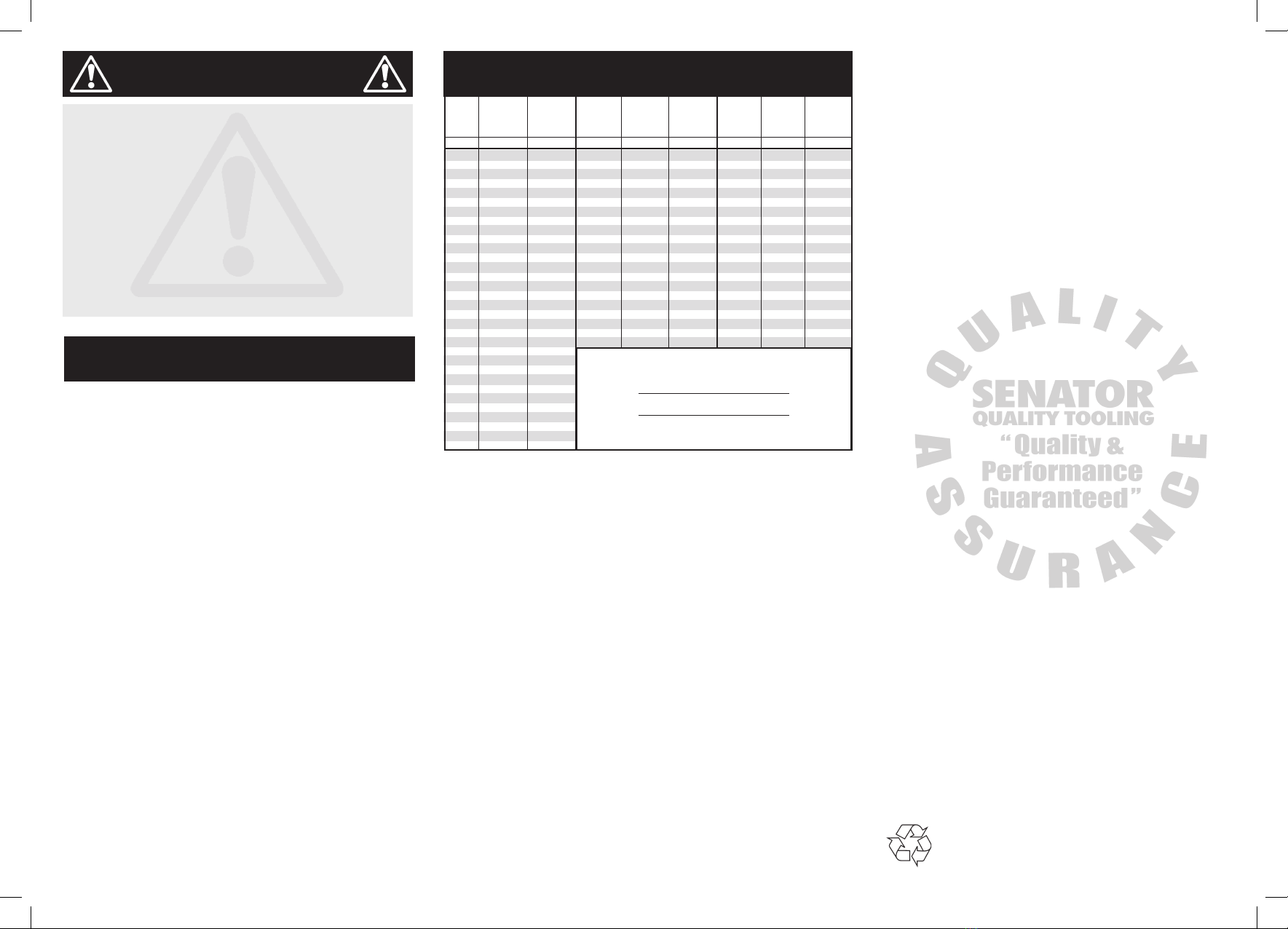

IDENTIFICATION INSTRUCTIONS FOR USE

Torque setting adjustment:

Example: To set the torque to 10Nm.

1. To unlock the handle turn the lock nut (1)

anti-clockwise.

2. Turn the knurled handle (2) until the ‘0’ marked on

the scale (3) is in line with the next lowest torque

setting on the Newton meter linear scale (4). In this

case 9Nm.

3. Continue to turn the knurled handle clockwise until

the‘1’ graduation on the horizontal scale is lined up

with the centre line on the newton meter linear scale.

The wrench is now set at 10Nm.

4. Tighten the lock nut (1) to secure the setting.

Method of use:

IMPORTANT!

Always use the correct size socket and if necessary

an accessory. Preferably do not use knuckle or

universal joints, as these could result in incorrect

torque settings.

1. Place the square drive onto the socket or extension

bar so that the wrench is perpendicular to the nut or

bolt that you wish to be tightened.

2. Gripping the knurled handle

(2)

with the right hand,

whilst supporting the square drive end with the left

hand, gently but firmly apply a steady pull to the

handle (in a clockwise direction) until a click is

heard and a slight ‘break’ in the handle is felt.

Do not turn any further.

Please note: This torque wrench has a reversible

ratchet head (see fig. 2). Set the direction indicator

(5) to clockwise or anti-clockwise.

1. Lock nut

2. Knurled handle

3. Horizontal scale

4. Linear scale

5. Reversing switch

FIG. 1

FIG. 2

3

1

2

4

You have purchased a quality product that is designed

for high performance and a long service life. If safety

and maintenance procedures are followed and the tool

is used correctly it will last for many years.

•Always follow instructions for assembly

before operation.

•Ensure your workpiece is firmly held or fixed before

commencing work.

•When using torque tools it is possible that

fasteners may break or slip. Always stand with both

feet on the floor and avoid applying torque in

awkward positions.

•The drive part of the tool and any accessories

should always be in line with the fastener.

Misalignment and uncontrolled movement

will affect accuracy.

•Only use the tool on the job for which it has

been designed.

•Keep the tool clean by wiping. Never dip in

cleaning fluid.

•Always store tools away from dirt, oil and swarf as

this can damage mechanisms.

• We recommend that your torque tool be

calibrated annually.

SAFETY & MAINTENANCE

Senator Tools continually strives to improve its products.

Specifications may change without prior notice.

SENATOR TOOLS

P.O. Box 14, Wigston, Leicester, England, LE18 1AT.

Senator is a registered trade mark of The Kennedy Group Ltd.

QUALITY GUARANTEE &

WARRANTY

SENATOR TOOLS carry a one year manufacturer’s warranty.

SENATOR TOOLS are designed & manufactured

to the highest standards & specifications.

Assuring the quality and performance required by all sectors

of industry.

SENATOR TOOLS are fully guaranteed against

faulty materials & workmanship.

Should they be found to be defective, they will either be repaired or

replaced free of charge (fair wear and tear and/or misuse excepted).

Please retain supplier invoice as proof of purchase.

Always dispose of unwanted tools, accessories and

packaging materials in an environmentally friendly

manner. Never allow lubricants to contaminate rivers,

water ways or drains.

SENATOR

Torque Wrenches are manufactured and tested to

ISO 6789-2:2017 (BS EN 26789 : 2003)

Accuracy = ± 4% of the set load.

After use always adjust to the lowest torque setting.

•Release the wrench immediately when the click is

heard/felt as continuing will result in an incorrect

torque setting being applied and may cause possible

damage to parts.

•Please note that the ‘click’ becomes weaker with

the lower torque settings.

•If the wrench is new or has not been used for a while

then operate it a few times on a lower torque setting

to allow the internal lubrication to recoat working

parts.

•Do not turn adjustment below lowest torque setting.

WARNING

Foot Kilo-gram Newton

Pounds Metres Metres

lbf.ft kgf.m N.m

5 0.69 6.78

10 1.38 13.55

15 2.07 20.33

20 2.77 27.10

25 3.46 33.88

30 4.15 40.65

35 4.84 47.43

40 5.53 54.20

45 6.22 60.98

50 6.91 67.75

55 7.60 74.53

60 8.30 81.30

65 8.99 88.08

70 9.68 94.85

75 10.37 101.63

80 11.06 108.40

85 11.75 115.18

90 12.44 121.95

95 13.13 128.73

100 13.83 135.50

105 14.52 142.28

110 15.21 149.05

115 15.90 155.83

120 16.59 162.60

125 17.28 169.3

130 17.97 176.15

135 18.66 182.93

140 19.36 189.70

145 20.05 196.48

150 20.74 203.25

155 21.43 210.03

Newton Foot Kilo-gram

Metres Pounds Metres

N.m lbf.ft kgf.m

10 7.38 1.02

20 14.76 2.04

30 22.14 3.06

40 29.52 4.08

50 36.90 5.10

60 44.28 6.12

70 51.66 7.14

80 59.04 8.16

90 66.42 9.18

100 73.80 10.20

110 81.18 11.22

120 88.56 12.24

130 95.94 13.26

140 103.32 14.28

150 110.70 15.30

160 118.08 16.31

170 125.46 17.33

180 132.84 18.35

190 140.22 19.37

200 147.60 20.39

210 154.98 21.41

Kilo-gram Newton Foot

Metres Metres Pounds

kgf.m N.m lbf.ft

1 9.81 7.23

2 19.61 14.47

3 29.42 21.70

4 39.23 28.93

5 49.04 36.17

6 58.84 43.40

7 68.65 50.63

8 78.46 57.86

9 88.26 65.10

10 98.07 72.33

11 107.88 79.56

12 117.68 86.80

13 127.49 94.03

14 137.30 101.26

15 147.11 108.50

16 156.91 115.73

17 166.72 122.96

18 176.53 130.19

19 186.33 137.43

20 196.14 144.66

21 205.95 151.89

SAFETY & MAINTENANCE

WARNING TORQUE CONVERSION CHART

TORQUE CONVERSION CHART

CONVERSION FORMULAS

1kgf.cm = 13.887 ozf.in

1kgf.cm = 0.868 lbf.in

1kgf.cm = 0.098 N.m

1kgf.m = 7.233 lbf.ft

1kgf.m = 9.807 N.m

1N.m = 141.6 ozf.in

1N.m = 0.738 lbf.ft

1N.m = 8.851 lbf.in

Other Senator Power Tools manuals

Popular Power Tools manuals by other brands

VONROC

VONROC S-OT501DC Original instructions

Parkside

Parkside PMFW 310 D2 Translation of the original instructions

Hitachi

Hitachi N 5010A Instruction and safety manual

Stanley

Stanley FATMAX SCD700 Original instructions

EINHELL

EINHELL TC-JS 18/2700 Li Original operating instructions

Makita

Makita HM1213C instruction manual